مرحباً بك في دليلنا الشامل حول الحث الكهربائي بالذوبان بالغاز الخامل بالحث الكهربائي (EIMIG)، وهي تقنية متطورة تُستخدم في إنتاج مساحيق معدنية عالية الجودة. وسواء كنت مهندس مواد أو باحثًا أو مجرد باحث أو باحثًا مهتمًا بالعمليات المعدنية المتقدمة، فإن هذه المقالة مصممة لتزويدك بفهم مفصل عن تقنية EIMIG. سوف نتعمق في ميكانيكياته، ونستكشف نماذج محددة من المسحوق المعدني، ونسلط الضوء على تطبيقاته المختلفة. لذا، دعونا نبدأ!

لمحة عامة عن الغاز الخامل بالذوبان بالحث الكهربائي

الصهر بالغاز الخامل بالحث الكهربائي بالحث الكهربائي (EIMIG) هو عملية معدنية متطورة تتضمن صهر المعادن باستخدام قوس كهربائي متولد بين الأقطاب الكهربائية في بيئة غاز خامل. وتعد هذه الطريقة مفيدة بشكل خاص لإنتاج مساحيق معدنية عالية النقاء، وهي ضرورية في صناعات تتراوح من الفضاء إلى الهندسة الطبية الحيوية.

ما الذي يميز EIMIG؟

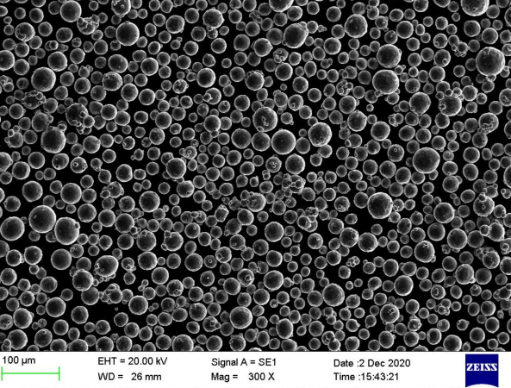

وتتميز EIMIG بقدرتها على إنتاج مساحيق معدنية بنقاوة فائقة وأحجام جسيمات يمكن التحكم فيها. وباستخدام جو غاز خامل، عادة ما يكون الأرجون أو الهيليوم، يتم تقليل الأكسدة والتلوث إلى الحد الأدنى، مما يضمن إنتاج مساحيق معدنية عالية الجودة. كما أن هذه العملية متعددة الاستخدامات، مما يسمح بصهر مجموعة واسعة من المعادن والسبائك.

المكونات الأساسية لمجموعة الإدارة المتكاملة للمعلومات والتحليلات الإلكترونية

- الأقطاب الكهربائية: عادةً ما تكون مصنوعة من الجرافيت أو التنجستن، وهي تولد القوس الكهربائي اللازم للصهر.

- بيئة الغازات الخاملة: يشيع استخدام الأرجون أو الهيليوم لمنع الأكسدة.

- نظام التدفئة بالحث الحثي: يوفر الطاقة اللازمة للحفاظ على عملية الصهر.

- بوتقة: يحمل المعدن أثناء ذوبانه وتبريده إلى شكل مسحوق.

أنواع المساحيق المعدنية التي تنتجها شركة EIMIG

يمكن أن تنتج EIMIG مجموعة متنوعة من المساحيق المعدنية، لكل منها خصائص فريدة مناسبة لتطبيقات مختلفة. فيما يلي عشرة نماذج محددة:

1. سبائك التيتانيوم (Ti-6Al-4V)

التركيب: التيتانيوم والألومنيوم والفاناديوم

الخصائص: نسبة عالية من القوة إلى الوزن ومقاومة ممتازة للتآكل

التطبيقات: مكونات الفضاء الجوي، الغرسات الطبية

2. سبائك النيكل الفائقة (Inconel 718)

التركيب: النيكل والكروم والحديد والنيوبيوم والنيوبيوم والنيكل والكروم والحديد والنيوبيوم

