1. ¿Qué es el polvo atomizado SS-304L?

El polvo atomizado de SS-304L es un producto finamente procesado acero inoxidable polvo creado principalmente mediante técnicas de atomización con gas o agua. El “304L” se refiere a una versión baja en carbono de la aleación de acero inoxidable 304, ampliamente utilizada, que ofrece una excelente resistencia a la corrosión, solidez y soldabilidad. Este polvo se utiliza mucho en aplicaciones de pulvimetalurgia (PM), fabricación aditiva (AM) y moldeo por inyección de metales (MIM).

Métodos comunes de atomización:

| Tipo de atomización | Descripción | Ventajas |

|---|---|---|

| Atomización de gases | El gas inerte a alta presión rompe el metal fundido en polvo | Produce partículas esféricas de gran pureza |

| Atomización del agua | El chorro de agua a alta presión desintegra el metal fundido | Rentable, ideal para formas no críticas |

| Atomización híbrida | Combinación de atomización con gas y agua | Rendimiento y coste equilibrados |

Se prefiere el polvo SS-304L por su:

- Bajo contenido en carbono (menos del 0,03%)

- Excelentes propiedades mecánicas

- Excelente resistencia a la corrosión

- Soldabilidad y conformabilidad superiores

Palabras clave B2B de gran interés integradas:

- Proveedores de polvo de acero inoxidable

- Polvo SS-304L al por mayor

- Distribuidores de acero inoxidable atomizado

- Polvo de acero inoxidable a granel

- Polvo para fabricación aditiva de metales

2. Aplicaciones industriales del polvo SS-304L

El polvo de SS-304L es un material esencial en diversas industrias debido a su resistencia a la corrosión, su resistencia mecánica y su versatilidad en los procesos de sinterización y AM. A continuación se indican sectores clave que dependen en gran medida del polvo atomizado de SS-304L:

Aplicaciones industriales clave:

- Fabricación aditiva (impresión 3D)

- Componentes aeroespaciales

- Implantes médicos personalizados

- Prototipos de automoción

- Pulvimetalurgia (PM)

- Piezas estructurales

- Engranajes y bujes

- Válvulas y accesorios

- Moldeo por inyección de metales (MIM)

- Piezas de alta precisión para electrónica

- Componentes del reloj

- Herramientas quirúrgicas

- Sistemas de filtración

- Filtros metálicos porosos

- Entornos de alta presión y corrosivos

Ejemplo de tabla de casos de uso:

| Industria | Componente | Ventajas del polvo SS-304L |

|---|---|---|

| Aeroespacial | Soportes de motor | Ligero, resistente a la corrosión |

| Médico | Mangos de herramientas quirúrgicas | Biocompatibilidad |

| Automotor | Piezas del sistema de escape | Resistencia al calor y a la corrosión |

| Energía | Placas de pilas de combustible | Alta conductividad, resistencia |

3. Propiedades principales y especificaciones técnicas

El polvo SS-304L se distingue por una combinación única de propiedades físicas y químicas que lo hacen ideal para aplicaciones industriales exigentes.

Composición química típica (%):

| Elemento | Contenido |

|---|---|

| Fe (Hierro) | Saldo |

| Cr (Cromo) | 18.0 - 20.0 |

| Ni (Níquel) | 8.0 - 12.0 |

| Mn (Manganeso) | ≤ 2.0 |

| Si (Silicio) | ≤ 1.0 |

| C (Carbono) | ≤ 0.03 |

| S (Azufre) | ≤ 0.03 |

| P (Fósforo) | ≤ 0.045 |

Propiedades mecánicas clave:

- Resistencia a la tracción: 480 MPa - 620 MPa

- Densidad (Sinterizado): ~7,6 g/cm³

- Alargamiento: ≥ 40%

- Dureza: 150 - 190 HB (Brinell)

