1. Introducción: Por qué el polvo SS-410L es crucial en la fabricación moderna

En el panorama en evolución de la fabricación aditiva (AM) y la pulvimetalurgia (PM), acero inoxidable como el SS-410L están ganando adeptos entre los fabricantes de equipos originales, los vendedores de comercio electrónico y los fabricantes de componentes industriales. El SS-410L, un acero inoxidable martensítico con bajo contenido en carbono, ofrece un equilibrio entre resistencia a la corrosión, resistencia mecánica y rentabilidad, lo que lo hace muy adecuado para piezas estructurales, filtros sinterizados y componentes de automoción.

Palabras clave de búsqueda B2B:

- Venta al por mayor de polvo de acero inoxidable SS-410L

- Comprar SS-410L en polvo a granel

- Polvo SS-410L para fabricación aditiva

- Proveedores de polvo SS-410L para impresión 3D

- Distribuidores industriales de polvo de acero inoxidable

Por qué es importante el SS-410L atomizado:

- Permite piezas sinterizadas de alta densidad

- Mejora de la fluidez en los procesos AM y PM

- Adecuado para la producción de alto rendimiento

- Reduce los costes de tratamiento posterior gracias a un mejor acabado superficial

Shanghai Truer Technology Co., Ltd, proveedor líder de polvos de acero inoxidable en China, ha sido un innovador clave en este espacio. Desde 2019, su división de fabricación aditiva ha desarrollado polvos de alta calidad adaptados a aplicaciones AM y PM. Con técnicas avanzadas de atomización con agua y gas, Truer proporciona polvo SS-410L de calidad superior a clientes B2B globales.

más información Tecnología Truer de Shanghai

2. Aplicaciones del polvo SS-410L en sectores industriales

La versatilidad del polvo SS-410L lo hace ideal para diversos usos industriales. Su resistencia a la corrosión y sus prestaciones mecánicas bajo calor y tensión son especialmente valiosas en los siguientes sectores:

| Industria | Ejemplos de aplicación | Ventajas del uso del polvo SS-410L |

|---|---|---|

| Automotor | Componentes de frenos, bujes, piezas de engranajes | Alta resistencia al desgaste, rentable |

| Aeroespacial | Soportes estructurales, carcasas | Estabilidad dimensional, resistencia a la corrosión |

| Petróleo y gas | Filtros, piezas de bombas | Resistencia a fluidos corrosivos |

| Productos sanitarios | Herramientas ortopédicas, soportes quirúrgicos | Biocompatibilidad, excelente acabado superficial |

| Electrodomésticos | Elementos calefactores, piezas de aparatos | Resistencia al calor, conformabilidad |

Ventajas para los compradores mayoristas:

- Fácilmente escalable para grandes volúmenes de producción

- Compatible con el moldeo por inyección de metal (MIM) y la fusión selectiva por láser (SLM)

- Conforme a las normas PM internacionales como MPIF e ISO

Shanghai Truer apoya a los compradores a granel con un suministro constante, asistencia técnica y opciones de personalización para aplicaciones específicas. Consulte su Gama de productos en polvo SS-410L para más detalles.

3. Propiedades físicas y mecánicas del polvo SS-410L atomizado

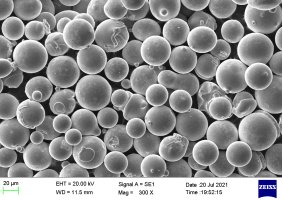

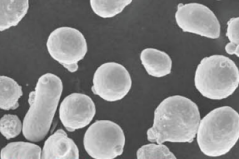

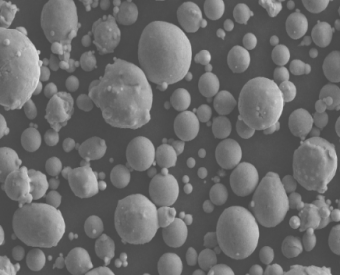

El polvo de acero inoxidable SS-410L está disponible en varias distribuciones granulométricas y puede personalizarse según el proceso de sinterización utilizado por el comprador. Shanghai Truer ofrece versiones atomizadas con agua y atomizadas con gas, cada una de ellas adecuada para diferentes necesidades de fabricación.

