1. مقدمة: لماذا يعتبر مسحوق CT-1000 ضروريًا في المعادن المسحوقة

مسحوق CT-1000 هو مسحوق عالي الأداء يعتمد على الحديد ويستخدم على نطاق واسع في تطبيقات المعادن المسحوقة (PM) نظرًا لقابليته الممتازة للضغط، وتوزيع الجسيمات المتسق، والقوة الملبدة العالية. مع نمو سوق PM في صناعات السيارات والفضاء والآلات الصناعية، يستمر الطلب على مساحيق أساسية موثوقة وفعالة من حيث التكلفة مثل CT-1000 في الارتفاع.

أبرز الملامح الرئيسية:

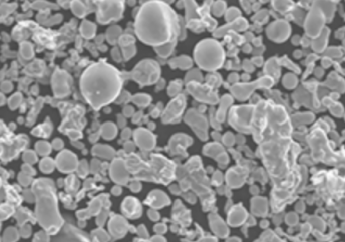

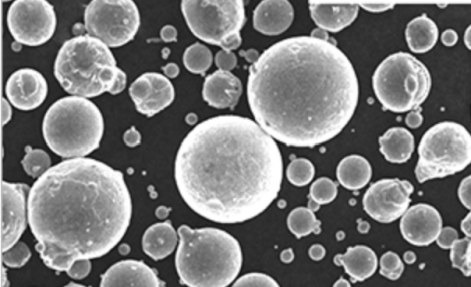

- CT-1000 هو مسحوق حديد منحل بالماء.

- إنه مثالي لأجزاء PM الهيكلية التي تتطلب قوة خضراء عالية وثباتًا الأبعاد.

- يوفر توافقًا ممتازًا في المزج مع إضافات السبائك والتشحيم.

- الخيار المفضل للهندسة المعقدة في المكونات الملبدة.

المشترون المستهدفون:

- مصنعي قطع غيار السيارات

- موردي المكونات الدقيقة

- منتجو أجزاء PM

- موزعي المواد الخام للتصنيع الإضافي

- منصات التجارة الإلكترونية التي توفر المساحيق الصناعية

يعمل مسحوق CT-1000 كأساس للأنظمة الهجينة والسبائك المنتشرة المستخدمة في الإنتاج الضخم لأجزاء PM. تجعل خصائصه الفيزيائية المحسنة مناسبة للتصنيع عالي الحجم، وهو مطلب أساسي لمشتري B2B الذين يبحثون عن موردين بالجملة موثوقين.

2. تطبيقات مسحوق CT-1000 في التصنيع الصناعي

تم تصميم مسحوق CT-1000 لتلبية احتياجات مجموعة واسعة من الصناعات. فيما يلي تفصيل لتطبيقاته الصناعية وكيف تستخدمه القطاعات المختلفة لإنتاج المكونات:

صناعة السيارات:

- مكونات المحرك

- تروس ناقل الحركة

- قضبان التوصيل

- ضرس عمود الحدبات

الهندسة العامة:

- الأقواس الهيكلية

- محامل وجلب

- آليات القفل

- مكونات أداة الطاقة

تصنيع الأجهزة:

- أجزاء ناقل الحركة الغسالة

- نوى المحركات

- علب التروس

الجدول: تطبيقات مسحوق CT-1000 حسب الصناعة

| الصناعة | مكونات PM المنتجة | فوائد استخدام CT-1000 |

|---|---|---|

| السيارات | التروس، والعجلات المسننة، والقضبان | مقاومة عالية للتآكل، قوة |

| الهندسة | البطانات، والأقواس، والمثبتات | دقة الأبعاد العالية |

| الأجهزة المنزلية | أجزاء المحركات، وأنظمة التروس | أداء ميكانيكي ثابت |

| الأدوات الكهربائية | أجزاء هيكلية عالية التحميل | فعالة من حيث التكلفة، وقابلية ضغط عالية |

في كل حالة، يمكّن CT-1000 المصنعين من تحقيق تفاوتات أكثر دقة وخصائص ميكانيكية محسنة مقارنة بطرق التشكيل أو الصب التقليدية. وهذا يجعله جذابًا بشكل خاص لفرق المشتريات بين الشركات التي تعطي الأولوية للجودة والتكرار والكفاءة التشغيلية.