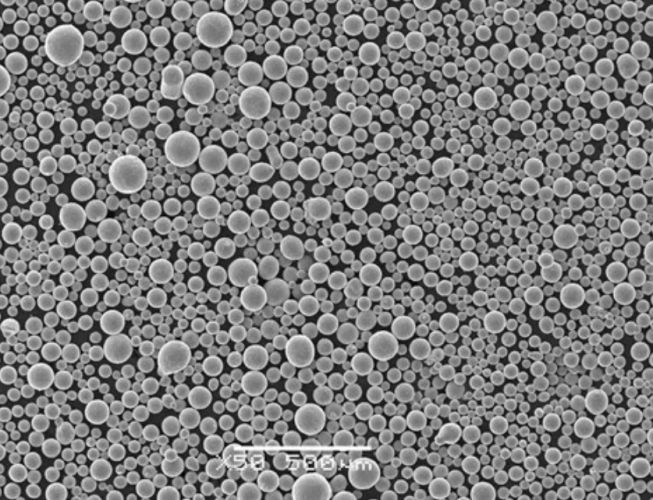

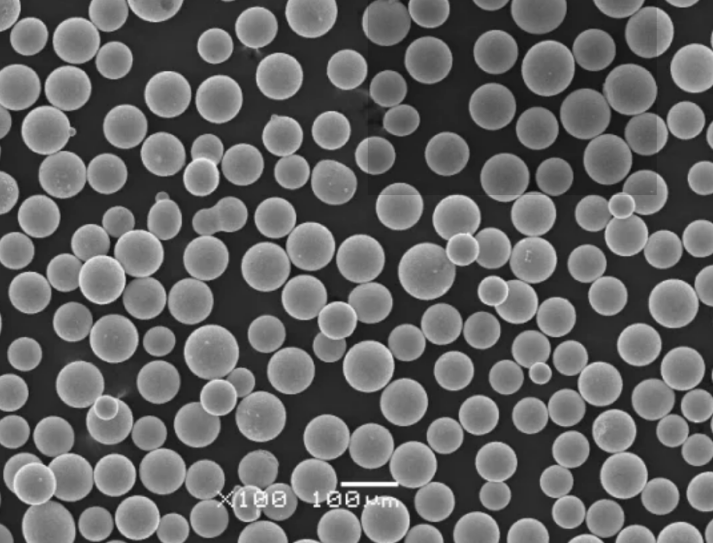

Características del polvo:

| Parámetro | Valor |

|---|---|

| Distribución del tamaño de las partículas | D50: 20-45 µm |

| Fluidez | Excelente (flujo Hall: <25s/50g) |

| Morfología | Esférica (atomizada con gas) |

| Densidad aparente | 2.5 - 3,5 g/cm³ |

| Pureza | 99,8% |

Para fabricantes, ingenieros y profesionales de la contratación que buscan polvos PM de alta calidadsS-304L ofrece un equilibrio fiable entre coste, rendimiento y versatilidad.

4. Perspectivas del mercado mundial y tendencias de la demanda

El mercado mundial de polvo atomizado de SS-304L está experimentando un crecimiento significativo, impulsado por la rápida adopción de soluciones de fabricación aditiva (AM), moldeo por inyección de metal (MIM) y pulvimetalurgia avanzada (PM) en múltiples sectores.

Principales impulsores del mercado:

- Mayor adopción de la AM en los sectores aeroespacial y médico

- Demanda de piezas ligeras y resistentes a la corrosión

- Diseño personalizado y fabricación de series cortas

- Aumento de la demanda en el sector del automóvil

- Los objetivos de ahorro de combustible fomentan las piezas ligeras de acero inoxidable

- Los componentes de los vehículos eléctricos requieren precisión y conductividad

- Avances tecnológicos en atomización

- Los métodos híbridos de atomización mejoran la relación calidad-coste

- Mejor control de la distribución granulométrica y la pureza

- Expansión de la fabricación en Asia-Pacífico

- China e India se convierten en centros de fabricación

- Abastecimiento rentable de materias primas y polvos

Previsión del mercado mundial de SS-304L en polvo (2023-2030)

| Región | 2023 Tamaño del mercado (millones de USD) | proyección 2030 (millones USD) | TACC (%) |

|---|---|---|---|

| Norteamérica | 112 | 180 | 7.2% |

| Europa | 95 | 160 | 8.1% |

| Asia-Pacífico | 150 | 300 | 10.5% |

| Resto del mundo | 60 | 95 | 6.5% |

Palabras clave SEO B2B utilizadas:

- Polvo de acero inoxidable mercado mundial

- Tendencias del polvo SS-304L

- Proveedores de polvo atomizado en Asia

- Perspectivas de la pulvimetalurgia industrial

5. Cómo seleccionar un proveedor fiable de polvo SS-304L

Elegir un proveedor de polvo SS-304L de confianza es crucial para fabricantes, OEM y productores de piezas metálicas que requieren una calidad constante y una entrega puntual. A continuación se indican los criterios clave para evaluar a los proveedores:

A. Garantía de calidad y certificaciones

- ISO 9001, ISO 14001 y otras acreditaciones pertinentes

- Informes de análisis de polvo de terceros

- Trazabilidad y control de lotes para cada envío

B. Capacidad de producción

- Método de atomización (gas, agua o híbrido)

- Capacidad para atender pedidos al por mayor

- Servicios de polvo a medida (granulometría, mezclas)

C. Asistencia técnica e I+D

- Equipo interno de ingeniería

- Personalización de materiales para AM, PM o MIM

- Asistencia posventa y resolución de problemas

D. Logística y plazos

- Capacidad de envío a todo el mundo

- Envasado fiable para evitar la oxidación/humedad

- Entrega rápida e inventario estable

E. Reputación del proveedor

- Años de experiencia en empresas y mercados

- Casos prácticos y testimonios de clientes

- Reseñas en línea y asociaciones B2B

Lista de comprobación para evaluar a un proveedor:

| Factor de evaluación | Importancia | El proveedor debe tener |

|---|---|---|

| Certificación ISO | Alta | ✓ |

| Tamaño uniforme de las partículas | Alta | ✓ |

| Capacidad de mezcla personalizada | Medio | ✓ |

| Precios competitivos | Alta | ✓ |

| Equipo de asistencia técnica | Medio | ✓ |

Para los que buscan soluciones pulvimetalúrgicasestos criterios ayudan a mitigar los riesgos en la cadena de suministro.

6. Top SS-304L Polvo Fabricantes y Distribuidores

Estos son algunos de los principales proveedores mundiales y regionales de polvo de acero inoxidable SS-304L que atienden a compradores B2B, OEM y distribuidores.

A. Shanghai Truer Technology Co., Ltd

- Establecido: 2009

- Especialidades: Polvos de acero inoxidable PM y AM (atomización con agua/gas/híbrida)

- Productos clave: PM 304L, PM 316L, PM 4600, PM Acero infiltrado

- Certificaciones: ISO 9001, laboratorio avanzado de análisis de polvo

- Por qué elegir: Diversas calidades de polvo, mezclas personalizadas, asistencia técnica

🔗 Visita Página de contacto de Shanghai Truer para solicitar un presupuesto o una consulta técnica.

B. Höganäs AB (Suecia)

- Especialidad: Polvos PM de alta calidad para los sectores médico y de automoción

- Puntos fuertes: Distribución mundial, soluciones innovadoras en encuadernación

- Limitaciones: Precios más altos para pedidos pequeños

C. Sandvik Osprey (Reino Unido)

- Especialidad: Polvos metálicos atomizados con gas para fabricación aditiva

- Puntos fuertes: Alta esfericidad y pureza

- Limitaciones: Plazos de entrega más largos para pedidos personalizados

D. Carpenter Additive (EE.UU.)

- Especialidad: Materias primas metálicas para fabricación aditiva

- Puntos fuertes: Apoyo a la certificación AM avanzada

- Limitaciones: Atiende principalmente al mercado norteamericano

E. CNPC Powder (China)

- Especialidad: Polvos de acero inoxidable atomizados con agua y gas

- Puntos fuertes: Rentable para compradores a granel

- Limitaciones: Investigación y desarrollo internos limitados en comparación con las marcas premium

