لمحة عامة عن التصنيع بالحزمة الإلكترونية المضافة (EBAM)

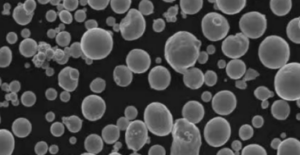

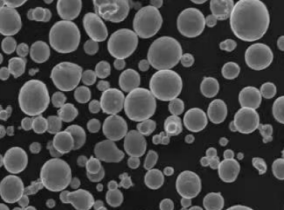

تخيل أن تكون قادرًا على بناء أجزاء معدنية معقدة طبقة تلو الأخرى بدقة لا تصدق وأقل قدر من النفايات. يبدو وكأنه شيء من فيلم خيال علمي، أليس كذلك؟ حسنًا، مرحبًا بكم في عالم التصنيع بالإضافة بالحزمة الإلكترونية (EBAM). تستخدم هذه التكنولوجيا المتطورة حزمة إلكترونية لصهر مسحوق أو سلك معدني، مما يؤدي إلى إنشاء كائنات ثلاثية الأبعاد بتفاصيل معقدة وخصائص قوية.

تبرز EBAM في مشهد التصنيع بالإضافة لقدرتها على إنتاج مكونات عالية الجودة وعالية القوة، خاصة لتطبيقات الفضاء والسيارات والطبية. دعنا نتعمق في تفاصيل كيفية عمل EBAM، وأنواع مساحيق المعادن المستخدمة، وخصائصها، ولماذا تُحدث هذه التكنولوجيا ثورة في التصنيع.

أنواع مساحيق المعادن لـ EBAM

| المسحوق المعدني | التركيب | الخصائص | صفات |

|---|---|---|---|

| التيتانيوم (Ti-6Al-4V) | Ti، Al، V | متانة عالية ومقاومة للتآكل | خفيف الوزن ومتوافق حيوياً |

| انكونيل 718 | Ni, Cr, Fe, Nb, Mo | مقاومة درجات الحرارة العالية والمتانة | مثالي للفضاء والتوربينات |

| فولاذ مقاوم للصدأ (316L) | الحديد، الكروم، النيكل، المونيوم | مقاومة التآكل، قوة عالية | شائع في الصناعات الطبية والغذائية |

| الألومنيوم (AlSi10Mg) | Al، Si، Mg | خفة الوزن وخصائص حرارية جيدة | يستخدم في صناعة السيارات والفضاء |

| الكوبالت والكروم (CoCr) | كولورادو، كروم، مو | مقاومة للاهتراء وقوة عالية | شائع في الغرسات الطبية |

| فولاذ الأدوات (H13) | الحديد، الكروم، المونيوم، V | صلابة عالية، مقاومة للتآكل | يستخدم في الأدوات والقوالب |

| سبائك النيكل (Hastelloy X) | النيكل، الكروم، الحديد، الحديد، المونيوم | مقاوم للأكسدة والتآكل | يستخدم في الصناعات الكيميائية والفضاء |

| النحاس (النحاس) | النحاس | موصلية ممتازة، ليونة | يستخدم في التطبيقات الكهربائية والحرارية |

| التيتانيوم (CP-Ti) | تي | نسبة عالية من القوة إلى الوزن ومقاومة للتآكل | يستخدم في الفضاء والطب |

| فولاذ مصهور (18Ni300) | الحديد، النيكل، الكوكس، المونيوم | قوة وصلابة وصلابة عالية | تُستخدم في صناعة الطيران والأدوات |

تكوين التصنيع بالحزمة الإلكترونية المضافة (EBAM)

تكمن سحر EBAM في موادها وتكوينها. المواد الأكثر شيوعًا المستخدمة هي مساحيق أو أسلاك معدنية، يتم اختيار كل منها لخصائص معينة تناسب التطبيقات الصناعية المختلفة. دعنا نقسم بعض مساحيق المعادن الأكثر شيوعًا المستخدمة في EBAM:

- التيتانيوم (Ti-6Al-4V): مزيج من التيتانيوم والألومنيوم والفاناديوم، توفر هذه السبيكة قوة عالية وخصائص خفيفة الوزن ومقاومة ممتازة للتآكل. يفضل استخدامه بشكل خاص في الفضاء والغرسات الطبية نظرًا لتوافقه الحيوي.

- إنكونيل 718: تتكون Inconel 718 من النيكل والكروم والحديد والنيوبيوم والموليبدينوم، وهي معروفة بمقاومتها العالية لدرجات الحرارة ومتانتها، مما يجعلها مثالية لمحركات التوربينات والتطبيقات الفضائية الأخرى.

- الفولاذ المقاوم للصدأ (316L): تشتهر هذه السبيكة القائمة على الحديد، مع الكروم والنيكل والموليبدينوم، بمقاومتها للتآكل وقوتها العالية، مما يجعلها مثالية للأجهزة الطبية ومعدات الصناعات الغذائية.

