1. 1. Introducción: Qué es el polvo FN-0205 y por qué es importante en la industria PM

El polvo FN-0205 es un polvo aleado por difusión compuesto principalmente de hierro y níquel. Se utiliza ampliamente en pulvimetalurgia (PM) para la producción de componentes estructurales que requieren un buen equilibrio entre resistencia, tenacidad y estabilidad dimensional. La designación "FN" sigue las normas MPIF, donde:

- F indica una base ferrosa (hierro),

- norte indica que el níquel es el principal elemento de aleación,

- 0205 se refiere a un contenido nominal de níquel de 2% y de carbono de 0,5%.

Este polvo es la opción preferida para aplicaciones de automoción, maquinaria e industriales debido a sus propiedades mecánicas superiores y su facilidad de procesamiento. Fabricantes, fabricantes de equipos originales y compradores B2B de diversos sectores optan por FN-0205 por sus:

- Excelente relación resistencia-peso

- Mayor resistencia al desgaste

- Endurecimiento superior

A medida que crece la demanda de piezas PM de alto rendimiento, el polvo FN-0205 destaca por su rentabilidad y rendimiento, especialmente en entornos de producción de gran volumen.

2. Aplicaciones industriales del polvo FN-0205 en la fabricación

El polvo FN-0205 se utiliza habitualmente en la producción de componentes sinterizados de alta resistencia en industrias como:

Industria del automóvil

- Engranajes de transmisión

- Cubos sincronizadores

- Bielas

- Piñones del árbol de levas

Componentes de maquinaria

- Bujes

- Soportes

- Engranajes

- Poleas

Herramientas eléctricas y electrodomésticos

- Rotores

- Piezas de embrague

- Soportes estructurales

- Bridas

Ventajas industriales:

- Alternativa rentable al material forjado

- La fabricación de formas casi netas reduce los costes de mecanizado

- Buen control dimensional y repetibilidad

- Compatible con operaciones de endurecimiento por sinterización

| Sector industrial | Componentes típicos del FN-0205 | Ventajas de rendimiento |

|---|---|---|

| Automotor | Engranajes, bujes, bielas | Alta resistencia a la fatiga y al desgaste |

| Maquinaria industrial | Poleas, soportes | Precisión dimensional, tenacidad |

| Herramientas eléctricas | Piezas de embrague, bridas | Diseño compacto, peso reducido |

