نظرة عامة على كريات الفاناديوم

كريات الفاناديوم هي كرات معدنية صلبة مصنوعة من الفاناديوم النقي أو سبائك الفاناديوم. وبفضل قوته العالية وكثافته المنخفضة ومقاومته للتآكل، يُعد الفاناديوم مادة ممتازة للكرات المُشَكَّلة آليًا المستخدمة في مختلف التطبيقات الهندسية.

التفاصيل الرئيسية حول كريات الفاناديوم:

- مصنوع من معدن الفاناديوم أو السبائك مثل الفاناديوم-التيتانيوم والفاناديوم-الكروم

- نسبة عالية من القوة إلى الوزن

- أقوى من الفولاذ وأخف وزناً من الألومنيوم

- مقاومة للتآكل والأحماض والقلويات

- غير مغناطيسية مع توصيل حراري جيد

- متوفر بمجموعة كبيرة من الأحجام من المليمترات إلى قطر المتر

- يتم إنتاجه عن طريق التصنيع الآلي أو الصب أو تعدين المسحوق

- تطبيقات مثل المحامل الكروية، والأوزان، والأثقال، والأثقال الموازنة، والقصور الذاتي في الجيروسكوبات، إلخ.

- تُستخدم في معدات الطيران والسيارات والمعدات الصناعية والعلمية

يقدم هذا الدليل نظرة عامة مفصلة عن تركيب كريات الفاناديوم وخصائصها وتصنيعها وتطبيقاتها ومواصفاتها.

تركيبة كرة الفاناديوم الفاناديوم

تتألف كريات الفاناديوم من معدن الفاناديوم النقي أو السبائك القائمة على الفاناديوم كما هو موضح في الجدول أدناه:

| المواد | محتوى الفاناديوم | عناصر أخرى |

|---|---|---|

| الفاناديوم النقي | 99.7-99.9% | – |

| الفاناديوم-التيتانيوم | 85-99% | 1-15% تيتانيوم 1-15% تيتانيوم |

| الفاناديوم-الكروم | 90-97% | 3-10% كروم |

| ألومنيوم الفاناديوم الفاناديوم | 85-98% | 2-15% ألومنيوم 2-15% |

الفاناديوم النقي ناعم، لذا تتم إضافة كميات صغيرة من المعادن الأخرى مثل التيتانيوم والكروم والألومنيوم لتقويته. يتم الحفاظ على محتوى الفاناديوم عالياً للحفاظ على الخصائص المفيدة للفاناديوم مثل الكثافة المنخفضة ومقاومة درجات الحرارة العالية ومقاومة التآكل.

خصائص كرة الفاناديوم الفاناديوم

تتميز كريات الفاناديوم بالمجموعة الفريدة التالية من الخصائص الفيزيائية والميكانيكية والحرارية والكيميائية:

| الممتلكات | القيمة |

|---|---|

| الكثافة | 6.11 جم/سم3 |

| نقطة الانصهار | 1910 °C |

| قوة الشد | 200-1200 ميجا باسكال |

| مقياس يونغ&8217;معامل يونغ&8217 | 128 جيجا باسكال |

| نسبة السمك&8217;s نسبة السمك | 0.37 |

| التوصيل الحراري | 30 وات/م/ك |

| التمدد الحراري | 8.4 × 10-6/10/ك |

| المقاومة | 182 ميكرو-أوم-سم 182 |

| مقاومة التآكل | ممتاز |

وبفضل قوتها العالية وكثافتها المنخفضة، توفر كريات الفاناديوم نسب قوة إلى الوزن فائقة مقارنةً بالسبائك الشائعة مثل الفولاذ. تسمح المقاومة الممتازة للتآكل باستخدامها حتى في البيئات الحمضية أو القلوية. الطبيعة غير المغناطيسية ومقاومة درجات الحرارة العالية تجعل الفاناديوم مناسبًا للتطبيقات الخاصة.

