Bienvenido a nuestra completa guía sobre Electrodo Inducción Fusión Gas Inerte (EIMIG), una sofisticada técnica utilizada en la producción de polvos metálicos de alta calidad. Si usted es ingeniero de materiales, investigador o simplemente siente curiosidad por los procesos metalúrgicos avanzados, este artículo está diseñado para proporcionarle un conocimiento detallado de la EIMIG. Nos adentraremos en su mecánica, exploraremos modelos específicos de polvo metálico y destacaremos sus diversas aplicaciones. Así pues, ¡empecemos!

Visión general de la fusión por inducción con electrodos de gas inerte

La fusión por inducción con electrodos de gas inerte (EIMIG) es un proceso metalúrgico de vanguardia que consiste en fundir metales mediante un arco eléctrico generado entre electrodos en un entorno de gas inerte. Este método es especialmente ventajoso para producir polvos metálicos de gran pureza, esenciales en industrias que van de la aeroespacial a la ingeniería biomédica.

¿Qué hace especial al EIMIG?

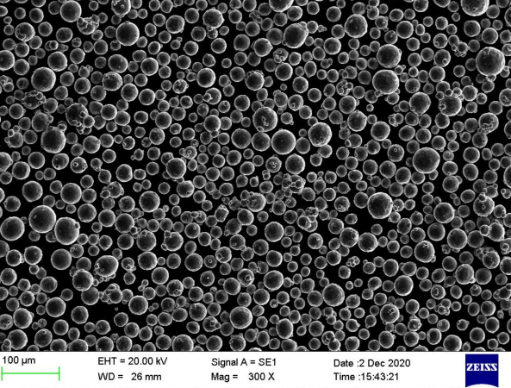

EIMIG destaca por su capacidad de producir polvos metálicos con una pureza superior y tamaños de partícula controlados. Al utilizar una atmósfera de gas inerte, normalmente argón o helio, se minimizan la oxidación y la contaminación, lo que garantiza la producción de polvos metálicos de alta calidad. El proceso también es muy versátil, ya que permite fundir una amplia gama de metales y aleaciones.

Componentes básicos de EIMIG

- Electrodos: Generalmente de grafito o tungsteno, generan el arco eléctrico necesario para la fusión.

- Entorno de gas inerte: Se suele utilizar argón o helio para evitar la oxidación.

- Sistema de calefacción por inducción: Proporciona la energía necesaria para mantener el proceso de fusión.

- Crisol: Mantiene el metal mientras se funde y se enfría en forma de polvo.

Tipos de polvos metálicos producidos por EIMIG

EIMIG puede producir una gran variedad de polvos metálicos, cada uno con propiedades únicas adecuadas para diferentes aplicaciones. He aquí diez modelos específicos:

1. Aleación de titanio (Ti-6Al-4V)

Composición: Titanio, aluminio, vanadio

Propiedades: Elevada relación resistencia/peso, excelente resistencia a la corrosión

