1. Introducción: Qué es el polvo FX-2008 y por qué es importante en la PM

FX-2008 es un polvo de acero híbrido de baja aleación desarrollado específicamente para aplicaciones pulvimetalúrgicas (PM). Reconocido por su excelente equilibrio entre compresibilidad, templabilidad y mecanizabilidad, el polvo FX-2008 se utiliza ampliamente en componentes estructurales que exigen una gran solidez y resistencia al desgaste, como piezas de automoción, maquinaria industrial y engranajes de alta resistencia.

FX-2008 forma parte de una familia de polvos de PM aleados por difusión, que combinan polvos elementales y componentes prealeados para permitir unas características de sinterización avanzadas. Esto lo convierte en una opción versátil para fabricantes y OEM que buscan rendimiento sin renunciar a la rentabilidad.

Por qué FX-2008 es importante en PM:

- Permite formas complejas con un conformado casi en forma de red

- Reduce los costes de mecanizado gracias a un mejor control dimensional

- Mejora las propiedades mecánicas mediante aleación por difusión

- Apoya la producción de grandes volúmenes en los sectores de la automoción y la maquinaria

Palabras clave B2B integradas:

- FX-2008 polvo al por mayor

- Proveedor de polvo de acero híbrido de baja aleación

- Polvo metálico FX-2008 para piezas de automóvil

- Distribuidores de materias primas pulvimetalúrgicas

- Polvo PM de alto rendimiento China

2. Aplicaciones industriales del polvo FX-2008

El polvo FX-2008 se utiliza ampliamente en industrias en las que son esenciales componentes de alto rendimiento. Gracias a sus sólidas propiedades mecánicas y a su adaptabilidad a diversos procesos de sinterización, encuentra aplicaciones tanto en piezas estructurales ferrosas como en conjuntos mecánicos complejos.

Principales aplicaciones del polvo FX-2008:

| Industria | Solicitud | Beneficios |

|---|---|---|

| Automotor | Engranajes, piñones, bielas | Alta resistencia, resistencia a la fatiga |

| Maquinaria industrial | Bujes, palancas, soportes | Alta resistencia al desgaste, baja fricción |

| Herramientas eléctricas | Componentes de transmisión, acoplamientos | Estabilidad dimensional, desgaste reducido |

| Agricultura | Ejes de transmisión, articulaciones, enlaces mecánicos | Producción en serie rentable |

Por qué los fabricantes eligen FX-2008:

- La excelente compresibilidad permite geometrías de piezas complejas

- Gran rendimiento mecánico en condiciones de carga

- Compatible con líneas de producción PM automatizadas

Para los fabricantes que buscan reducir el desperdicio de material y mejorar la eficiencia de la producción, FX-2008 es una buena opción. Permite la sinterización de alta densidad, lo que mejora la resistencia mecánica y la calidad de la superficie.

3. Propiedades clave y especificaciones técnicas del FX-2008

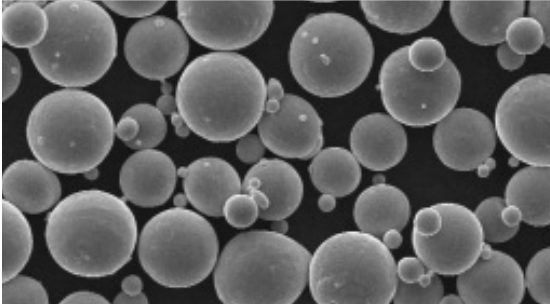

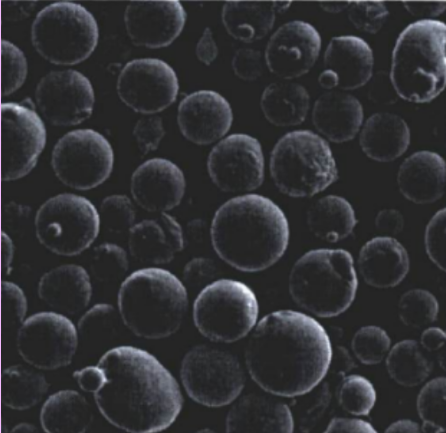

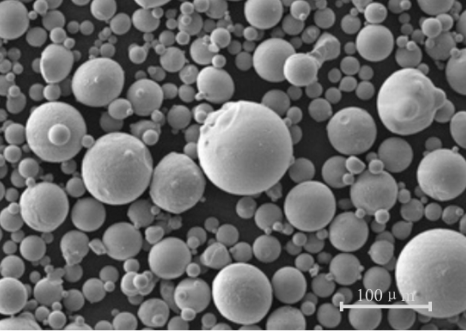

FX-2008 está diseñado para ofrecer un rendimiento equilibrado: alta resistencia, dureza moderada y mecanizabilidad superior. Suele ser un polvo de acero aleado por difusión que contiene una mezcla de hierro, cobre y otros elementos de aleación que mejoran el comportamiento de sinterización.