3. الخصائص الفنية وحالات استخدام مسحوق CT-1000

يُعرف مسحوق CT-1000 بقدرته الممتازة على التلبيد وقوته الميكانيكية. خصائص أدائه تجعله مناسبًا لتطبيقات PM القياسية والمتقدمة.

المواصفات الفنية الرئيسية:

| الممتلكات | المواصفات |

|---|---|

| المادة الأساسية | حديد نقي (مذرر بالماء) |

| توزيع حجم الجسيمات | عادةً ما يكون -100 شبكة |

| الكثافة الظاهرة | 2.8–3.0 جم/سم³ |

| معدل التدفق | 24–28 ثانية/50 جرام |

| القوة الخضراء | عالية |

| قابلية الانضغاط | ممتاز |

| التوافق | عناصر السبائك، زيوت التشحيم |

حالات الاستخدام:

- تلبيد مضغوط: يستخدم في عملية الضغط لإنتاج مكونات عالية الكثافة بأقل مسامية.

- المزج: يمكن مزجه مع مساحيق PM أخرى مثل النحاس أو النيكل أو الجرافيت لإنشاء سبائك مخصصة.

- مادة خام التصنيع المضافة: يمكن استخدام درجات معدلة من CT-1000 في تقنية الربط بالنفث و قولبة حقن المعادن (MIM).

فوائد لمشتري الجملة:

- توفر كميات كبيرة للإنتاج بكميات كبيرة

- مراقبة الجودة المتسقة من مجموعة إلى أخرى

- متعدد الاستخدامات في عمليات PM التقليدية والهجينة

بالنسبة لأولئك المهتمين بالحصول على مسحوق CT-1000 عالي الجودة، تقدم شركة Shanghai Truer Technology Co., Ltd حلاً موثوقًا به وبأسعار تنافسية. بصفتها واحدة من أكثر موردي المواد المضافة احترافًا في الصين، توفر Truer مسحوق CT-1000 من الدرجة الممتازة مع دعم فني كامل وتغليفًا قابلاً للتخصيص لمصنعي المعدات الأصلية والموزعين. تعرف على المزيد حول عروض Truer في مجال تعدين المساحيق.

4. العوامل الرئيسية التي يجب مراعاتها عند اختيار مورد مسحوق CT-1000

بالنسبة لمشتري B2B، فإن الحصول على مسحوق CT-1000 لا يقتصر فقط على السعر — بل يتعلق بالاتساق وقابلية التوسع والدعم الفني. يضمن المورد المناسب أن خط الإنتاج الخاص بك يعمل بسلاسة وأن المكونات النهائية تلبي معايير الجودة الصارمة.

معايير الاختيار الهامة لمشتري الجملة:

| عامل الاختيار | لماذا يهم لمشتري B2B |

|---|---|

| قوام المسحوق | يضمن توحيد الخصائص الميكانيكية عبر دفعات الإنتاج |

| الدعم الفني | يساعد على تحسين عملية التلبيد والخلط المضاف |

| خيارات التخصيص | القدرة على تصميم حجم الجسيمات والتغليف والمواد المضافة |

| الشهادات | الامتثال لمعايير ISO و REACH و RoHS للتوزيع الدولي |

| التسليم والخدمات اللوجستية | التسليم في الوقت المحدد، والتخزين القابل للتطوير، وقدرات التصدير |

| شفافية التسعير | تسعير مستقر لتخطيط المشتريات على المدى الطويل |

الأسئلة التي يجب أن يطرحها الموزعون:

- هل يمكن للمورد تقديم تقارير اختبار خاصة بالدفعات (TDS/MSDS)؟

- هل يقدمون مساحيق مسبقة السبائك أو الهجينة بالإضافة إلى CT-1000؟

- هل هناك دعم فني متاح للاختبار وتحسين التلبيد؟

- هل تتوفر خصومات على الكميات الكبيرة أو عقود طويلة الأجل؟

إن اختيار مورد يتمتع بقدرات إنتاج داخلية ودعم البحث والتطوير يمنح مشتري B2B ميزة تنافسية طويلة الأجل. على سبيل المثال، لا تقوم شركة Shanghai Truer Technology Co., Ltd بتصنيع مسحوق CT-1000 فحسب، بل تساعد العملاء أيضًا في تكامل المواد المضافة المخصصة وتحسين تركيبة المسحوق.