| Propiedad | Valores típicos |

|---|---|

| Composición química | Fe: Equilibrio, Cr: 11.5-13,5%, C: <0,03%, Si: <1% |

| Distribución del tamaño de las partículas | D50: 30-60 µm (personalizable) |

| Caudal (Hall, s/50g) | 25-35 |

| Densidad aparente | 2.5-3,2 g/cm³ |

| Densidad sinterizada | Hasta 7,3 g/cm³ |

| Dureza (HRB) | 70-85 |

| Resistencia a la tracción | 480-620 MPa |

Características del polvo atomizado SS-410L:

- Excelente fluidez para procesos AM

- Bajo contenido de oxígeno para obtener mejores resultados de sinterización

- Una morfología homogénea garantiza un rendimiento uniforme

- Impurezas reducidas para una mayor fiabilidad

Opciones de personalización en Truer:

- Ajuste del tamaño de las partículas para MIM, SLM o Binder Jetting

- Optimización de la mezcla de aleaciones

- Etiquetado y envasado OEM para distribuidores

🔍 Explore más especificaciones de polvo de acero inoxidable en AM-Material.com

4. Tendencias del mercado y demanda mundial de acero inoxidable en polvo

El mercado mundial del polvo de acero inoxidable está experimentando una importante tendencia al alza, impulsada por su rápida adopción en los sectores de la fabricación aditiva (AM), la pulvimetalurgia (PM) y el moldeo por inyección de metales (MIM). El polvo atomizado SS-410L, en particular, ha experimentado un aumento de la demanda debido a su equilibrio entre resistencia a la corrosión, asequibilidad y resistencia mecánica.

📊 Perspectivas clave del mercado:

| Métrica | estimación para 2023 | previsión 2028 |

|---|---|---|

| Tamaño del mercado mundial de SS en polvo | 1.300 millones de dólares | 2.100 millones de dólares |

| CAGR (2023-2028) | 9.2% | |

| Principales sectores en crecimiento | Automoción, aeroespacial, AM | Energía, productos sanitarios |

| Principales mercados regionales | China, EE.UU., Alemania, Japón | India, Corea del Sur, Brasil |

🔎 Tendencias B2B que impulsan la demanda:

- Localización de la cadena de suministro: Los fabricantes de equipos originales y los proveedores de primer nivel están diversificando sus fuentes para reducir la dependencia de mercados singulares.

- Cambio hacia una fabricación sostenible: La reciclabilidad de la SS-410L’ se ajusta a los objetivos de sostenibilidad.

- Demanda de personalización: Los usuarios finales buscan soluciones en polvo a medida para geometrías de pieza específicas.

Mayoristas: Los distribuidores y compradores al por mayor favorecen cada vez más las relaciones directas con fabricantes como Shanghai Truer Technology para garantizar el control de calidad, plazos de entrega más rápidos y asistencia técnica.

👉 Descubra más sobre nuestras capacidades pulvimetalúrgicas en nuestra página de inicio

5. Factores a tener en cuenta al elegir un proveedor de polvo SS-410L

Seleccionar al proveedor de polvo atomizado SS-410L adecuado es fundamental para garantizar la consistencia del producto, la eficacia de la producción y el cumplimiento de la normativa en los flujos de trabajo de fabricación B2B.