Especificaciones técnicas del polvo FX-2008:

| Propiedad | Rango de valores |

|---|---|

| Composición básica | Hierro + Cu + Ni + Mo |

| Densidad aparente | 2.9 - 3,1 g/cm³ |

| Caudal (Hall) | 25 - 30 s/50g |

| Fuerza Verde | ≥ 35 MPa |

| Densidad sinterizada | 6.9 - 7,2 g/cm³ |

| Dureza (HRB) | 80 - 90 (sinterizado) |

| Resistencia a la tracción | 600 - 750 MPa |

| Límite elástico | 400 - 500 MPa |

| Alargamiento | 1.5% - 3% |

Características adicionales:

- Excelente estabilidad dimensional

- Buena respuesta al tratamiento térmico

- Adecuado tanto para sinterización en prensa simple como en prensa doble

FX-2008 satisface las necesidades de los exigentes clientes B2B de los sectores de automoción, mecánica y utillaje. Su versatilidad lo convierte en un material básico en el catálogo de los principales proveedores de polvo de PM.

Para conocer más datos técnicos y una selección más amplia de polvos PM, visite nuestro catálogo de polvos pulvimetalúrgicos.

4. Demanda y tendencias del mercado de aceros PM de baja aleación

La industria pulvimetalúrgica (PM) mundial ha experimentado un aumento significativo de la demanda de aceros de baja aleación como el FX-2008. Esto se debe a la creciente necesidad de componentes ligeros y de alta resistencia en sectores como la automoción, el aeroespacial y la maquinaria industrial. A medida que los fabricantes buscan alternativas rentables a las piezas de acero forjado, los polvos aleados por difusión como FX-2008 ofrecen una propuesta de valor convincente.

Principales tendencias del mercado que impulsan la demanda de FX-2008:

- Iniciativas de aligeramiento en automoción: Los fabricantes de automóviles recurren cada vez más a los componentes de PM para reducir el peso y mejorar la eficiencia del combustible sin sacrificar la resistencia.

- Hacia una fabricación casi en red: El objetivo de las empresas es minimizar las operaciones de postprocesado y mecanizado utilizando polvos que ofrezcan una excelente precisión dimensional y sinterabilidad.

- Demanda emergente en Asia-Pacífico: La rápida industrialización de países como China, India y Vietnam está ampliando el mercado de piezas PM, sobre todo en vehículo eléctrico y la automatización industrial.

Tamaño del mercado y previsiones:

| Región | 2023 Tamaño del mercado (millones de USD) | CAGR (2024-2029) |

|---|---|---|

| Norteamérica | 620 | 4.8% |

| Europa | 540 | 4.2% |

| Asia-Pacífico | 890 | 6.5% |

| Resto del mundo | 310 | 3.9% |

| Total mundial | 2,360 | 5.4% |

Términos habituales de búsqueda B2B:

- Polvo de acero FX-2008 para automoción

- Proveedor de acero PM de baja aleación Asia

- Material de piezas sinterizadas a medida

- Acero aleado por difusión FX-2008

- Comprar FX-2008 en polvo a granel

A medida que el mercado se expande, el FX-2008 se ha convertido en un material estratégico para los fabricantes de equipos originales y de piezas que buscan alternativas de alto rendimiento a las aleaciones de acero tradicionales.

5. Cómo elegir un proveedor fiable de polvo FX-2008

Para las empresas que se abastecen de polvo FX-2008 a gran escala, la fiabilidad del proveedor es fundamental. El proveedor adecuado no sólo debe ofrecer precios competitivos, sino también calidad constante, asistencia técnica y documentación completa para cumplir la normativa.

Criterios clave de evaluación:

| Factor | En qué fijarse |

|---|---|

| Pureza & Consistencia | Uniformidad entre lotes, composiciones fiables |

| Capacidad de producción | Capacidad para satisfacer pedidos a gran escala o recurrentes |

| Asistencia técnica | Asistencia en I+D, opciones de personalización |

| Certificaciones | Cumplimiento de las normas ISO 9001, RoHS y REACH |

| Logística | Envíos internacionales, plazos de entrega garantizados, almacenamiento local |

| Precios | Precios competitivos al por mayor con descuentos por volumen |

Preguntas para posibles proveedores:

- ¿Puede facilitar un certificado de análisis (COA) de cada lote?

- ¿Ofrecen mezclas de aleaciones o distribución granulométrica personalizadas?