- الألومنيوم (AlSi10Mg): مع تركيبة من الألومنيوم والسيليكون والمغنيسيوم، هذه السبيكة خفيفة الوزن وتتميز بخصائص حرارية جيدة، مما يجعلها المفضلة في قطاعي السيارات والفضاء.

- الكوبالت والكروم (CoCr): سبيكة من الكوبالت والكروم والموليبدينوم، CoCr مقاوم للتآكل وعالي القوة، ويستخدم بشكل شائع في الغرسات الطبية.

- فولاذ الأدوات (H13): تحتوي سبيكة الفولاذ هذه على الحديد والكروم والموليبدينوم والفاناديوم، وهي معروفة بصلابتها العالية ومقاومتها للتآكل، وتستخدم في صناعة القوالب والأدوات.

- سبائك النيكل (Hastelloy X): تتكون هذه السبيكة من النيكل والكروم والحديد والموليبدينوم، وهي مقاومة للأكسدة والتآكل، وتستخدم على نطاق واسع في الصناعات الكيميائية والفضاء.

- النحاس (النحاس): يشتهر النحاس النقي بموصلته الكهربائية والحرارية الممتازة، ويستخدم في العديد من التطبيقات الكهربائية وتطبيقات التبادل الحراري.

- التيتانيوم (CP-Ti): يوفر التيتانيوم النقي تجاريًا نسبة قوة إلى وزن عالية ومقاومة ممتازة للتآكل، ومناسب لتطبيقات الفضاء والطب.

- فولاذ Maraging (18Ni300): توفر سبيكة الفولاذ هذه، التي تتكون من الحديد والنيكل والكوبالت والموليبدينوم، قوة وصلابة عالية، وهي مثالية لتطبيقات الفضاء والأدوات.

خصائص التصنيع بالإضافة بالحزمة الإلكترونية (EBAM)

EBAM لا يقتصر فقط على صهر المعدن؛ يتعلق الأمر بالدقة والكفاءة والجودة. إليك نظرة مفصلة على الخصائص التي تجعل EBAM متميزًا:

- الدقة: يمكن لـ EBAM إنتاج تصميمات معقدة بتفاوتات ضيقة، وهو أمر ضروري للمكونات عالية الأداء في مجالات الفضاء والطب.

- الكفاءة: باستخدام حزمة إلكترونية، يمكن لـ EBAM صهر مساحيق أو أسلاك معدنية بسرعة، مما يؤدي إلى تسريع عملية التصنيع بشكل كبير مقارنة بالطرق التقليدية.

- تعدد الاستخدامات: EBAM متوافق مع مجموعة واسعة من المعادن والسبائك، من الألومنيوم خفيف الوزن إلى التيتانيوم فائق القوة و Inconel المقاوم للحرارة.

- القوة والمتانة: تُظهر الأجزاء المنتجة باستخدام EBAM خصائص ميكانيكية ممتازة، غالبًا ما تتجاوز تلك المصنوعة بتقنيات التصنيع التقليدية.

- الحد الأدنى من النفايات: EBAM هي عملية إضافة، مما يعني أنها تبني الأجزاء طبقة تلو الأخرى، باستخدام المادة المطلوبة فقط، مما يقلل من الهدر ويقلل التكاليف.

- قابلية التوسع: سواء كان الأمر يتعلق بإنتاج نموذج أولي واحد أو تصنيع على نطاق واسع، فإن تقنية EBAM توفر قابلية للتوسع لتلبية احتياجات الإنتاج المختلفة.

- التخصيص: تسمح تقنية EBAM بالتخصيص السهل للأجزاء، مما يجعلها مثالية لإنشاء مكونات مصممة خصيصًا لتلبية متطلبات محددة.

مزايا التصنيع الإضافي باستخدام شعاع الإلكترون (EBAM)

لماذا يجب عليك التفكير في استخدام تقنية EBAM لتلبية احتياجات التصنيع الخاصة بك؟ إليك بعض الأسباب المقنعة:

- مرونة التصميم: تسمح تقنية EBAM بتشكيل هندسات معقدة غالبًا ما يكون من المستحيل تحقيقها باستخدام طرق التصنيع التقليدية. فكر في هياكل شبكية معقدة أو قنوات داخلية تعزز الوظائف دون إضافة وزن.

- الكفاءة المادية: نظرًا لأن تقنية EBAM تستخدم فقط الكمية المطلوبة من المواد، فإنها تقلل بشكل كبير من النفايات، مما يجعلها خيارًا أكثر استدامة مقارنة بعمليات التصنيع بالطرح.