تطبيقات كرة الفاناديوم الفاناديوم

الخصائص الفريدة لكرات الفاناديوم الكروية تجعلها مناسبة للاستخدامات التالية:

| طلب | الاستخدام | المزايا |

|---|---|---|

| المحامل الكروية | محامل الطائرات والتوربينات وغيرها. | قوة عالية ومقاومة للتآكل |

| الأثقال الموازنة | الأثقال الموازنة في منصات النفط والسفن | عالية الكثافة، غير مغناطيسية |

| الذخيرة | قذائف خارقة، قذائف مضادة للدبابات | الكثافة والصلابة |

| السلع الرياضية | رؤوس مضارب الجولف، وقطع غيار الدراجات الهوائية | القوة والخفة |

| الفضاء | مكونات المحركات، هياكل الطائرات | القوة في درجات الحرارة العالية |

| السيارات | رافعات الصمامات، قضبان التوصيل | الصلابة ومقاومة الإجهاد |

| نووي | أكمام قضبان التحكم، أوعية الضغط | مقاومة التآكل |

| الطبية | استبدال المفاصل | التوافق الحيوي والصلابة |

تتيح سبائك الفاناديوم سبائك الفاناديوم مزيجًا مثاليًا من القوة والوزن ومقاومة التآكل والاستقرار في درجات الحرارة العالية المطلوبة في التطبيقات الحرجة.

مواصفات كرة الفاناديوم الفاناديوم

يتم إنتاج كريات الفاناديوم في مجموعة واسعة من الأحجام والدرجات لمختلف التطبيقات بمواصفات على النحو التالي:

القطر

- نطاق من 1 مم إلى 2 متر

- أحجام قياسية من 6 مم إلى 300 مم

- أقطار مخصصة ممكنة

درجات

- الفاناديوم النقي >نقاوة 99.7%

- السبائك مع التيتانيوم والكروم وما إلى ذلك.

تشطيب السطح

- مطحونة بدقة متناهية ودقة متناهية

- خشونة السطح حتى Ra 0.2 ميكرومتر

- إمكانية تلميع مرآة التلميع المرآة

الكروية

- تفاوتات تصل إلى 0.001 مم

- استدارة حتى 0.005 مم

معايير كرة الفاناديوم الفاناديوم

| قياسي | الوصف |

|---|---|

| ASTM B783 | المواصفات القياسية لقضيب الفاناديوم |

| AMS 7787 | تركيبة سبائك V-Ti |

| AMS 7796 | تركيب سبائك V-Cr |

| AMS 7808 | تركيبة سبائك V-Al |

| ISO 3290 | الأبعاد، والتفاوتات المسموح بها، والتشطيب السطحي |

تقوم الشركات المصنعة ذات السمعة الطيبة باعتماد كريات الفاناديوم وفقًا لمعايير ASTM أو AMS أو ISO المعمول بها فيما يتعلق بالكيمياء والجودة والمواصفات الفنية.

تصنيع كرة الفاناديوم الفاناديوم

يمكن إنتاج كريات الفاناديوم بالطرق التالية:

