نظرة عامة: فهم مسحوق NiCrBSi

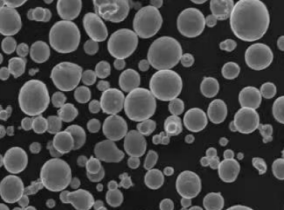

مسحوق النيكل والكروم والبورون والسيليكون (NiCrBSi) هو مادة حيوية في التطبيقات الصناعية نظرًا لمجموعته الرائعة من الخصائص، مثل مقاومة التآكل الممتازة، ومقاومة التآكل، والأداء في درجات الحرارة العالية. غالبًا ما تُستخدم مساحيق NiCrBSi في طلاء الرش الحراري، خاصة للأجزاء المعرضة لظروف التشغيل القاسية. تُستخدم هذه المساحيق على نطاق واسع في قطاعات مثل الفضاء والنفط والغاز والتصنيع، حيث تكون متانة المكونات وطول عمرها أمرًا بالغ الأهمية.

في هذا الدليل، سوف نتعمق في عالم مسحوق NiCrBSi. سوف نستكشف تركيبه، ونماذج مسحوق المعادن المحددة، والخصائص الرئيسية، والتطبيقات، والمزايا، والعيوب. سنقدم أيضًا جداول لمقارنة الأنواع والتركيبات والدرجات والتسعير. دعنا ننتقل إلى ذلك!

تركيبة مسحوق NiCrBSi NiCrBSi

يتكون مسحوق NiCrBSi من مزيج من المعادن وأشباه الفلزات، بشكل أساسي النيكل (Ni)، والكروم (Cr)، والبورون (B)، والسيليكون (Si). يساهم كل من هذه العناصر في الأداء العام للمسحوق بطرق مختلفة

- النيكل (ني): يوفر مقاومة للتآكل

- الكروم (Cr): يحسن مقاومة الأكسدة ويعزز أداء التآكل.

- البورون (B): يعمل على خفض نقطة الانصهار وكعامل تصلب.

- السيليكون (Si): يضيف إلى مقاومة الأكسدة ويحسن قابلية التدفق أثناء الرش الحراري.

يمكن أن تختلف النسب المحددة لهذه المكونات، مما يؤثر على الخصائص العامة والملاءمة للتطبيقات المختلفة.

التركيبات الشائعة لمسحوق NiCrBSi

| المكوّن | النطاق (%) | الوظيفة |

|---|---|---|

| النيكل (ني) | 60-80 | مقاومة التآكل، والليونة |

| الكروم (Cr) | 10-20 | مقاومة التآكل، مقاومة الأكسدة |

| البورون (B) | 1-4 | الصلابة، خفض نقطة الانصهار |

| السيليكون (Si) | 3-5 | قابلية التدفق، مقاومة الأكسدة |

| الكربون (C) | 0.5-1 | يعزز الصلابة والمتانة |

يوضح الجدول أعلاه نطاق التركيب النموذجي لمساحيق NiCrBSi. يمكن تعديل هذه النسب المئوية بدقة اعتمادًا على الأداء والبيئة والاحتياجات الصناعية المحددة المطلوبة.

خصائص مسحوق NiCrBSi

يُظهر مسحوق NiCrBSi العديد من الخصائص الرئيسية التي تجعله الخيار المفضل لطلاء الأسطح وتطبيقات الإصلاح. دعنا نستكشف أهم الخصائص:

- مقاومة ممتازة للتآكل: نظرًا لوجود أطوار صلبة، مثل البوريدات والكربيدات، توفر طلاءات NiCrBSi مقاومة تآكل فائقة. وهذا مهم بشكل خاص للمكونات المعرضة للتآكل أو التآكل أو التآكل الانزلاقي.

- الاستقرار في درجات الحرارة العالية: يمكن لمساحيق NiCrBSi أن تتحمل درجات حرارة تصل إلى 1000 درجة مئوية، مما يجعلها مناسبة للتطبيقات ذات درجات الحرارة العالية مثل شفرات التوربينات أو أجزاء الفرن.

- مقاومة التآكل والأكسدة: يوفر مزيج النيكل والكروم حماية ممتازة ضد البيئات المسببة للتآكل، بما في ذلك التعرض للأحماض والأملاح.

- خصائص التدفق الذاتي: تتمتع مساحيق NiCrBSi بخصائص التدفق الذاتي بسبب محتوى البورون والسيليكون، مما يسمح للمادة بتكوين طلاء موحد وخالٍ من العيوب أثناء الرش الحراري.

