1. Introducción: Por qué el polvo FLC-4805 atrae la atención de la industria

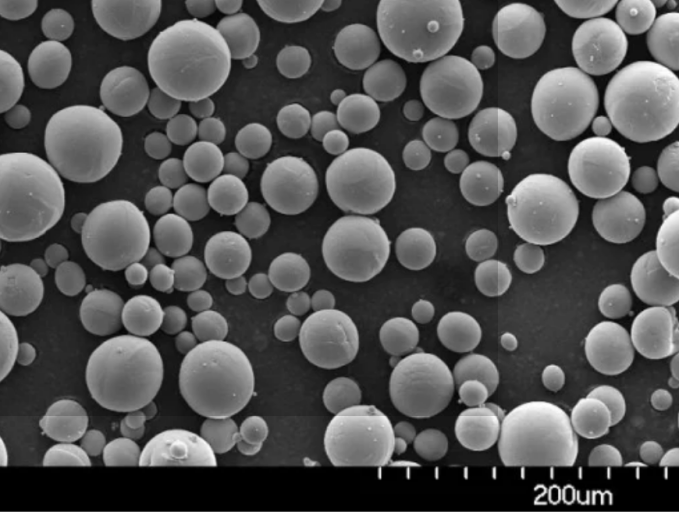

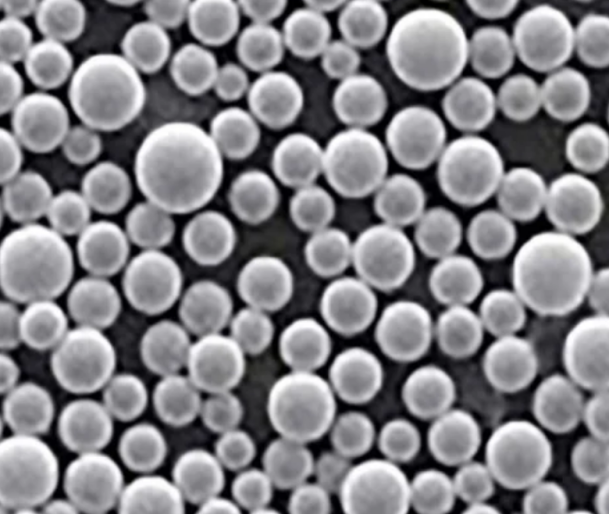

El polvo FLC-4805 es un material de acero pulvimetalúrgico (PM) aleado por difusión conocido por su excelente compresibilidad, rendimiento mecánico y estabilidad dimensional. Está diseñado principalmente para componentes estructurales de alto rendimiento en aplicaciones industriales y de automoción. En los últimos años, los ingenieros y equipos de compras de todo el mundo han adoptado cada vez más el FLC-4805 por su capacidad para cumplir tolerancias estrictas, reducir los costes de mecanizado y mejorar la eficacia de la producción.

Principales ventajas B2B del polvo FLC-4805:

- ✔️ Alta resistencia en verde para prensados complejos

- ✔️ Excelente templabilidad y propiedades mecánicas

- ✔️ Menor necesidad de operaciones secundarias

- ✔️ Rentable para la producción en serie

A medida que las industrias avanzan hacia el aligeramiento, la precisión y la reducción de costes, los materiales de PM avanzados como el FLC-4805 se están convirtiendo en una opción estratégica para los fabricantes de equipos originales, los proveedores de primer nivel y los fabricantes de componentes.

2. Aplicaciones industriales del polvo FLC-4805

El polvo FLC-4805 está diseñado para satisfacer múltiples sectores de uso final, especialmente cuando se requieren piezas de precisión de alta resistencia. Su composición equilibrada y su calidad constante lo convierten en un material de elección en los sectores de la automoción y la maquinaria.

Principales ámbitos de aplicación:

| Industria | Ejemplos de aplicación | Ventajas de FLC-4805 |

|---|---|---|

| Automotor | Engranajes de transmisión, cubos sincronizadores, piñones del árbol de levas | Alta resistencia, resistencia al desgaste, rentabilidad |

| Herramientas eléctricas | Carcasas de engranajes, soportes de montaje | Precisión dimensional, excelente maquinabilidad |

| Maquinaria agrícola | Casquillos, acoplamientos, palancas | Dureza y resistencia a la corrosión |

| Equipamiento industrial | Juntas robóticas, asientos de válvulas | Rendimiento constante bajo cargas dinámicas |

| Electrodomésticos | Piezas de compresores, rotores de bombas | Bajo nivel de ruido, ciclo de vida fiable |

Ventajas para los compradores B2B:

- 🔧 Ideal para grandes volúmenes de producción

- 💰 Permite ahorrar costes gracias a la fabricación casi en forma de red

- ⚙️ Aumenta la durabilidad de las piezas mecánicas

Para más información sobre las aplicaciones pulvimetalúrgicas, visite nuestra página de soluciones en polvo PM.