Aplicaciones: Componentes aeroespaciales, implantes médicos

2. Superaleación de níquel (Inconel 718)

Composición: Níquel, Cromo, Hierro, Niobio

Propiedades: Resistencia a altas temperaturas, excelentes propiedades mecánicas

Aplicaciones: Álabes de turbina, motores a reacción

3. Acero inoxidable (316L)

Composición: Hierro, Cromo, Níquel, Molibdeno

Propiedades: Alta resistencia a la corrosión, buena conformabilidad

Aplicaciones: Dispositivos biomédicos, equipos de procesamiento de alimentos

4. Aleación de cobalto-cromo (Co-Cr-Mo)

Composición: Cobalto, cromo, molibdeno

Propiedades: Alta resistencia al desgaste, biocompatibilidad

Aplicaciones: Implantes dentales, implantes ortopédicos

5. Aleación de aluminio (AlSi10Mg)

Composición: Aluminio, Silicio, Magnesio

Propiedades: Ligero, buena conductividad térmica

Aplicaciones: Piezas de automóvil, estructuras aeroespaciales

6. Aleación de cobre (CuNi2SiCr)

Composición: Cobre, Níquel, Silicio, Cromo

Propiedades: Alta conductividad eléctrica, buena resistencia mecánica

Aplicaciones: Conectores eléctricos, intercambiadores de calor

7. Acero para herramientas (H13)

Composición: Hierro, Cromo, Molibdeno, Vanadio

Propiedades: Gran tenacidad, excelente resistencia al calor

Aplicaciones: Moldes para fundición a presión, herramientas de extrusión

8. Acero martensítico envejecido (18Ni300)

Composición: Hierro, níquel, cobalto, molibdeno

Propiedades: Alta resistencia, buena tenacidad

Aplicaciones: Componentes aeroespaciales, utillaje

9. Carburo de wolframio (WC-Co)

Composición: Tungsteno, Cobalto

Propiedades: Extremadamente duro, alta resistencia al desgaste

Aplicaciones: Herramientas de corte, equipos de minería

10. Aleación de circonio (Zr702)

Composición: Circonio, hafnio, hierro

Propiedades: Excelente resistencia a la corrosión, buenas propiedades mecánicas

Aplicaciones: Reactores nucleares, equipos de procesamiento químico

Características de Electrodo Inducción Fusión Gas Inerte

La EIMIG es conocida por varias características clave que la convierten en una opción atractiva para producir polvos metálicos.

Pureza

El entorno de gas inerte reduce significativamente la contaminación, lo que da como resultado polvos metálicos con altos niveles de pureza.

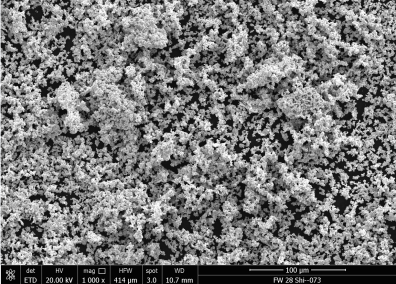

Control del tamaño de las partículas

EIMIG permite un control preciso de la distribución del tamaño de las partículas, lo que es crucial para aplicaciones que requieren características específicas del polvo.

Versatilidad

El proceso se adapta a una amplia gama de metales y aleaciones, por lo que es adecuado para diversas aplicaciones industriales.

Eficacia

La EIMIG es un proceso energéticamente eficiente, capaz de producir altos rendimientos de polvo metálico con un mínimo de residuos.

Aplicaciones de la fusión por inducción de electrodos Gas inerte

Los polvos metálicos producidos por EIMIG se utilizan en diversas industrias de alta tecnología gracias a sus propiedades superiores.

Industria aeroespacial

Las aleaciones ligeras y de alta resistencia como el Ti-6Al-4V son cruciales para los componentes aeronáuticos, donde el rendimiento y la fiabilidad son primordiales.

Ingeniería biomédica

Los materiales biocompatibles como el Co-Cr-Mo se utilizan en implantes y dispositivos médicos, garantizando la seguridad y eficacia para los pacientes.

Sector del automóvil

Las aleaciones de aluminio como AlSi10Mg se utilizan en piezas de automoción para reducir el peso y mejorar la eficiencia del combustible.

Electrónica

Las aleaciones de cobre con alta conductividad eléctrica son esenciales para los conectores y otros componentes electrónicos.

Herramientas y fabricación

Los aceros para herramientas y los polvos de carburo de tungsteno se utilizan para crear moldes duraderos y herramientas de corte para diversos procesos de fabricación.

Especificaciones detalladas de los polvos metálicos EIMIG

Propiedades y características

| Polvo metálico | Densidad (g/cm³) | Punto de fusión (°C) | Dureza (HV) | Resistencia a la tracción (MPa) | Alargamiento (%) |

