1. Introducción: Por qué es importante el polvo de hierro de reducción en la fabricación moderna

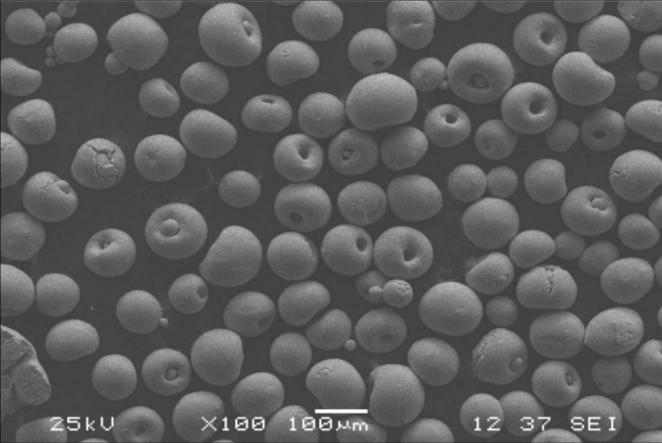

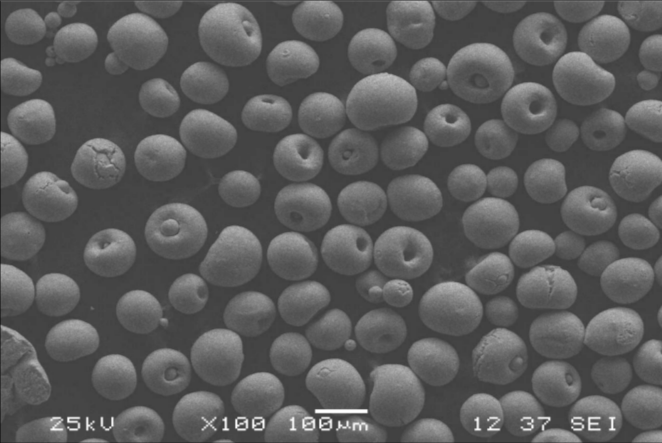

El polvo de hierro de reducción, también conocido como polvo de hierro esponjoso, es una materia prima fundamental en varios sectores manufactureros, como la pulvimetalurgia (PM), los materiales magnéticos, los electrodos de soldadura, las piezas de fricción y los catalizadores químicos. Se produce mediante la reducción de óxidos de hierro utilizando hidrógeno o monóxido de carbono como agentes reductores. Este proceso da como resultado una forma altamente porosa, reactiva y pura de polvo de hierro.

En el contexto de las cadenas de suministro B2B y las aplicaciones industriales, el polvo de hierro de reducción es apreciado por su:

- Alta pureza y consistencia

- Excelente compresibilidad

- Comportamiento de sinterización superior

- Bajo contenido de oxígeno

- Rentabilidad en la producción de grandes volúmenes

Debido a estas propiedades, desempeña un papel fundamental en múltiples sectores, especialmente cuando se requieren componentes de PM de alto rendimiento. A medida que aumenta la demanda mundial de componentes metálicos ligeros, duraderos y rentables, la relevancia del polvo de hierro de reducción sigue creciendo.

Los compradores B2B -especialmente los de los sectores de automoción, aeroespacial y manufacturero- recurren cada vez más a proveedores mayoristas fiables para conseguir polvo de hierro reductor de alta calidad en cantidades a granel. La elección del proveedor adecuado garantiza no solo un rendimiento constante, sino también el cumplimiento de normas internacionales como ISO 4491 y MPIF.

2. Aplicaciones industriales del polvo de hierro de reducción

El polvo de hierro de reducción es muy versátil y se utiliza en muchas industrias. A continuación se presenta un desglose de sus principales aplicaciones industriales para compradores y fabricantes B2B:

| Industria | Área de aplicación | Beneficios de la reducción de hierro en polvo |

|---|---|---|

| Pulvimetalurgia | Engranajes, bujes, piezas estructurales | Alta compresibilidad, microestructura uniforme |

| Industria química | Catalizadores para la síntesis de amoníaco y las reacciones de hidrogenación | Alta reactividad y superficie |

| Industria de la soldadura | Material de relleno en electrodos | Garantiza una fusión y una resistencia adecuadas |

| Materiales magnéticos | Componentes magnéticos blandos en electrónica | Baja coercitividad, alta permeabilidad |

| Materiales de fricción | Pastillas de freno, discos de embrague | Mejora la conductividad térmica y la resistencia |

| Herramientas de diamante | Matriz aglomerante para herramientas de corte y rectificado | Gran dureza y durabilidad |

Por qué es importante para los compradores B2B:

- Fabricantes de equipos originales y proveedores de primer nivel en automoción y electrónica requieren polvo de hierro que cumpla tolerancias estrictas.

