لمحة عامة عن مسحوق FeCoNiCrMn

مسحوق FeCoNiCrMnالذي يُشار إليه غالبًا باسم سبيكة عالية الاستوائية (HEA)، يمثل تقدمًا ثوريًا في علم المواد. يشتهر هذا المسحوق المعدني بخصائصه الميكانيكية والكيميائية والحرارية الرائعة، ويستخدم على نطاق واسع في التطبيقات التي تتطلب القوة ومقاومة التآكل وتعدد الاستخدامات. وقد اكتسبت سبائك HEAs، بما في ذلك FeCoNiCrMn، شعبية بسبب تصميمها الفريد متعدد العناصر الرئيسية، مما يختلف عن السبائك التقليدية التي يهيمن عليها عنصر أو عنصرين رئيسيين.

في هذا الدليل الشامل، سنتعمق في هذا الدليل الشامل في مسحوق FeCoNiCrMn، ونستكشف تركيبته وخصائصه ونماذجه وتطبيقاته. كما سنناقش أيضًا المزايا والقيود والموردين الرئيسيين، مما يمنحك الصورة الكاملة لاتخاذ قرارات مستنيرة.

ما هو مسحوق FeCoNiCrMn؟

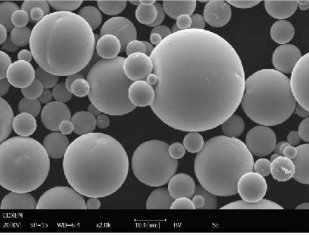

مسحوق FeCoNiCrMn عبارة عن مسحوق سبيكة خماسي العناصر يجمع بين الحديد (Fe) والكوبالت (Co) والنيكل (Ni) والكروم (Cr) والمنجنيز (Mn) بنسب متساوية تقريبًا. تشكل هذه التركيبة المتوازنة أساس خصائصها عالية الاستوائية، مما يؤدي إلى خصائص هيكلية ووظيفية ممتازة.

أبرز الملامح الرئيسية

- قوة وصلابة عالية: خصائص ميكانيكية استثنائية بسبب ترتيبه الذري الفريد.

- الاستقرار الحراري: مثالية للاستخدامات ذات درجات الحرارة العالية.

- مقاومة التآكل: مقاومة للأكسدة والتحلل الكيميائي.

- تعدد الاستخدامات: تُستخدم على نطاق واسع في التصنيع المضاف، والفضاء، والصناعات الطبية الحيوية.

تكوين مسحوق FeCoNiCrMn

يعد فهم التركيبة أمرًا بالغ الأهمية لفهم سبب أداء هذا المسحوق بشكل جيد. إليك التفاصيل

| العنصر | النسبة المئوية (النطاق النموذجي) | الدور في السبيكة |

|---|---|---|

| الحديد (Fe) | 19-23% | يعزز الخصائص المغناطيسية والمتانة. |

| الكوبالت (Co) | 19-23% | يوفر قوة ومقاومة حرارية. |

| النيكل (ني) | 19-23% | يحسّن مقاومة التآكل والليونة. |

| الكروم (Cr) | 19-23% | يوفر مقاومة للتآكل والصلابة. |

| المنجنيز (Mn) | 19-23% | يساهم في قابلية التشغيل وخصائص مقاومة التآكل. |

يقلل هذا التوزيع شبه الذري من تشوه الشبكة البلورية، مما يؤدي إلى أداء فائق في ظل الظروف الصعبة.

خصائص مسحوق FeCoNiCrMn مسحوق FeCoNiCrMn

خصائص هذه المادة تجعلها خياراً متميزاً في مختلف الصناعات. دعونا نفحص هذه الخصائص عن كثب:

| الممتلكات | التفاصيل |

|---|---|

| إنتروبية عالية | ترتيب ذري فريد بسبب التوزيع المتساوي للعناصر. |

| الاستقرار الحراري | هيكل وأداء مستقر في درجات الحرارة المرتفعة (حتى 1000 درجة مئوية وما بعدها). |

| مقاومة التآكل | مقاومة ممتازة للأكسدة والهجوم الكيميائي، حتى في البيئات القاسية. |

| القوة الميكانيكية | قوة الشد العالية، والليونة، ومقاومة التآكل. |

| الخصائص المغناطيسية | يحتفظ بالسلوك المغناطيسي المفيد في الإلكترونيات والآلات المتخصصة. |

تضمن هذه الخصائص أداء FeCoNiCrMn في السيناريوهات الصعبة مثل المحركات النفاثة والطباعة ثلاثية الأبعاد والبيئات البحرية.

تطبيقات مسحوق FeCoNiCrMn

يُعد مسحوق FeCoNiCrMn جزءًا لا يتجزأ من العديد من الصناعات عالية التقنية. فيما يلي مصفوفة تطبيق لتوضيح أفضل:

| الصناعة | التطبيقات | المزايا الرئيسية |

|---|---|---|

| الفضاء | مكونات المحرك النفاث وشفرات التوربينات. | مقاومة الحرارة والقوة تحت الضغط. |

| التصنيع الإضافي | الطباعة ثلاثية الأبعاد للهياكل المعقدة. | تعدد الاستخدامات والتشطيبات عالية الجودة. |

| الطب الحيوي | الأدوات الجراحية والغرسات. | التوافق الحيوي ومقاومة التآكل. |

| البحرية | أجزاء السفن، آلات تحت الماء | مقاومة التآكل والتآكل. |

| الطاقة | محطات توليد الطاقة والمفاعلات النووية | الثبات تحت درجات الحرارة والضغط العاليين. |

