M2 Powder in Precision Manufacturing: A Complete B2B Guide

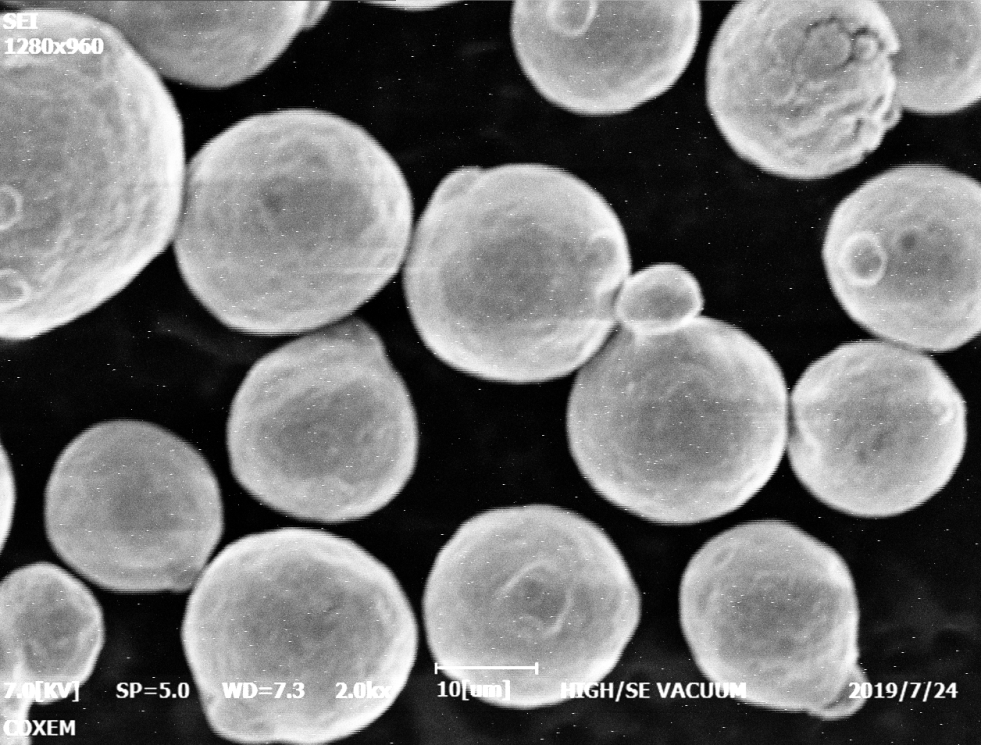

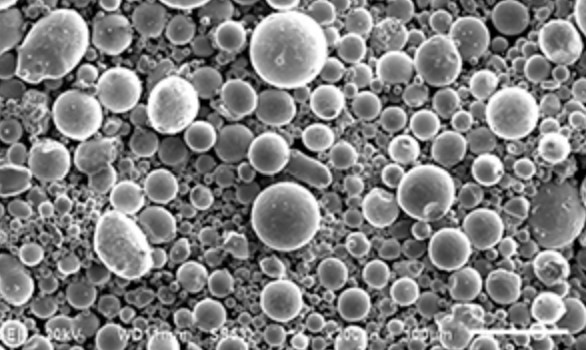

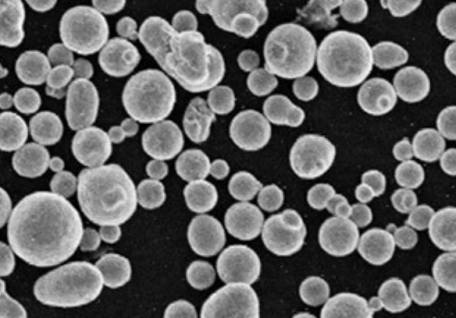

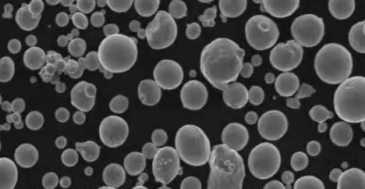

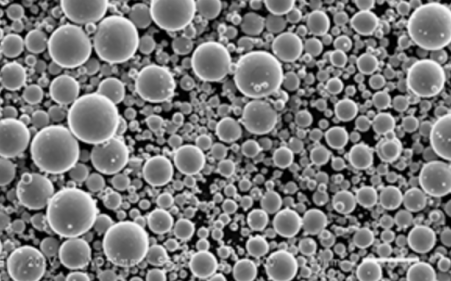

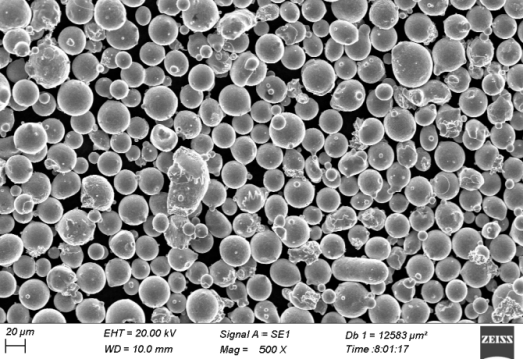

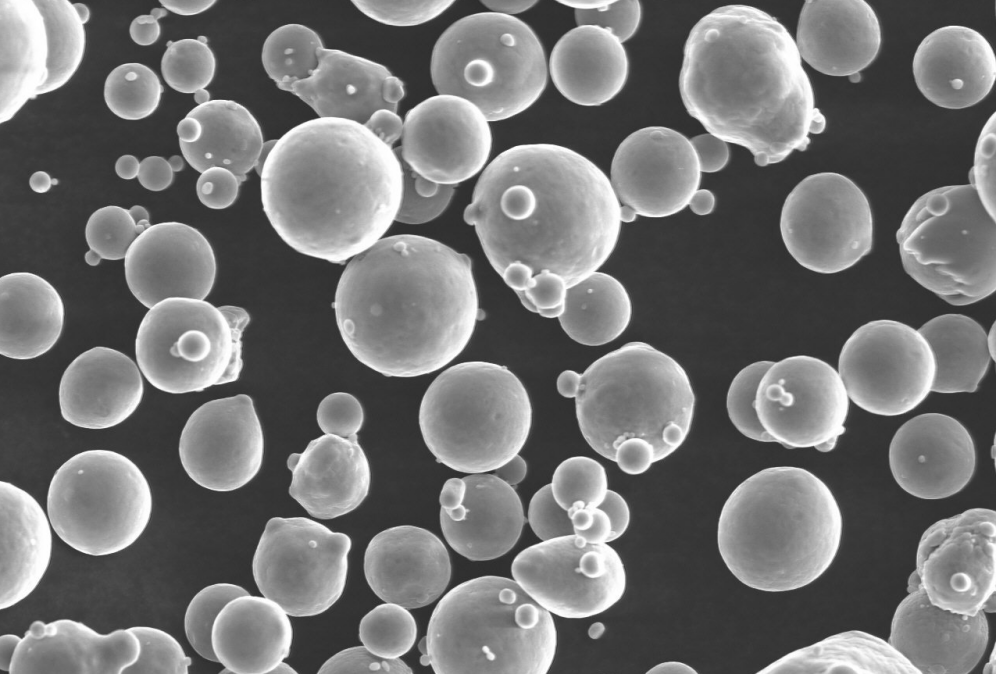

1. Introduction: The Role of M2 Powder in Modern Manufacturing M2 powder, derived from high-speed steel (HSS), is a critical material for industries requiring wear resistance, toughness, and high red hardness. As industries continue to shift toward precision, additive manufacturing (AM), and powder metallurgy (PM), M2 powder has emerged as a key input for manufacturers […]

M2 Powder in Precision Manufacturing: A Complete B2B Guide Daha Fazla Oku "