- Fabricantes de productos químicos buscar polvos de hierro con alta actividad superficial para reacciones catalíticas.

- Distribuidores y mayoristas se benefician de abastecerse directamente de los fabricantes para reducir costes.

Esta demanda multisectorial convierte al polvo de hierro reductor en un material estratégico para la planificación de adquisiciones a largo plazo.

3. Propiedades clave y características técnicas

Comprender las propiedades físicas y químicas del polvo de hierro de reducción es crucial para seleccionar el material adecuado para su aplicación. A continuación encontrará una comparación técnica de las características clave que los compradores B2B deben evaluar:

| Propiedad | Alcance típico | Importancia en la aplicación |

|---|---|---|

| Tamaño de las partículas (µm) | 20-200 | Afecta a la fluidez, el empaquetado y la sinterización |

| Densidad aparente (g/cm³) | 2.2-3.0 | Impacta en el llenado del molde y en la uniformidad de la pieza |

| Pureza (%) | 98.5 | Garantiza un rendimiento constante |

| Contenido de oxígeno (%) | <0.5 | Menos oxígeno mejora la sinterización y la ductilidad |

| Contenido de carbono (%) | <0.1 | Crítico para la estabilidad metalúrgica |

| Compresibilidad (MPa) | 550 | Indica la formabilidad bajo presión |

| Caudal (s/50g) | 25-35 | Imprescindible para la alimentación automatizada de la prensa |

Grados disponibles de polvo de hierro de reducción

Shanghai Truer Technology Co., Ltd ofrece una amplia gama de grados de polvo de hierro reductor para diversas aplicaciones. Ejemplo de grados incluyen:

- F-0000: Pureza ultraelevada para componentes de precisión

- FD-0200: Polvo de acero aleado por difusión con propiedades mecánicas superiores

- FD-0208: Para piezas estructurales sinterizadas que requieren resistencia y densidad

Estos polvos están disponibles en varias distribuciones granulométricas y se fabrican mediante técnicas de reducción avanzadas para garantizar la uniformidad y la calidad.

Para conocer la gama completa de polvos PM, visite la página PM Polvo Página de producto para obtener especificaciones detalladas y fichas técnicas descargables.

4. Panorama del mercado mundial y tendencias de crecimiento

El mercado mundial del polvo de hierro reductor ha experimentado un crecimiento significativo en la última década, impulsado por la creciente demanda de múltiples sectores verticales como la pulvimetalurgia, la automoción, la electrónica y la industria química. Para los compradores B2B, comprender la dinámica del mercado es esencial para las estrategias de adquisición y abastecimiento a largo plazo.

Tamaño y previsiones del mercado mundial

Según un reciente estudio de mercado:

- tamaño del mercado 2023: 2.100 millones de dólares

- CAGR (2024-2030): 5.8%

- Tamaño del mercado previsto para 2030: 3.200 millones de dólares

Principales impulsores del mercado

- Aumento de la producción de automóviles: La creciente demanda de componentes sinterizados en vehículos eléctricos y de bajo consumo.

- Expansión de la fabricación aditiva: Crecimiento de la impresión 3D y la creación de prototipos basados en PM.

- Demanda de la industria química: Utilización de polvo de hierro reductor en catalizadores y sistemas de depuración de aguas.

- Fabricación sostenible: El polvo de hierro permite métodos de producción con pocos residuos y casi sin red.

Perspectivas de los mercados regionales

| Región | Cuota de mercado (%) | Tendencias destacadas |

|---|---|---|

| Asia-Pacífico | 45% | Centros de producción líderes en China e India; fabricación rentable |

| Norteamérica | 25% | Fuerte demanda de los sectores automovilístico y aeroespacial |

| Europa | 20% | Centrarse en la fabricación ecológica y las piezas PM de alto rendimiento |

| América Latina | 5% | Potencial de mercado emergente con la minería y la industria pesada |

| Oriente Medio | 5% | Crecimiento de las aplicaciones en la industria del petróleo y el gas |

En Región Asia-Pacíficoen particular Chinachina, por su parte, domina la producción debido a sus bajos costes de fabricación, sus avanzadas tecnologías de reducción y su sólida industria PM. Esto hace que el aprovisionamiento en China resulte muy atractivo para los distribuidores internacionales y los fabricantes de equipos originales.