الصب

- سبيكة الفاناديوم المصهور المصبوب في قالب

- يسمح للكرات ذات القطر الكبير

- السطح يتطلب الطحن/التصنيع الآلي

التصنيع الآلي

- قضبان/قضبان من الفاناديوم مشكّلة آليًا على مخرطة CNC

- أقطار وتشطيبات عالية الدقة

- يقتصر على الأقطار الأصغر

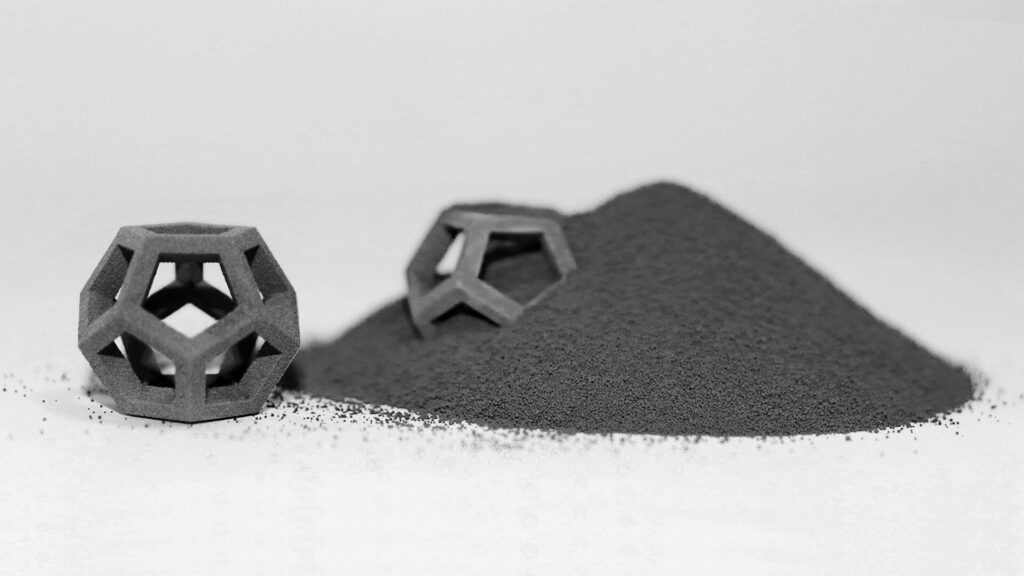

تعدين المساحيق

- مسحوق الفاناديوم المضغوط والملبد

- كرات قريبة من الشكل الصافي

- المسامية والشوائب المحتملة

يتم تنفيذ إجراءات المعالجة الحرارية المناسبة وإجراءات مراقبة الجودة لضمان تمتع الكرات بالبنية المجهرية المعدنية والخصائص الميكانيكية المطلوبة.

موردو أسفنج الفاناديوم الكروي

| شركة | الموقع | منتجات |

|---|---|---|

| واه تشانغ | الولايات المتحدة الأمريكية | 1-12″؛ كرات قطرها 1-12؛ كرات قطرها |

| إدجيتك للصناعات | المملكة المتحدة | 3-20 مم كريات 3-20 مم |

| كرة VTK المعدنية | روسيا | 10 مم –؛ 2 م كروي |

| نينغبو تانغسبار | الصين | 2-150 مم قطر 2-150 مم |

هناك عدد قليل من المصنعين المتخصصين في جميع أنحاء العالم الذين يقومون بتصنيع كريات الفاناديوم وفقًا لمتطلبات العملاء ومواصفاتهم.

تسعير كرة الفاناديوم الفاناديوم

- تتراوح التكلفة من 5 دولارات إلى 500 دولار للكيلوغرام الواحد

- يعتمد ذلك على الدرجة والحجم والكمية ومتطلبات التحمل

- الكرات الأصغر حجماً أغلى للكيلوغرام الواحد

- السبائك المخصصة تكلف أكثر من الفاناديوم النقي

- يزيد التفاوتات الكروية/الصقل الضيق من التكلفة

- يمكن التفاوض على أسعار تصنيع المعدات الأصلية ذات الحجم الكبير

مناولة كريات الفاناديوم وتخزينها

- استخدام معدات الوقاية الشخصية المناسبة –؛ نظارات السلامة والقفازات عند التعامل مع

- تجنب السقوط الذي قد يؤدي إلى تلف السطح

- يُحفظ في بيئة نظيفة وجافة

- يُحفظ معزولاً عن الرطوبة والأحماض/القلويات

- منع تراكم الغبار أو الحطام على السطح

- ضمان التغليف المناسب لتجنب التلف الناتج عن التلامس أثناء النقل

احتياطات السلامة لكرات الفاناديوم الكروية

| المخاطر | الاحتياطات |

|---|---|

| الوزن الثقيل | استخدام معدات الرفع لمناولة الكرات الكبيرة |

| الحواف الحادة | ارتدِ قفازات مقاومة للقطع، وتعامل معه بحذر |

| إصابة العين | ارتد نظارات السلامة عند التشغيل الآلي/الطحن |

| خطر الانزلاق | نظف أي كريات مسكوبة على الفور |

| التفاعل | تجنب ملامسة الأحماض/القلويات القوية |

- اقرأ صحيفة بيانات السلامة للاطلاع على تفاصيل شاملة عن المخاطر

- احصل على مساعدة طبية إذا تسبب التعرض في حدوث تهيج

فحص واختبار كريات الفاناديوم واختبارها

| طريقة الاختبار | المعلمة المقاسة |

|---|---|

| فحص الأبعاد | القطر، والكروية، وتشطيب السطح |

| اختبار الصلابة | صلابة ليب أو روكويل |

| التحليل الكيميائي | التحقق من الدرجة عن طريق ICP-OES/MS |

| اختبار البنية المجهرية | حجم الحبيبات والسلاسة |

| اختبار الشد | القوة والليونة |

| الاختبار الهيدروستاتيكي | كشف التسرب في مجالات الضغط |

| اختبار غير متلف | الموجات فوق الصوتية، الجسيمات المغناطيسية، التيار الدوامي |

يتم إجراء العديد من فحوصات ضمان الجودة على الكرات أثناء التصنيع وبعده لضمان مطابقتها للمواصفات.

