1. Qué es el polvo Inconel y por qué es importante en la fabricación moderna

El polvo de Inconel es una aleación de níquel de alto rendimiento conocida por su excepcional resistencia al calor, la oxidación y la corrosión. Se utiliza ampliamente en industrias como la aeroespacial, la generación de energía, el procesamiento químico y la fabricación aditiva (AM).

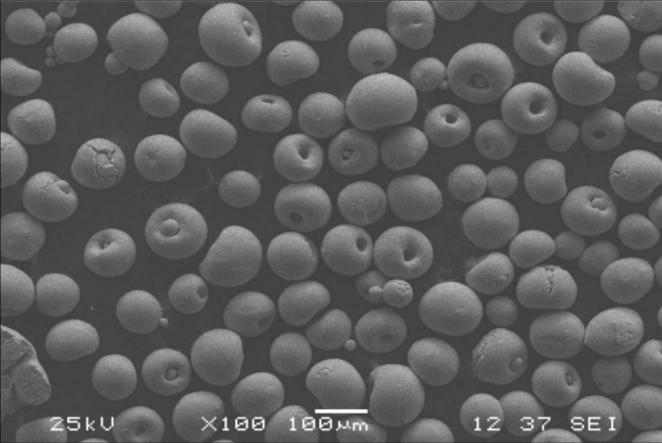

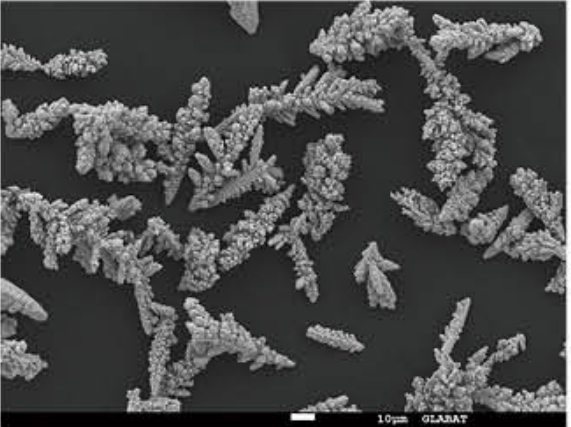

Los polvos de Inconel se producen mediante diversas técnicas de atomización, como la atomización con gas, que garantiza una morfología esférica ideal para Impresión 3d y aplicaciones pulvimetalúrgicas (PM). La composición exclusiva de Inconel’ le permite conservar la integridad mecánica incluso en entornos extremos.

Características principales

| Propiedad | Descripción |

|---|---|

| Estabilidad a altas temperaturas | Mantiene la resistencia y la integridad hasta 982°C (1800°F) |

| Resistencia a la corrosión | Resistente a la oxidación, los ácidos y el agua de mar |

| Resistencia mecánica | Excelente resistencia a la tracción y a la fatiga |

| Compatibilidad AM | Forma de polvo esférico ideal para sinterizado láser, inyección de ligante y DMLM |

Grados comunes de Inconel utilizados en forma de polvo

- Inconel 625: Alta resistencia a la corrosión y soldabilidad

- Inconel 718: Gran solidez y resistencia a la fluencia, muy utilizado en la industria aeroespacial

- Inconel 738: Diseñado para álabes de turbina y entornos de alta tensión

2. Aplicaciones industriales del polvo de Inconel

El polvo de Inconel tiene una gran demanda en sectores que requieren materiales que funcionen en condiciones extremas. A continuación se indican los principales sectores que utilizan polvo de Inconel:

Industria aeroespacial

- Álabes de turbina: Inconel 718 y 738 se utilizan debido a su alta resistencia a la fluencia

- Cámaras de combustión: Resiste altas temperaturas y presiones

- Boquillas de combustible: impreso en 3D con Inconel 625 para mayor precisión y durabilidad

Sector de la energía

- Turbinas de gas: Los polvos de Inconel se utilizan para fabricar componentes de sección en caliente

- Reactores nucleares: Piezas resistentes a la corrosión con una larga vida útil

- Intercambiadores de calor: Ideal para entornos de ciclos térmicos

Procesado químico

- Recipientes a presión: Soporta productos químicos corrosivos y alta presión

- Tuberías: Revestimientos interiores resistentes a la corrosión

- Válvulas y bombas: Alta fiabilidad en entornos corrosivos

Fabricación aditiva e impresión 3D

- Creación de prototipos: Creación rápida de prototipos de componentes complejos de alto rendimiento