3. Propiedades y especificaciones técnicas de FLC-4805

FLC-4805 es una fundición en polvo de acero aleado por difusión, níquel, cobre y molibdeno. Esta composición le confiere un sólido equilibrio entre resistencia, compresibilidad y respuesta al tratamiento térmico, lo que lo hace adecuado para piezas mecánicas sinterizadas de alto rendimiento.

Composición química típica (% en peso)

| Elemento | Peso % |

|---|---|

| Fe | Saldo |

| Ni | ~1.75 |

| Cu | ~4.0 |

| Mes | ~0.5 |

| C | 0,5 máx. |

Propiedades mecánicas tras la sinterización y el tratamiento térmico

| Propiedad | Rango de valores |

|---|---|

| Densidad sinterizada | 6.8-7,2 g/cm³ |

| Resistencia a la tracción | 850-1000 MPa |

| Límite elástico | 600-800 MPa |

| Dureza (HRB/HRC) | 80-90 HRB / 25-35 HRC (sinterizado) |

| Tolerancia dimensional | ±0,05 mm o mejor |

Otros aspectos técnicos destacados:

- 📐 Excelente control dimensional tras la sinterización

- 🔩 Buena compatibilidad con el mecanizado secundario

- 🔥 Responde bien al endurecimiento por sinterización y al temple en aceite

Estas propiedades hacen que el FLC-4805 sea muy apreciado por los fabricantes de piezas de precisión y los ingenieros de productos OEM.

4. Tendencias del mercado y potencial de crecimiento del polvo FLC-4805

La industria pulvimetalúrgica mundial está experimentando una importante transformación, impulsada por la creciente demanda en los sectores de la automoción, la industria y la electrónica de consumo. Dentro de este ciclo de crecimiento, los polvos aleados por difusión como el FLC-4805 están experimentando una mayor adopción debido a su resistencia superior y a su relación coste-rendimiento.

Principales impulsores del mercado de FLC-4805:

- 🚗 Aligeramiento en automoción: Los fabricantes de equipos originales y los proveedores de primer nivel están cambiando a componentes de PM como FLC-4805 para reducir el peso del vehículo y mejorar la eficiencia del combustible.

- ⚙️ Automatización industrial: A medida que crece el uso de la robótica y la maquinaria de precisión, la fiabilidad mecánica del FLC-4805 lo hace ideal para aplicaciones de alta carga.

- 🌱 Objetivos de sostenibilidad: La pulvimetalurgia ofrece una fabricación de forma casi neta, lo que reduce el desperdicio de material, un factor importante para los fabricantes concienciados con el medio ambiente.

Crecimiento previsto (2024-2028):

| Región | TACC (estimación) | Principales impulsores |

|---|---|---|

| Asia-Pacífico | 6.5% | Industria del automóvil, maquinaria y utillaje |

| Norteamérica | 4.8% | Producción de vehículos eléctricos y demanda aeroespacial |

| Europa | 4.2% | Fabricación ecológica y utillaje industrial |

Según los estudios del sector, se espera que la demanda de materiales de PM avanzados como el FLC-4805 supere el crecimiento general de PM. Los responsables de compras B2B buscan materiales de alto rendimiento que cumplan los requisitos técnicos y económicos, por lo que el FLC-4805 es un material estratégico para la próxima generación de componentes de ingeniería.

5. Criterios clave para elegir un proveedor fiable de polvo FLC-4805

La selección del proveedor adecuado de FLC-4805 en polvo es fundamental para conseguir una calidad constante de las piezas, control de costes y eficacia de la producción. Ya sea fabricante, distribuidor u OEM, estos son los factores clave que debe evaluar a la hora de adquirir FLC-4805.

Lista de comprobación para la selección de proveedores:

| Factor de evaluación | Por qué es importante para los compradores B2B |

|---|---|

| Normas de fabricación | ISO, ASTM y los protocolos internos de control de calidad garantizan la coherencia |

| Consistencia en polvo | El tamaño y la composición uniformes de las partículas reducen los defectos |

| Capacidad de personalización | Mezclas o granulometrías a medida para prensas específicas |

| Fiabilidad de la entrega | La puntualidad es fundamental para los inventarios JIT |

| Asistencia técnica | Orientación técnica sobre sinterización, compactación, etc. |

| Cumplimiento y seguridad | Disponibilidad de documentación sobre RoHS, REACH y MSDS |

Consejos profesionales:

- Solicite siempre una ficha técnica y un lote de muestra para su evaluación.