5. أفضل موردي مسحوق CT-1000 في الصين والسوق العالمية

برزت الصين كمورد عالمي رائد لمساحيق الحديد الأساسية مثل CT-1000، حيث تقدم مزايا الجودة والتكلفة. ومع ذلك، يأخذ المشترون العالميون أيضًا في الاعتبار الموردين الإقليميين في أوروبا وأمريكا الشمالية للحصول على شهادات أو تفضيلات لوجستية معينة.

أفضل موردي مسحوق CT-1000 في الصين:

| اسم الشركة | نقاط القوة | الموقع |

|---|---|---|

| شركة شنغهاي تروير تكنولوجي المحدودة (Shanghai Truer Technology Co., Ltd.) | مجموعة واسعة من مسحوق PM، والاستشارات الفنية، وشهادة ISO | شنغهاي |

| مجموعة CNPC للمساحيق | قدرة إنتاجية كبيرة، وصادرات في جميع أنحاء العالم | سيتشوان |

| شركة Jiande Yitong Metal Powder Co. | متخصصة في مساحيق الحديد المذررة بالماء | تشجيانغ |

الموردون العالميون:

| اسم الشركة | المنطقة | الميزات الرئيسية |

|---|---|---|

| هوغاناس إيه بي | السويد | رائد عالمي في مساحيق PM، وتسعير متميز |

| مساحيق ريو تينتو للمعادن | كندا | مساحيق حديد عالية النقاء، وبحث وتطوير قوي |

| GKN Hoeganaes | الولايات المتحدة الأمريكية | تركز على مصنعي المعدات الأصلية، وتركيبات خاصة |

لماذا يكتسب الموردون الصينيون حصة في السوق:

- إنتاج فعال من حيث التكلفة

- دورات تسليم سريعة

- تركيبات قابلة للتخصيص

- دعم فني قوي لتطبيقات PM

ومع ذلك، لا يقدم جميع الموردين الصينيين نفس مستوى الجودة والخدمة. هذا هو السبب في أن الشركات مثل Shanghai Truer Technology Co., Ltd مفضلة بين الموزعين العالميين ومصنعي المعدات الأصلية — فهي تجمع بين كفاءة التكلفة والتميز الفني وتشتهر بموثوقيتها في طلبات B2B ذات الحجم الكبير.

6. لماذا يقوم المزيد من الموزعين بالحصول على مسحوق CT-1000 من الصين

هناك تحول واضح في اتجاهات المصادر العالمية. يتحول الموزعون والمصنعون في جميع أنحاء أوروبا وجنوب شرق آسيا وأمريكا الشمالية بشكل متزايد إلى الموردين الصينيين للحصول على مسحوق CT-1000 والمواد ذات الصلة بـ PM. إليك السبب:

1. نسبة السعر إلى الأداء:

يوفر مسحوق CT-1000 الصيني أداءً مشابهًا للعلامات التجارية الغربية ولكن بتكلفة أقل بنسبة 20-40٪. هذا هو المحرك الرئيسي لمشتري B2B الخاضعين لضغوط الهامش.

2. مرونة سلسلة التوريد:

قام العديد من موردي PM الصينيين بتنويع مصادر المواد الخام الخاصة بهم واستثمروا في الخدمات اللوجستية المحلية لضمان التسليم حتى أثناء الاضطرابات العالمية.

3. التصنيع كامل الخدمات:

يقدم الموردون مثل Shanghai Truer خدمات شاملة — من إنتاج المسحوق إلى الاستشارات الإضافية، مما يسهل على المشترين في الخارج إدارة علاقات الموردين.

