1. Introduction to TA1 Powder in Industrial Applications

TA1 powder refers to pure titanium powder made from Grade 1 titanium, known for its excellent corrosion resistance, ductility, and biocompatibility. In B2B sectors like aerospace, automotive, medical, and chemical processing, TA1 powder is used extensively in both additive manufacturing (AM) and traditional powder metallurgy (PM) techniques.

What Is TA1 Powder?

- Material Grade: Commercially pure titanium (Grade 1)

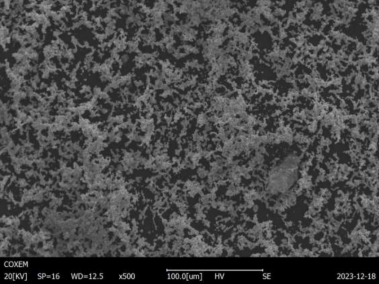

- أساليب الانتاج: Gas atomization, plasma atomization, or hydride-dehydride (HDH)

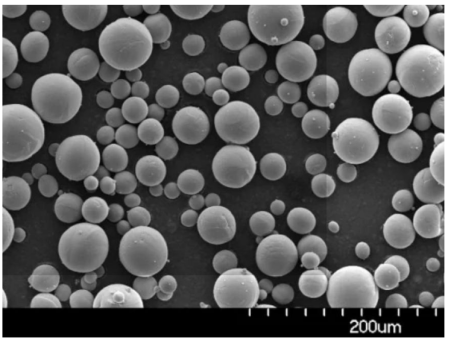

- Forms: Spherical or irregular powder particles

- النقاء: ≥ 99.5% Ti content

Why TA1 Powder Matters for B2B Buyers

- Enables lightweight, high-strength component manufacturing

- Ideal for corrosion-resistant and biocompatible applications

- Compatible with طباعة ثلاثية الأبعاد technologies like SLM, EBM, and DED

- Suitable for sintering and hot isostatic pressing in PM processes

| المواصفات | القيمة |

|---|---|

| Titanium Purity | ≥ 99.5% |

| محتوى الأكسجين | ≤ 0.18% (typical) |

| نطاق حجم الجسيمات | 15–45 µm, 45–105 µm |

| المظهر | Grey metallic powder |

| أساليب الانتاج | Gas Atomized, HDH |

| التطبيقات | Aerospace, Medical, PM |

2. Key Applications of TA1 Powder in Manufacturing

As a high-performance raw material, TA1 powder finds significant usage across multiple industries. Its versatility makes it highly attractive to wholesale buyers and industrial manufacturers.

الطيران والفضاء والدفاع

- Airframe and engine components

- Lightweight structural parts

- Additively manufactured brackets and connectors

الطب وطب الأسنان

- Orthopedic implants and surgical tools

- Dental crowns and bridges

- Biocompatible 3D-printed implants

السيارات

- أجزاء نظام العادم

- Lightweight chassis components

- High-performance racing parts

المعالجة الكيميائية

- Heat exchangers and reactors

- Anti-corrosive components for acid handling

- Pump and valve housings

Powder Metallurgy and Additive Manufacturing

- Net-shape and near-net-shape components

- Prototyping and small-batch production

- Complex geometries not possible with conventional methods

Application Overview Table

| الصناعة | Common TA1 Powder Use Cases |

|---|---|

| الفضاء | Lightweight brackets, engine parts |

| الطبية | Bone implants, dental prosthetics |

| السيارات | Performance parts, exhaust systems |

| الصناعة الكيميائية | Corrosion-resistant valves, reactors |

| تعدين المساحيق | HIP components, sintered parts |

| التصنيع الإضافي | Complex geometries, prototypes, end-use parts |

3. Material Properties and Technical Advantages of TA1 Powder

TA1 powder is widely regarded for its combination of superior material characteristics and processability, making it a preferred choice among suppliers and OEM customers.