- ¿Qué comportamiento de sinterización puedo esperar de su polvo FX-2008?

- ¿Puede ayudar a nuestro equipo de desarrollo de productos con datos técnicos?

- ¿Ofrecen muestras de prueba o flexibilidad en las cantidades mínimas?

Elegir un proveedor que comprenda las necesidades de su aplicación y le ofrezca un servicio de asistencia completo puede marcar una diferencia significativa en la fiabilidad del producto y la rentabilidad a largo plazo.

6. Principales proveedores mundiales y chinos de FX-2008

He aquí una comparación de los principales proveedores de polvo FX-2008, entre los que se incluyen tanto operadores mundiales como fabricantes chinos rentables y de alta calidad.

Tabla comparativa: Principales proveedores de FX-2008

| Nombre del proveedor | Región | Productos clave | Puntos fuertes |

|---|---|---|---|

| Höganäs AB | Suecia | FX-2008, serie Astaloy | Calidad superior, alcance mundial |

| Polvos metálicos de Río Tinto | Canadá | Aceros aleados por difusión | Alta capacidad, soporte de I+D |

| GKN Hoeganaes | EE.UU. | Ancorsteel FX-2008 equivalente | Aplicaciones de automoción, asistencia técnica |

| Tecnología Truer de Shanghai | China | FX-2008, FL-4605, FN-0205, etc. | Personalizable, precios competitivos, asistencia local |

| Pometon S.p.A | Italia | Polvos de aleación híbridos | Amplia cartera, certificación europea |

Aunque los proveedores europeos y norteamericanos han liderado tradicionalmente el mercado, fabricantes chinos como Shanghai Truer Technology están ganando rápidamente el reconocimiento mundial por su innovación, calidad y rentabilidad.

Por qué las empresas eligen Truer:

- Ofrece polvo FX-2008 estándar y personalizado

- Servicio postventa eficaz y envío rápido

- Con la confianza de los principales fabricantes nacionales e internacionales de PM

Para obtener más información sobre la oferta completa de pulvimetalurgia de Truer, explore su perfil y capacidades de la empresa.

7. Por qué cada vez más compradores B2B recurren a fuentes nacionales chinas de FX-2008

En los últimos años, un número cada vez mayor de compradores internacionales han recurrido a proveedores chinos de materiales PM como el FX-2008. Este cambio se debe no sólo a las ventajas de costes, sino también a las mejoras en el control de calidad, las normas de producción y la logística global.

Ventajas de recurrir a proveedores chinos:

- Precios más bajos sin comprometer la calidad: Gracias a las economías de escala y la fabricación avanzada, los polvos FX-2008 fabricados en China ofrecen hasta un 30% de ahorro de costes.

- Plazos de entrega más cortos: Con almacenes localizados y sistemas de exportación eficientes, los proveedores chinos pueden entregar más rápidamente que muchos competidores occidentales.

- Capacidades de personalización: Los fabricantes chinos son más flexibles a la hora de ofrecer composiciones, tamaños de partículas y opciones de envasado a medida.

- Mejora del cumplimiento: Las principales empresas chinas cumplen ahora las normas internacionales ISO y REACH, lo que las convierte en proveedores viables para los fabricantes de equipos originales de todo el mundo.

Ejemplo de caso: Shanghai Truer Technology

Shanghai Truer Technology Co., Ltd destaca en el sector chino de la PM. Tras iniciar su actividad de fabricación aditiva en 2019, la empresa se ha convertido en un proveedor de primer nivel de polvos de impresión 3D y materiales de PM.

Lo que diferencia a Truer:

- Ofrece una amplia variedad de polvos PM, incluidos FX-2008, FL-4605, FN-5000 y aceros personalizados

- Admite métodos de producción atomizados tanto con agua como con gas

- Proporciona asesoramiento técnico, orientación sobre sinterización y personalización de productos

- Suministros a los sectores de la automoción, la industria y el utillaje a escala nacional e internacional

Visite Página de Shanghai Truer para saber más sobre sus capacidades y líneas de productos.

8. Cómo pedir polvo FX-2008 al por mayor a proveedores de confianza

Para los fabricantes, OEM y distribuidores que deseen comprar polvo FX-2008 a granel, es esencial establecer un proceso de adquisición ágil y fiable. He aquí una guía paso a paso para realizar pedidos de polvo FX-2008 a proveedores de confianza como Shanghai Truer Technology Co.

Proceso de pedido paso a paso:

- Solicitud de información sobre productos y confirmación de especificaciones

- Definir los requisitos técnicos (granulometría, caudal, comportamiento de sinterización).

- Confirmar las necesidades específicas de la aplicación (automoción, estructuras, etc.).