الخصائص: مقاومة درجات الحرارة العالية والخصائص الميكانيكية الممتازة

التطبيقات: شفرات التوربينات، المحركات النفاثة

3. الفولاذ المقاوم للصدأ (316L)

التركيب: الحديد، الكروم، النيكل، النيكل، الموليبدينوم

الخصائص: مقاومة عالية للتآكل، قابلية تشكيل جيدة

التطبيقات: الأجهزة الطبية الحيوية، معدات تجهيز الأغذية

4. سبيكة الكوبالت والكروم (Co-Cr-Mo)

التركيب: الكوبالت، والكروم، والموليبدينوم

الخصائص: مقاومة عالية للتآكل، والتوافق الحيوي

التطبيقات: زراعة الأسنان، زراعة الأسنان وزراعة العظام

5. سبائك الألومنيوم (AlSi10Mg)

التركيب: الألومنيوم والسيليكون والمغنيسيوم

الخصائص: خفيف الوزن وموصلية حرارية جيدة

التطبيقات: قطع غيار السيارات، والهياكل الفضائية

6. سبائك النحاس (CuNi2SiCr)

التركيب: النحاس، النيكل، النيكل، السيليكون، الكروم

الخصائص: موصلية كهربائية عالية، قوة ميكانيكية جيدة

التطبيقات: الموصلات الكهربائية، المبادلات الحرارية

7. فولاذ الأدوات (H13)

التركيب: الحديد، الكروم، الموليبدينوم، الموليبدينوم، الفاناديوم

الخصائص: صلابة عالية، مقاومة ممتازة للحرارة

التطبيقات: قوالب الصب بالقالب وأدوات البثق

8. فولاذ مصهور (18Ni300)

التركيب: الحديد، النيكل، النيكل، الكوبالت، الموليبدينوم

الخصائص: قوة عالية، صلابة جيدة

التطبيقات: مكونات الفضاء الجوي، والأدوات

9. كربيد التنغستن (WC-Co)

التركيب: التنغستن، الكوبالت

الخصائص: صلبة للغاية، مقاومة عالية للتآكل

التطبيقات: أدوات القطع، معدات التعدين

10. سبيكة الزركونيوم (Zr702)

التركيب: الزركونيوم، والهافنيوم، والحديد

الخصائص: مقاومة ممتازة للتآكل، وخصائص ميكانيكية جيدة

التطبيقات: المفاعلات النووية، معدات المعالجة الكيميائية

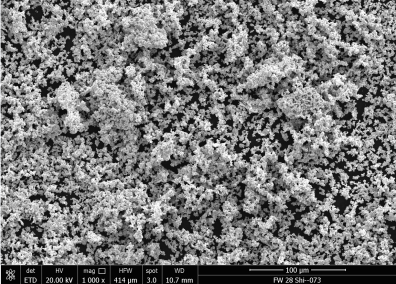

خصائص الحث الكهربائي بالذوبان بالغاز الخامل بالحث الكهربائي

يشتهر EIMIG بالعديد من الخصائص الرئيسية التي تجعله خيارًا جذابًا لإنتاج مساحيق المعادن.

النقاء

تقلل بيئة الغاز الخامل بشكل كبير من التلوث، مما ينتج عنه مساحيق معدنية بمستويات نقاء عالية.

التحكم في حجم الجسيمات

يسمح EIMIG بالتحكم الدقيق في توزيع حجم الجسيمات، وهو أمر بالغ الأهمية للتطبيقات التي تتطلب خصائص مسحوق محددة.

تعدد الاستخدامات

هذه العملية قابلة للتكيف مع مجموعة واسعة من المعادن والسبائك، مما يجعلها مناسبة للتطبيقات الصناعية المتنوعة.

الكفاءة

عملية EIMIG هي عملية موفرة للطاقة، وقادرة على إنتاج كميات عالية من مسحوق المعادن بأقل قدر من النفايات.