- النماذج الأولية الفعالة من حيث التكلفة: باستخدام تقنية EBAM، يصبح إنشاء النماذج الأولية أسرع وأرخص، مما يتيح تكرارًا وابتكارًا أسرع دون التكاليف المرتفعة للأدوات والقوالب.

- تعزيز الخصائص الميكانيكية: غالبًا ما تُظهر الأجزاء التي تنتجها تقنية EBAM خصائص ميكانيكية فائقة نظرًا للبنية المجهرية الدقيقة التي يتم تحقيقها من خلال عملية التبريد السريع.

- معدلات الترسيب العالية: يمكن لتقنية EBAM تحقيق معدلات ترسيب عالية، مما يترجم إلى أوقات إنتاج أسرع، وهو أمر بالغ الأهمية للصناعات التي تتطلب تحولًا سريعًا.

- تقليل المهلات الزمنية: من خلال القضاء على الحاجة إلى أدوات مكثفة والسماح بالإنتاج السريع، تقلل تقنية EBAM بشكل كبير من المهلات الزمنية، مما يساعد الشركات على طرح المنتجات في السوق بشكل أسرع.

تطبيقات التصنيع الإضافي باستخدام شعاع الإلكترون (EBAM)

تفتح براعة ودقة تقنية EBAM مجموعة واسعة من التطبيقات عبر مختلف الصناعات. دعنا نستكشف بعض المجالات الرئيسية التي تحدث فيها تقنية EBAM تأثيرًا كبيرًا:

| الصناعة | طلب | المزايا |

|---|---|---|

| الفضاء | مكونات المحرك، الأجزاء الهيكلية | خفيف الوزن، عالي القوة، مرونة التصميم |

| السيارات | أجزاء مخصصة، مكونات خفيفة الوزن | تقليل الوزن، زيادة الأداء |

| الطبية | الغرسات والأطراف الصناعية والأدوات الجراحية | التوافق الحيوي، التخصيص |

| الطاقة | شفرات التوربينات، والمبادلات الحرارية | مقاومة درجات الحرارة العالية، الكفاءة |

| الأدوات | القوالب، القوالب، الأدوات المخصصة | المتانة، الدقة، تقليل المهلات الزمنية |

| الإلكترونيات | مبددات الحرارة، الأجزاء الموصلة | توصيل حراري وكهربائي ممتاز |

| الدفاع | مكونات الأسلحة، الدروع خفيفة الوزن | القوة، المتانة، الخصائص خفيفة الوزن |

المواصفات والأحجام والدرجات والمعايير الخاصة بمواد EBAM

عندما يتعلق الأمر بتقنية EBAM، فإن فهم مواصفات المواد وأحجامها ودرجاتها ومعاييرها أمر بالغ الأهمية لضمان الأداء والجودة المطلوبين. إليك جدول شامل لإرشادك:

| المواد | المواصفات | المقاسات | درجات | المعايير |

|---|---|---|---|---|

| التيتانيوم (Ti-6Al-4V) | أستم B348، أم أس 4928 | 10-45 ميكرومتر | الصف الخامس | أستم F2924، أم أس 4998 |

| انكونيل 718 | أستم ب 637، أم أس 5662 | 15-53 ميكرومتر | – | AMS 5663، ASTM F3055 |

| فولاذ مقاوم للصدأ (316L) | ASTM A276، AMS 5653 | 15-45 ميكرومتر | – | ASTM F138، ASTM F799 |

| الألومنيوم (AlSi10Mg) | DIN EN 1706 | 20-63 ميكرومتر | – | ISO 3522 |

| الكوبالت والكروم (CoCr) | astm f75، ISO 5832-4 | 15-45 ميكرومتر | – | ASTM F1537 |

| فولاذ الأدوات (H13) | ASTM A681، AMS 6487 | 15-53 ميكرومتر | – | ASTM A681 |

| سبائك النيكل (Hastelloy X) | أستم ب435، أم أس 5754 | 15-45 ميكرومتر | – | AMS 5536، ASTM B619 |

| النحاس (النحاس) | ASTM B170، ASTM B224 | 15-45 ميكرومتر | ASTM F68 | |

| التيتانيوم (CP-Ti) | ASTM B348، ASTM F67 | 10-45 ميكرومتر | الصف 1، الصف 2 | AMS 4900، ASTM F1580 |

| فولاذ مصهور (18Ni300) | ASTM A538، AMS 6521 | 15-45 ميكرومتر | أم أس 6514، أستم A538، أستم A538 |