- Pregunte al proveedor por sus métodos de atomización: la atomización con gas frente a la atomización con agua puede afectar a las propiedades de la pieza.

- Tenga en cuenta a los proveedores que ofrecen aditivos PM adicionales, lubricantes o materiales de apoyo para racionalizar la adquisición.

Para profundizar en las capacidades de los proveedores y las opciones de materiales, recomendamos explorar nuestro Quiénes somos.

6. Principales fabricantes y proveedores de FLC-4805 en polvo

Tanto si busca proveedores para la producción nacional como para la distribución mundial, es esencial que identifique a los mejores proveedores de FLC-4805. A continuación se muestran algunos de los fabricantes más reconocidos y de confianza en la industria mundial de PM.

Principales proveedores mundiales:

| Nombre del proveedor | Región | Características notables |

|---|---|---|

| Tecnología Truer de Shanghai | China | Polvos PM de gama completa, mezclas personalizadas, asistencia I+D |

| Höganäs AB | Suecia | Líder mundial en polvos metálicos, fuerte I+D |

| GKN Hoeganaes | EE.UU. | Formulaciones avanzadas de polvo aleado por difusión |

| Polvos metálicos de Río Tinto | Canadá | Producción de alta capacidad, centrada en la automoción |

| JFE Steel Corporation | Japón | Polvos de gran pureza y calidad constante |

Foco de atención: Shanghai Truer Technology Co., Ltd

Shanghai Truer, fundada en 2009, es un proveedor de confianza de polvo FLC-4805 y otros materiales PM avanzados. Con un fuerte enfoque en la fabricación aditiva y la pulvimetalurgia, Truer ofrece:

- 🔬 Desarrollo de aleaciones a medida para aplicaciones específicas

- ⚙️ Una amplia gama de métodos de producción de polvo (agua, gas y atomización híbrida)

- 📦 Suministro fiable a granel con capacidad de envío mundial

Su polvo FLC-4805 cumple las normas del sector en cuanto a compresibilidad, resistencia y respuesta de sinterización. Además, Truer ofrece una línea completa de aditivos de PM, lubricantes y agentes de corte, lo que les convierte en una solución integral para los compradores de pulvimetalurgia.

Puede consultar más información sobre su oferta de pulvimetalurgia en la página Página de polvos PM.

7. Por qué cada vez más compradores compran polvo FLC-4805 en China

En los últimos años, China se ha convertido en una potencia mundial en pulvimetalurgia, sobre todo para materiales avanzados como el FLC-4805. Para los compradores B2B -especialmente OEM, fabricantes de componentes y distribuidores- China ofrece una combinación de rentabilidad, capacidad de producción e innovación técnica difícil de igualar.

Razones principales por las que los compradores B2B prefieren a los proveedores chinos:

| Ventaja | Descripción |

|---|---|

| precios competitivos | Los menores costes de fabricación y mano de obra se traducen en mejores precios para los pedidos al por mayor |

| 🏭 Producción a gran escala | Las instalaciones de gran volumen garantizan un suministro constante para contratos a largo plazo |

| capacidades avanzadas de I+D | Empresas líderes como Shanghai Truer invierten mucho en innovación metalúrgica |

| 📦 Logística flexible | Las redes mundiales de transporte y la experiencia en exportación simplifican el comercio transfronterizo |

| 🛠️ Servicios de personalización y OEM | Muchos proveedores ofrecen grados y distribuciones granulométricas de FLC-4805 a medida |

La posición de China en el mercado:

- Más del 30% de la producción mundial de polvo de PM se realiza actualmente en China.

- Los polvos FLC-4805 fabricados en China cumplen o superan las normas ASTM e ISO.

- Las asociaciones estratégicas con empresas europeas y estadounidenses han mejorado las prácticas de control de calidad.

Para los responsables de compras que buscan material de gran volumen y alta calidad sin sacrificar el rendimiento, adquirir FLC-4805 de China es una decisión estratégica, especialmente si se trabaja con proveedores certificados y de confianza.