تطبيقات غاز الذوبان الخامل بالحث الكهربائي بالحث الكهربائي

تُستخدم المساحيق المعدنية التي تنتجها شركة EIMIG في العديد من الصناعات عالية التقنية نظرًا لخصائصها الفائقة.

صناعة الطيران والفضاء

تُعد السبائك عالية القوة وخفيفة الوزن مثل Ti-6Al-4V ضرورية لمكونات الطائرات، حيث يكون الأداء والموثوقية أمرًا بالغ الأهمية.

الهندسة الطبية الحيوية

تُستخدم المواد المتوافقة حيويًا مثل Co-Cr-Mo في الغرسات والأجهزة الطبية، مما يضمن السلامة والفعالية للمرضى.

قطاع السيارات

تُستخدم سبائك الألومنيوم مثل AlSi10Mg في قطع غيار السيارات لتقليل الوزن وتحسين كفاءة استهلاك الوقود.

الإلكترونيات

تعتبر سبائك النحاس ذات الموصلية الكهربائية العالية ضرورية للموصلات والمكونات الإلكترونية الأخرى.

الأدوات والتصنيع

يتم استخدام فولاذ الأدوات ومساحيق كربيد التنجستن لإنشاء قوالب وأدوات قطع متينة لعمليات التصنيع المختلفة.

المواصفات التفصيلية لمساحيق المعادن EIMIG

الخصائص والخصائص

| المسحوق المعدني | الكثافة (جم/سم مكعب) | درجة الانصهار (درجة مئوية) | الصلابة (HV) | قوة الشد (ميجا باسكال) | الاستطالة (%) |

|---|---|---|---|---|---|

| Ti-6Al-4V | 4.43 | 1660 | 349 | 895 | 10 |

| انكونيل 718 | 8.19 | 1350 | 330 | 1240 | 12 |

| فولاذ مقاوم للصدأ 316L | 7.99 | 1375 | 217 | 620 | 40 |

| كو-كر-مو | 8.29 | 1330 | 450 | 900 | 8 |

| AlSi10 ملغ | 2.68 | 570 | 85 | 310 | 7 |

| CuNiNi2SiCr | 8.78 | 1083 | 100 | 450 | 20 |

| فولاذ الأدوات H13 | 7.80 | 1427 | 750 | 1450 | 12 |

| فولاذ مغلف 18Ni300 | 8.00 | 1413 | 340 | 2000 | 10 |

| WC-Co | 15.60 | 2870 | 1600 | – | – |

| Zr702 | 6.50 | 1855 | 250 | 550 | 30 |

التطبيقات والاستخدامات

| المسحوق المعدني | التطبيقات الأساسية | الاستخدامات الإضافية |

|---|---|---|

| Ti-6Al-4V | مكونات الفضاء الجوي، الغرسات الطبية | السلع الرياضية، والتطبيقات البحرية |

| انكونيل 718 | شفرات التوربينات، المحركات النفاثة | المفاعلات النووية، والمركبات الفضائية |

| فولاذ مقاوم للصدأ 316L | الأجهزة الطبية الحيوية، وتجهيز الأغذية | المعالجة الكيميائية والتطبيقات البحرية |

| كو-كر-مو | زراعة الأسنان وزراعة الأسنان وزراعة العظام | مكونات الساعة، المحامل الصناعية |

| AlSi10 ملغ | قطع غيار السيارات، والهياكل الفضائية | الإلكترونيات الاستهلاكية والدراجات الهوائية |

| CuNiNi2SiCr | الموصلات الكهربائية، والمبادلات الحرارية | التطبيقات البحرية، العملات المعدنية |

| فولاذ الأدوات H13 | قوالب الصب بالقالب وأدوات البثق | قوالب الحقن، قوالب الحقن، قوالب التشكيل |

| فولاذ مغلف 18Ni300 | مكونات الفضاء الجوي، والأدوات | تروس وأعمدة تروس عالية الأداء |

| WC-Co | أدوات القطع، معدات التعدين | الأجزاء المقاومة للاهتراء، وأدوات الحفر |

| Zr702 | المفاعلات النووية، المعالجة الكيميائية | الأجهزة الطبية، والمكونات الفضائية |

