1. Introducción: Por qué el polvo FL-4605 está ganando terreno en la pulvimetalurgia

El polvo FL-4605 es un polvo de acero híbrido de baja aleación diseñado específicamente para aplicaciones pulvimetalúrgicas (PM) que exigen alta resistencia, resistencia al desgaste y un rendimiento de sinterización constante. A medida que sectores como la automoción, el aeroespacial y la maquinaria industrial recurren cada vez más a la PM para obtener componentes rentables y ligeros, la demanda de materiales avanzados como el FL-4605 ha aumentado en el mercado B2B mundial.

Para compradores mayoristas, fabricantes y distribuidores, FL-4605 ofrece varias ventajas:

- Excelente templabilidad y resistencia tras la sinterización

- Rendimiento uniforme en distintas geometrías de piezas

- Ideal para piezas estructurales con requisitos mecánicos de medios a altos

- Compatible con los procesos de sinterización de una prensa y de doble prensa

Su amplia aceptación en la industria PM se debe a sus sólidas propiedades mecánicas y a su adaptabilidad a diseños de componentes complejos, lo que lo convierte en una opción de primer orden para los fabricantes de equipos originales y los proveedores de primer nivel.

2. Aplicaciones industriales del polvo FL-4605

FL-4605 es preferido en industrias donde la resistencia, durabilidad y maquinabilidad son críticas. A continuación se indican los principales sectores y las piezas típicas fabricadas con polvo FL-4605:

| Industria | Aplicaciones Típicas | Beneficios |

|---|---|---|

| Automotor | Engranajes, piñones, bielas, componentes del árbol de levas | Alta resistencia al desgaste, precisión dimensional |

| Equipamiento industrial | Piezas hidráulicas, soportes, acoplamientos | Excelente resistencia mecánica |

| Electrónica de consumo | Bastidores estructurales, carcasas de motores | Ligero y duradero |

| Aeroespacial | Piezas estructurales secundarias | Elevada relación resistencia/peso |

Principales ventajas para los compradores B2B:

- Reducción del material desechado gracias a la fabricación con forma casi neta

- Menor coste por unidad con una producción de gran volumen

- Adecuado para piezas que requieren tratamiento térmico y acabado superficial

Para los productores de grandes volúmenes y los fabricantes de equipos originales, FL-4605 ofrece una opción de material fiable y asequible que equilibra el coste y el rendimiento.

3. Composición, propiedades y especificaciones técnicas de FL-4605

FL-4605 es un acero híbrido de baja aleación que suele incluir hierro, carbono, níquelmolibdeno y manganeso. Está diseñado para ofrecer un equilibrio entre compresibilidad, resistencia y tenacidad, lo que lo hace ideal para componentes estructurales sinterizados.

Composición química (típica):

| Elemento | Contenido (%) |

|---|---|

| Hierro (Fe) | Saldo |

| Carbono (C) | 0.5 – 0.6 |

| Molibdeno (Mo) | 0.5 – 0.7 |

| Níquel (Ni) | 1.3 – 1.5 |

| Manganeso (Mn) | 0.3 – 0.5 |

Propiedades mecánicas (después de sinterización & tratamiento térmico):

| Propiedad | Valor |

|---|---|

| Densidad | 6.8 – 7,2 g/cm³ |

| Resistencia a la tracción (UTS) | Hasta 900 MPa |

| Límite elástico | 600 - 800 MPa |

| Dureza | 30 - 40 HRC |

| Alargamiento | 1 - 3% |

Ventajas para los fabricantes de PM:

- Excelente resistencia en verde para su manipulación antes de la sinterización

- Los altos niveles de densidad tras la sinterización mejoran la integridad mecánica

- Buena respuesta a tratamientos térmicos secundarios como el temple y el revenido

