1. Introducción: Qué es el polvo FL-5208 y por qué es importante en la PM

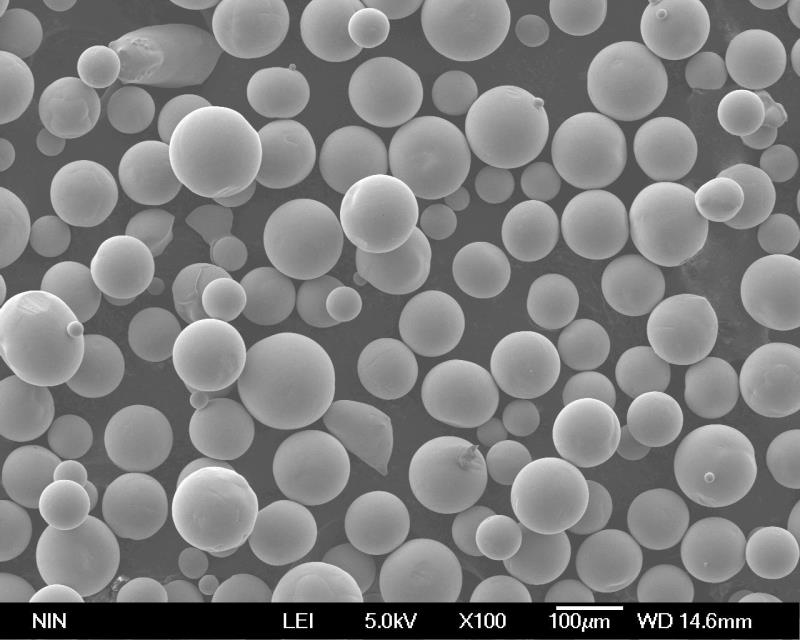

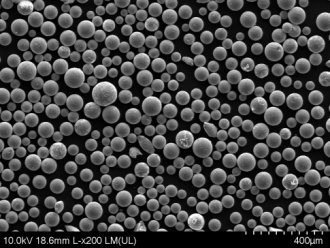

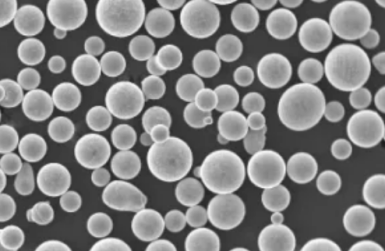

El polvo FL-5208 es un polvo de acero híbrido de baja aleación diseñado específicamente para aplicaciones pulvimetalúrgicas (PM) que exigen alta resistencia, excelente templabilidad y estabilidad dimensional superior. Este polvo de hierro prealeado y unido por difusión se utiliza ampliamente en componentes estructurales, especialmente en las industrias de automoción y maquinaria.

Características principales del polvo FL-5208

| Característica | Descripción |

|---|---|

| Composición | A base de Fe con Ni, Mo, Cu unidos por difusión |

| Densidad Potencial | Hasta 7,4 g/cm³ en piezas sinterizadas |

| Resistencia mecánica | Excelente resistencia a la tracción y a la fatiga |

| Endurecimiento | Adecuado para aplicaciones con tratamiento térmico y cargas elevadas |

| Compatibilidad de aplicaciones | Engranajes, ruedas dentadas, piezas estructurales, componentes de transmisión |

Este polvo es ideal para fabricantes que buscan producir piezas PM complejas con elevados requisitos de carga sin comprometer la rentabilidad.

2. Aplicaciones en los sectores de automoción, industria y herramientas

El polvo FL-5208 es uno de los favoritos entre los fabricantes de equipos originales y los proveedores de primer nivel debido a su versatilidad y sólido rendimiento bajo tensión. He aquí un resumen de sus aplicaciones en distintos sectores:

Industria del automóvil

- Componentes de transmisión: FL-5208 es excelente para cubos de sincronizadores, engranajes y tapas de cojinetes debido a su templabilidad.