المواصفات والمقاسات والدرجات والمعايير

| المسحوق المعدني | الصف | نطاق الحجم (ميكرومتر) | قياسي |

|---|---|---|---|

| Ti-6Al-4V | الصف الخامس | 15-45 | ASTM B348 |

| انكونيل 718 | UNS N07718 | 15-53 | AMS 5662 |

| فولاذ مقاوم للصدأ 316L | 316 لتر | 10-45 | ASTM F138 |

| كو-كر-مو | ASTM F75 | 20-63 | الأيزو 5832-4 ISO 5832-4 |

| AlSi10 ملغ | – | 15-45 | DIN EN 1706 |

| CuNiNi2SiCr | – | 20-50 | ASTM B422 |

| فولاذ الأدوات H13 | H13 | 20-63 | ASTM A681 |

| فولاذ مغلف 18Ni300 | 18ni300 | 10-45 | AMS 6514 |

| WC-Co | 1-20 | الأيزو 4499-1 ISO 4499-1 | |

| Zr702 | R60702 | 15-45 | ASTM B551 |

تفاصيل الموردين والأسعار

| المورد | المسحوق المعدني | السعر (بالكيلوغرام) | التوفر |

|---|---|---|---|

| شركة المساحيق المتقدمة | Ti-6Al-4V | $150 | متوفر في المخزون |

| شركة المعادن المتخصصة | انكونيل 718 | $200 | مخزون محدود |

| المواد الطبية ذ.م.م.م | فولاذ مقاوم للصدأ 316L | $120 | متوفر في المخزون |

| شركة بيوميتالز كورب | كو-كر-مو | $180 | الطلب المسبق مطلوب |

| شركة لايت ميتالز | AlSi10 ملغ | $100 | متوفر في المخزون |

| السبائك الكهربائية المحدودة | CuNiNi2SiCr | $160 | متوفر في المخزون |

| شركة توريد أدوات الصلب | فولاذ الأدوات H13 | $140 | مخزون محدود |

| معادن عالية القوة | فولاذ مغلف 18Ni300 | $220 | متوفر في المخزون |

| مجموعة المعادن الصلبة | WC-Co | $300 | الطلب المسبق مطلوب |

| شركة المواد النووية | Zr702 | $250 | متوفر في المخزون |

مقارنة الإيجابيات والسلبيات والمزايا والقيود

| المسحوق المعدني | مزايا | محددات |

|---|---|---|

| Ti-6Al-4V | متانة عالية وخفيفة الوزن ومقاومة للتآكل | باهظة الثمن وصعبة التشغيل الآلي |

| انكونيل 718 | خصائص ممتازة في درجات الحرارة العالية | التكلفة العالية والمعالجة المعقدة |

| فولاذ مقاوم للصدأ 316L | مقاوم للتآكل ومتوافق حيوياً | قوة أقل مقارنة بالسبائك الأخرى |

| كو-كر-مو | مقاومة عالية للتآكل، وتوافق حيوي | هشاشة وباهظة الثمن |

| AlSi10 ملغ | خفة الوزن وخصائص حرارية جيدة | قوة أقل بالمقارنة مع سبائك الصلب |

| CuNiNi2SiCr | موصلية كهربائية عالية، ومقاومة للتآكل | غالية الثمن، قوة ميكانيكية محدودة |

| فولاذ الأدوات H13 | صلابة عالية ومقاومة للحرارة | عرضة للتشقق تحت الضغط |

| فولاذ مغلف 18Ni300 | قوة عالية وصلابة جيدة | تتطلب معالجة حرارية باهظة الثمن ومعقدة |

| WC-Co | شديدة الصلابة ومقاومة عالية للتآكل | الهشاشة والتكلفة العالية |

| Zr702 | مقاومة ممتازة للتآكل، وخصائص ميكانيكية جيدة | تكلفة عالية، وتوافر محدود |

أسئلة وأجوبة

ما هو الحث الكهربائي بالذوبان بالغاز الخامل بالحث الكهربائي (EIMIG)؟

EIMIG عبارة عن عملية يتم فيها صهر المعادن باستخدام قوس كهربائي بين أقطاب كهربائية في جو غاز خامل، مما ينتج عنه مساحيق معدنية عالية النقاء.