Comparación de proveedores:

| Proveedor | Atomización | MOQ | Personalización | Región |

|---|---|---|---|---|

| más cierto | Gas/Agua/Híbrido | Bajo | Alta | China |

| Höganäs | Agua | Medio | Limitado | Europa |

| Sandvik | Gas | Alta | Alta | Europa |

| Carpintero | Gas | Alta | Medio | EE.UU. |

| CNPC | Agua | Bajo | Bajo | China |

Si busca un proveedor flexible y técnicamente competente, Shanghai Truer Technology Co., Ltd ofrece polvos SS-304L estándar y personalizados para diversas aplicaciones, incluidos los procesos PM, AM y MIM.

7. Por qué cada vez más empresas recurren a fuentes de suministro chinas

A medida que los fabricantes mundiales buscan la optimización de costes y la resistencia de la cadena de suministro, más compradores B2B optan por abastecerse de polvo SS-304L y otros materiales metálicos procedentes de China. Este cambio se debe a varias ventajas estratégicas que ofrecen los proveedores chinos en los sectores de la pulvimetalurgia y la fabricación aditiva.

Razones clave para abastecerse en China:

precios competitivos

- Los menores costes de producción y mano de obra permiten precios asequibles por volumen

- Economías de escala en instalaciones pulvimetalúrgicas a gran escala

✅ Infraestructura de fabricación madura

- Tecnología de atomización avanzada (gas, agua, híbrida)

- Líneas de producción de alta capacidad para polvos PM y AM

personalización y flexibilidad

- Los fabricantes chinos son más flexibles a la hora de satisfacer requisitos personalizados de granulometría, mezcla y aleación

- Mayor rapidez en la creación de prototipos de lotes pequeños y la producción en serie

✅ Innovación rápida

- Fuerte apoyo gubernamental a la fabricación avanzada y la impresión 3D

- Inversiones en I+D y ciencia de los materiales

✅ Experiencia en exportación

- Sistemas logísticos y de cumplimiento de las normas de exportación bien establecidos

- Colaboraciones frecuentes con OEM y distribuidores internacionales

Qué hay que tener en cuenta al comprar en China:

| Factor de riesgo | Estrategia de mitigación |

|---|---|

| Variabilidad de la calidad | Elija proveedores con certificación ISO e informes de pruebas |

| Barreras de comunicación | Trabajar con proveedores que ofrezcan equipos de asistencia en inglés |

| Plazos de entrega | Confirmar el estado del inventario y los plazos de envío antes de realizar los pedidos |

| Derechos de importación | Conozca la normativa y los aranceles de importación de su país |

Por ejemplo, Shanghai Truer Technology se ha labrado la reputación de suministrar polvos SS-304L uniformes y de gran pureza a clientes de todo el mundo combinando conocimientos técnicos con un servicio centrado en el cliente.

8. Por qué elegir Shanghai Truer Technology Co., Ltd como su proveedor

Shanghai Truer Technology Co., Ltd, fundada en 2009, es pionera en el mercado chino de la pulvimetalurgia y los materiales de fabricación aditiva. Desde el lanzamiento de su división de AM en 2019, Truer se ha convertido en un proveedor líder de polvos metálicos de alto rendimiento, incluido el SS-304L atomizado.

Lo que hace destacar a Truer:

✔ Integración vertical plena

Truer gestiona toda la cadena de suministro, desde la producción de polvo hasta las pruebas de calidad y la logística. Esto garantiza una calidad constante y plazos de entrega fiables.