5. Elección del proveedor adecuado de polvo de hierro de reducción

Seleccionar un proveedor fiable es fundamental para los compradores B2B que necesitan una calidad constante, una documentación adecuada y una entrega puntual. He aquí una lista de los factores clave que hay que tener en cuenta:

Consideraciones clave para la evaluación de proveedores

| Criterios | Por qué es importante |

|---|---|

| Método de producción | Impacta la pureza, la forma de las partículas y el rendimiento |

| Certificaciones (ISO, MPIF) | Garantiza la calidad y el cumplimiento internacional |

| Opciones de personalización | Posibilidad de adaptar el tamaño de las partículas, la densidad o la composición de la aleación |

| Logística y embalaje | Embalaje fiable para la exportación y capacidad de envío a todo el mundo |

| Asistencia técnica | Acceso al equipo de I+D e ingeniería para asistencia en aplicaciones |

| MOQ y plazo de entrega | Flexibilidad para pedidos de pequeño y gran volumen |

Preguntas al proveedor

- ¿Puede facilitar un certificado de análisis (COA) para cada lote?

- ¿Ofrecen mezclas personalizadas o polvos prealeados para aplicaciones específicas?

- ¿Cuáles son sus plazos de entrega y su capacidad de exportación?

- ¿Puede ofrecer asistencia técnica para el desarrollo de nuevos productos?

Shanghai Truer Technology Co., Ltd marca todas estas casillas, ofreciendo un conjunto completo de polvos de hierro de reducción y materiales aditivos adaptados a los compradores industriales. Su equipo técnico está equipado para dar soporte a aplicaciones pulvimetalúrgicas estándar y avanzadas.

6. Los 5 mejores proveedores de hierro en polvo de reducción de Asia

Si busca hierro en polvo reductor a granel, éstos son los principales fabricantes y proveedores de Asia por gama de productos, capacidad de exportación y reputación en el sector.

| Nombre del proveedor | País | Puntos fuertes |

|---|---|---|

| Shanghai Truer Technology Co., Ltd | China | Amplia cartera de polvos de polimerización, grados personalizados, fuerte apoyo en I+D |

| JFE Steel Corporation | Japón | Polvos de hierro de gran pureza para automoción y electrónica |

| Hoganas AB (filial en China) | Suecia/China | Marca mundial, polvos de alto rendimiento, precios superiores |

| CNPC Polvo | China | Polvos rentables para soldadura, PM y componentes de fricción |

| Fabricación de polvos Jiande Xinxin | China | Fuerte presencia nacional, grados PM estándar |

Entre ellas, Shanghai Truer Technology Co., Ltd destaca por su equilibrio de calidad, soporte técnico y precios. Fundada en 2009, Truer entró en el espacio de la fabricación aditiva en 2019 y desde entonces se ha convertido en un proveedor de confianza de polvos de impresión 3D y materiales PM de alta calidad. Sus polvos de hierro de reducción se diseñan utilizando procesos avanzados de reducción y atomización, lo que garantiza un rendimiento estable para diversas aplicaciones.

¿Por qué asociarse con Shanghai Truer?

- Ofrece grados de polvo estándar y personalizados

- Proporciona documentación completa y fichas técnicas

- Admite pedidos al por mayor con precios competitivos

- Entrega rápida y envasado listo para la exportación

- Con el respaldo de una década de experiencia en innovación PM

Para obtener información sobre precios al por mayor o solicitar muestras, póngase en contacto con Truer a través de su Página de contacto.

7. Por qué cada vez más compradores eligen fabricantes chinos

En los últimos años, China se ha convertido en el líder mundial en la producción y exportación de polvo de hierro reductor. Los compradores B2B -desde distribuidores mundiales hasta fabricantes OEM- recurren cada vez más a proveedores chinos por varias razones estratégicas y económicas.

Principales ventajas de los proveedores chinos de polvo de hierro de reducción:

| Ventaja | Descripción |

|---|---|

| Eficiencia de costes | Precios competitivos gracias a economías de escala y menores costes laborales |

| Fabricación avanzada | Uso de tecnologías modernas de reducción, atomización y mezcla |

| Amplia gama de productos | Calidades estándar y personalizadas para diversos sectores |

| Logística de exportación | Cadenas de suministro maduras y capacidad de transporte mundial |

| I+D y personalización | Capacidad para desarrollar polvos a medida para requisitos específicos de los clientes |

Un ejemplo: Shanghai Truer Technology Co

Shanghai Truer ejemplifica los puntos fuertes de la cadena de suministro china. Fundada en 2009, la empresa se ha convertido en uno de los proveedores de pulvimetalurgia más fiables de China. A través de su División de pulvimetalurgia, Truer ofrece una amplia gama de polvos y aditivos de hierro reductor, entre los que se incluyen:

- PM Hierro

- Acero PM

- PM Cobre-Acero (Fe-Cu)

- PM Níquel-acero (Fe-Ni)

- PM Hierro infiltrado

- Polvos aleados por difusión e híbridos como FD-0208, FL-4605, FN-5000

Estos polvos se fabrican mediante técnicas de reducción, atomización con agua y atomización combinada, lo que garantiza altos niveles de pureza y una calidad constante de los lotes.