- Herramientas: Moldes y matrices de alta resistencia al desgaste

- Partes funcionales: Componentes ligeros y resistentes con geometrías complejas

Aplicaciones médicas

- Implantes: Componentes biocompatibles y resistentes a la corrosión

- Herramientas quirúrgicas: Precisión y alta resistencia a la esterilización

Resumen del uso industrial

| Industria | Solicitud | Grado Inconel |

|---|---|---|

| Aeroespacial | Álabes de turbina, toberas | Inconel 718, 625 |

| Energía | Turbinas, intercambiadores, reactores | Inconel 738, 625 |

| Procesado químico | Válvulas, recipientes, tuberías | Inconel 625 |

| Fabricación de aditivos | Prototipos, utillaje, producción | Inconel 625, 718 |

| Médico | Implantes, instrumental quirúrgico | Inconel 625 |

3. Principales propiedades y calidades del polvo de Inconel

Conocer las propiedades y las calidades disponibles del polvo de Inconel es esencial para obtener el material adecuado para las aplicaciones industriales.

Propiedades mecánicas

| Propiedad | Inconel 625 | Inconel 718 |

|---|---|---|

| Resistencia a la tracción | ~827 MPa | ~1375 MPa |

| Límite elástico | ~414 MPa | ~1034 MPa |

| Alargamiento | ~30% | ~12-18% |

| Dureza (HRB) | ~94 | ~130-140 (HRC) |

Propiedades térmicas y químicas

- Punto de fusión: 1290-1350°C

- Conductividad térmica: Bajo (~9,8 W/m-K)

- Resistencia a la corrosión: Excelente en entornos marinos y químicos

- Resistencia a la oxidación: Mantiene sus propiedades incluso a altas temperaturas de funcionamiento

Distribución del tamaño de las partículas

En función de las necesidades de fabricación, los polvos de Inconel están disponibles en varios tamaños de malla:

- 15-45 µm: Ideal para la fusión selectiva por láser (SLM)

- 45-105 µm: Apto para la fusión por haz de electrones (EBM)

- 105-150 µm: Utilizado en Binder Jetting y PM tradicional

Tabla comparativa de calidades de Inconel

| Grado | Característica principal | Caso típico |

|---|---|---|

| Inconel 625 | Resistencia superior a la corrosión | Química, marina y nuclear |

| Inconel 718 | Alta resistencia, soldable, resistente a la fluencia | Componentes aeroespaciales y energéticos |

| Inconel 738 | Resistencia a la oxidación a altas temperaturas | Álabes de turbina, motores a reacción |

¿Por qué elegir polvo Inconel de alta calidad?

- Porosidad reducida en piezas AM

- Propiedades mecánicas mejoradas

- Mayor coherencia del proceso

- Riesgo de contaminación minimizado

Shanghai Truer Technology Co., Ltd, experto en pulvimetalurgia y materiales de fabricación aditiva, ofrece soluciones fiables de polvo de Inconel. Su avanzada tecnología de atomización garantiza partículas esféricas, superficies limpias y una calidad constante. Obtenga más información sobre su amplia selección de Polvos PM aquí.

4. Tendencias del mercado mundial y crecimiento del polvo de Inconel

El mercado mundial de polvo de Inconel está experimentando un fuerte crecimiento, impulsado por los avances en la fabricación aditiva, el aumento de la demanda de los sectores aeroespacial y energético, y la rápida industrialización de las economías emergentes.

Principales impulsores del mercado

- Auge de la fabricación aditiva: la impresión 3D de piezas aeroespaciales y médicas está aumentando la demanda de polvos de alto rendimiento como Inconel 625 y 718.

- Expansión aeroespacial: Los programas de aviación comercial y militar están invirtiendo en componentes fabricados con aleaciones resistentes a altas temperaturas.

- Crecimiento del sector energético: La necesidad de eficiencia en turbinas y reactores está impulsando la demanda de polvos de aleaciones de níquel fiables.

- Materiales resistentes a la corrosión: Las industrias química y naval se inclinan por las aleaciones basadas en níquel por su durabilidad a largo plazo.

Previsión del tamaño del mercado

| Año | Tamaño del mercado mundial del polvo de Inconel (miles de millones de USD) |

|---|---|

| 2022 | 1.12 |

| 2023 | 1.32 |

| 2024 | 1.56 (est.) |

| 2027 | 2.35 (proyectado) |

Desglose regional de la demanda

- Norteamérica: Los sectores aeroespacial y de defensa son los principales contribuyentes.

- Europa: Fuerte demanda de los sectores del automóvil y la energía.