لماذا استخدام غاز خامل في EIMIG؟

تعمل الغازات الخاملة مثل الأرجون أو الهيليوم على منع الأكسدة والتلوث أثناء عملية الصهر، مما يضمن الحصول على مساحيق معدنية عالية الجودة.

ما هي المعادن التي يمكن صهرها باستخدام EIMIG؟

إن EIMIG متعدد الاستخدامات ويمكنه صهر مجموعة واسعة من المعادن والسبائك، بما في ذلك التيتانيوم والنيكل والفولاذ المقاوم للصدأ والكوبالت والكروم وغيرها.

ما هي استخدامات مساحيق المعادن EIMIG؟

تُستخدم مساحيق المعادن EIMIG في صناعات الطيران والهندسة الطبية الحيوية والسيارات والإلكترونيات والأدوات نظرًا لخصائصها الفائقة.

كيف يتحكم EIMIG في حجم الجسيمات؟

يمكن ضبط معلمات العملية في EIMIG بدقة للتحكم في توزيع حجم الجسيمات، مما يضمن الاتساق والدقة في المنتج النهائي.

هل المساحيق المعدنية EIMIG باهظة الثمن؟

تختلف تكلفة المساحيق المعدنية EIMIG بناءً على نوع المعدن ونقاوته ولكنها تميل عمومًا إلى أن تكون أعلى بسبب الطبيعة المتقدمة للعملية.

ما هي الفوائد الرئيسية لـ EIMIG؟

يوفر EIMIG درجة نقاء عالية وتحكمًا دقيقًا في حجم الجسيمات وتنوعًا في أنواع المعادن وإنتاجًا فعالاً، مما يجعله مفيدًا للغاية لإنتاج مساحيق المعادن المتخصصة.

كيف يختلف EIMIG عن تقنيات الصهر الأخرى؟

ويستخدم EIMIG جوًا خاملًا من الغاز الخامل والتسخين بالحثّ، مما يقلل من التلوث ويسمح بالتحكم الدقيق في عملية الصهر، مما يميزه عن التقنيات الأخرى مثل الصهر القوسي التقليدي.

هل يمكن استخدام EIMIG للإنتاج على نطاق واسع؟

نعم، يمكن توسيع نطاق EIMIG للإنتاج الصناعي، مما يجعله مناسبًا للأبحاث على نطاق صغير والتصنيع على نطاق واسع.

من هم الموردون الرئيسيون لمساحيق المعادن EIMIG؟

وتشمل قائمة الموردين الرئيسيين شركة Advanced Powders Inc. وشركة Specialty Metals Co. وشركة Medical Materials LLC وشركة BioMetals Corp. وغيرها، حيث تقدم مجموعة متنوعة من مساحيق المعادن لمختلف التطبيقات.

خاتمة

يُعد غاز الذوبان الخامل بالحث الكهربائي بالحث الكهربائي (EIMIG) تقنية تحويلية في مجال علم المعادن، حيث توفر نقاءً ودقة لا مثيل لهما في إنتاج مسحوق المعادن. تمتد تطبيقاتها عبر الصناعات الهامة، مما يضمن الأداء العالي والموثوقية في البيئات الصعبة. وسواء كنت تبحث في مكونات الطيران أو الأجهزة الطبية الحيوية أو الأدوات عالية الأداء، فإن EIMIG يوفر المواد المتقدمة اللازمة لتخطي حدود الابتكار.