عملية حقن المسحوق المعدني MIM هي عملية تصنيع يتم فيها حقن مسحوق معدني في قالب لإنتاج أجزاء معدنية معقدة وعالية الكثافة. تجمع عملية MIM بين مرونة التصميم في عملية التشكيل بالحقن البلاستيكي مع قوة وسلامة الأجزاء المعدنية المُشَكَّلة آليًا.

يشير مسحوق MIM إلى مساحيق المعادن المستخدمة كمادة خام في عملية MIM. وتؤثر تركيبة وخصائص مسحوق التصنيع بقطع التصنيع بقطع التصنيع بقطع التصنيع بقطع التصنيع بقطع التصنيع بقطع التصنيع بقطع التصنيع بقطع غيار المعادن تأثيرًا كبيرًا على خصائص الأجزاء المصنوعة من هذه المادة وجودتها وفعاليتها من حيث التكلفة.

أنواع مسحوق MIM وتركيبته

تتوفر مساحيق MIM في مجموعة واسعة من السبائك، بما في ذلك الفولاذ المقاوم للصدأ، وفولاذ الأدوات، والسبائك المغناطيسية، وسبائك النحاس، والسبائك الفائقة، وسبائك التيتانيوم. ويشكل الحديد والنيكل والكوبالت قاعدة معظم مساحيق التصنيع المدمج المتعدد المعادن.

الفئات الأكثر شيوعًا من المساحيق المعدنية MIM تشمل:

| نوع مسحوق MIM | التركيب |

|---|---|

| الفولاذ المقاوم للصدأ | الحديد والكروم والنيكل + العناصر النزرة مثل المونيوم والنيكل والنيكلينوم |

| فولاذ الأدوات | حديد-كروم-مو-ف + مُشكِّلات الكربيد مثل W، Cr |

| السبائك المغناطيسية اللينة | Fe-Si، Fe-Ni، Fe-Co + Cu، Nb، إلخ. |

| سبائك النحاس | النحاس والزنك، والنحاس والأل والنحاس والزنك، إلخ. |

| سبائك فائقة | Ni/Co-Cr + Al، Ti، Ti، Nb، Ta، W، إلخ. |

| سبائك التيتانيوم | Ti-Al-V، Ti-Mn، Ti-Mo، إلخ. |

يمكن تغيير التركيب الدقيق للحصول على الخصائص المحددة التي يتطلبها التطبيق. يتم التحكم في العناصر النزرة بعناية.

تحدد تركيبة وكيمياء السبيكة أداء مسحوق MIM وقابليته للمعالجة وسعره.

خصائص مسحوق MIM وخصائصه

بالإضافة إلى التركيب، تتميز مساحيق MIM بخصائص فيزيائية وكيميائية معينة تجعلها مناسبة لعملية MIM:

الجدول 1: الخصائص والخصائص الرئيسية لمساحيق MIM

| الممتلكات | القيم المرغوبة | الأهمية |

|---|---|---|

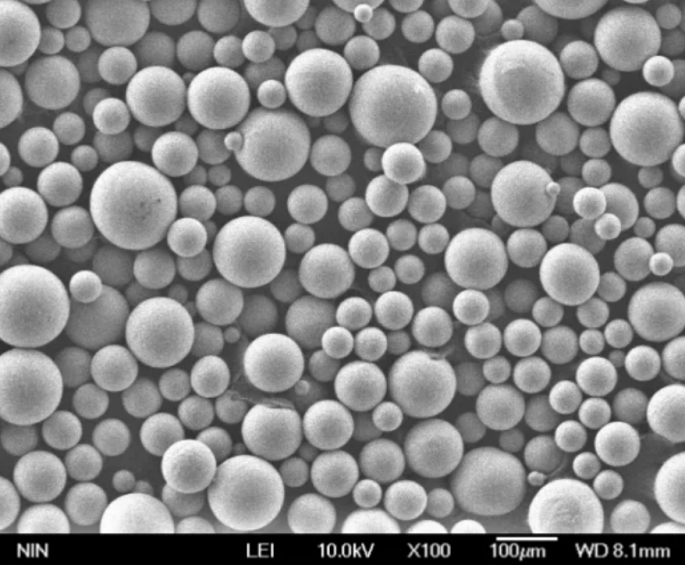

| حجم الجسيمات | 10-20 ميكرومتر | يؤثر على تدفق المسحوق وكثافة التعبئة |

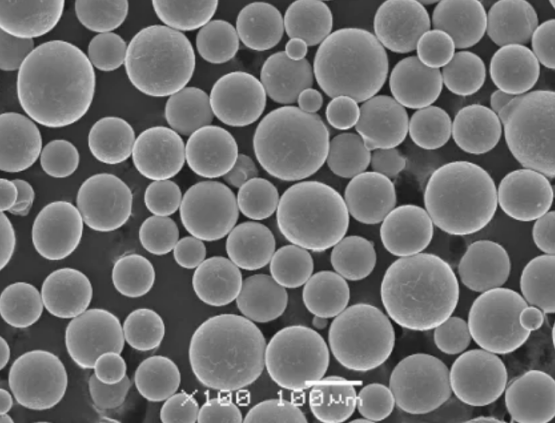

| علم الصرف | كروية وخالية من الأقمار الصناعية | يحدد قابلية تدفق المسحوق |

| محتوى الأكسجين | <0.5% | تأثيرات إزالة الصلب والتلبيد |

| الكثافة الظاهرة | >80٪ من الكثافة الحقيقية | يؤثر على كثافة الجزء النهائي |

| كثافة الحنفية | >90٪ من الكثافة الحقيقية | يحدد سلوك الخلط والتدفق |

| نسبة هاوزنر | <1.25 | يشير إلى قابلية المسحوق للتدفق |

| الكثافة البايكنومترية | حسب السبيكة | تعيين الحد الأعلى لكثافة الجزء النهائي |

| معدل التدفق | >؛ 28 ثانية/50 جم | ضمان سلاسة قولبة الحقن بالحقن |

هناك حاجة إلى التحكم الدقيق في خصائص المسحوق مثل حجم الجسيمات وشكلها وكثافتها وتدفقها لإنتاج أجزاء MIM عالية الجودة.

تطبيقات واستخدامات مسحوق MIM

يُستخدم التصنيع بقطع التصنيع المقلدة لتصنيع قطع صغيرة ومعقدة ذات خواص ميكانيكية ممتازة في صناعات مثل

الجدول 2: التطبيقات الرئيسية لمساحيق MIM

| الصناعة | تطبيقات نموذجية | درجات السبائك المستخدمة |

|---|---|---|

| الفضاء | شفرات التوربينات، الدفاعات | سبائك النيكل الفائقة، وسبائك التيتانيوم |

| السيارات | التروس، قضبان التوصيل | الفولاذ المقاوم للصدأ، فولاذ الأدوات |

| المستهلك | مشاهدة الأجسام، وأقواس تقويم الأسنان | الفولاذ المقاوم للصدأ، وسبائك التيتانيوم |

| الإلكترونيات | المستشعرات، دبابيس الموصلات | السبائك المغناطيسية، وسبائك النحاس |

| الطبية | شفرات مشرط، ملقط | الفولاذ المقاوم للصدأ، فولاذ الأدوات |

| الأسلحة النارية | المشغلات والمطارق والمنزلقات | الفولاذ المقاوم للصدأ، فولاذ الأدوات |

يسمح التصنيع متعدد النماذج بدمج أجزاء متعددة في مكون واحد معقد. تتيح مرونة مساحيق MIM استخدامها في صناعات متنوعة وعالية القيمة.

مواصفات ومعايير مسحوق التصنيع المدمج MIM

تتوفر مساحيق MIM بدرجات قياسية ومخصصة متنوعة مصممة خصيصًا لتلبية احتياجات الصناعة/التطبيق:

الجدول 3: مواصفات مسحوق MIM وأحجامه ومعاييره

| قياسي | درجات | حجم الجسيمات | كيمياء |

|---|---|---|---|

| ASTM F2885 | الرتب الشائعة مثل SS316L، SS17-4PH، SS410، Inconel 718 | 16-20 ميكرومتر | محددة حسب نوع السبيكة |

| ISO 22068 | الدرجات المعادلة | على غرار ASTM | على غرار ASTM |

| أدلة Epma/MIMA الإرشادية | الدرجات المخصصة ممكنة | 10-22 ميكرومتر نموذجي | العميل المحدد |

تقدم معظم الشركات المصنعة لمساحيق التصنيع بقطع التصنيع المدمج (MIM) درجات قياسية ومخصصة تتماشى مع متطلبات الصناعة.

يمكن الحصول على درجات خاصة للتطبيقات الأكثر تطلبًا في مجال الفضاء والطب وما إلى ذلك.