3. Propiedades clave y ventajas de rendimiento del material FN-0205

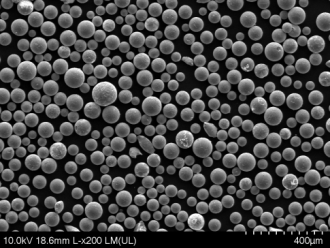

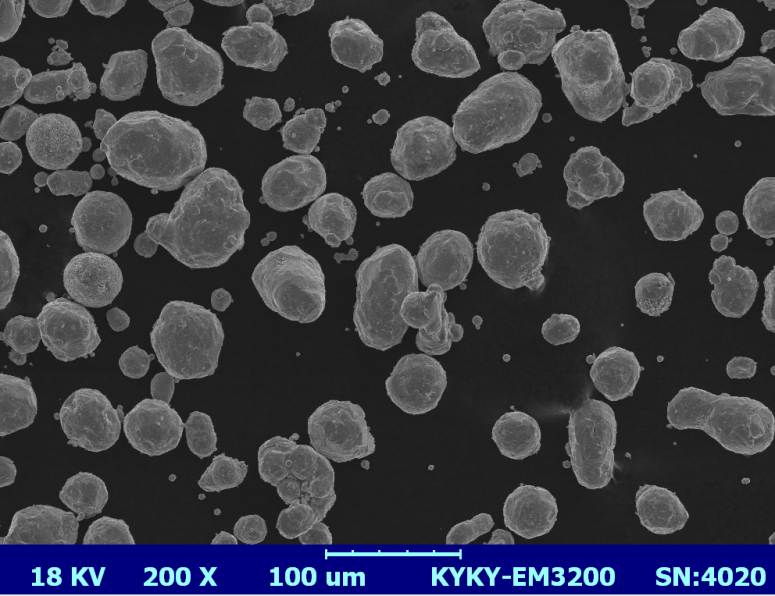

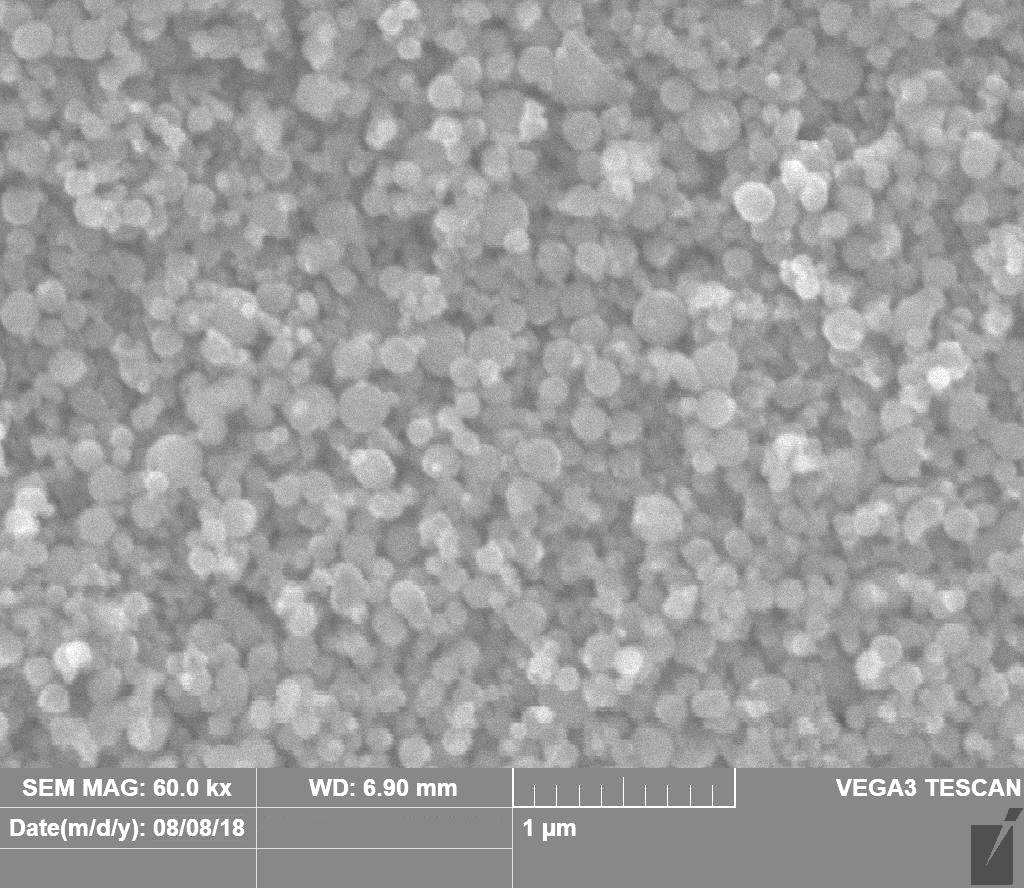

El polvo FN-0205 es conocido por su equilibrada combinación de propiedades físicas y mecánicas, que lo convierten en una opción fiable para aplicaciones exigentes. Se trata de un polvo aleado por difusión, lo que significa que elementos de aleación como el níquel se difunden parcialmente en las partículas de hierro. Esto proporciona un buen compromiso entre compresibilidad y templabilidad.

Propiedades clave:

- Composición: Fe + ~2% Ni + ~0,5% C

- Densidad (Verde): ~6,8 - 7,2 g/cm³

- Densidad sinterizada: ~7,1 - 7,4 g/cm³

- Resistencia a la tracción: Hasta 700 MPa

- Dureza (HRB): 80 – 100

- Energía de impacto20-25 J (Charpy, sin entallar)

Beneficios de tramitación:

- Excelente compresibilidad para una alta resistencia en verde

- Adecuado para la sinterización a alta temperatura

- Respuesta mejorada al endurecimiento por sinterización

- Compatible con diversos lubricantes y aditivos

Mejoras de rendimiento con aditivos:

Para mejorar la maquinabilidad o las propiedades magnéticas del FN-0205, se pueden mezclar aditivos:

- Lubricantes: SUW-5000B para una mayor capacidad de prensado

- Grafito: TBC-400 o TBC-1000 para la adición controlada de carbono

- Agentes de corte: SME-100 para maquinabilidad sin azufre

Shanghai Truer Technology Co., Ltd ofrece una línea completa de aditivos pulvimetalúrgicos diseñados específicamente para mejorar el FN-0205 y otros polvos aleados por difusión. Obtenga más información sobre estas innovaciones en nuestra página de soluciones en polvo PM.