- Asia-Pacífico: La región de más rápido crecimiento debido a la expansión de la fabricación en China e India.

Tendencias emergentes

- Mayor uso del polvo de Inconel en la inyección de aglutinantes y el DMLS (sinterizado directo de metales por láser)

- Desarrollo de tecnologías de atomización híbridas para mejorar la morfología de las partículas

- Creciente preferencia por la producción sostenible y el reciclado de polvos de superaleaciones

5. Cómo elegir el proveedor de polvo de Inconel adecuado

Elegir al proveedor de polvo de Inconel adecuado es fundamental para garantizar el rendimiento, la uniformidad y la rentabilidad del producto. Estos son los factores clave que hay que tener en cuenta:

1. Calidad y consistencia del polvo

- Distribución del tamaño de las partículas: La uniformidad garantiza una impresión y compactación más suaves

- Esfericidad: La alta esfericidad mejora la fluidez y la densidad de empaquetamiento

- Pureza: Los bajos niveles de oxígeno e impurezas reducen el riesgo de defectos

- Propiedades mecánicas: Debe cumplir las normas específicas de la aplicación

2. Capacidad de producción

- ¿Ofrece el proveedor múltiples métodos de atomización (por ejemplo, gas, agua, híbrido)?

- ¿Pueden personalizar el tamaño de las partículas para aplicaciones específicas de AM o PM?

3. Certificación y conformidad

- ISO 9001, AS9100D o sistemas de gestión de la calidad equivalentes

- Certificaciones de materiales (por ejemplo, ASTM B243, AMS 5662/5663)

- Análisis de composición química por terceros

4. Logística y cadena de suministro

- Plazos de entrega y capacidad de producción

- Fiabilidad de los envíos y redes mundiales de distribución

- Disponibilidad de existencias para pedidos al por mayor o recurrentes

5. Asistencia técnica y personalización

- Consultas de ingeniería in situ o a distancia

- Colaboración en I+D para el desarrollo de aleaciones personalizadas

- Asistencia posventa y resolución de problemas

Lista de comprobación para la evaluación de proveedores

| Criterios | Nivel de importancia | ✓/✗ |

|---|---|---|

| PSD y morfología coherentes | Crítica | |

| Certificación (ISO, ASTM, etc.) | Esencial | |

| Opciones de personalización | Alta | |

| Plazos de entrega y disponibilidad de existencias | Medio | |

| Precios competitivos para pedidos al por mayor | Alta |

Shanghai Truer Technology Co., Ltd destaca en todas estas áreas, ofreciendo polvos de Inconel estandarizados y personalizados adaptados a sus necesidades de fabricación. Sus múltiples tecnologías de atomización proporcionan flexibilidad en el tamaño y la esfericidad de las partículas, garantizando la compatibilidad con su equipo y aplicación.

6. Los 5 mejores proveedores de Inconel en polvo de Asia

Asia cuenta con varios fabricantes de polvo de Inconel de renombre que prestan apoyo a las crecientes industrias aeroespacial, energética y de fabricación aditiva de la región. Estos son los principales proveedores:

1. Shanghai Truer Technology Co., Ltd (China)

Visión general:

- Fundada en 2009, entró en el mercado de la fabricación aditiva en 2019

- Ofrece polvos de Inconel de alta calidad producidos mediante atomización con gas, agua e híbrida

- Conocida por su calidad constante, su cadena de suministro fiable y su experiencia técnica

Productos clave:

- Inconel 625 polvo

- polvo inconel 718

- Polvos de superaleación a medida para AM y PM

Por qué elegir Truer:

- Ofrece asistencia completa, desde el desarrollo del polvo hasta los servicios postventa

- Amplia gama de soluciones pulvimetalúrgicas

- Uno de los proveedores de aditivos más profesionales de China

2. JG Precision Powder (China)

Visión general:

- Especializada en polvos metálicos atomizados por gas

- Suministra polvos de Inconel de calidad aeroespacial

- Centrado en aplicaciones SLM y EBM

3. Sandvik Additive Manufacturing (India)

Visión general:

- Líder mundial con instalaciones de AM en la India

- Ofrece polvos de aleación de níquel patentados, incluidas variantes de Inconel

- Fuerte presencia en los sectores energético y aeroespacial

4. CNPC Polvo (China)

Visión general:

- Principal proveedor de polvos metálicos para AM y PM

- Ofrece una amplia distribución en Asia y Europa

- Suministra polvos de Inconel de alta esfericidad y bajo contenido en oxígeno

5. GKN Hoeganaes (Japón)

Visión general:

- Conocida por sus materiales PM, incluidas las aleaciones Inconel

- Suministra soluciones de polvo a medida para los sectores de automoción y aeroespacial

- Posee múltiples certificaciones de calidad para aplicaciones críticas

Tabla comparativa de proveedores

| Nombre del proveedor | País | Método de atomización | Calidades de Inconel | Personalización | Plazos de entrega |

|---|---|---|---|---|---|

| Shanghái Truer | China | Gas/Agua/Híbrido | 625, 718 | Sí | Rápido |

| Polvo de precisión JG | China | Gas | 718 | Sí | Medio |

| Sandvik AM | India | Gas | 625, 718 | Sí | Medio |

| CNPC Polvo | China | Gas | 625 | Limitado | Medio |

| GKN Hoeganaes | Japón | Agua/Gas | 718 | Sí | Lento |

Para obtener más información sobre la línea de productos de Shanghai Truer y los antecedentes de la empresa, visite su Quiénes somos.

7. Por qué cada vez más fabricantes eligen fuentes chinas de polvo de Inconel

Los sectores de la pulvimetalurgia y la fabricación aditiva de China han avanzado rápidamente en los últimos años, y los fabricantes mundiales recurren cada vez más a fuentes chinas para obtener polvo de Inconel debido a varias ventajas estratégicas.

Ventajas económicas

- Eficiencia de costes: Menores costes de producción y mano de obra

- Precios por volumen: Tarifas competitivas para pedidos de gran volumen

- Incentivos públicos: Subvenciones a la exportación y ventajas fiscales para los materiales de alta tecnología

Avances tecnológicos

- Modernas instalaciones de atomización: En la actualidad, muchos proveedores utilizan atomizadores de gas e híbridos con estrictos controles de proceso

- Sistemas avanzados de control de calidad: Adopción creciente de las normas ISO y ASTM

- Inversión en I+D: Centrados en el desarrollo de nuevas aleaciones y la mejora de la morfología del polvo

Logística y escalabilidad

- Entrega rápida: Plazos de entrega más cortos que los de los proveedores europeos o estadounidenses

- Alcance mundial: Centros estratégicos de exportación en Shanghai, Shenzhen y Tianjin

- MOQ flexible: Muchos proveedores aceptan pedidos de lotes pequeños y grandes

Un ejemplo: Shanghai Truer

Shanghai Truer es un ejemplo destacado del ascenso de China en el mercado mundial del polvo de Inconel:

- Ofrece grados Inconel estándar y personalizados

- Utiliza métodos avanzados de atomización con gas y atomización híbrida

- Suministros a clientes de los sectores aeroespacial, automovilístico y energético

- Proporciona un apoyo fiable en I+D, producción y logística

Para explorar los detalles del producto o solicitar un presupuesto, puede póngase en contacto con Shanghai Truer aquí.

8. Cómo pedir polvo de Inconel al por mayor a Shanghai Truer

El pedido de polvo de Inconel a granel requiere una cuidadosa coordinación entre los equipos técnicos, de compras y de logística. Shanghai Truer Technology Co., Ltd simplifica el proceso para los clientes B2B ofreciendo una experiencia de pedido al por mayor racionalizada y consultiva adaptada a los requisitos de su proyecto.

Paso a paso: Pedido de polvo Inconel a Shanghai Truer

Paso 1: Consulta inicial

- Enviar consulta: Contacto a través del sitio web oficial o correo electrónico para iniciar el proceso.

- Requisitos técnicos: Comparta los detalles de la aplicación (por ejemplo, método de AM, tamaño de partícula deseado, grado de aleación).

- Volumen estimado: Indique el tonelaje estimado o los kilogramos necesarios mensual o anualmente.

Paso 2: Muestra & Confirmación de especificaciones

- Polvo de muestra: Truer puede enviar una pequeña muestra (por ejemplo, 500 g o 1 kg) para realizar pruebas internas.

- Certificación de materiales: Composición química completa y análisis granulométrico.

- Hoja de especificaciones: Confirmar grado de aleación, PSD, morfología y tipo de atomización.

Paso 3: Presupuesto y acuerdo comercial

- Presupuesto personalizado: Según aleación, MOQ y condiciones de entrega (EXW, FOB, CIF).

- Condiciones de pago: Opciones flexibles para socios B2B a largo plazo (T/T, L/C o Net30).

- Firma del contrato: NDA y acuerdos de suministro para una cooperación a largo plazo.

Paso 4: Producción y rampa; control de calidad

- Fabricación por lotes: La producción comienza según el plazo de entrega acordado (normalmente de 2 a 4 semanas).