4. ميزة التخصيص:

المصنعون الصينيون أكثر مرونة في التخصيص:

- توزيع حجم الجسيمات

- نسب المواد المضافة (مثل الجرافيت والنحاس)

- خلطات مواد التشحيم

- تنسيقات التغليف (أكياس كبيرة، أسطوانات، مغلقة بتفريغ الهواء)

5. تعزيز الاستعداد للتصدير:

يمتثل موردي PM الصينيون الحديثون لشهادات دولية رئيسية ويتقنون التواصل باللغة الإنجليزية والتوثيق وإجراءات الجمارك.

حالة في النقطة: شركة Shanghai Truer Technology Co., Ltd

Truer هي واحدة من أكثر موردي المواد المضافة والمسحوق احترامًا في الصين. بفضل خبرتها العميقة في تعدين المساحيق والتصنيع المتقدم، تدعم الشركة المشترين العالميين من خلال:

- إنتاج مسحوق متقدم (الذر بالهجين المائي والغاز)

- مواد مضافة خاصة مثل Lube-W و SUW-5000B والجرافيت TBC-1000

- تركيبات مخصصة مثل PM 4600 و FL-4605 و CT-1000

- قنوات الاتصال للمشترين في الخارج

- الامتثال لإدارة الجودة ISO 9001:2015

إذا كنت تحصل على مسحوق CT-1000 بكميات كبيرة، فإن Truer تقدم الدعم الفني والمرونة التجارية التي يحتاجها المشترون العالميون من B2B.

7. كيفية طلب مسحوق CT-1000 بالجملة من مصادر موثوقة

يتطلب طلب مسحوق CT-1000 بكميات كبيرة أكثر من مجرد أمر شراء — فهو يتضمن تنسيق الخدمات اللوجستية والمواصفات الفنية ووثائق الامتثال وتخطيط التوريد على المدى الطويل. بالنسبة للموزعين ومصنعي المعدات الأصلية وشركات التصنيع، فإن العمل مع مورد موثوق به مثل شركة Shanghai Truer Technology Co., Ltd يضمن عملية شراء سلسة من الاستفسار إلى التسليم.

عملية الطلب خطوة بخطوة

الخطوة 1: إرسال استفسار أو طلب عرض أسعار (RFQ)

- تحديد الكمية (بالكيلوجرام أو الأطنان المترية)

- اذكر الدرجة المطلوبة (CT-1000) وأي احتياجات إضافية

- الإشارة إلى تفضيل التغليف (أكياس كبيرة، أسطوانات مختومة، إلخ)

- تضمين موقع التسليم وشروط التجارة المفضلة (FOB، CIF، DDP)

الخطوة 2: التأكيد الفني واختبار العينة

- طلب عينة (500 جرام–1 كجم) لاختبار المعمل أو الإنتاج التجريبي

- مراجعة ورقة البيانات الفنية (TDS) وورقة بيانات سلامة المواد (MSDS)

- اختبار معلمات مثل التدفق، وقابلية الضغط، والقوة الخضراء

الخطوة 3: الانتهاء من العقد

- تأكيد التسعير والمهلة وشروط الدفع

- توقيع العقد أو اتفاقية الشراء

- الموافقة على متطلبات الفحص والشهادة (ISO، SGS، إلخ)

الخطوة 4: الإنتاج ومراقبة الجودة

- يتم إنتاج المسحوق واختباره على دفعات لتحقيق الاتساق

- الخلط المخصص مع المواد المضافة مثل الجرافيت أو مواد التشحيم إذا لزم الأمر

الخطوة 5: الشحن والتوثيق

- تغليف التصدير مع وضع العلامات المناسبة

- وثائق الامتثال: COA، REACH، RoHS، بوليصة الشحن، الفاتورة التجارية

- تتبع في الوقت الفعلي متاح عند الطلب

الطلب من Truer: النقاط البارزة

| الميزة | الفائدة لمشتري B2B |

|---|---|

| الحد الأدنى لكمية الطلب من 500 كجم | مناسبة للمصنعين الصغار والمتوسطين |

| خلط المواد المضافة المخصصة | تتوفر خيارات الخلط الجاهزة للضغط |

| دعم التصدير العالمي | الشحن إلى أكثر من 50 دولة |

| البحث والتطوير والمساعدة الفنية | استشارة مجانية مع خبراء تعدين المساحيق |

| إرسال الاستفسارات عبر الإنترنت | سهولة الاتصال عبر نموذج الموقع الإلكتروني |

تقدم Shanghai Truer أيضًا أوامر شاملة وعمليات تسليم مجدولة للمشترين على المدى الطويل، مما يقلل من تحميل المستودعات ويضمن التوريد في الوقت المناسب — وهي ميزة رئيسية لمنتجي أجزاء PM ذات الحجم الكبير.