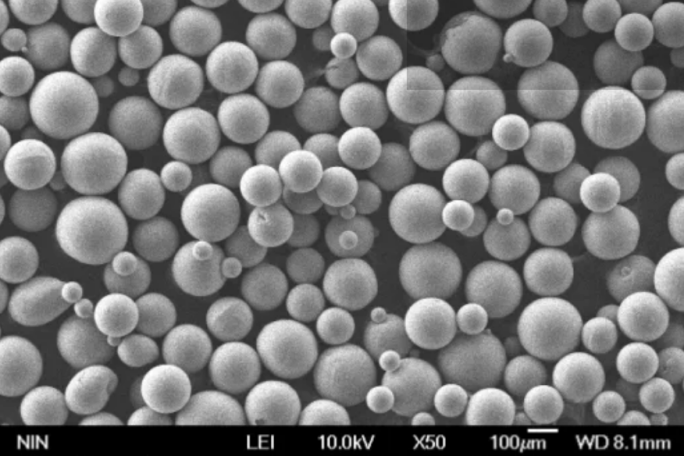

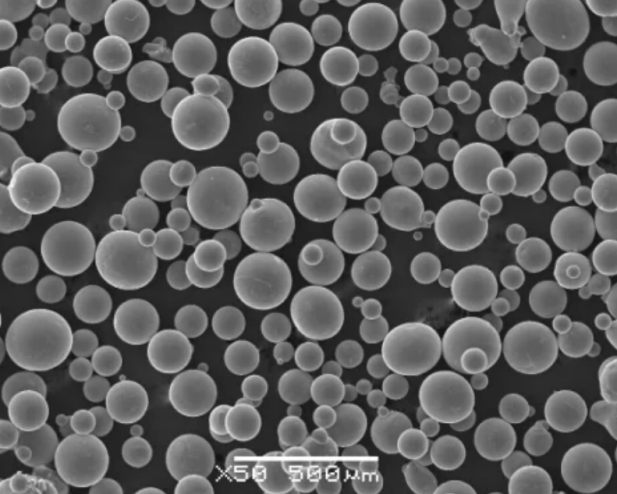

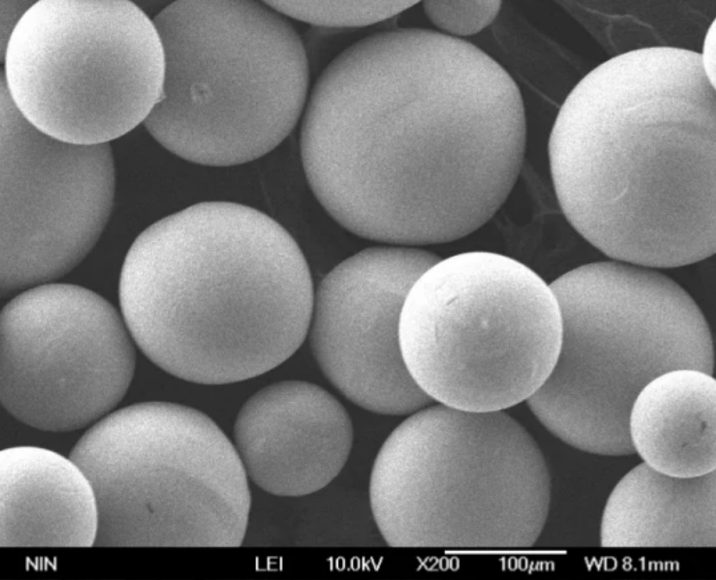

Shanghai Truer Technology Co., Ltd ofrece el polvo FL-4605 con una consistencia garantizada en la distribución del tamaño de las partículas, la fluidez y la pureza, asegurando unos resultados de sinterización y un rendimiento de los componentes óptimos.

Si desea conocer más polvos PM, incluido el FL-4605, visite nuestro catálogo completo de productos para obtener especificaciones detalladas y fichas técnicas descargables.

4. Consideraciones clave al elegir un proveedor de polvo FL-4605

Al comprar polvo FL-4605 para aplicaciones pulvimetalúrgicas, especialmente en entornos B2B, es fundamental elegir el proveedor adecuado. La calidad del polvo influye directamente en el rendimiento del producto, la eficacia de la producción y, en última instancia, en su cuenta de resultados. A continuación se indican los factores más importantes a tener en cuenta:

✅ Coherencia técnica

- Distribución del tamaño de las partículas (PSD): Una PSD uniforme garantiza una compactación y sinterización uniformes.

- Pureza: Impurezas como el azufre o el fósforo pueden afectar negativamente a las propiedades mecánicas.

- Fluidez y humedad; Densidad aparente: Esto afecta al llenado del molde y a la uniformidad de la prensa.