✔ Amplia cartera de productos

- Acero inoxidable PM: SS-304L, SS-316L y más

- Aceros aleados: PM4600, PM4200, FN-5000, FX-2008

- Polvos infiltrados: PM infiltrado en hierro/acero

- Aditivos: Lube-W, QHP-330, SME-100, sulfuro de manganeso, aditivos magnéticos blandos

✔ Técnicas avanzadas de atomización

- Atomización del agua

- Atomización de gas

- Atomización híbrida (agua + gas) para un equilibrio óptimo entre coste y rendimiento

✔ Servicios de personalización

- Granulometría a medida (10-150μm)

- Mezcla de aleaciones a medida

- Desarrollo de polvos específicos para AM, PM, MIM y herramientas de diamante

✔ Con la confianza de los líderes del sector

Truer suministra a fabricantes de los sectores aeroespacial, automovilístico, electrónico y médico de Asia, Europa y Norteamérica.

✔ Asistencia técnica y consultas

Los equipos internos de I+D e ingeniería ofrecen asesoramiento experto para la selección de polvos, el desarrollo de aplicaciones y la optimización de la sinterización.

Resumen de ventajas clave:

| Característica | Beneficio |

|---|---|

| Atomización interna | Control de calidad y coherencia |

| Certificado ISO 9001 | Normas internacionales de calidad |

| Flexibilidad de los pedidos B2B | Suministro de lotes pequeños a granel |

| Red Logística Mundial | Entrega puntual en todo el mundo |

| Desarrollo de polvos a medida | Optimizado para aplicaciones específicas |

Para obtener más información sobre las ofertas de polvo de acero inoxidable de Truer o solicitar una muestra, visite la página Página de productos en polvo PM en su página web.

9. Preguntas frecuentes: Compra de polvo atomizado SS-304L a granel

Q1: ¿Cuál es la cantidad mínima de pedido (MOQ) para el polvo SS-304L de Truer?

R: Truer ofrece MOQ flexibles a partir de 10 kg para prototipos, con precios escalonados para pedidos al por mayor.

P2: ¿Qué tamaños de partícula hay disponibles para el polvo SS-304L?

R: Los tamaños estándar incluyen D50 de 15-45μm, 45-105μm, o personalizados bajo pedido. Existen morfologías esféricas e irregulares en función del tipo de atomización.

P3: ¿Puede utilizarse el polvo para los procesos AM y PM?

R: Sí, el polvo SS-304L de Truer está optimizado para aplicaciones de pulvimetalurgia, fabricación aditiva (incluyendo SLM, DMLS) y moldeo por inyección de metales.

P4: ¿Qué opciones de envasado existen?

R: Los polvos se envasan al vacío en recipientes de 5 kg, 10 kg o 25 kg con protección de gas inerte. También se ofrecen envases personalizados para la exportación.

P5: ¿Cuánto se tarda en recibir un pedido al por mayor internacional?

R: El plazo de entrega estándar es de 7-15 días laborables, dependiendo del tamaño del pedido y del destino. Hay disponibles opciones de envío exprés.

P6: ¿Cómo puedo solicitar una ficha técnica o una muestra?

R: Puede ponerse en contacto directamente con Truer a través de su formulario de contacto o envíe un correo electrónico a su equipo de ventas para recibir TDS, MSDS y precios.

P7: ¿Hay asistencia técnica disponible después de la compra?

R: Sí, Truer proporciona asistencia técnica continua para la aplicación del polvo, los parámetros de sinterización y la optimización del rendimiento.

Resumen de enlaces internos incrustados

| Texto de anclaje | URL |

|---|---|

| polvos PM de alta calidad | https://am-material.com/pm-powder/ |

| soluciones pulvimetalúrgicas | https://am-material.com/about/ |

| Shanghai Truer Technology Co., Ltd | https://am-material.com/ |

| Página de contacto | https://am-material.com/contact-us/ |

| Página de productos en polvo PM | https://am-material.com/pm-powder/ |

Shanghai Truer Technology Co., Ltd es su socio de confianza para el abastecimiento de polvos atomizados de acero inoxidable SS-304L de primera calidad. Si usted es un distribuidor, fabricante o especialista AM, Truer ofrece la calidad, el apoyo técnico y la personalización necesaria para escalar su producción de manera eficiente. Explore su gama completa de productos y servicios hoy.