1. Introduction: Why MoS₂ Powder is Vital for Industrial Applications

Molybdenum disulfide (MoS₂) powder is a solid lubricant and performance-enhancing material widely used across multiple industries. Known for its excellent lubricating properties, thermal stability, and resistance to high pressure, MoS₂ powder plays a critical role in:

- Aerospace engineering

- Automotive manufacturing

- Electronics and semiconductors

- Pulvimetalurgia (PM)

- Industrial lubrication

For B2B buyers, wholesalers, and distributors, sourcing high-purity MoS₂ powder with consistent performance is essential for maintaining product quality and operational efficiency. As demand grows in additive manufacturing and powder metallurgy sectors, industrial buyers are increasingly seeking reliable suppliers with advanced manufacturing capabilities and technical support.

2. Key Industrial Applications of MoS₂ Powder

MoS₂ powder is a versatile material that adds significant value across numerous high-performance applications. Here’s a breakdown of its major B2B use cases:

a. Solid Lubricants for High-Temperature Applications

MoS₂ powder is known for its low friction coefficient and high load-bearing capacity, especially under extreme conditions.

Industries Using It:

- Automotive (engine components, gear assemblies)

- Aerospace (turbine engines, space mechanisms)

- Heavy machinery (conveyors, presses)

b. Additive in Powder Metallurgy

MoS₂ is widely used in PM processes to enhance sintering performance, reduce tool wear, and improve machinability.

Key Use Cases:

- Rodamientos sinterizados

- Engranajes y bujes

- Structural PM components

c. Electronics and Semiconductors

Due to its semiconducting properties, MoS₂ is also being explored in nanoelectronics and flexible electronic devices.

Ventajas:

- High electron mobility

- Thin-film transistors

- Potential graphene alternative

d. Coatings and Paints

MoS₂ is added to coatings to impart wear resistance, corrosion protection, and reduction in friction.

Aplicaciones:

- Anti-corrosive industrial coatings

- Aerospace component protection

- High-performance lubricating paints

e. Metal Forming & Die Casting Lubrication

MoS₂ acts as a die lubricant in metal forming processes, enhancing tool life and reducing friction.

Industries Involved:

- Forja

- Extrusion

- Die casting

🔗 Learn more about industrial-grade powders and additives on our PM powder page

3. Physical and Chemical Properties of MoS₂ Powder

Understanding the core properties of MoS₂ powder is critical for selecting the right grade for your application. Below is a detailed breakdown:

| Propiedad | Valor/Rango |

|---|---|

| Fórmula química | MoS₂ |

| Apariencia | Dark gray to black powder |

| Densidad | 5.06 g/cm³ |

| Punto de fusión | 1,185°C |

| Estabilidad térmica | Up to 450°C in air, 1,100°C in inert gas |

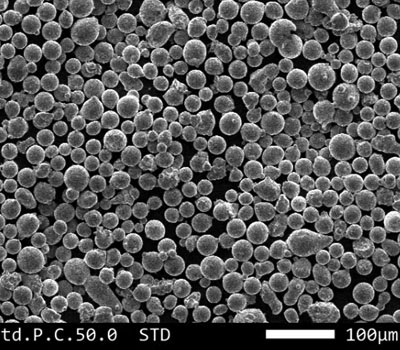

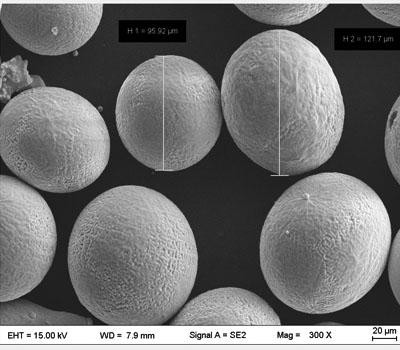

| Gama de tamaños de partículas | 0.5 µm to 50 µm (customizable) |

| Lubricity (μ) | 0.03 – 0.09 (dry) |

| Niveles de pureza | 98% – 99.9% |

Características clave:

- Layered Structure: MoS₂ has a hexagonal layered structure, enabling it to slide easily, ideal for lubrication.

- Inertness: Chemically stable and non-reactive in most industrial environments.

- Conductividad térmica: Excellent heat dissipation properties make it suitable for thermal interface materials.

Grades of MoS₂ Powder Available for B2B Buyers:

| Grado | Descripción | Área de aplicación |

|---|---|---|

| Technical Grade | ~98% purity, cost-effective | General lubrication, coating |

| High Purity Grade | 99.5%+, low impurity content | Electronics, PM, aerospace |

| Nano MoS₂ | Particle size <100nm | Advanced materials, electronics |

🛠 Shanghai Truer Technology offers customizable MoS₂ powder grades for powder metallurgy, sintered parts, and high-temperature lubricants. Visit our Quiénes somos to learn more about our advanced production capabilities.