4. Tendencias del mercado mundial y potencial de crecimiento del polvo FN-0205

La industria pulvimetalúrgica mundial está experimentando un importante crecimiento, sobre todo en los sectores de la automoción y la maquinaria industrial. El polvo FN-0205 destaca como una de las calidades más demandadas por sus propiedades mecánicas favorables y su rentabilidad.

Principales impulsores del mercado:

- Electrificación de vehículos: Vehículos eléctricos (VE) requieren componentes más ligeros y eficientes. FN-0205 ofrece una buena relación resistencia-peso, ideal para piezas estructurales en plataformas EV.

- Iniciativas de aligeramiento: Los fabricantes de equipos originales están reduciendo el peso de los vehículos para mejorar la eficiencia del combustible. FN-0205 permite la fabricación de formas casi netas, reduciendo la necesidad de mecanizado pesado.

- Mayor adopción de piezas endurecidas por sinterización: FN-0205 es compatible con los procesos de endurecimiento por sinterización, lo que elimina la necesidad de un tratamiento térmico secundario y reduce los costes de producción.

Tamaño del mercado y previsiones:

| Año | Tamaño estimado del mercado mundial de PM (miles de millones de USD) | FN-0205 Contribución (%) |

|---|---|---|

| 2023 | 26.8 | 7.4% |

| 2025 | 30.5 | 8.1% |

| 2028 | 36.2 | 9.0% |

Regiones con demanda emergente:

- Asia-Pacífico: Dominado por China, India y Corea del Sur: rápido crecimiento del sector del automóvil y menores costes laborales.

- Norteamérica: Gran demanda de engranajes y componentes estructurales endurecidos por sinterización

- Europa: Fuerte impulso a los materiales sostenibles y ligeros en los sectores automovilístico y aeroespacial

La adaptabilidad del FN-0205 a los modernos procesos de PM y su capacidad para cumplir los parámetros de rendimiento especificados por los OEM lo convierten en un material clave en el futuro de la fabricación de componentes.

5. Cómo elegir el proveedor de polvo FN-0205 adecuado

El aprovisionamiento de polvo FN-0205 a granel requiere una evaluación cuidadosa de las capacidades del proveedor, la calidad de la producción y la infraestructura logística. Para los compradores B2B, especialmente los de los sectores de automoción e industrial, elegir al proveedor equivocado puede provocar retrasos, problemas de calidad y un aumento de los costes.

Criterios clave para la evaluación de proveedores:

| Criterios | Descripción |

|---|---|

| Método de producción | Comprobar si el polvo está aleado por difusión, atomizado por agua o atomizado por gas. |

| Consistencia en polvo | Evaluar la uniformidad del tamaño de las partículas y la distribución de las aleaciones |

| Embalaje y logística | Asegurarse de que los polvos se envasan para evitar la oxidación, la contaminación o la humedad. |

| Certificaciones | ISO 9001, IATF 16949 o certificaciones industriales pertinentes |

| Personalización | Capacidad para adaptar grados, aditivos y mezclas en función de las necesidades de la aplicación. |

Preguntas para su proveedor:

- ¿Cuál es la distribución media del tamaño de las partículas de su FN-0205?

- ¿Ofrecen mezclas personalizadas con grafito o lubricantes?

- ¿Pueden proporcionar asistencia técnica para los parámetros de sinterización?

- ¿Cuál es su MOQ y plazo de entrega para pedidos al por mayor?

- ¿Ofrecen almacenamiento regional o entrega "justo a tiempo"?

Un proveedor fiable no sólo debe ofrecer una calidad constante, sino también actuar como su socio técnico en la optimización de los procesos de PM.

6. Principales fabricantes y distribuidores de polvo FN-0205 en Asia

Asia alberga varios fabricantes de pulvimetalurgia competitivos a escala mundial, especialmente en China, donde el ecosistema es maduro y está integrado verticalmente. Estos son algunos de los proveedores de polvo FN-0205 más fiables:

6.1 Shanghai Truer Technology S.L.

Shanghai Truer es uno de los proveedores de pulvimetalurgia más consolidados e innovadores de China. Fundada en 2009 y con el lanzamiento de su división de fabricación aditiva en 2019, Truer cuenta con una década de experiencia en el suministro de polvos PM y soluciones aditivas de alta calidad.