Mechanical and Physical Properties

- نسبة قوة إلى وزن عالية: Ideal for aerospace and automotive

- مقاومة ممتازة للتآكل: Performs well in seawater and acidic environments

- Superior Ductility: Enables forming and shaping

- High Thermal Stability: Suitable for high-temperature environments

Technical Advantages for Manufacturers

- عالية النقاء: Ensures predictable mechanical properties

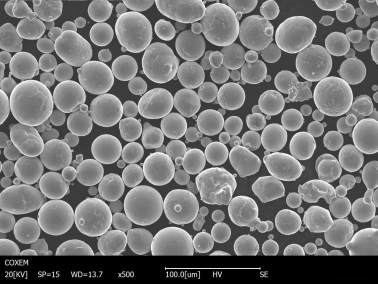

- Good Flowability: Important for AM processes like laser powder bed fusion

- Spherical Shape (Gas Atomized): Promotes uniform layer deposition

- انخفاض محتوى الأكسجين: Enhances ductility and toughness

TA1 vs. Other Titanium Grades

| الممتلكات | TA1 (Grade 1) | TA2 (Grade 2) | TA6V (Ti-6Al-4V) |

|---|---|---|---|

| النقاء | الأعلى | عالية | سبيكة |

| القوة | معتدل | Higher than TA1 | عالية جداً |

| الليونة | ممتاز | جيد | معتدل |

| مقاومة التآكل | ممتاز | ممتاز | جيد |

| AM Compatibility | ممتاز | جيد جداً | ممتاز |

Why B2B Buyers Prefer TA1 Powder

- Consistency in Quality: Critical for mass production

- Custom Particle Size Distributions: Tailored to specific AM or PM processes

- Reliable Supply Chains: Available from top Chinese and global suppliers

To learn more about other PM powder options that pair well with TA1 for hybrid applications, visit our materials page.

4. Global Market Trends and Demand for TA1 Powder

The global demand for TA1 powder is rising steadily due to the rapid advancement of additive manufacturing (AM), powder metallurgy (PM), and lightweight component production. These sectors are increasingly reliant on high-purity titanium powders, especially in aerospace, defense, and medical industries.

محركات السوق الرئيسية

- Aerospace Industry Growth: Increasing use of 3D-printed titanium parts in commercial and military aircraft.

- Medical Sector Expansion: Rising demand for biocompatible implants and surgical tools.

- Shift Toward Lightweight Materials: Automotive and industrial OEMs are focusing on weight reduction for improved performance and fuel efficiency.

رؤى السوق العالمية

- آسيا والمحيط الهادئ: Fastest-growing market due to increasing investments in AM and local manufacturing.

- أمريكا الشمالية: Mature market with high usage in aerospace and medical sectors.

- أوروبا: Strong focus on sustainable manufacturing and innovation in powder metallurgy.

Market Forecast Table

| المنطقة | حجم السوق لعام 2023 (مليون دولار أمريكي) | معدل النمو السنوي المركب (2024-2029) | الصناعات الرئيسية |

|---|---|---|---|

| آسيا والمحيط الهادئ | $120 | 14.5% | Aerospace, AM, PM |

| أمريكا الشمالية | $105 | 11.2% | Medical, Defense |

| أوروبا | $98 | 10.8% | Automotive, AM |

| الشرق الأوسط | $35 | 9.5% | Oil & Gas, Chemical |

| أمريكا اللاتينية | $22 | 8.1% | Industrial, PM |

✅ أسعار تنافسية مع التسليم العالمي

- Customization of Particle Size Distribution for application-specific needs.

- Integration of Smart Manufacturing with real-time monitoring of powder characteristics.

- التكامل الرأسي by suppliers to offer complete AM and PM solutions.

5. How to Select a Reliable TA1 Powder Supplier

Sourcing high-quality TA1 powder requires due diligence. For B2B buyers, especially those involved in high-performance applications, identifying a reputable supplier is critical to ensuring consistent quality, compliance, and timely delivery.