- Compresibilidad: Importante para conseguir una alta resistencia y densidad en verde.

capacidad de producción

- ¿Puede el proveedor gestionar pedidos al por mayor y mantener la calidad?

- ¿Ofrecen polvos que cumplan las normas internacionales PM, como MPIF o ISO?

- ¿Proporcionan polvos de aleación premezclados o personalizados?

✅ Logística & Plazo de entrega

- Ubicación: ¿Están ubicados en un lugar céntrico para un transporte mundial eficaz?

- Plazo de entrega: ¿Pueden cumplir sus plazos de producción?

- Envasado: ¿Se envían los polvos en recipientes antiestáticos a prueba de humedad?

soporte técnico y documentación

- Fichas de datos de los materiales (FDS)

- Fichas de datos de seguridad (FDS)

- Disponibilidad de muestras

- Asesoramiento técnico in situ o a distancia

certificaciones

Busque proveedores con certificaciones como

- ISO 9001 para la gestión de la calidad

- Cumplimiento de las normas medioambientales y de seguridad REACH y RoHS

- Informes de pruebas de terceros para validar las propiedades

Estos criterios ayudan a garantizar que su proveedor es fiable, coherente y se ajusta a sus requisitos de fabricación y rendimiento.

5. Principales proveedores de FL-4605 Powder en Asia y su oferta

Asia se ha convertido en un importante centro de materiales pulvimetalúrgicos debido a su sólido ecosistema de fabricación, su rentabilidad y los avances tecnológicos en la producción de polvo metálico. A continuación figuran algunos de los proveedores de FL-4605 más destacados de la región:

| Proveedor | País | Características notables | Polvo PM Focus |

|---|---|---|---|

| Shanghai Truer Technology Co., Ltd | China | Gama completa de soluciones aditivas PM, producción propia, personalización | Aceros híbridos de baja aleación, aceros inoxidables, aleaciones de cobre |

| Hoganas | China/Suecia | Marca mundial, fuerte I+D, amplia cartera de productos PM | Aceros PM de alto rendimiento |

| GKN Hoeganaes | China/Estados Unidos | Enfoque automovilístico, calidad global constante | Prealeados & polvos aleados por difusión |

| Pometon | Italia/China | Polvos de aleaciones especiales, integración de la impresión 3D | Polvos a base de hierro y cobre |

| Polvos metálicos de Río Tinto | Canadá/Asia | Producción a gran escala de polvos de PM para automoción | Polvos a base de hierro y aleados por difusión |

Aunque las marcas mundiales ofrecen una calidad contrastada, muchos fabricantes recurren ahora a proveedores chinos:

- Plazos de entrega más cortos

- Menor coste por kilogramo

- Desarrollo de aleaciones personalizadas

- Asistencia técnica localizada

Shanghai Truer Technology Co., Ltd destaca por su producción integrada verticalmente, su capacidad de I+D y su amplia gama de grados híbridos de polvo de baja aleación, como FL-4605.

6. ¿Por qué cada vez más fabricantes compran FL-4605 en China?

La industria pulvimetalúrgica china ha madurado considerablemente en la última década, especialmente en la producción de polvos metálicos de alto rendimiento como el FL-4605. El cambio hacia el abastecimiento chino se debe a varias ventajas competitivas:

🔍 Rentabilidad

- El polvo chino FL-4605 puede ser 20-40% más rentable en comparación con sus homólogos norteamericanos o europeos.

- El abastecimiento local de materias primas reduce los costes de fabricación.

🔧 Avances tecnológicos

- Adopción de atomización automática de agua y atomización combinada gas-agua para una mejor morfología del polvo.

- I+D en polvos PM híbridos que compiten con marcas mundiales en resistencia y consistencia.

🚢 Resiliencia de la cadena de suministro

- Infraestructura logística madura (puertos de Shanghai, Shenzhen y Ningbo)

- Reservas nacionales de materias primas y elementos de aleación

- Plazos de entrega más cortos para pedidos B2B al por mayor

🤝 Servicios B2B a medida

- Composiciones en polvo premezcladas a medida

- Servicios OEM y ODM para la mezcla de polvos

- Asistencia localizada en varios idiomas

Por ejemplo, Shanghai Truer Technology ofrece grado FL-4605 polvo con tamaño de partícula personalizable, opciones de mezcla con lubricantes como SUW-5000B, y agentes de corte como SME-100 para mejorar la maquinabilidad durante el procesamiento secundario.