- Control de calidad: Forma de las partículas, fluidez y pureza comprobadas por lote.

- Embalaje: Bidones seguros y resistentes a la humedad o bolsas selladas al vacío.

Paso 5: Logística y entrega

- Opciones de envío: Flete aéreo para pedidos urgentes, flete marítimo para grandes cantidades.

- Documentación de exportación: Incluye MSDS, CoA, RoHS/REACH certificados si es necesario.

- Plazo de entrega: Normalmente 7-21 días dependiendo de la región y la cantidad.

Formatos de envasado disponibles

| Cantidad | Tipo de envase | Aplicaciones |

|---|---|---|

| 1-10 kg | Bolsas al vacío | Uso en laboratorio, I+D, creación de prototipos |

| 20-50 kg | Bidones de plástico | Producción de lotes pequeños |

| 100-500 kg | Bidones de acero | Fabricación a media escala |

| ≥1 tonelada métrica | Baterías paletizadas | Producción industrial de gran volumen |

Shanghai Truer ofrece documentación completa y trazabilidad para cada lote de polvo de Inconel, garantizando el cumplimiento de los requisitos de aprovisionamiento y la garantía de calidad para sectores industriales críticos.

9. Preguntas frecuentes: Preguntas frecuentes sobre la compra de polvo de Inconel al por mayor

P1: ¿Cuál es la cantidad mínima de pedido (MOQ) para la venta al por mayor de polvo de Inconel?

R: El MOQ suele ser de 20-50 kg, pero Truer puede aceptar pedidos de prueba más pequeños para nuevos clientes y fines de I+D.

P2: ¿Qué aleaciones Inconel ofrece Shanghai Truer?

R: Los principales grados de Inconel son:

- Inconel 625

- Inconel 718

- Inconel 738 (a petición)

Se pueden desarrollar composiciones personalizadas para aplicaciones especializadas.

P3: ¿Qué métodos de atomización se ofrecen?

R: Shanghai Truer usa:

- Atomización con gas (para polvos esféricos de gran pureza)

- Atomización de agua (para aplicaciones PM rentables)

- Atomización híbrida de gas y agua (para un rendimiento y un precio equilibrados)

P4: ¿Puedo solicitar distribuciones granulométricas personalizadas?

R: Sí. Truer ofrece opciones de personalización PSD tales como:

- 15-45 μm (SLM, DMLS)

- 45-105 μm (EBM, DED)

- 105-150 μm (Binder Jetting, prensado PM)

P5: ¿Están certificados los polvos?

R: Todos los polvos se suministran con:

- Certificado de análisis (CdA)

- Ficha de datos de seguridad (FDS)

- Informes de laboratorio de terceros (previa solicitud)

- Cumplimiento de las normas ASTM, AMS e ISO

P6: ¿Cuál es el plazo de entrega de los pedidos grandes?

R: El plazo de entrega estándar es de 2-4 semanas. Para pedidos urgentes, existen opciones de producción acelerada y transporte aéreo.

P7: ¿Puedo visitar las instalaciones de fabricación?

R: Sí. Shanghai Truer acepta visitas y auditorías de planta. Póngase en contacto con el equipo a través de este formulario para programar una visita o una visita virtual.

P8: ¿Exporta Shanghai Truer a todo el mundo?

R: Por supuesto. La empresa ha realizado envíos a Norteamérica, Europa, Sudeste Asiático y Oriente Medio. La documentación de exportación y el apoyo logístico se gestionan íntegramente en la empresa.

Enlaces de anclaje interno

Aquí hay 5 enlaces internos estratégicamente incrustados para SEO y la navegación del usuario:

- Más información sobre Shanghai Truer's soluciones pulvimetalúrgicas

- Visite el sitio web de la empresa Quiénes somos para explorar su historia y capacidades

- Póngase en contacto con el equipo técnico y de ventas formulario

- Consulte el catálogo completo de material AM en página de inicio

- Navegue hasta el Sección de polvo PM para una lista completa de aleaciones y calidades

Siguiendo esta completa guía, los compradores industriales, los distribuidores y los directores de aprovisionamiento pueden tomar decisiones seguras y basadas en datos a la hora de comprar polvo de Inconel a granel. Shanghai Truer Technology Co., Ltd se destaca como un socio de confianza con capacidades llave en mano, experiencia técnica y capacidad de distribución global.

¿Está listo para obtener polvo de Inconel de alta calidad? Póngase en contacto con el equipo de Truer’ para solicitar un presupuesto, una muestra o una consulta técnica.