- Piezas del motor: Su elevada resistencia a la fatiga lo hace adecuado para poleas de árbol de levas y componentes de cigüeñal.

- Aplicaciones de chasis: Utilizado en soportes y componentes de sistemas de suspensión que requieren alta resistencia al impacto.

Maquinaria industrial

- Engranajes y acoplamientos: Su fuerza y resistencia al desgaste son ideales para aplicaciones de alto par.

- Sistemas hidráulicos: Se utiliza en bombas y piezas de válvulas sometidas a cargas cíclicas.

Herramientas y hardware

- Herramientas manuales: Martillos, alicates y llaves se benefician de la resistencia de FL-5208.

- Componentes de herramientas eléctricas: Los soportes de motor y las carcasas de engranajes se benefician de su precisión dimensional y resistencia.

Tabla resumen: Aplicaciones industriales del polvo FL-5208

| Industria | Tipo de componente | Ventajas del uso de FL-5208 |

|---|---|---|

| Automotor | Cubos sincronizadores, engranajes, poleas | Alta resistencia, tratable térmicamente, resistente al desgaste |

| Industrial | Acoplamientos, hidráulico pistones | Capacidad de carga, resistencia a la fatiga |

| Herramientas | Herramientas manuales, piezas mecánicas | Resistencia a los golpes, precisión dimensional |

3. Propiedades del material y casos de uso del polvo FL-5208

FL-5208 es un polvo aleado por difusión compuesto de hierro con níquelmolibdeno y cobre. Combina las ventajas de los polvos prealeados y mezclados, ofreciendo rentabilidad y rendimiento.

Composición química (típica)

| Elemento | Contenido (%) |

|---|---|

| Hierro (Fe) | Saldo |

| Níquel (Ni) | ~1.5 - 2.0 |

| Molibdeno (Mo) | ~0.5 - 0.7 |

| Cobre (Cu) | ~1.0 - 1.5 |

| Carbono (C) | ~0.4 - 0.6 |

Propiedades mecánicas tras la sinterización y el tratamiento térmico

| Propiedad | Gama de valores (sinterizado & tratado térmicamente) |

|---|---|

| Resistencia a la tracción | 680 - 900 MPa |

| Límite elástico | 500 - 700 MPa |

| Dureza (HRB) | 80 - 95 |

| Resistencia a la fatiga | 250 MPa |

| Estabilidad dimensional | Alta |

Ventajas de procesamiento

- Buena compresibilidad: Adecuado para geometrías de pieza complejas.

- Excelente maquinabilidad: Las operaciones posteriores al sinterizado son eficaces.

- Alto control dimensional: Ideal para componentes de precisión.

FL-5208 se utiliza a menudo en piezas que se someten a operaciones secundarias como el dimensionado, el mecanizado o el tratamiento térmico. Estas propiedades lo hacen muy deseable para los fabricantes de piezas de rendimiento crítico.

Para obtener una visión completa de nuestros materiales pulvimetalúrgicos, visite nuestro PM Polvo Página de producto.

4. Tendencias del mercado mundial y demanda de aceros híbridos de baja aleación

La demanda de polvos híbridos de acero de baja aleación como el FL-5208 crece constantemente, impulsada por los avances en pulvimetalurgia (PM) y la creciente adopción en los sectores de automoción e industrial. Los fabricantes de equipos originales y los proveedores de primer nivel buscan materiales más eficientes y de alto rendimiento que reduzcan los costes y aumenten la fiabilidad mecánica de los componentes.

Principales impulsores del mercado

- Peso ligero de automoción: Los fabricantes de automóviles están sustituyendo las piezas forjadas y fundidas por componentes de PM para reducir el peso y mejorar la eficiencia del combustible sin comprometer la resistencia.

- Rentabilidad de la producción en serie: Las piezas PM fabricadas con FL-5208 reducen las necesidades de mecanizado, ahorrando costes y desperdicio de material.