Ventajas clave:

- Ofrece FN-0205 polvo con excelente aleación de difusión

- Producción con certificación ISO y estricto control de calidad

- Admite mezclas personalizadas con grafito, lubricantes y aditivos magnéticos blandos

- Ofrece métodos de atomización con agua e híbridos

- Embalaje listo para la exportación

Grados populares disponibles:

- FN-0205

- FC-0208

- FD-0208

- FL-4605

- FX-2008

Puede obtener más información sobre su antecedentes e instalaciones de la empresa.

6.2 Otros proveedores destacados

| Nombre del proveedor | País | Puntos fuertes |

|---|---|---|

| Höganäs AB | Suecia/Asia | Presencia mundial, I+D avanzada, precios superiores |

| Pulvimetalurgia GKN | China/Global | Producción de gran volumen, especialización en automoción |

| Pometon S.p.A. | Italia/Asia | Polvos de aleaciones especiales, buenos para aplicaciones especializadas |

| Polvo de acero JFE | Japón | Polvos de hierro de alta calidad, estricto control de calidad |

| CNPC Powder Material Co. | China | Precios competitivos, producción a gran escala |

Aunque estas marcas mundiales gozan de buena reputación, muchos compradores B2B consideran que trabajar directamente con un proveedor con sede en China como Shanghai Truer ofrece mejores precios, plazos de entrega más rápidos y un servicio personalizado.

7. Por qué cada vez más compradores B2B compran polvo FN-0205 en China

En los últimos años, China se ha convertido en un centro mundial de materiales pulvimetalúrgicos, incluido el polvo FN-0205. Los compradores B2B -especialmente en los sectores de automoción, aeroespacial y fabricación industrial- están cambiando sus estrategias de abastecimiento a proveedores chinos por varias razones de peso:

7.1 Competitividad de costes

- El acceso a las materias primas y los menores costes de mano de obra permiten a los fabricantes chinos ofrecer el polvo FN-0205 a un precio 15-30% precio más bajo que los competidores occidentales.

- Los proveedores chinos suelen ofrecer descuentos por volumen, mezclas personalizadas, y MOQs flexibleslo que les convierte en socios ideales tanto para grandes fabricantes de equipos originales como para fabricantes de tamaño medio.

7.2 Capacidades de fabricación avanzada

- Muchos productores chinos de polvo utilizan ahora atomización automática de agua, aleación por difusión, y técnicas combinadas de atomizacióngarantizando la uniformidad y la calidad del polvo.

- Proveedores como Shanghai Truer también invierten en I+D y servicios integrados de aditivosque ofrece no sólo polvos, sino también apoyo para la optimización de procesos.

7.3 Plazos de entrega y logística fiables

- La madura infraestructura logística de China y su acceso a las redes mundiales de transporte permiten atender los pedidos con mayor rapidez.

- Oferta de los proveedores envío justo a tiempo, almacenamiento regional, y envases para la exportación para evitar la oxidación o la contaminación.

7.4 Asistencia técnica y personalización

- Los fabricantes chinos, como Truer, ofrecen metalúrgicos internos y servicios de formulación a medida para satisfacer los requisitos de aplicaciones específicas.

- Para los compradores que necesiten piezas PM de precisiónLos proveedores chinos pueden colaborar en la creación de prototipos y la realización de pruebas.

| Beneficio | Ventaja del proveedor chino |

|---|---|

| Precio | 15-30% inferior a la media mundial |

| Plazos de entrega | 7-21 días para la mayoría de los pedidos |

| Personalización | Aditivos mezclados, tamaños de partícula adaptados |

| Logística | Embalaje para exportación, opciones de flete marítimo/aéreo |

| Asistencia técnica | Ingenieros de procesos y metalúrgicos internos |

Para conocer los polvos FN-0205 y otros polvos PM disponibles, visite nuestro catálogo de productos.