- قوة الترابط: تُظهر المساحيق التصاقًا قويًا بالمواد الأساسية، مما يضمن بقاء الطلاءات سليمة حتى في ظروف التشغيل القاسية.

الخصائص الرئيسية لمسحوق NiCrBSi

| الخصائص | الوصف |

|---|---|

| مقاومة التآكل | عالية بسبب الأطوار الصلبة (البوريدات، الكربيدات) |

| مقاومة درجات الحرارة | يتحمل ما يصل إلى 1000 درجة مئوية |

| مقاومة التآكل | ممتاز بسبب محتوى النيكل والكروم |

| مقاومة الأكسدة | مقاومة عالية للأكسدة في بيئات درجات الحرارة المرتفعة |

| ذاتي التدفق | يسمح بطلاءات ناعمة وخالية من العيوب |

| قوة الترابط | التصاق قوي بالركائز، الحد الأدنى من خطر التقشر أو التشقق |

نماذج مسحوق معدني محددة من NiCrBSi

عند اختيار مسحوق NiCrBSi المناسب، من الضروري مراعاة النماذج المحددة التي تتناسب مع تطبيقك. قد يختلف كل نموذج قليلاً في التركيب أو حجم الجسيمات، مما يؤثر على أدائه. فيما يلي 10 نماذج مسحوق NiCrBSi شائعة مع أوصافها:

- ميتكو 16C

- الوصف: تشتهر Metco 16C بمقاومتها الممتازة للتآكل والتآكل، وهي مثالية للبيئات ذات درجات الحرارة المرتفعة مثل التوربينات الغازية. يحتوي على نسبة عالية من الكروم لتعزيز مقاومته للأكسدة.

- التطبيقات: شفرات التوربينات، أنابيب الغلايات، والمعدات البتروكيماوية.

- Praxair NiCrBSi-180

- الوصف: مسحوق متعدد الاستخدامات بحجم جسيمات متوسط. يوفر توازنًا بين الصلابة والمتانة، مما يجعله مناسبًا للطلاءات ذات الأغراض العامة.

- التطبيقات: الآلات الزراعية، معدات التعدين، ومكونات المضخات.

- Höganäs AMPERIT 578

- الوصف: يوفر محتوى بورون أعلى، مما يؤدي إلى صلابة ومقاومة تآكل فائقتين. يستخدم بشكل شائع في بيئات التآكل الشديدة.

- التطبيقات: الأسطوانات الهيدروليكية والصمامات وأدوات حقول النفط.

- Deloro 50

- الوصف: مسحوق شائع بسبب توزيع الجسيمات الدقيقة. يفضل Deloro 50 للرش الحراري والكسوة بالليزر، مما يوفر تشطيبًا سطحيًا ممتازًا.

- التطبيقات: لفائف الطباعة، معدات صناعة الورق، وأدوات القطع.

- Powder Alloy 1276F

- الوصف: يتميز بسيولة عالية، مما يجعله مثاليًا للرش بالبلازما. يشكل طلاءات كثيفة وعالية الجودة بأقل مسامية.

- التطبيقات: قطع غيار السيارات، مكونات الفضاء، ومعدات المعالجة الكيميائية.

- Wall Colmonoy 88F

- الوصف: تشتهر Wall Colmonoy 88F بخصائصها ذاتية التدفق، ويمكن تطبيقها باستخدام تقنيات الرش الحراري المختلفة، مما يوفر مقاومة ممتازة للتآكل والتآكل.

- التطبيقات: قوالب الزجاج، أدوات التشكيل، وآلات تجهيز الأغذية.

- Oerlikon Metco 12C

- الوصف: مع محتوى الكروم والسيليكون العالي، تم تحسين Metco 12C للبيئات التي تكون فيها الأكسدة والتآكل مصدر قلق كبير.

- التطبيقات: أجزاء الفرن، أنظمة العادم، والمبادلات الحرارية.

- Praxair NiCrBSi-400

- الوصف: يتميز هذا المسحوق بحجم جسيمات أكثر خشونة للطلاءات الأكثر سمكًا. غالبًا ما يستخدم في التطبيقات التي تتطلب حماية كبيرة من التآكل.

- التطبيقات: مطارق الكسارة، شاشات التعدين، وقضبان السكك الحديدية.

- Sandvik 9562

- الوصف: Sandvik 9562 هو مسحوق NiCrBSi متعدد الاستخدامات يتفوق في تطبيقات الكسوة بالليزر نظرًا لخصائصه الممتازة في التدفق وتوزيع الجسيمات الموحد.

- التطبيقات: معدات الحفر، الحفارات البحرية، والآلات الثقيلة.