|---|---|---|---|---|---|

| Ti-6Al-4V | 4.43 | 1660 | 349 | 895 | 10 |

| Inconel 718 | 8.19 | 1350 | 330 | 1240 | 12 |

| Acero inoxidable 316L | 7.99 | 1375 | 217 | 620 | 40 |

| Co-Cr-Mo | 8.29 | 1330 | 450 | 900 | 8 |

| AlSi10Mg | 2.68 | 570 | 85 | 310 | 7 |

| CuNi2SiCr | 8.78 | 1083 | 100 | 450 | 20 |

| Acero para herramientas H13 | 7.80 | 1427 | 750 | 1450 | 12 |

| acero martensítico envejecido 18Ni300 | 8.00 | 1413 | 340 | 2000 | 10 |

| WC-Co | 15.60 | 2870 | 1600 | – | – |

| Zr702 | 6.50 | 1855 | 250 | 550 | 30 |

Aplicaciones y usos

| Polvo metálico | Aplicaciones primarias | Usos adicionales |

|---|---|---|

| Ti-6Al-4V | Componentes aeroespaciales, implantes médicos | Artículos deportivos, aplicaciones marinas |

| Inconel 718 | Álabes de turbina, motores a reacción | Reactores nucleares, vehículos espaciales |

| Acero inoxidable 316L | Dispositivos biomédicos, procesamiento de alimentos | Procesamiento químico, aplicaciones marinas |

| Co-Cr-Mo | Implantes dentales, implantes ortopédicos | Componentes de relojería, rodamientos industriales |

| AlSi10Mg | Piezas de automóvil, estructuras aeroespaciales | Electrónica de consumo, bicicletas |

| CuNi2SiCr | Conectores eléctricos, intercambiadores de calor | Aplicaciones marinas, acuñación de moneda |

| Acero para herramientas H13 | Moldes para fundición a presión, herramientas de extrusión | Moldes de inyección, matrices de forja |

| acero martensítico envejecido 18Ni300 | Componentes aeroespaciales, utillaje | Engranajes y ejes de alto rendimiento |

| WC-Co | Herramientas de corte, equipos de minería | Piezas resistentes al desgaste, herramientas de perforación |

| Zr702 | Reactores nucleares, procesamiento químico | Dispositivos médicos, componentes aeroespaciales |

Especificaciones, tamaños, calidades, normas

| Polvo metálico | Grado | Gama de tamaños (µm) | Estándar |

|---|---|---|---|

| Ti-6Al-4V | 5º curso | 15-45 | ASTM B348 |

| Inconel 718 | UNS N07718 | 15-53 | AMS 5662 |

| Acero inoxidable 316L | 316L | 10-45 | ASTM F138 |

| Co-Cr-Mo | ASTM F75 | 20-63 | ISO 5832-4 |

| AlSi10Mg | – | 15-45 | DIN EN 1706 |

| CuNi2SiCr | – | 20-50 | ASTM B422 |

| Acero para herramientas H13 | H13 | 20-63 | ASTM A681 |

| acero martensítico envejecido 18Ni300 | 18Ni300 | 10-45 | AMS 6514 |

| WC-Co | 1-20 | ISO 4499-1 | |

| Zr702 | R60702 | 15-45 | ASTM B551 |

Proveedores y precios

| Proveedor | Polvo metálico | Precio (por kg) | Disponibilidad |

|---|---|---|---|

| Advanced Powders Inc. | Ti-6Al-4V | $150 | En stock |

| Specialty Metals Co. | Inconel 718 | $200 | Existencias limitadas |

| Materiales médicos LLC | Acero inoxidable 316L | $120 | En stock |

| BioMetals Corp. | Co-Cr-Mo | $180 | Se requiere pedido previo |

| Metales ligeros Inc. | AlSi10Mg | $100 | En stock |

| Electrical Alloys Ltd. | CuNi2SiCr | $160 | En stock |

| Tool Steel Supply Co. | Acero para herramientas H13 | $140 | Existencias limitadas |

| Metales de alta resistencia | acero martensítico envejecido 18Ni300 | $220 | En stock |

| Grupo de Metales Duros | WC-Co | $300 | Se requiere pedido previo |

| Nuclear Materials Inc. | Zr702 | $250 | En stock |

Comparación de pros y contras, ventajas y limitaciones

| Polvo metálico | Ventajas | Limitaciones |

|---|---|---|

| Ti-6Al-4V | Alta resistencia, ligereza y resistencia a la corrosión | Caro, difícil de mecanizar |