8. الأسئلة الشائعة: أسئلة شائعة حول شراء مسحوق CT-1000 بكميات كبيرة

فيما يلي الأسئلة المتداولة من قبل مشتري الجملة والموزعين ومديري المصادر فيما يتعلق بمسحوق CT-1000:

س1: مما يتكون مسحوق CT-1000؟

A: CT-1000 هو مسحوق حديد نقي مذرر بالماء معروف بقابليته العالية للضغط وخصائص التدفق الممتازة، ويستخدم في المقام الأول كمسحوق أساسي في تطبيقات تعدين المساحيق.

س2: ما هو الحد الأدنى لكمية الطلب (MOQ)؟

A: يبدأ الحد الأدنى لكمية الطلب عادةً من 500 كجم. ومع ذلك، بالنسبة للعملاء الجدد أو التحقق من صحة العينات، يمكن لـ Shanghai Truer توفير دفعات تجريبية أصغر عند الطلب.

س3: هل يمكن تخصيص مسحوق CT-1000 بمواد مضافة؟

A: نعم. يمكن خلط CT-1000 مسبقًا مع الجرافيت والنحاس والنيكل ومواد التشحيم مثل Lube-W أو SUW-5000B اعتمادًا على تطبيقك. تقدم Truer خدمات التخصيص الكاملة.

س4: ما هي الشهادات التي يأتي بها المسحوق؟

A: يتوافق مسحوق CT-1000 من Truer مع معايير ISO 9001:2015 ويمكن تو

س5: كم يستغرق التسليم؟

A: المدة الزمنية القياسية هي 7-15 يوم عمل حسب حجم الطلب واحتياجات التخصيص. تدعم Truer خيارات التسليم السريع للمشاريع العاجلة.

س6: هل يمكنني زيارة المصنع الخاص بكم أو طلب فحص بالفيديو؟

A: بالتأكيد. تستقبل شركة Shanghai Truer زيارات المصانع للمشترين الجادين من الشركات إلى الشركات ويمكنها توفير جولات فيديو مباشرة أو تقارير فحص من طرف ثالث.

س7: كيف يمكنني معرفة المزيد عن منتجات تعدين المساحيق الخاصة بكم؟

A: يمكنك استكشاف مجموعة مساحيق وتشكيلات Truer الكاملة مباشرة على صفحة المنتج، والتي تتضمن CT-1000 و FL-4605 و FN-0205 وحلول إضافية متخصصة.

ملخص روابط المرساة الداخلية

لدعم تحسين محركات البحث وتصفح المستخدم، تم تضمين الروابط الداخلية التالية بشكل طبيعي في هذه المدونة:

- حول تقنية Truer – مضمن في قسم اختيار المورد.

- اتصل بنا – مضمن في قسم عملية الطلب.

- مجموعة مساحيق PM – مضمن في الأسئلة الشائعة والمناقشة الفنية.

- الصفحة الرئيسية – يمكن إضافته في المشاركات المستقبلية للتصفح المباشر.

- خيارات اتصال إضافية – معززة لتحسين التحويل.

مع تزايد الطلب الصناعي على المواد الخام عالية الأداء وفعالة من حيث التكلفة لتعدين المساحيق، لا يزال مسحوق CT-1000 هو الحل الأمثل للمصنعين في جميع أنحاء العالم. تجمع شركة Shanghai Truer Technology Co., Ltd بين الخبرة الفنية والجودة المتسقة والخدمات المرنة لتلبية الاحتياجات المتطورة للمشترين والموزعين من الشركات إلى الشركات.

هل أنت مستعد لتبسيط مصادر مسحوق CT-1000 الخاص بك؟ تواصل مع Truer اليوم واطلب استشارة أو حزمة عينات مجانية.