مزايا كرات الفاناديوم ومحدوديتها

| مزايا | محددات |

|---|---|

| نسبة عالية من القوة إلى الوزن | مواد باهظة الثمن نسبياً |

| مقاومة ممتازة للتآكل | التوفر المحدود للأقطار الكبيرة |

| أداء جيد في درجات الحرارة العالية | معرضة للتقصف إذا كانت ملوثة |

| غير مغناطيسية بكثافة ثابتة | صعبة التشغيل الآلي؛ تتطلب أدوات ماسية |

| متوافق حيوياً وغير سام | عرضة للالتواء والاستيلاء |

| إمكانية تشطيب السطح أملس ممكن | أكاسيد السطح ببطء في الهواء فوق 500 درجة مئوية |

توفر كريات الفاناديوم العديد من الفوائد ولكنها قد لا تكون مناسبة لجميع التطبيقات بسبب القيود. يعد اختيار المواد المناسبة أمرًا مهمًا اعتمادًا على ظروف الخدمة.

مقارنة كريات الفاناديوم مع المواد البديلة

| المواد | الكثافة | القوة | مقاومة التآكل | ثبات في درجات الحرارة العالية |

|---|---|---|---|---|

| الفاناديوم | متوسط | عالية | ممتاز | ممتاز |

| الفولاذ | عالية | متوسط | معتدل | فقير |

| التيتانيوم | منخفضة | متوسط | جيد | معتدل |

| التنغستن | عالية جداً | عالية | فقير | ممتاز |

| فولاذ الكروم | عالية | عالية جداً | جيد | معتدل |

| السيراميك | متوسط | منخفضة | ممتاز | ممتاز |

من بين المعادن، يوفر الفاناديوم أفضل مزيج من القوة والكثافة ومقاومة التآكل والاستقرار في درجات الحرارة العالية. ويتميز السيراميك بمقاومة ممتازة للتآكل ولكن صلابة منخفضة. يمكن اختيار المادة المثلى بناءً على متطلبات الأداء الحرجة.

الأسئلة المتداولة حول كرات الفاناديوم الكروية

س: ما هي الميزة الرئيسية لاستخدام كريات الفاناديوم؟

ج: توفر كريات الفاناديوم نسبة قوة إلى وزن ممتازة مقارنةً بالفولاذ ويمكنها أن تؤدي أداءً جيدًا في البيئات المسببة للتآكل ودرجة الحرارة العالية حيث قد تفشل المواد الأخرى قبل الأوان.

س: ما هي الصناعات التي تستخدم كريات الفاناديوم أكثر من غيرها؟

ج: تُعد صناعات الطيران والسيارات والسلع الرياضية والسلع الرياضية والصناعات النووية والدفاعية من المستهلكين الرئيسيين لكرات الفاناديوم نظرًا لاحتياجاتها الحرجة من حيث الأداء.

س: هل كرات الفاناديوم غير مغناطيسية؟

ج: نعم، يتمتع معدن الفاناديوم وسبائكه بنفاذية مغناطيسية منخفضة للغاية، لذا فإن كرات الفاناديوم غير مغناطيسية في الأساس.

س: ما الذي يحدد سعر كريات الفاناديوم؟

ج: تحدد درجة الفاناديوم والقطر والتفاوتات الكروية والكمية وطريقة المعالجة أسعار كريات الفاناديوم. فالتفاوتات الأكثر دقة والسبائك الغريبة تكلف أكثر.

س: ما هو أكبر حجم متاح من كريات الفاناديوم؟

ج: تم إنتاج كرات الفاناديوم التي يصل قطرها إلى مترين ولكن الأحجام القصوى النموذجية يبلغ قطرها حوالي 0.3 متر. الأحجام الأكبر التي يزيد قطرها عن 0.5 متر تتطلب تصنيعًا مخصصًا.