Key Factors to Evaluate Suppliers

| المعايير | ما أهمية ذلك |

|---|---|

| Powder Purity & Certification | Ensures mechanical reliability and regulatory compliance |

| توزيع حجم الجسيمات | Must match specific AM or PM machinery requirements |

| Packaging & Storage Conditions | Prevents oxidation and contamination |

| طريقة الإنتاج | Gas atomized preferred for AM due to sphericity |

| اتساق الدُفعات | Important for repeatability in production |

| الدعم الفني | Provides guidance on usage and troubleshooting |

Certifications to Look For

- ISO 9001: إدارة الجودة

- ISO 13485: Medical Device Manufacturing (for medical-grade TA1)

- ASTM B348 / ASTM F67 Compliance

Common Red Flags When Choosing a Supplier

- عدم وجود وثائق أو إمكانية التتبع

- شكل الجسيمات غير المتسق

- Poor customer service or delayed deliveries

6. Top TA1 Powder Manufacturers and Distributors in Asia

Asia, particularly China, has emerged as a leading hub for high-quality TA1 powder production. Several key players supply both domestic and international markets with competitively priced, certified titanium powders.

Leading Asian Suppliers of TA1 Powder

| اسم الشركة | الموقع | العروض الرئيسية | الشهادات |

|---|---|---|---|

| شركة شنغهاي تروير تكنولوجي المحدودة (Shanghai Truer Technology Co., Ltd.) | الصين | AM & PM powders, powder atomization equipment | آيزو 9001 |

| التقنيات الغربية فائقة التوصيل الغربي | الصين | High-purity titanium and alloy powders | ASTM، ISO |

| Osaka Titanium Technologies | اليابان | Premium titanium powders for aerospace | ISO, JIS |

| Toho Titanium | اليابان | Medical and industrial-grade TA1 powders | ISO، ASTM |

| مضافات AP&C (GE المضافة) | عالمي | Spherical titanium powders for AM | ISO, AS9100 |

لماذا تبرز شركة Shanghai Truer Technology

- Integrated Manufacturing: Offers both powder production and equipment solutions, reducing supply chain complexity.

- Wide Range of Grades: Supplies TA1 powder along with a diverse portfolio of PM and AM powders.

- حلول مخصصة: Offers tailored particle size distributions to match specific application requirements.

- Industry Recognition: A trusted name in China’s powder metallurgy and additive manufacturing sectors.

➡️ Learn more about شنغهاي تروير تكنولوجي and its powder manufacturing capabilities.

7. Why More Buyers Are Sourcing TA1 Powder from China

China has rapidly become a global leader in the supply of TA1 titanium powder. B2B buyers worldwide are increasingly sourcing from Chinese manufacturers due to a combination of cost-efficiency, technological advancements, and growing supply chain reliability.

Advantages of Chinese TA1 Powder Suppliers

- تسعير فعال من حيث التكلفة: Lower manufacturing and labor costs allow for competitive pricing.

- Advanced Equipment: Use of modern atomization and production technologies.

- الإنتاج على نطاق واسع: Ability to meet high-volume orders for OEMs and distributors.

- Government Support: Strong backing for high-tech manufacturing and export initiatives.

Shanghai Truer Technology: Leading the Charge

Shanghai Truer Technology Co., Ltd., established in 2009, entered the additive manufacturing business in 2019. Since then, it has become a top-tier supplier of high-quality powders for 3D printing and powder metallurgy. The company offers:

- TA1 Powder for AM and PM uses

- Custom Particle Sizes for SLM, EBM, and HIP

- الإضافات ومواد التشحيم for sintering and machining applications

- Integrated 3D Printing Powder Equipment for in-house production

Truer is also known for its specialty in diffusion alloyed powders, soft magnetic additives، و custom lubricants, making it a one-stop solution for PM and AM needs.

✅ For custom TA1 powder inquiries or bulk orders, visit the صفحة الاتصال to get in touch with Truer’s technical sales team.

8. How to Order Wholesale TA1 Powder from Chinese Suppliers

For B2B buyers—whether you’re a distributor, OEM, or additive manufacturing service provider—ordering wholesale TA1 powder from a reliable supplier like Shanghai Truer Technology is straightforward but requires attention to detail to ensure you receive the right grade, quantity, and specifications for your application.