8. Por qué elegir Shanghai Truer Technology como su proveedor de FLC-4805

Shanghai Truer Technology Co., Ltd es ampliamente reconocido como uno de los proveedores más profesionales y confiables de China de materiales pulvimetalúrgicos, incluido FLC-4805. Fundada en 2009 y expandiéndose a la fabricación aditiva en 2019, Truer se ha forjado una sólida reputación en los mercados nacionales e internacionales.

Lo que diferencia a Truer:

| Característica | Detalles |

|---|---|

| 🌐 Ecosistema PM integrado | Ofrece producción de polvo + fabricación aditiva + servicios técnicos |

| ⚙️ Tecnología de atomización avanzada | Atomización con agua, gas e híbrida para un rendimiento a medida |

| 🧪 Cartera completa de materiales | FLC-4805, FD-0208, FL-4605, FX-2008, y varios aditivos de PM |

| 📋 Certificaciones de calidad | Procesos conformes con las normas ISO y un sólido control de calidad interno |

| 🤝 Atención al cliente | Asistencia técnica, presupuestos rápidos y volúmenes de pedido flexibles |

Productos de valor añadido adicionales:

Truer no sólo vende polvos, sino que ofrece soluciones PM completas. Junto con FLC-4805, Truer ofrece:

- Lubricantes como Lube-W y SUW-8000 para mejorar el flujo del polvo

- Agentes de corte, incluidos SME-100 y TD-8

- Aditivos de grafito como TBC-400 para optimizar la sinterización

- Aditivos magnéticos blandos para componentes eléctricos PM

Estas ofertas convierten a Shanghai Truer en un socio estratégico ideal para fabricantes y distribuidores que necesitan un proveedor de PM fiable y verticalmente integrado.

🔗 Obtenga más información sobre las capacidades de Truer y los antecedentes de la empresa en el Quiénes somos.

9. Preguntas frecuentes: Todo lo que los compradores B2B necesitan saber sobre el polvo FLC-4805

A continuación se incluyen algunas de las preguntas más frecuentes de ingenieros, responsables de compras y diseñadores de productos que desean integrar el polvo FLC-4805 en sus flujos de trabajo de producción.

❓ ¿De qué está compuesto el polvo FLC-4805?

El FLC-4805 es un polvo de acero aleado por difusión compuesto principalmente de hierro, al que se añade cobre (~4%), níquel (~1,75%) y molibdeno (~0,5%). Suele combinarse con fuentes de carbono y lubricantes antes de la compactación y sinterización.

❓ ¿Cuáles son las aplicaciones típicas del FLC-4805?

- Componentes de la transmisión

- Engranajes industriales de alta carga

- Bujes y piñones sincronizadores

- Piezas mecánicas diversas en agricultura y robótica

❓ ¿Puede Truer Technology personalizar FLC-4805 para necesidades específicas?

Sí. Shanghai Truer proporciona formulaciones en polvo a medida, ajustes del tamaño de las partículas y recomendaciones de aditivos para satisfacer necesidades mecánicas o de producción específicas. Más información sobre Soluciones PM aquí.

¿Cuál es la cantidad mínima de pedido?

El MOQ depende de los requisitos del cliente, pero Truer es flexible y puede acomodar pequeños lotes de prueba, así como contratos de gran volumen.

❓ ¿Cómo puedo hacer un pedido al por mayor o solicitar una muestra?

Puede ponerse en contacto con el equipo de ventas de Truer en Shanghai visitando la página Página de contacto. Ofrecen tiempos de respuesta rápidos y un servicio de presupuesto detallado.

❓ ¿Realiza Truer envíos internacionales?

Sí. Truer tiene una amplia experiencia en logística global y puede suministrar FLC-4805 en polvo a Norteamérica, Europa, Sudeste Asiático y otros mercados clave con la documentación y el embalaje adecuados.

Al trabajar con un proveedor de confianza como Shanghai Truer Technology, los compradores B2B pueden asegurarse de recibir polvo FLC-4805 de alta calidad a precios competitivos, respaldados por un soporte experto y una entrega consistente.

▶️ ¿Está listo para obtener su próximo lote de polvo FLC-4805? Visite la página página de inicio para conocer más productos o póngase en contacto con nosotros hoy mismo.

🔗 Resumen de enlaces internos de anclaje incluidos:

| Texto de anclaje | Enlace URL de destino |

|---|---|

| Página de soluciones en polvo PM | https://am-material.com/pm-powder/ |

| Quiénes somos | https://am-material.com/about/ |

| Soluciones PM aquí | https://am-material.com/pm-powder/ |

| Página de contacto | https://am-material.com/contact-us/ |

| página de inicio | https://am-material.com/ |