✅ Lista de comprobación para la evaluación de proveedores:

| Criterios de evaluación | Por qué es importante para los compradores B2B |

|---|---|

| Calidad del polvo & Composición | Influye en el rendimiento de la pieza y en el éxito de la sinterización |

| Tecnología de atomización | Determina la morfología y la fluidez del polvo |

| Consistencia de los lotes | Esencial para la producción de grandes volúmenes y la repetibilidad |

| Certificaciones | Cumplimiento de las normas ISO, RoHS y REACH para la exportación |

| Capacidades de personalización | Posibilidad de modificar la distribución de tamaños o el contenido de aleación |

| Plazos de entrega y logística | Afecta a la planificación de la producción y al control de las existencias |

| Asistencia técnica | Fundamental para la resolución de problemas y la optimización de aplicaciones |

| Precios y cantidades mínimas | Repercusión en el presupuesto y la competitividad de su cadena de suministro |

🌟 Shanghai Truer Technology Advantage:

- Procesos de atomización dual (gas + agua) para satisfacer diversas necesidades de fabricación

- I+D propio para mezclas en polvo a medida

- Producción y trazabilidad con certificación ISO

- Calidad homogénea en todos los lotes

- MOQ flexibles para distribuidores y OEM

🔗 Consulte toda nuestra oferta de productos en Polvos de acero inoxidable PM

6. Principales proveedores mundiales de SS-410L en polvo

Al comprar SS-410L en polvo a granel, las empresas deben evaluar no sólo el precio, sino también la capacidad del proveedor, sus conocimientos técnicos y su alcance mundial. He aquí una comparación de proveedores de primer nivel que atienden a compradores B2B:

| Nombre de la empresa | País | Especialidad | Tecnología de atomización | Servicios B2B ofrecidos |

|---|---|---|---|---|

| Tecnología Truer de Shanghai | China | PM & Polvos de impresión 3D | Gas y agua | Personalización OEM, suministro a granel, asesoramiento técnico |

| Höganäs AB | Suecia | Polvos metálicos de gran pureza | Agua | Distribución mundial, I+D avanzada |

| Aditivo para carpinteros | EE.UU. | Polvos de fabricación aditiva | Gas | Ingeniería de aplicaciones, apoyo logístico |

| Aditivos Sandvik | Suecia | Polvos AM & MIM de primera calidad | Gas | Polvos ultrafinos, servicios internos de impresión |

| Pometon S.p.A. | Italia | Polvos PM industriales | Agua | Suministro de piezas de automoción, formación técnica |

Por qué destaca Shanghai Truer:

- Uno de los proveedores de aditivos más profesionales de China en la industria PM

- Ofrece una solución completa: producción de polvo + equipos + asistencia en la aplicación

- Fuerte presencia en los mercados asiático, europeo y norteamericano

- Precios competitivos y entregas más rápidas gracias a la producción localizada

📞 ¿Listo para conectar con nosotros? Póngase en contacto con el equipo Truer para consultas al por mayor.

7. Por qué cada vez más compradores eligen fabricantes chinos para el polvo SS-410L

En la última década, China se ha convertido en una fuerza dominante en la cadena de suministro mundial de pulvimetalurgia (PM) y fabricación aditiva (AM). Cada vez más compradores B2B -desde fabricantes de equipos originales a distribuidores de materiales- se abastecen de polvos de acero inoxidable como el SS-410L atomizado de proveedores chinos debido a varias ventajas estratégicas.

📈 Razones principales por las que los compradores se abastecen en China:

- Eficiencia de costes

- Los menores costes de materias primas y mano de obra reducen el coste total de producción.

- Unos precios competitivos permiten mejores márgenes a revendedores y fabricantes de equipos originales.

- Escala de producción & Capacidad

- Fabricantes chinos como Shanghai Truer operan líneas de atomización a gran escala.

- Capaz de satisfacer pedidos a granel de gran volumen con una calidad constante.

- Avances tecnológicos

- Uso de tecnologías de atomización híbridas (gas y agua) para optimizar las propiedades.

- La I+D interna permite un rápido desarrollo de aleaciones personalizadas.

- Plazos de entrega más cortos

- Sólida logística nacional y redes de transporte internacional.

- Reducción del tiempo de comercialización, especialmente para los compradores de Asia Oriental y el Pacífico.

- Cumplimiento de la normativa

- Los principales proveedores chinos cumplen las normas ISO 9001, RoHS y REACH.

- Apoyo a la trazabilidad y la documentación para la distribución mundial.