Compradores de todo el mundo confían en nosotros

La reputación internacional de Truer sigue creciendo gracias a:

- Certificaciones listas para la exportación (ISO9001, ROHS, etc.)

- Asistencia B2B y documentación en inglés

- Relaciones duraderas con compradores de los sectores de la automoción, la electrónica y la química

Con los crecientes cambios geopolíticos y las reevaluaciones de la cadena de suministro, muchos compradores mundiales ven a los proveedores chinos no sólo como proveedores de bajo coste, sino como socios estratégicos a largo plazo.

8. Por qué elegir Shanghai Truer Technology Co, Ltd

Si usted es un comprador B2B, distribuidor u OEM que busca una fuente fiable de polvo de hierro de reducción, Shanghai Truer Technology Co., Ltd ofrece un valor inigualable. He aquí por qué:

1. Soluciones integrales para materiales PM

Truer no es sólo un fabricante de polvo, es un proveedor de soluciones. Su experiencia abarca:

- Producción de polvo metálico (hierro, cobre, acero, aleaciones)

- Materiales aditivos como lubricantes, agentes de corte y aditivos magnéticos blandos

- Formulación de polvo a medida para aplicaciones avanzadas

2. Capacidades de producción avanzadas

Truer utiliza una combinación de tecnologías de reducción, atomización con agua y atomización con gas para fabricar polvos con:

- Alta compresibilidad

- Bajo contenido de oxígeno

- Distribución uniforme del tamaño de las partículas

- Fluidez superior para procesos automatizados

3. Experiencia demostrada

Con más de 15 años en la industria pulvimetalúrgica y más de 5 años en la fabricación aditiva, Truer ha construido una base sólida en:

- I+D industrial

- Colaboración OEM

- Logística de exportación

- Cumplimiento de la normativa

4. Atención al cliente B2B

Tanto si realiza pedidos de grandes lotes para la producción de piezas de automoción como de pequeñas cantidades para la creación de prototipos, Truer le ofrece:

- Tiempos de respuesta rápidos

- Soporte multilingüe

- Asesoramiento técnico

- MOQs flexibles

¿Está listo para hablar de las necesidades de su proyecto? Visite Página de contacto de Truer para conectar con sus ingenieros de ventas.

9. Preguntas frecuentes: Compra de hierro de reducción en polvo a granel

Estas son algunas de las preguntas más frecuentes de los compradores B2B sobre el abastecimiento de polvo de hierro de reducción:

P1: ¿Cuál es la diferencia entre el polvo de hierro de reducción y el polvo de hierro atomizado?

- Reducción de hierro en polvo se produce mediante la reducción de óxidos de hierro con hidrógeno o monóxido de carbono, lo que da lugar a partículas porosas similares a esponjas.

- Polvo de hierro atomizado se fabrica pulverizando hierro fundido en una cámara para formar partículas esféricas. Tiene mejor fluidez pero mayor coste.

P2: ¿Puedo solicitar granulometrías personalizadas o composiciones prealeadas?

Sí. Shanghai Truer ofrece soluciones personalizadas para la distribución del tamaño de las partículas, la composición de la aleación, el caudal y la compresibilidad, adaptadas a su aplicación específica.

P3: ¿Cuál es el plazo de entrega habitual para los pedidos al por mayor?

El plazo de entrega depende del volumen y de los requisitos de personalización. Los pedidos a granel estándar suelen enviarse en un plazo de 7 a 10 días laborables. Truer proporciona plazos de entrega detallados con cada presupuesto.

P4: ¿Qué opciones de envasado existen?

Truer ofrece envases de calidad para la exportación:

- bolsas de 25 kg selladas al vacío

- contenedores a granel de 1 tonelada

- Envíos paletizados con barreras antihumedad

P5: ¿Hay muestras disponibles antes de hacer un pedido grande?

Sí. Truer proporciona cantidades de muestra para pruebas y validación. Póngase en contacto con el equipo de ventas a través del sitio web de la empresa para solicitar una muestra y una ficha técnica.

Resumen de enlaces internos incrustados

Aquí están los enlaces internos incrustados en el artículo para una navegación fluida:

- PM Polvo Página de producto - Para obtener información detallada sobre grados y especificaciones del polvo

- Acerca de Truer - Antecedentes y capacidades de la empresa

- Página de contacto - Consultas y pedidos

- Página de inicio - Productos y servicios

- PM Polvo Página de producto - Reutilizado para hacer hincapié en los grados disponibles

Siguiendo esta guía de aprovisionamiento y teniendo en cuenta a fabricantes de confianza como Shanghai Truer Technology, los compradores B2B pueden asegurarse polvos de hierro reductor de alta calidad adaptados a sus necesidades industriales. Gracias a su competitividad global, excelencia técnica y asistencia fiable, Truer destaca como proveedor de primer nivel en el panorama mundial de la PM.