- Impulso a la sostenibilidad: La fabricación con PM genera menos chatarra que los métodos tradicionales, en consonancia con los objetivos medioambientales mundiales.

Previsión del mercado mundial de FL-5208 en polvo (2024-2030)

| Región | CAGR (2024-2030) | Principales impulsores |

|---|---|---|

| Norteamérica | 5.2% | Innovación en automoción, vehículos eléctricos, maquinaria de precisión |

| Europa | 4.8% | Fabricación ecológica, automatización industrial |

| Asia-Pacífico | 6.5% | Expansión de OEM, centros de fabricación de bajo coste |

| China | 7.1% | Rápida localización de las cadenas de suministro de PM |

Tendencias de adopción en el sector

- Vehículos eléctricos (VE): Componentes ligeros de transmisión y motor PM

- Sistemas hidráulicos y neumáticos: Piezas de válvula complejas y de alta resistencia

- Fabricación ecológica: Demanda de capacidades cercanas a la red en la producción sostenible

Para conocer en profundidad cómo nuestra empresa se alinea con estas tendencias, visite la página Quiénes somos de Shanghai Truer Technology Co., Ltd.

5. Consideraciones clave al adquirir FL-5208 en polvo a granel

Cuando se adquiere polvo FL-5208 para la producción de grandes volúmenes, especialmente en contextos B2B, los compradores deben evaluar factores críticos que van más allá del precio. He aquí una lista de comprobación adaptada a gestores de compras, ingenieros de PM y compradores mayoristas.

① Consistencia y calidad del polvo

- ¿Está aleado correctamente el polvo de difusión?

- ¿La granulometría y la fluidez están optimizadas para su prensa?

- ¿Ha superado el proveedor la certificación ISO 9001 o IATF 16949?

② Fiabilidad de la cadena de suministro

- ¿Puede el proveedor ofrecer un tonelaje mensual constante?

- ¿Mantienen existencias para entregas justo a tiempo?

③ Asistencia técnica y personalización

- ¿Puede el proveedor adaptar la química de la aleación a aplicaciones específicas?

- ¿Ofrecen asesoramiento sobre sinterización y procesos secundarios?

④ Precios y condiciones de pago

- Precios competitivos por kg para pedidos al por mayor

- Condiciones de pago flexibles para contratos a largo plazo

logística y envíos

- Plazos de entrega nacionales frente a internacionales

- Cumplimiento de la normativa sobre exportación

Modelo de matriz de evaluación de proveedores

| Criterios | Importancia | Shanghái Truer | Competidor A | Competidor B |

|---|---|---|---|---|

| Calidad del polvo | Alta | ✅ | ✅ | ✅ |

| Desarrollo de aleaciones personalizadas | Medio | ✅ | ❌ | ✅ |

| Flexibilidad MOQ | Alta | ✅ | ❌ | ❌ |

| Plazos de entrega | Alta | ✅ | ⚠️ | ⚠️ |

| Asistencia técnica | Medio | ✅ | ❌ | ⚠️ |

6. Principales proveedores mundiales y chinos de FL-5208 en polvo

Si desea obtener polvo FL-5208 a gran escala, aquí tiene algunos de los principales proveedores mundiales y regionales que ofrecen este tipo de polvo de acero híbrido de baja aleación:

Principales proveedores mundiales

- Höganäs AB (Suecia)

- Líder en polvos PM prealeados y aglomerados por difusión

- Red mundial de distribución

- GKN Hoeganaes (EE.UU.)

- Ofrece calidades comparables como Ancorsteel 4600

- Fuerte presencia en Norteamérica

- Rio Tinto Metal Powders (Canadá)

- Producción de gran volumen con sistemas avanzados de control de calidad

Principales proveedores chinos

- Shanghai Truer Technology Co., Ltd

- Ofrece polvos híbridos de baja aleación equivalentes a FL-5208

- Formulaciones personalizadas y aditivos disponibles

- Experiencia en atomización con agua y gas

- Grupo CNPC Powder

- Producción a gran escala de grados PM estándar

- Centrados principalmente en el mercado nacional chino

- Hunan Rare Earth Metal Powder Co.