- AMPERIT 595.4

- الوصف: مسحوق NiCrBSi دقيق الحبيبات يوفر تشطيبًا سطحيًا وصلابة فائقتين. إنه مناسب للمكونات الدقيقة في الصناعات المتطلبة.

- التطبيقات: الفضاء والأجهزة الطبية وتوربينات توليد الطاقة.

مزايا مسحوق NiCrBSi المسحوق

يبرز مسحوق NiCrBSi في عالم الطلاءات الحرارية نظرًا لعدد من المزايا المميزة:

1. تنوع التطبيق

يمكن تطبيق مساحيق NiCrBSi باستخدام تقنيات الرش الحراري المختلفة مثل الرش بالبلازما، والأكسجين عالي السرعة (HVOF)، والكسوة بالليزر. وهذا يجعله قابلاً للتكيف عبر صناعات وتطبيقات متعددة.

2. متانة محسنة

يؤدي المزيج الفريد من العناصر إلى طلاءات تقاوم التآكل والتآكل والأكسدة، مما يطيل بشكل كبير عمر الأجزاء والمكونات المعرضة للبيئات القاسية.

3. قوة ربط عالية

تشكل الطلاءات المصنوعة من مساحيق NiCrBSi روابط قوية مع المواد الأساسية، مما يجعلها أقل عرضة للتقشر أو التشقق، حتى في ظل الظروف القاسية.

4. كفاءة التكلفة

نظرًا لطبيعتها طويلة الأمد، تقلل طلاءات NiCrBSi من الحاجة إلى استبدال الأجزاء بشكل متكرر، مما يقلل من تكاليف الصيانة الإجمالية للعمليات الصناعية.

استخدامات مسحوق NiCrBSi

يستخدم مسحوق NiCrBSi في مجموعة واسعة من الصناعات، في المقام الأول للطلاءات الواقية. يوجد أدناه جدول يوضح التطبيقات الشائعة لمسحوق NiCrBSi عبر مختلف القطاعات.

الجدول 3: تطبيقات مسحوق NiCrBSi حسب الصناعة

| الصناعة | التطبيقات |

|---|---|

| الفضاء | شفرات التوربينات، أنظمة العادم، الدروع الحرارية |

| النفط والغاز | الصمامات، أدوات الحفر، مكونات خطوط الأنابيب |

| السيارات | مكونات المحرك، رؤوس الأسطوانات، حاقنات الوقود |

| التصنيع | أدوات القطع، أجزاء الآلات، قوالب البثق |

| الطاقة | توربينات توليد الطاقة، أنابيب الغلايات، المبادلات الحرارية |

| تجهيز الأغذية | الخلاطات، الشرائح، أدوات التشكيل |

| الورق والطباعة | لفائف الطباعة، أسطوانات المجفف |

| التعدين | مطارق الكسارة، معدات الحفر، أنظمة النقل |

| البتروكيماويات | المفاعلات، الحواف، خزانات التخزين |

درجات ومواصفات مسحوق NiCrBSi

تتوفر درجات مختلفة من مساحيق NiCrBSi اعتمادًا على التركيب وحجم الجسيمات. يتم توحيد هذه الدرجات عادةً من قبل الشركات المصنعة لتلبية الاحتياجات المحددة للصناعات المختلفة.

الجدول 4: الدرجات الشائعة لمسحوق NiCr BSi

| الصف | حجم الجسيمات (ميكرومتر) | درجة الانصهار (درجة مئوية) | طلب |

|---|---|---|---|

| NiCrBSi-180 | 45-106 | 980-1050 | طلاءات ذات أغراض عامة |

| NiCrBSi-250 | 63-150 | 950-1020 | طلاءات مقاومة للتآكل |

| NiCrBSi-400 | 150-250 | 920-1000 | طلاءات شديدة التحمل |

| NiCrBSi-88F | 15-53 | 980-1060 | طلاءات رقيقة للأجزاء عالية الدقة |

تسعير وموردين مسحوق NiCrBSi

يعتمد تسعير مسحوق NiCrBSi على عدة عوامل، بما في ذلك الدرجة وحجم الجسيمات والكمية. تتراوح التكلفة عادةً بين 50 دولارًا و 200 دولارًا للكيلوغرام اعتمادًا على المواصفات.