موردو مسحوق MIM وأسعاره

يوفر كبار الموردين العالميين الرئيسيين التاليين مساحيق MIM عالية الجودة:

الجدول 4: كبار موردي مساحيق MIM وأسعارها الإرشادية

| المورد | الدرجات المقدمة | الأسعار |

|---|---|---|

| ساندفيك أوسبري | محفظة تقديرات واسعة النطاق | $$$ |

| هوجاناس | الدرجات القيادية | $$ |

| مجموعة AMES | الدرجات المصممة خصيصاً | $-$$ |

| BASF | درجات نقاء عالية النقاء | $$$ |

| كيميرا إنترناشيونال | نطاق واسع | $-$$ |

تتراوح الأسعار من 20 دولارًا/كجم لدرجات الفولاذ المقاوم للصدأ الشائعة إلى 200 دولار/كجم للسبائك الفائقة الغريبة حسب حجم الطلب والتركيب الدقيق.

تتطلب مساحيق MIM رقابة صارمة على الجودة ومعالجة كبيرة، وهو ما ينعكس في الأسعار الممتازة للدرجات النهائية.

إيجابيات مسحوق MIM وسلبياته

الجدول 5: مزايا مساحيق MIM وقيودها

| مزايا | محددات |

|---|---|

| الأجزاء المعقدة ذات الشكل الصافي | تكلفة الجزء الأعلى مقابل العمليات الأخرى |

| خواص ميكانيكية ممتازة | نطاق حجم محدود |

| مرونة واسعة في المواد | الأشكال هندسية مقيدة |

| مثبتة في مختلف القطاعات | يتطلب خبرة عالية |

تتيح عملية MIM قطعًا معدنية عالية الأداء لا يمكن تحقيقها بتقنيات أخرى، شريطة اتباع إرشادات التصميم.

أدى مسحوق MIM إلى توسيع نطاق تطبيق MIM على الرغم من ارتفاع تكلفة القطع المرتبطة به.

أسئلة وأجوبة حول المسحوق المعدني MIM

س: ما هي التركيبة النموذجية لمسحوق MIM؟

ج: معظم مساحيق MIM عبارة عن سبائك قائمة على الحديد أو النيكل أو الكوبالت مع 15-30% من الكروم، وما يصل إلى 20% من الموليبدينوم، وإضافات ضئيلة من التيتانيوم والنيوبيوم وغيرها. تتم مطابقة تركيبة المسحوق مع متطلبات التطبيق.

س: ما هي خصائص المسحوق الأكثر أهمية للمواد الأولية لتصنيع القوالب النمطية MIM؟

ج: إن حجم الجسيمات والمورفولوجيا والكثافة الظاهرية ومعدل التدفق ومحتوى الأكسجين لها التأثير الأكبر على سلوك المادة الأولية لقولبة التصنيع المدمجة وخصائص الجزء الملبد. تحتاج سمات المسحوق هذه إلى تحكم محكم.

س: هل تسمح عملية MIM باستخدام المعادن الثمينة؟

ج: نعم، يمكن بسهولة استخدام المعادن الثمينة مثل سبائك الذهب والفضة الإسترليني في تصنيع ميمات MIM للمجوهرات والتطبيقات عالية القيمة، وذلك بسبب استخدام مادة 100% في تصنيع ميمات MIM.

س: ما هي المعايير التي توجه مواصفات مسحوق MIM؟

ج: تشمل المعايير الرئيسية ASTM F2885 وISO 22068 وأدلة هيئة الصناعة من Epma وMIMA، والتي تسرد الدرجات الشائعة وإجراءات الاختبار. الدرجات المخصصة ممكنة أيضًا.

س: كيف يتم تحديد أسعار مسحوق MIM؟

ج: يعتمد تسعير التصنيع الميكانيكي المتعدد الوسائط بشدة على التركيب وحجم الإنتاج ومستوى الجودة وطريقة المعالجة. وبصفة عامة، تتصاعد التكلفة بشكل عام بالنسبة للمساحيق عالية النظافة والكروية والمخصصة.

خاتمة

يستمر تصنيع القوالب النمذجة MIM في إزاحة طرق التصنيع التقليدية في مختلف الصناعات، وذلك بفضل مساحيق MIM المتخصصة المصممة خصيصًا لكل تطبيق. من خلال مراقبة الجودة الصارمة والابتكار في السبائك، يضمن موردو مساحيق التصنيع بقطع التصنيع المدمجة مثل Sandvik Osprey و BASF الأداء الأمثل للمادة الأولية وجودة الأجزاء الملبدة دفعة بعد دفعة، مما يسهل اعتماد قولبة حقن المعادن على نطاق أوسع.