الموردون وتفاصيل التسعير الخاصة بمواد EBAM

يعد العثور على المورد المناسب أمرًا بالغ الأهمية لضمان جودة واتساق مواد EBAM. إليك قائمة ببعض الموردين ذوي السمعة الطيبة بالإضافة إلى تفاصيل التسعير:

| المورد | المواد | السعر (بالكيلوغرام) | اتصل بنا |

|---|---|---|---|

| تكنولوجيا النجار | التيتانيوم (Ti-6Al-4V) | $250 – $300 | www.carpentertechnology.com |

| ساندفيك | انكونيل 718 | $400 – $450 | www.materials.sandvik |

| براكسير للتقنيات السطحية | فولاذ مقاوم للصدأ (316L) | $150 – $200 | www.praxairsurfacetechnologies.com |

| تقنية LPW | الألومنيوم (AlSi10Mg) | $100 – $150 | www.lpwtechnology.com |

| أركام إيه بي | الكوبالت والكروم (CoCr) | $350 – $400 | www.arcam.com |

| هوغاناس | فولاذ الأدوات (H13) | $180 – $220 | www.hoganas.com |

| هاينز إنترناشيونال | سبائك النيكل (Hastelloy X) | $500 – $550 | www.haynesintl.com |

| العناصر الأمريكية | النحاس (النحاس) | $50 – $100 | www.americanelements.com |

| مركز معالجة التيتانيوم | التيتانيوم (CP-Ti) | $200 – $250 | www.titaniumprocessingcenter.com |

| رينيشو | فولاذ مصهور (18Ni300) | $300 – $350 | www.renishaw.com |

إيجابيات وسلبيات التصنيع بالحزمة الإلكترونية المضافة (EBAM)

مثل أي تقنية، تأتي تقنية EBAM مع مجموعة من المزايا والقيود. إليك نظرة مقارنة:

| مزايا | سلبيات |

|---|---|

| دقة عالية | تكلفة إعداد أولية عالية |

| تقليل نفايات المواد | تتطلب معرفة وتدريب متخصصين |

| القدرة على إنتاج هندسات معقدة | خيارات مواد محدودة مقارنة بالطرق الأخرى |

| أوقات إنتاج أسرع | ارتفاع استهلاك الطاقة |

| منتجات نهائية قوية ومتينة | حجم بناء محدود |

| التخصيص والمرونة | غالبًا ما تكون المعالجة اللاحقة مطلوبة |

| معدلات ترسيب عالية | قد تتطلب التشطيبات السطحية عملًا إضافيًا |

التعليمات

| سؤال | الإجابة |

|---|---|

| ما هي تقنية EBAM؟ | تقنية EBAM هي عملية طباعة ثلاثية الأبعاد تستخدم شعاع إلكترونيًا لصهر مسحوق أو سلك معدني لبناء الأجزاء طبقة تلو الأخرى. |

| كيف تختلف تقنية EBAM عن طرق التصنيع الإضافي الأخرى؟ | تستخدم تقنية EBAM شعاعًا إلكترونيًا، مما يوفر دقة عالية والقدرة على العمل مع المواد ذات درجة الحرارة العالية. |

| ما هي المواد التي يمكن استخدامها في تقنية EBAM؟ | تشمل المواد الشائعة سبائك التيتانيوم، و Inconel، والفولاذ المقاوم للصدأ، وسبائك الألومنيوم، والكروم الكوبالت. |

| ما هي التطبيقات الرئيسية لتقنية EBAM؟ | تُستخدم تقنية EBAM في صناعات الفضاء والسيارات والطب والطاقة والأدوات والإلكترونيات والدفاع. |

| هل تقنية EBAM فعالة من حيث التكلفة؟ | في حين أن تقنية EBAM لديها تكاليف إعداد أولية عالية، فإنها تقلل من هدر المواد ووقت الإنتاج، مما يوفر وفورات في التكاليف على المدى الطويل. |

| ما هي قيود تقنية EBAM؟ | تتطلب تقنية EBAM معدات ومعرفة متخصصين، ولديها استهلاك طاقة مرتفع، وهي محدودة بحجم البناء. |

| كيف تضمن تقنية EBAM جودة الأجزاء؟ | توفر تقنية EBAM دقة عالية، ولكن قد تكون المعالجة اللاحقة مطلوبة للتشطيب السطحي وتحقيق الخصائص المطلوبة. |

| هل يمكن استخدام تقنية EBAM للإنتاج الضخم؟ | نعم، تقنية EBAM قابلة للتطوير ويمكن استخدامها لكل من النماذج الأولية والإنتاج الضخم، اعتمادًا على التطبيق. |

| ما هي الفوائد البيئية لتقنية EBAM؟ | تنتج تقنية EBAM الحد الأدنى من النفايات وتستخدم المواد بكفاءة، مما يساهم في ممارسات التصنيع الأكثر استدامة. |

| كيف أختار المادة المناسبة لتقنية EBAM؟ | يعتمد اختيار المواد على الخصائص والتطبيق المطلوبة. يمكن أن يساعد التشاور مع الموردين والخبراء في اتخاذ القرار الصحيح. |