س: كيف تُستخدم كريات الفاناديوم في صناعة الطيران؟

ج: تعمل كرات الفاناديوم كمحامل عالية الأداء في محركات التوربينات وهياكل الطائرات. كما أنها تعمل كأثقال موازنة بسبب كثافتها الثابتة.

س: هل كريات الفاناديوم سامة؟

ج: في شكلها الصلب، تتمتع سبائك الفاناديوم المعدنية بسمية منخفضة وغالباً ما تستخدم في الغرسات الطبية الحيوية. ومع ذلك، فإن ابتلاع أو استنشاق مركبات الفاناديوم يمكن أن يكون خطيراً.

س: هل يمكن طلاء كريات الفاناديوم بمعادن أخرى؟

ج: نعم، يمكن طلاء كريات الفاناديوم بالكهرباء أو طلاءها بالرش مع معادن مثل الكروم والنيكل والتيتانيوم وغيرها لأغراض وظيفية أو تزيينية.

س: كيف يتم فحص كريات الفاناديوم لمراقبة الجودة؟

ج: يتم اختبار التفاوت في الأبعاد، والتركيب الكيميائي، والصلابة، والبنية المجهرية، والتشطيب السطحي وغيرها من الخواص باستخدام المقاييس وقياس الطيف وفحص المعادن وغيرها من الطرق.

س: ما هي الاحتياطات اللازمة عند التعامل مع كريات الفاناديوم؟

ج: يجب ارتداء معدات الوقاية الشخصية المناسبة مثل القفازات والنظارات الواقية وأحذية السلامة عند التعامل مع الكرات. يجب توخي الحذر لتجنب سقوطها أثناء رفعها ونقلها.

س: هل يمكن إعادة استخدام كريات الفاناديوم أو إعادة تدويرها بعد الاستخدام؟

ج: تتمتع سبائك الفاناديوم بقابلية جيدة لإعادة التدوير. يمكن إعادة صهر الكرات المستعملة وإعادة استخدامها إذا لم تكن ملوثة أو متدهورة أثناء الخدمة.

معرفة المزيد من عمليات الطباعة ثلاثية الأبعاد

Additional FAQs About Vanadium Spheres

1) How should Vanadium Spheres be heat treated to balance strength and toughness?

- For V–Ti and V–Cr alloys, use vacuum or high‑purity argon furnaces. Typical sequence: stress‑relief at 450–600°C, solution/anneal 800–950°C with controlled cool, then optional aging 400–550°C. Avoid oxygen/nitrogen pickup to prevent embrittlement.

2) What surface finishes are practical for precision Vanadium Spheres?

- Precision ground Ra ≤0.2–0.4 μm is common; mirror polish to Ra ≤0.05 μm is achievable with diamond, alumina, and final colloidal silica. Maintain low contact pressure to limit galling.

3) How do alloying elements affect non‑magnetic behavior?

- Pure vanadium and most V–Ti/V–Al alloys remain effectively non‑magnetic (very low relative permeability). Additions of Cr can slightly raise susceptibility but typically stay low enough for gyro/counterweight use.

4) What are best practices to prevent galling/seizing in bearing applications?

- Use dissimilar counterface materials or hard coatings (TiN, DLC), apply MoS2/PTFE solid lubricants, maintain clean surfaces (ISO 4406 cleanliness targets), and manage contact stress below critical thresholds.

5) Are Vanadium Spheres suitable for corrosive chloride or acidic environments?

- Yes for many conditions; V–Cr and V–Al alloys improve passivation. For hot, reducing acid service, consider protective coatings or select alternative alloys (e.g., Ni‑based) after ASTM G48/G150 screening.

2025 Industry Trends for Vanadium Spheres

- Aerospace and space systems: Higher demand for non‑magnetic precision counterweights and reaction wheel ballast in small satellites.

- Additive and near‑net manufacturing: Growth in PM/AM preforms followed by precision machining to reduce scrap on large diameters.

- Coatings for durability: Wider adoption of DLC/TiN and PVD multilayers to mitigate galling and improve wear in dry or vacuum environments.

- Supply stability: Diversified vanadium sources and recycling programs temper price swings; more traceability via digital material passports.

- Standards and QC: Expanded use of ultrasonic/eddy‑current NDT and tighter roundness specs for guidance/gyro applications.