الجدول 5: الموردون والتسعير لمسحوق NiCrBSi

| المورد | الدرجة المتاحة | السعر (بالكيلوغرام) | معلومات الاتصال |

|---|---|---|---|

| هوغاناس | AMPERIT 578 | $150-$180 | www.hoganas.com |

| براكسير | NiCrBSi-180, NiCrBSi-400 | $100-$140 | www.praxair.com |

| وول كولمونوي | 88F, 50 | $120-$170 | www.wallcolmonoy.com |

| أورليكون ميتكو | Metco 16C, Metco 12C | $130-$200 | www.oerlikon.com |

| ساندفيك | 9562 | $80-$150 | www.home.sandvik |

مقارنة مسحوق NiCrBSi بمساحيق الرش الحراري الأخرى

عندما يتعلق الأمر بمقارنة مسحوق NiCrBSi بمساحيق الرش الحراري الأخرى، هناك اختلافات واضحة من حيث الأداء والتكلفة والتطبيقات.

الجدول 6: NiCrBSi مقابل مساحيق الرش الحراري الشائعة الأخرى

| المعلمة | مسحوق NiCrBSi | مسحوق WC-Co | مسحوق أكسيد الألومنيوم |

|---|---|---|---|

| مقاومة التآكل | ممتاز (بسبب البوريدات) | متميز | معتدل |

| مقاومة التآكل | عالي (محتوى النيكل والكروم) | معتدل | منخفضة |

| مقاومة الأكسدة | عالية | معتدل | منخفضة |

| مقاومة درجات الحرارة | حتى 1000 درجة مئوية | حتى 800 درجة مئوية | ما يصل إلى 650 درجة مئوية |

| التكلفة | متوسط (80-200 دولارًا للكيلوغرام) | مرتفع (200-400 دولارًا للكيلوغرام) | منخفض (30-60 دولارًا للكيلوغرام) |

إيجابيات وسلبيات مسحوق NiCrBSi

لمسحوق NiCrBSi نصيبه من نقاط القوة والضعف، اعتمادًا على التطبيق والبيئة.

الجدول 7: مزايا وعيوب مسحوق NiCrBSi

| مزايا | سلبيات |

|---|---|

| مقاومة استثنائية للتآكل والتآكل | قد يكون أكثر تكلفة من المساحيق الأبسط |

| أداء ممتاز في درجات الحرارة العالية | يتطلب معدات متخصصة للرش الحراري |

| متعدد الاستخدامات في التطبيقات عبر العديد من الصناعات | قد يكون لبعض الدرجات توافر محدود |

| ترابط قوي بالمواد الأساسية | من الضروري التحكم الدقيق في معلمات العملية |

التعليمات

| سؤال | الإجابة |

|---|---|

| ما هي الاستخدامات الأساسية لمسحوق NiCrBSi؟ | يستخدم مسحوق NiCrBSi في الطلاءات الواقية للمكونات في صناعات الفضاء والسيارات والنفط. |

| كيف يتم تطبيق مسحوق NiCrBSi؟ | يتم تطبيقه من خلال تقنيات الرش الحراري مثل الرش بالبلازما أو HVOF أو الكسوة بالليزر. |

| لماذا يعتبر مسحوق NiCrBSi متعدد الاستخدامات؟ | يوفر مقاومة ممتازة للتآكل والتآكل ودرجة الحرارة، مما يجعله مناسبًا للبيئات المختلفة. |

| ما هو النطاق السعري لمسحوق NiCrBSi؟ | اعتمادًا على الدرجة والمورد، تتراوح تكلفة مسحوق NiCrBSi بين 80 و 200 دولارًا للكيلوغرام. |

| هل يمكن استخدام مسحوق NiCrBSi في التطبيقات ذات درجة الحرارة العالية؟ | نعم، يمكن لمساحيق NiCrBSi أن تتحمل درجات حرارة تصل إلى 1000 درجة مئوية. |

| إلى متى تدوم طلاءات NiCrBSi؟ | يمكن أن تدوم الطلاءات المصنوعة من NiCrBSi عدة سنوات اعتمادًا على بيئة التشغيل والصيانة. |

| هل مساحيق NiCrBSi صديقة للبيئة؟ | تعتبر مساحيق NiCrBSi بشكل عام صديقة للبيئة لأنها تساعد على إطالة عمر الأجزاء، مما يقلل من النفايات. |

خاتمة

مسحوق NiCrBSi يبرز كمادة متعددة الاستخدامات ومتينة ومقاومة للتآكل. تجد تطبيقات واسعة الانتشار عبر الصناعات التي تتعرض فيها المكونات لظروف قاسية. من خلال توفير مقاومة تآكل فائقة وترابط قوي وثبات عالي في درجة الحرارة، توفر مساحيق NiCrBSi حلاً فعالاً من حيث التكلفة لإطالة عمر المعد

سواء كنت تتعامل مع التآكل الشديد في معدات التعدين أو البيئات