8. Por qué elegir Shanghai Truer Technology Co., Ltd como su proveedor

Shanghai Truer Technology Co., Ltd es reconocido como un fabricante líder de polvos y aditivos de PM, que ofrece una de las carteras más completas de polvos a base de hierro y aleaciones del mercado. Con más de 10 años de experiencia y una división dedicada a la fabricación aditiva desde 2019, Truer es el socio ideal para los compradores B2B que buscan calidad, consistencia e innovación.

8.1 Soluciones integrales FN-0205

Truer proporciona FN-0205 polvo que es:

- Aleación por difusión con níquel

- Producido mediante agua o atomización combinada

- Optimizado para piezas PM de alta densidad y resistencia

8.2 Experiencia aditiva

La división de aditivos de Truer ofrece una amplia gama de lubricantes, grafitos, agentes de corte, y aditivos magnéticos para mejorar el rendimiento del FN-0205:

- SUW-5000B: Lubricante de alta eficacia

- QHP-330: Aditivo magnético blando

- SME-100: Mejorador de la maquinabilidad sin azufre

- TBC-1000: grafito de gran pureza para un control constante del carbono

8.3 Apoyo global B2B

- Equipo de ventas multilingüe para compradores internacionales

- Envases a medida para exportación (sellado al vacío, antihumedad)

- Entrega rápida de muestras y servicios de formulación a medida

- Asistencia técnica permanente durante la creación de prototipos y la producción

8.4 Garantía de calidad

- Instalaciones de producción conformes con la norma ISO

- Pruebas internas de laboratorio para determinar el tamaño de las partículas, el caudal y la densidad aparente

- Control de calidad constante lote a lote

| Característica | Mayor capacidad |

|---|---|

| FN-0205 Polvo | Disponible en mezclas estándar y personalizadas |

| Certificación | ISO 9001, protocolos internos de control de calidad |

| Apoyo a la exportación | Envío a todo el mundo, fichas técnicas incluidas |

| Innovación técnica | I+D de aditivos, consultoría de optimización de procesos |

Para ponerse en contacto con el equipo técnico comercial de Truer, contáctenos directamente aquí.

9. Preguntas frecuentes: Todo lo que los compradores B2B necesitan saber sobre el polvo FN-0205

Éstas son las preguntas más frecuentes de compradores mayoristas, fabricantes de equipos originales y fabricantes de componentes PM que desean abastecerse de polvo FN-0205:

P1: ¿Qué método de fabricación se utiliza para producir el polvo FN-0205 de Truer?

R: Truer utiliza la aleación por difusión mediante atomización del agua y atomización combinada para producir el polvo FN-0205, garantizando una compresibilidad y una templabilidad equilibradas.

P2: ¿Puedo solicitar mezclas personalizadas con grafito o lubricantes?

R: Sí. Truer ofrece mezclas de polvos personalizadas con grafito (por ejemplo, TBC-400, TBC-1000), lubricantes (por ejemplo, Lube-W, SUW-5000B) y agentes de corte (por ejemplo, SME-100).

P3: ¿Cuál es el plazo de entrega habitual para los pedidos internacionales?

R: Los plazos de entrega dependen del volumen, pero normalmente oscilan entre De 7 a 21 días. Truer ofrece envíos flexibles por vía aérea o marítima.

P4: ¿Hay fichas técnicas e informes de calidad disponibles?

R: Sí. Todos los envíos de polvo FN-0205 incluyen fichas técnicas, COAs, y informes de análisis granulométricos.

P5: ¿Qué opciones de embalaje hay para los pedidos al por mayor?

R: Los polvos FN-0205 se envasan en Contenedores precintados de 25KG, 50KG o 1 tonelada con barreras antihumedad y sellado al vacío para evitar la contaminación.

P6: ¿Cómo hago un pedido al por mayor?

R: Puede empezar rellenando el formulario de consulta de la página sitio web oficial o poniéndose en contacto directamente con Truer por correo electrónico o teléfono.

Al adquirir el polvo FN-0205 de Shanghai Truer, no sólo obtiene un material de alto rendimiento, sino también un socio estratégico en pulvimetalurgia de precisión. Tanto si produce engranajes para automóviles, bujes industriales o piezas avanzadas de PM, Truer le ofrece la calidad y el apoyo que su empresa necesita para escalar de forma eficiente.

¿Quiere hacer su primer pedido al por mayor o solicitar una muestra?

👉 Póngase en contacto con el equipo de ventas de Truer para empezar.