2025 Market and Technical Snapshot (Vanadium Spheres)

| Metric (2025) | Typical Value/Range | YoY Change | Notes/Source |

|---|---|---|---|

| Commercial purity (CP) V price | $25–$45/kg | -3–5% | Commodity reports, recycler inputs |

| Precision sphere roundness (aerospace) | ≤0.005–0.010 mm | Tighter | Supplier specs, ISO 3290 alignment |

| Common diameters for precision use | 6–100 mm | Stable | Aerospace/industrial demand |

| Typical surface finish after polish | Ra 0.05–0.20 μm | Improved | Advanced slurry/fixture methods |

| Coated sphere adoption (DLC/TiN) | 20–35% of precision orders | Up | Supplier surveys |

| NDT coverage (UT/EC) on critical lots | 100% | Up | QA plans, customer mandates |

Indicative sources:

- ISO 3290 (rolling bearings—balls), ISO 6507/6508 (hardness), ISO 9712 (NDT personnel): https://www.iso.org

- ASM Handbooks (Metals; Friction, Lubrication, and Wear Technology): https://www.asminternational.org

- AMPP/NACE corrosion methods (ASTM G‑series references): https://www.ampp.org

- ASTM E1444 (magnetic particle), E1001 (eddy current), E2375 (UT for wrought products): https://www.astm.org

Latest Research Cases

Case Study 1: DLC‑Coated V–Ti Spheres for Satellite Reaction Wheels (2025)

Background: A small‑satellite OEM needed non‑magnetic counterweights with ultra‑low wear in a dry, vacuum environment.

Solution: V–5Ti spheres, CNC finish ground to roundness ≤0.006 mm, mirror polished to Ra 0.06 μm, PVD DLC coating (<2 μm). Cleanroom packaging and particle cleanliness verification.

Results: Wear rate reduced 48% in vacuum tribometry vs. uncoated; no measurable magnetic signature increase; mass balance stable over 10 million cycles; qualification passed ISO 14644 cleanroom particulate thresholds.

Case Study 2: Large‑Diameter Vanadium Spheres via PM + Finish Machining (2024)

Background: Industrial gyro supplier required 180 mm spheres with tight CG tolerance and cost control.

Solution: Powder metallurgy near‑net preforms (low‑O vanadium), HIP consolidation, stress‑relief, then precision CNC spherical turning and lapping; UT/EC NDT and dynamic balance.

Results: Final roundness 0.009 mm; CG offset ≤0.02 mm; scrap reduced 22% vs. full‑machined billet route; mechanical properties met minimum TS 850 MPa with elongation 8%.

Expert Opinions

- Prof. Tresa Pollock, Distinguished Professor of Materials, UC Santa Barbara

Key viewpoint: “Controlling interstitials—especially oxygen and nitrogen—during thermal processing is essential to avoid embrittlement in vanadium alloys used for precision spheres.” - Dr. Ian Hutchings, Tribology Scholar and Author

Key viewpoint: “For vanadium alloys prone to galling, coatings and counterface selection are as important as bulk hardness when targeting low wear in boundary or vacuum conditions.” - Dr. John Slotwinski, Manufacturing Metrology Expert (former NIST)

Key viewpoint: “Roundness and center‑of‑gravity verification, combined with robust NDT, are now standard acceptance criteria for high‑reliability Vanadium Spheres.”

Practical Tools and Resources

- Standards and testing

- ISO 3290 (ball dimensions/finish); ASTM E2375, E1001, E1444 (NDT); ISO 14644 (cleanrooms): https://www.iso.org | https://www.astm.org

- Materials and processing data

- ASM Handbooks (Metals; Heat Treating; Wear): https://www.asminternational.org

- Corrosion and environment

- AMPP/NACE resources for screening environments: https://www.ampp.org

- Metrology and balancing

- Roundness/CG measurement systems from precision metrology vendors; ISO‑compliant calibration practices

- Surface engineering

- PVD/DLC application notes for galling reduction in reactive metals

Last updated: 2025-08-26

Changelog: Added 5 targeted FAQs; introduced 2025 market/technical snapshot with table; included two recent case studies; compiled expert viewpoints; provided practical tools/resources for Vanadium Spheres

Next review date & triggers: 2026-02-01 or earlier if ISO/ASTM revise ball/sphere standards, AMPP releases new corrosion guidance for vanadium alloys, or major OEMs update coating/roundness acceptance criteria