- Solicite fichas técnicas y muestras de certificados de análisis.

- Solicitud de presupuesto (RFQ)

- Proporcione la cantidad de pedido (MOQ suele ser flexible con Truer).

- Indique el formato de envasado (barriles sellados, bolsas selladas al vacío, etc.).

- Incluya el lugar de entrega y las condiciones de envío preferidas (FOB, CIF, DDP).

- Muestra de evaluación (si es necesario)

- Muchos proveedores, entre ellos Truer, ofrecen cantidades de muestra para realizar pruebas.

- Evaluar la compresibilidad, el comportamiento de sinterización y los resultados mecánicos.

- Orden de compra y pago

- Presente un pedido formal con las condiciones acordadas.

- Truer acepta condiciones de pago flexibles (T/T, LC para grandes pedidos).

- Confirme el plazo de producción y el calendario de envíos.

- Producción y humedad; Garantía de calidad

- El polvo FX-2008 se produce conforme a estrictos protocolos que cumplen las normas ISO.

- En cada lote se comprueba la composición química, el caudal y la densidad.

- Embalaje y envío

- Se entrega en envases herméticos para evitar la contaminación y la oxidación.

- Truer ofrece apoyo logístico nacional e internacional.

- Asistencia posventa

- Incluye consultas técnicas, resolución de problemas de aplicación y asistencia para futuros pedidos.

Ventajas de los pedidos de Truer:

- Flexibilidad de las cantidades máximas para I+D y creación de prototipos en lotes pequeños

- Producción escalable para pedidos de gran volumen

- Apoyo multilingüe a los equipos de contratación internacionales

- Envío rápido a Asia, Europa y Norteamérica

Para agilizar su proceso de adquisición, póngase en contacto con el equipo de Truer a través de su formulario de contacto y reciba un presupuesto en 24-48 horas.

9. Preguntas frecuentes: Todo lo que debe saber sobre la compra de polvo FX-2008 al por mayor

A continuación figuran algunas de las preguntas más frecuentes de responsables de compras, equipos de ingeniería y compradores B2B sobre el polvo FX-2008.

P1: ¿Cuál es el plazo de entrega habitual del polvo FX-2008?

A: Los pedidos de polvo FX-2008 en stock pueden enviarse en un plazo de 3 a 5 días laborables. Para composiciones personalizadas o grandes volúmenes, los plazos de entrega oscilan entre 10 y 20 días en función de la complejidad del pedido y la logística.

P2: ¿Es FX-2008 adecuado para aplicaciones de automoción de alta carga?

A: Sí, el FX-2008 ofrece una excelente resistencia a la tracción, al desgaste y al mecanizado, lo que lo hace ideal para engranajes, palancas y componentes de carga en sistemas de automoción.

P3: ¿Puedo solicitar distribuciones granulométricas personalizadas?

A: Absolutamente. Shanghai Truer Technology puede personalizar el tamaño de las partículas en función del método de sinterización, los requisitos de compresión o la aplicación final.

P4: ¿En qué se diferencia FX-2008 de FL-4605 o FN-0205?

A: FX-2008 es un acero híbrido de baja aleación con propiedades equilibradas adecuado para aplicaciones estructurales. FL-4605 ofrece mayor resistencia pero menor compresibilidad, mientras que FN-0205 es más mecanizable pero menos resistente al desgaste. Póngase en contacto con Equipo técnico de Truer para un análisis comparativo.

P5: ¿El polvo FX-2008 cumple las normas RoHS y REACH?

A: Sí, todos los productos FX-2008 suministrados por Truer se fabrican bajo las normas ISO 9001:2015 y se ajustan a las directivas RoHS y REACH para su distribución mundial.

P6: ¿Qué industrias suelen comprar polvo FX-2008 a granel?

A: Principalmente OEM de automoción, fabricantes de piezas mecánicas, fabricantes de herramientas y proveedores de componentes PM. Los distribuidores también la compran para revenderla en Asia, Europa y América.

P7: ¿Cómo puedo asegurarme de la calidad del polvo FX-2008 antes de hacer un pedido grande?

A: Truer proporciona muestras gratuitas para su evaluación, trazabilidad completa de los lotes e informes de pruebas de terceros previa solicitud. También puede visitar su catálogo de productos para obtener especificaciones más detalladas y opciones de materiales.

Resumen del texto de anclaje interno (5 en total)

- nuestro catálogo de polvos pulvimetalúrgicos - utilizado en la sección 3

- Página de Shanghai Truer - utilizado en la sección 7

- perfil y capacidades de la empresa - utilizado en la sección 6

- formulario de contacto - utilizado en la sección 8

- Equipo técnico de Truer - utilizado en la sección de preguntas frecuentes