💡 Consejo profesional para distribuidores:

Cuando se abastezca en China, elija empresas consolidadas con un historial de exportación probado, como Tecnología Truer de Shanghaipara garantizar la fiabilidad y la asistencia técnica.

8. Por qué elegir Shanghai Truer Technology como su socio de polvo SS-410L

Shanghai Truer Technology Co., Ltd. ha surgido como uno de los proveedores de metalurgia en polvo más confiables de China. Desde su entrada en el sector de la fabricación aditiva en 2019, Truer ha desarrollado una sólida cartera de polvos metálicos, incluido el SS-410L atomizado de alta pureza.

🏆 Lo que distingue a Shanghai Truer:

| Característica | Ventajas para los compradores B2B |

|---|---|

| Doble atomización (gas + agua) | Fluidez y densidad adaptadas para AM & necesidades PM |

| Amplia gama de grados | De CT-1000 a FD-0208 y mezclas SS-410L personalizadas |

| I+D interno | Rápido desarrollo de composiciones de aleación personalizadas |

| Producción & Integración de equipos | Solución AM integral: polvo + equipos + asistencia |

| Compatible con OEM y distribuidores | MOQ flexible, embalaje de marca blanca y envío rápido |

✔ Garantía de calidad del producto:

- Morfología coherente de las partículas: Garantiza un comportamiento de sinterización predecible.

- Contaminación por bajo nivel de oxígeno: Mejora el rendimiento mecánico de las piezas finales.

- Coherencia entre lotes: Fundamental para la producción a gran escala de MIM/SLM.

🔧 Soporte de servicio completo:

- Consultoría técnica para la optimización de aplicaciones

- Distribución granulométrica personalizada

- Documentación de exportación y apoyo logístico

Explore la línea completa de polvos metálicos y aditivos de Truer en su página de productos

9. Preguntas frecuentes: Compra al por mayor de polvo atomizado SS-410L

Q1: ¿Cuál es el MOQ para pedidos al por mayor de polvo SS-410L de Shanghai Truer?

A: La cantidad mínima de pedido es flexible, a partir de 100 kg para pedidos de prueba. Para pedidos superiores a 500 kg se ofrecen precios por volumen.

P2: ¿Qué industrias se benefician más del polvo SS-410L?

A: Las industrias de automoción, aeroespacial, energética, médica y de fabricación en general utilizan habitualmente el SS-410L debido a su alta resistencia y a la corrosión.

P3: ¿Puedo solicitar una distribución granulométrica personalizada?

A: Sí. Truer ofrece personalización basada en sus requisitos de sinterización o proceso de impresión (SLM, MIM, Binder Jetting, etc.).

P4: ¿Están certificados los polvos Truer?

A: Absolutamente. Todos los polvos vienen con COA y cumplen las normas ISO 9001. La documentación RoHS y REACH también está disponible para las exportaciones mundiales.

P5: ¿Cómo hago un pedido al por mayor?

A: Puede ponerse en contacto directamente a través de Página de contacto para obtener un presupuesto, solicitar muestras o iniciar la adquisición.

✅ ¿Está listo para obtener polvo SS-410L de alta calidad?

Shanghai Truer Technology es su socio de confianza para el polvo SS-410L atomizado de alto rendimiento. Si usted es un OEM, distribuidor o proveedor de comercio electrónico, Truer ofrece una calidad constante, experiencia técnica y precios competitivos para satisfacer sus demandas de producción.

🔗 Visita AM-Material.com para consultar toda nuestra cartera de productos o ponerse en contacto con nuestro equipo hoy mismo.

📌 Enlaces internos utilizados en este blog:

- https://am-material.com/about/ - “Shanghai Truer Technology”

- https://am-material.com/pm-powder/ - “Gama de productos en polvo SS-410L”

- https://am-material.com/pm-powder/ - “Polvos de acero inoxidable PM”

- https://am-material.com/contact-us/ - “Póngase en contacto con el equipo Truer”

- https://am-material.com/ – “AM-Material.com”

Díganos cuál es el próximo tema que desea explorar