- Conocido por sus polvos de aleaciones especiales en pequeños volúmenes

Por qué Shanghai Truer es la mejor opción en China

Shanghai Truer Technology Co., Ltd es uno de los fabricantes más profesionales de polvos PM en China, ofreciendo:

- Polvos híbridos de baja aleación de grado FL-5208 y similares

- Variantes atomizadas con agua y con gas para diferentes métodos de compactación

- Servicios de aleación a medida para necesidades específicas

- Soluciones completas de aditivos incluidos lubricantes, grafito y agentes de corte

👉 Obtenga más información sobre nuestras capacidades y oferta de productos en el Página principal de Shanghai Truer.

7. Por qué cada vez más OEM y fabricantes de PM eligen fuentes chinas

En la última década, los OEM, los proveedores de primer nivel y los fabricantes de pulvimetalurgia (PM) han recurrido cada vez más a proveedores chinos para abastecerse de polvos de aleación de alto rendimiento como el FL-5208. Este cambio se debe a una combinación de rentabilidad, mejora de las normas de calidad y flexibilidad de la cadena de suministro.

Principales ventajas de los proveedores chinos de polvo FL-5208

precios competitivos

- Los menores costes de producción y mano de obra reducen los precios por kilogramo de polvo.

- Modelos de precios flexibles para contratos al por mayor y a largo plazo.

✅ Capacidades de fabricación avanzadas

- Instalaciones de atomización de agua y gas de última generación.

- Plantas con certificación ISO 9001 e IATF 16949.

personalización y asistencia técnica

- Modificaciones de aleación y mezclas personalizadas a la carta.

- Asistencia técnica localizada para clientes de todo el mundo.

✅ Plazos de entrega más cortos para los mercados asiáticos

- Entrega rápida para el Sudeste Asiático, India y Oceanía.

- Logística integrada por ferrocarril, mar y aire.

Tabla comparativa: FL-5208 Opciones de la cadena de suministro

| Característica | Proveedores Europa/Estados Unidos | Proveedores chinos (por ejemplo, Truer) |

|---|---|---|

| Precio por kg (a granel) | Alta | 15-30% menos |

| Opciones de aleación personalizadas | Limitado | Amplia |

| Flexibilidad MOQ | 1 tonelada | A partir de 100 kg |

| Plazo de entrega (entrega en Asia) | 4-6 semanas | 7-14 días |

| Soporte técnico | Regional | Experiencia mundial y local |

Esta propuesta de valor ha convertido a empresas como Shanghai Truer en un socio de referencia para distribuidores y fabricantes de todo el mundo que buscan una fuente de polvo fiable y escalable.

8. Por qué elegir Shanghai Truer para la venta al por mayor de FL-5208 en polvo

Shanghai Truer Technology Co., Ltd es una empresa pionera en la industria pulvimetalúrgica de China, que ofrece una amplia cartera de polvos de PM, incluido el acero híbrido de baja aleación de grado FL-5208. Desde 2009, Truer se ha comprometido a ofrecer una calidad constante, innovación técnica y un servicio centrado en el cliente.

🔧 Capacidades del producto

- FL-5208 Polvos equivalentes

- Polvo de acero híbrido de baja aleación con Ni, Mo, Cu unidos por difusión

- Producido mediante atomización con agua para una compresibilidad óptima

- Otros grados PM disponibles

- FL-4605, FD-0208, FN-5000, FD-0200, y difusión CuSn

- Polvos especializados para herramientas diamantadas y cojinetes sinterizados

- Tecnologías de atomización

- Atomización con agua, atomización con gas y atomización híbrida combinada

🧪 Soluciones de aditivos y lubricantes

Truer va más allá de los polvos base al ofrecer sistemas completos de aditivos PM:

- Lubricantes: Lube-W, SUW-8000, SUW-5000B

- Agentes de corte: SME-100 (sin azufre), TD-8

- Grafito: QHP-330, TBC-400

- Aditivos magnéticos blandos: QH-150

🤝 Lo que distingue a Truer

| Característica | Shanghai Truer Advantage |

|---|---|

| I+D interno | Desarrollo de aleaciones personalizadas y optimización del rendimiento |

| Cartera completa de aditivos | Solución integral para polvos y aditivos de PM |

| Entrega rápida a granel | Envíos nacionales e internacionales |

| Apoyo mundial | Equipos técnicos y comerciales anglófonos |

| Certificaciones de calidad | ISO 9001 & pruebas avanzadas de laboratorio de control de calidad |

📌 ¿Quieres hablar con un experto en productos? Visita nuestro Página de contacto para obtener asistencia personalizada.

9. Preguntas frecuentes: Compra al por mayor de FL-5208 en polvo

P1: ¿Cuál es la cantidad mínima de pedido (MOQ) para el polvo FL-5208?

R: El MOQ para el polvo FL-5208 en Shanghai Truer suele ser de 100 kg. Para mezclas personalizadas o pedidos de exportación, el MOQ puede variar ligeramente en función de los requisitos logísticos o de embalaje.

P2: ¿Se puede personalizar el polvo FL-5208 para mi aplicación?

R: Sí. El equipo de I+D de Truer puede adaptar la composición química, la distribución del tamaño de las partículas y los ingredientes de aleación del FL-5208 para satisfacer requisitos mecánicos o de sinterización específicos.

P3: ¿Cuáles son las opciones de envasado disponibles?

R: El embalaje estándar incluye:

- sacos precintados de 25 kg

- bidones de acero de 500 kg

- Palés o IBC personalizados para exportación

Todos los envases son resistentes a la humedad y están etiquetados con la información del lote para su trazabilidad.

P4: ¿Hacen envíos internacionales?

R: Sí. Exportamos polvo FL-5208 a Asia, Europa, Norteamérica y Oriente Medio. Truer trabaja con socios logísticos externos para garantizar una entrega puntual y segura.

P5: ¿Cómo puedo solicitar una ficha técnica o una muestra?

R: Sólo tiene que rellenar el formulario de nuestro Página de contacto y nuestro equipo de ventas le responderá en 24 horas. Hay muestras disponibles para compradores industriales y OEM cualificados.

P6: ¿Qué certificaciones de ensayo se proporcionan?

R: Cada lote de polvo FL-5208 viene con:

- Análisis de la composición química

- Prueba de caudal y densidad aparente

- Informe de propiedades mecánicas sinterizadas (a petición)

P7: ¿Puedo pedir polvo FL-5208 con otros materiales PM?

R: Por supuesto. Truer ofrece paquetes de pedidos que incluyen acero inoxidable, polvos a base de cobre y aditivos. Puede explorar nuestra completa Gama de polvos PM para más opciones.

Resumen de los enlaces internos utilizados:

| Texto de anclaje | URL |

|---|---|

| PM Polvo Página de producto | https://am-material.com/pm-powder/ |

| Quiénes somos | https://am-material.com/about/ |

| Página principal de Shanghai Truer | https://am-material.com/ |

| Página de contacto | https://am-material.com/contact-us/ |

| Gama de polvos PM | https://am-material.com/pm-powder/ |

Al elegir Shanghai Truer como su proveedor de confianza de polvo FL-5208 y materiales PM relacionados, usted obtiene algo más que un producto: obtiene un socio a largo plazo comprometido con el éxito de su fabricación. Deje que nuestra experiencia en personalización de aleaciones, integración aditiva y logística global le ayuden a escalar de forma más inteligente, rápida y eficiente.

📩 ¿Listo para solicitar un presupuesto o una muestra? Diríjase a nuestro Página de contacto hoy.