عملية الطلب خطوة بخطوة

- تحديد المتطلبات الخاصة بك

- Required grade (e.g., TA1 / Grade 1)

- Particle size distribution (e.g., 15–45 μm for SLM, 45–105 μm for EBM)

- Purity level and oxygen content

- Quantity needed (from pilot batches to bulk tons)

- Any special packaging or handling instructions

- Request a Quotation

- Contact the supplier via website or email

- Provide material specifications and delivery location

- Ask for certifications (ISO, ASTM, batch analysis)

- Evaluate the Quotation

- Check lead times, incoterms (FOB, CIF, EXW), and payment terms

- Assess total landed cost, including shipping and customs

- Sample Evaluation (Optional but Recommended)

- Request a sample batch to test flowability, purity, and compatibility

- Perform AM or PM trials to validate the powder performance

- Place Bulk Order

- Finalize technical data sheet and product specs

- Issue a purchase order (PO)

- Confirm payment terms and delivery schedule

- الانحلال المائي

- TA1 powder is typically shipped in sealed, vacuum-packaged containers

- Ensure compliance with international transportation regulations for metallic powders

- Post-Sale Support

- Request technical guidance for usage parameters

- Get documentation for traceability and quality assurance

- Maintain a relationship for future repeat orders or custom powder development

Wholesale Order Checklist

| البند | الوصف |

|---|---|

| Material Grade | TA1 / Titanium Grade 1 |

| حجم الجسيمات | e.g., 15–45 µm, 45–105 µm |

| النقاء | ≥ 99.5% Titanium |

| Certification Required | ISO 9001, ASTM F67, Material Safety Data Sheet |

| Packaging Format | 5kg, 25kg, or custom vacuum-sealed containers |

| Delivery Terms | FOB Shanghai, CIF, or as negotiated |

➡️ You can initiate your order process by visiting the official TA1 Powder page on the AM-Material website.

9. FAQs: Common Questions About Buying Wholesale TA1 Powder

Below are answers to the most frequently asked questions from B2B customers, distributors, and OEM procurement managers regarding TA1 powder.

Q1: What is the minimum order quantity (MOQ) for TA1 powder?

Most suppliers, including Shanghai Truer, have an MOQ of 5–10 kg for standard grades. Custom particle size distributions may require higher quantities.

Q2: Can I request a certificate of analysis (COA) for each batch?

Yes. Every batch of TA1 powder from reputable suppliers like Truer is accompanied by a COA detailing chemical composition, particle size, and morphology.

Q3: Is TA1 powder safe for shipping internationally?

Yes. TA1 (titanium) is non-toxic and non-combustible in sealed containers. It complies with international shipping regulations when properly packaged.

Q4: What additive manufacturing processes are compatible with TA1 powder?

TA1 powder is compatible with:

- SLM (Selective Laser Melting)

- EBM (Electron Beam Melting)

- DED (Directed Energy Deposition)

- Binder Jetting (with post-sintering)

Q5: How is TA1 powder stored to prevent contamination?

It is vacuum-sealed in moisture-proof containers and should be stored in a cool, dry environment away from direct sunlight and corrosive materials.

Q6: Do you offer technical support for AM and PM processing?

Absolutely. Shanghai Truer’s team provides post-sales support, including powder handling guidelines and process optimization advice. Learn more about our full capabilities on our صفحة من نحن.

Q7: Can I get customized TA1 powder formulations?

Yes, Truer offers customized particle size distributions and blends to suit your unique production needs. You can submit your request through our نموذج الاتصال.

Why Shanghai Truer Technology is Your Trusted TA1 Powder Partner

Shanghai Truer Technology Co., Ltd is a leading name in China’s powder metallurgy and additive manufacturing sectors. With over a decade of expertise in materials science and advanced equipment manufacturing, Truer offers:

- ✅ High-purity TA1 powder with multiple particle size options

- ✅ Advanced water, gas, and combined atomization techniques

- ✅ Full range of PM materials and 3D printing powders

- ✅ Custom formulations and additive solutions

- ✅ Technical support and global logistics capabilities

Whether you’re a distributor, contract manufacturer, or AM service provider, Truer is your ideal partner for consistent quality and supply reliability.

🔗 Ready to source premium TA1 powder for your business? Explore our titanium powder offerings and submit your requirements هنا.