4. Global Market Trends and Future Outlook for MoS₂ Powder

The global demand for molybdenum disulfide (MoS₂) powder is growing rapidly, driven by advancements in automotive engineering, powder metallurgy (PM), aerospace, and electronics. As industries shift toward more efficient and high-performance materials, MoS₂ is emerging as a strategic additive and lubricant in various B2B applications.

Principales impulsores del mercado

- Growth in Electric Vehicles (EVs): MoS₂ is used in EV components, solid-state lubricants, and battery technologies.

- Expansion of Powder Metallurgy: Increased use of PM parts in automotive and industrial machinery boosts MoS₂ demand.

- Miniaturization of Electronics: As devices become smaller and more powerful, MoS₂ is being explored for semiconducting and thermal management applications.

Market Size & Projections

| Año | Global Market Size (USD) | CAGR Forecast |

|---|---|---|

| 2022 | $240 million | 5.8% |

| 2026 | $320 million | - |

| 2030 | $430 million (est.) | - |

Regional Demand Outlook

- Asia-Pacific (APAC): Largest market, led by China, Japan, and South Korea.

- North America: High demand in aerospace and defense sectors.

- Europe: Focus on green energy and advanced manufacturing.

📈 With the upward trajectory of MoS₂ applications, it’s crucial to partner with a supplier that not only provides high-quality powder but also understands your industry needs.

5. How to Choose a Reliable MoS₂ Powder Supplier

For wholesalers, distributors, and OEMs, selecting the right MoS₂ supplier involves more than just price. Here are the critical factors to consider:

a. Purity and Consistency

- Ensure the supplier offers 98% to 99.9% purity levels

- Request batch-to-batch consistency data

b. Production Technology

- Look for suppliers who use advanced atomization or chemical synthesis methods

- Check if they can customize particle size and morphology

c. Certifications and Compliance

- ISO 9001 certification is a must

- RoHS, REACH compliance for global trade

d. Logistics and Lead Time

- Evaluate their global shipping capabilities

- Ask about average lead time for bulk orders

e. Technical Support and Documentation

- Availability of MSDS, COA, and technical datasheets

- On-site or remote application engineering support

| Criterios de evaluación | Por qué es importante |

|---|---|

| Pureza | Impacts product performance |

| Control del tamaño de las partículas | Critical for PM, coatings, and electronics |

| Capacidad de personalización | Tailored to your industry need |

| Delivery Speed | Ensures uninterrupted production |

| Asistencia posventa | Helps troubleshoot and optimize usage |

🔍 Looking for a supplier with deep industry expertise and technical support? Contáctenos para solicitar un presupuesto o una muestra.

6. Top 5 MoS₂ Powder Suppliers in Asia

Here’s a curated list of reputable suppliers of MoS₂ powder in Asia for wholesale and industrial buyers:

| Nombre del proveedor | País | Ofertas clave | Especialidad |

|---|---|---|---|

| Tecnología Truer de Shanghai | China | PM-grade MoS₂, additives, custom blends | Powder metallurgy and additive manufacturing |

| Molychem | India | High-purity MoS₂, nano-MoS₂ | Research and industrial-grade powders |

| Tanfac Industries Ltd. | India | Technical and electronic-grade MoS₂ | Bulk production with global export capabilities |

| Nanotecnología Nanografi | Turquía | Nano MoS₂, customized dispersions | Nanomaterials for electronics and coatings |

| Tribotecc GmbH | Austria | Friction-modifying MoS₂ powders | Automotive and aerospace lubrication solutions |

Por qué destaca Shanghai Truer

- In-house powder making equipment and R&D

- Specializes in PM and additive manufacturing powders

- Offers a wide range of lubricants and cutting agents

- Customizable solutions for B2B clients

🏭 Explore Shanghai Truer’s product portfolio on their home page and discover how they support your manufacturing goals.

7. Why More Buyers Are Sourcing MoS₂ Powder from China

In recent years, China has emerged as the leading global supplier of molybdenum disulfide (MoS₂) powder. With advancements in manufacturing technology, competitive pricing, and a robust supply chain, Chinese suppliers are increasingly favored by B2B buyers, OEMs, and material distributors worldwide.

Key Reasons to Source MoS₂ Powder from China:

✅ Alta capacidad de producción

Chinese manufacturers, like Shanghai Truer Technology, operate at scale, ensuring stable supply even for bulk industrial orders.