نماذج المسحوق FeCoNiCrMn

دعونا نتعمق في نماذج محددة من مسحوق FeCoNiCrMn لفهم الاختلافات وتطبيقاتها المحددة بشكل أفضل:

| اسم الموديل | الوصف |

|---|---|

| FeCoNiCrCrMn-101 | درجة قياسية لتصنيع الإضافات والطلاءات للأغراض العامة. |

| FeCoNiCrCrMn-202 | تركيبة محسنة مقاومة للتآكل للاستخدامات البحرية والطبية الحيوية. |

| FeCoNiCrMn-HT100 | متغير درجات الحرارة العالية المحسّن للفضاء وتوليد الطاقة. |

| FeCoNiCrMn-WR | طراز مقاوم للاهتراء مثالي للآلات الصناعية وأدوات التعدين. |

| FeCoNiCrMn-BM | نسخة متوافقة حيوياً مصممة خصيصاً للغرسات والأدوات الطبية. |

| FeCoNiCrMn-AM | درجة متطورة لتطبيقات الطباعة ثلاثية الأبعاد، مما يضمن تشطيبات أكثر سلاسة وتفاصيل دقيقة. |

| FeCoNiCrMn-Plus | مزيج من السبائك الممتازة مع قوة شد وليونة فائقة للظروف القاسية. |

| FeCoNiCrCrMn-Ceramix | تركيبة هجينة تشتمل على خصائص شبيهة بالسيراميك لمزيد من الصلابة ومقاومة التآكل. |

| FeCoNiCrMnLight | إصدار خفيف الوزن لتطبيقات الطيران والسيارات التي تتطلب نسبة عالية من القوة إلى الوزن. |

| هجين FeCoNiCrMnHybrid | نموذج متعدد الاستخدامات مصمم خصيصاً للتطبيقات الهجينة التي تنطوي على تحديات حرارية وتآكل. |

المواصفات والمعايير

عند الحصول على مسحوق FeCoNiCrMn، من الضروري فهم المواصفات:

| المعلمة | النطاق | الملاحظات |

|---|---|---|

| حجم الجسيمات | 15-150 ميكرون | مُحسّن للطباعة ثلاثية الأبعاد والتلبيد بالليزر. |

| النقاء | ≥99.5% | يضمن الأداء العالي والموثوقية. |

| الكثافة | 7.5 - 8.0 جم/سم مكعب | انعكاساً لإنتروبيته وتكوينه العاليين. |

| نقطة الانصهار | ~1350°C | يوفر ثبات حراري ممتاز. |

| الامتثال للمعايير | ISO 9001, ASTM E-8 | يضمن الجودة والاتساق عبر الدفعات. |

مزايا وعيوب مسحوق FeCoNiCrMn

كل مادة لها إيجابياتها وسلبياتها، ومسحوق FeCoNiCrMn ليس استثناءً. إليك مقارنة:

| مزايا | سلبيات |

|---|---|

| خصائص ميكانيكية استثنائية | تكلفة أعلى مقارنةً بالسبائك التقليدية. |

| متعدد الاستخدامات لمختلف التطبيقات | محدودية الموردين وتحديات التوريد. |

| مقاومة ممتازة للتآكل والأكسدة | تتطلب آلات متطورة للمعالجة. |

| ثبات حراري في درجات الحرارة القصوى | القيود المحتملة في التطبيقات خفيفة الوزن. |

الموردون والتسعير

إن العثور على موردين موثوقين أمر بالغ الأهمية لضمان الجودة. وفيما يلي قائمة مختارة:

| اسم المورد | الموقع | السعر (دولار أمريكي/كيلوغرام) | التخصص |

|---|---|---|---|

| حلول ألوي تك سوليوتيك | الولايات المتحدة الأمريكية | $250-$300 | مساحيق من فئة الفضاء الجوي. |

| شركة PowderMasters Inc. | ألمانيا | $220-$280 | تحجيم الجسيمات حسب الطلب. |

| موردو GlobalHEA | الصين | $200-$240 | الطلبات بالجملة والدرجات القياسية. |

| شركة ميتال ماتاتريكس | الهند | $180-$220 | خيارات فعالة من حيث التكلفة للاستخدام العام. |

| ديناميكيات HEA | اليابان | $270-$320 | سبائك فاخرة عالية الجودة. |

أسئلة وأجوبة

| سؤال | الإجابة |

|---|---|

| ما هو الاستخدام الأساسي لمسحوق FeCoNiCrMn؟ | يُستخدم في مجال الفضاء، والتصنيع المضاف، والتطبيقات الطبية الحيوية لتعدد استخداماته. |

| هل FeCoNiCrMn متوافق حيوياً؟ | نعم، تم تصميم نماذج محددة مثل FeCoNiCrMn-BM للاستخدامات الطبية الحيوية. |

| ما الذي يجعلها سبيكة عالية الاستقطاب؟ | تخلق النسبة المتساوية تقريبًا من العناصر الرئيسية الخمسة تكوينًا مستقرًا وعالي الإنتروبيا. |

| كيف تختلف عن السبائك التقليدية؟ | يوفر مقاومة أفضل للتآكل والاستقرار الحراري والقوة الميكانيكية. |

| هل يمكن استخدام FeCoNiCrMn في الطباعة ثلاثية الأبعاد؟ | بالتأكيد، يتم استخدامه على نطاق واسع في التصنيع المضاف نظرًا لتوزيع مسحوقه الناعم. |