| Inconel 718 | Excelentes propiedades a altas temperaturas | Coste elevado, tratamiento complejo |

| Acero inoxidable 316L | Resistente a la corrosión, biocompatible | Menor resistencia en comparación con otras aleaciones |

| Co-Cr-Mo | Alta resistencia al desgaste, biocompatibilidad | Fragilidad, caro |

| AlSi10Mg | Ligero, buenas propiedades térmicas | Menor resistencia que las aleaciones de acero |

| CuNi2SiCr | Alta conductividad eléctrica, resistente a la corrosión | Caro, resistencia mecánica limitada |

| Acero para herramientas H13 | Gran tenacidad, resistencia al calor | Susceptible de agrietarse bajo tensión |

| acero martensítico envejecido 18Ni300 | Alta resistencia, buena tenacidad | Tratamiento térmico costoso y complejo |

| WC-Co | Extremadamente duro, alta resistencia al desgaste | Fragilidad, coste elevado |

| Zr702 | Excelente resistencia a la corrosión, buenas propiedades mecánicas | Coste elevado, disponibilidad limitada |

preguntas frecuentes

¿Qué es la Electrodo Inducción Fusión Gas Inerte (EIMIG)?

EIMIG es un proceso en el que los metales se funden utilizando un arco eléctrico entre electrodos en una atmósfera de gas inerte, produciendo polvos metálicos de gran pureza.

¿Por qué utilizar un gas inerte en la EIMIG?

Gases inertes como el argón o el helio evitan la oxidación y la contaminación durante el proceso de fusión, garantizando polvos metálicos de alta calidad.

¿Qué metales pueden fundirse con EIMIG?

EIMIG es versátil y puede fundir una amplia gama de metales y aleaciones, como titanio, níquel, acero inoxidable, cromo-cobalto, etc.

¿Cuáles son las aplicaciones de los polvos metálicos EIMIG?

Los polvos metálicos EIMIG se utilizan en las industrias aeroespacial, de ingeniería biomédica, de automoción, electrónica y de herramientas debido a sus propiedades superiores.

¿Cómo controla EIMIG el tamaño de las partículas?

Los parámetros del proceso en EIMIG pueden ajustarse con precisión para controlar la distribución del tamaño de las partículas, lo que garantiza la consistencia y precisión del producto final.

¿Son caros los polvos metálicos EIMIG?

El coste de los polvos metálicos EIMIG varía en función del tipo de metal y su pureza, pero en general tiende a ser más elevado debido a la naturaleza avanzada del proceso.

¿Cuáles son las principales ventajas de EIMIG?

La EIMIG ofrece una gran pureza, un control preciso del tamaño de las partículas, versatilidad en los tipos de metal y una producción eficiente, lo que la hace muy beneficiosa para producir polvos metálicos especializados.

¿En qué se diferencia la EIMIG de otras técnicas de fusión?

EIMIG utiliza una atmósfera de gas inerte y calentamiento por inducción, lo que reduce la contaminación y permite un control preciso del proceso de fusión, diferenciándolo de otras técnicas como la fusión por arco convencional.

¿Puede utilizarse EIMIG para la producción a gran escala?

Sí, la EIMIG puede ampliarse para la producción industrial, por lo que es adecuada tanto para la investigación a pequeña escala como para la fabricación a gran escala.

¿Quiénes son los principales proveedores de polvos metálicos EIMIG?

Los principales proveedores son Advanced Powders Inc, Specialty Metals Co, Medical Materials LLC y BioMetals Corp, entre otros, que ofrecen una gran variedad de polvos metálicos para distintas aplicaciones.

Conclusión

El gas inerte de fusión por inducción de electrodos (EIMIG) es una tecnología transformadora en el campo de la metalurgia, que ofrece una pureza y precisión sin precedentes en la producción de polvo metálico. Sus aplicaciones se extienden a industrias críticas, garantizando un alto rendimiento y fiabilidad en entornos exigentes. Ya se trate de componentes aeroespaciales, dispositivos biomédicos o herramientas de alto rendimiento, EIMIG proporciona los materiales avanzados necesarios para superar los límites de la innovación.