✅ Eficiencia de costes

Due to lower labor and production costs, Chinese suppliers offer MoS₂ powder at significantly more competitive rates without compromising quality.

✅ Advanced Processing Technology

China leads in water atomization, gas atomization, and chemical reduction techniques—essential for producing high-purity and consistent MoS₂ powders.

✅ Capacidades de personalización

Suppliers in China are highly flexible, offering tailored particle sizes, purity levels, and packaging options to meet industry-specific requirements.

✅ Integrated Ecosystem for Powder Metallurgy

With integrated PM supply chains and expertise in lubricants and additives, China provides one-stop solutions for manufacturers.

| Benefit Category | What It Means for Buyers |

|---|---|

| Coste | Competitive pricing for better margin control |

| Plazos de entrega | Faster delivery to APAC and global markets |

| Personalización | Product specs tailored to your application |

| Innovación | Ongoing R&D investment supports new product grades |

| Supply Chain Resilience | Multiple sourcing hubs reduce risk of shortages |

🌍 For global distributors and e-commerce sellers, sourcing from China means better pricing, faster innovation access, and stronger B2B partnerships. Explore how we can support your sourcing strategy.

8. Why Choose Shanghai Truer as Your Trusted Supplier

Shanghai Truer Technology Co., Ltd is one of China’s most reliable and experienced suppliers of powder metallurgy materials, including high-quality MoS₂ powder. Established in 2009 and entering the additive manufacturing space in 2019, Truer combines technology, customization, and service to support global B2B clients.

¿Qué diferencia a Truer?

🧪 Conocimientos técnicos

With over a decade in the metal powder industry, Truer not only manufactures MoS₂ powder but also develops application-specific formulations for PM, sintering, and lubrication.

🏭 Fabricación avanzada

Truer employs both water and gas atomization techniques, ensuring high purity and custom particle sizes for specialized applications.

📦 Diversa cartera de productos

In addition to MoS₂, Truer provides a wide range of PM powders and additives:

- PM bronze, brass, iron, steel, and stainless steel powders

- Diffusion alloyed and pre-alloyed grades (e.g., FD-0208, FX-1005)

- Lubricants like Lube-W, SUW-5000B

- Cutting agents and soft magnetic additives

🔄 Soluciones a medida

Truer supports OEM manufacturers and distributors with tailored solutions including:

- Custom packaging (bulk drums, sealed bags, moisture-proof containers)

- Custom particle sizing and blending

- Technical support with application engineers

🤝 Global B2B Partner

Whether you’re a distributor, e-commerce seller, or OEM manufacturer, Truer provides:

- Fast international shipping

- COA, MSDS, and regulatory documentation

- Responsive customer support in multiple languages

🧭 Learn more about Truer’s full capabilities on the Quiénes somos and see how they can become your long-term strategic partner.

9. FAQs: Common Questions About Buying Wholesale MoS₂ Powder

Here are some of the most frequently asked questions from industrial buyers, OEMs, and distributors sourcing MoS₂ powder:

Q1: What purity grades of MoS₂ powder are available?

A: Shanghai Truer offers MoS₂ powders ranging from 98% technical grade to 99.9% high-purity grade. Custom purity levels are also available upon request.

Q2: Can I request a specific particle size for my application?

A: Yes. Particle sizes from nano-scale (<100nm) to 50µm can be customized. This is ideal for PM, coatings, or electronics applications.

P3: ¿Qué opciones de embalaje hay para los pedidos al por mayor?

A: Truer provides flexible packaging options including:

- 1kg, 5kg, 25kg sealed bags

- 50kg drums

- Moisture-proof and vacuum-sealed containers for sensitive applications

Q4: Is MoS₂ powder compatible with additive manufacturing?

A: While MoS₂ is primarily used as an additive or lubricant in PM processes, it can also be blended into AM powders for enhanced surface properties and wear resistance.

P5: ¿Cómo hago un pedido al por mayor?

A: Visit Truer’s página de contacto and provide your specifications (purity, particle size, quantity). A sales engineer will assist you with quotations, sample requests, and shipping options.

🔚 Final Thoughts & Call-to-Action

Whether you’re in automotive manufacturing, aerospace engineering, or powder metallurgy, MoS₂ powder is a strategic material that can improve performance and reduce operational costs. For B2B buyers, partnering with an experienced and technically advanced supplier like Shanghai Truer ensures consistent quality, technical support, and supply chain stability.

📩 Ready to request a quote or sample? Visit our PM polvo página de producto to learn more and connect with an expert today.