He aquí una rápida comparación de las ventajas de la contratación FL-4605:

| Factor | Proveedores occidentales | Proveedores chinos (por ejemplo, Truer) |

|---|---|---|

| Precio | Alta | Competitivo |

| Plazos de entrega | 4-8 semanas | 1-3 semanas |

| MOQ | A menudo alto | Flexible |

| Personalización | Limitado | Amplia |

| Asistencia técnica | Estándar | A la medida de los equipos locales |

Para obtener más información sobre el enfoque de Truer para FL-4605 y otros polvos PM, visite su página corporativa.

7. Por qué elegir Shanghai Truer Technology como su proveedor de FL-4605

Shanghai Truer Technology Co., Ltd es uno de los nombres más confiables en la industria pulvimetalúrgica de China. Desde 2009, Truer ha estado a la vanguardia de la fabricación de polvo metálico, con una división dedicada a la fabricación aditiva lanzada en 2019. Su polvo FL-4605 es ampliamente utilizado por OEM y fabricantes de piezas PM en los sectores de automoción, industrial y de consumo.

✅ Razones clave para elegir Truer para el polvo FL-4605:

| Característica | Ventajas para su empresa |

|---|---|

| Fabricación propia | Control total de la calidad y la coherencia |

| Múltiples métodos de atomización | Atomización con agua, gas y combinada para una morfología óptima del polvo |

| Amplia cartera de PM | FL-4605, FC-0208, FD-0200, FN-5000, etc |

| Soluciones aditivas | Lubricantes (Lube-W, SUW-5000B), agentes de corte (TD-8, SME-100) |

| Plazos de entrega rápidos | Ideal para programas de producción con plazos ajustados |

| Consulta técnica | Mezclas de polvos a medida y recomendaciones de proceso |

🌍 Distribución mundial y asistencia

Truer apoya a los compradores y distribuidores mayoristas globales con:

- Equipos de ventas multilingües

- Documentación lista para la exportación

- Cantidades mínimas de pedido (CMP) flexibles

- Cumplimiento de las normas internacionales (ISO, REACH, RoHS)

Truer's División de polvo PM es conocida por ofrecer no sólo materiales básicos como FL-4605, sino también soluciones completas de aditivos que mejoran la maquinabilidad, el rendimiento de sinterización y la calidad de las piezas.

8. Cómo pedir FL-4605 en polvo a granel a fuentes fiables

Pedir polvo FL-4605 para su empresa de fabricación o distribución requiere un enfoque sencillo pero minucioso. A continuación encontrará una guía paso a paso para ayudar a los compradores B2B a agilizar el proceso de abastecimiento.

Proceso de pedido paso a paso con Truer:

| Paso | Acción | Detalles |

|---|---|---|

| 1 | Enviar consulta | Visite Contáctenos y rellene el formulario de consulta o envíe directamente un correo electrónico a ventas |

| 2 | Definir los requisitos | Especifique el grado (por ejemplo, FL-4605), el tamaño de las partículas, la cantidad, el embalaje y el plazo de entrega |

| 3 | Recibir presupuesto | Truer proporciona precios, plazos de entrega y opciones de envío |

| 4 | Aprobar muestra | Pruebas de muestras opcionales para nuevos clientes |

| 5 | Confirmar pedido | Emisión de pedidos e inicio de la producción |

| 6 | Entrega y asistencia | Envío con documentación completa, soporte técnico postventa disponible |

📦 Opciones de embalaje

- sacos antihumedad de 25 kg

- bidones de 500 kg para compradores de gran volumen

- Envases a medida para fabricantes y distribuidores

🛠 Servicios añadidos

- Desarrollo de aleaciones personalizadas basadas en FL-4605

- Mezcla con lubricantes y aditivos

- Fabricación por contrato de polvos para MP de marca blanca

💡 Consejo profesional: Si no está seguro de cuál es la especificación de polvo adecuada, los ingenieros de Truer pueden recomendarle una formulación que se ajuste a su temperatura de sinterización, tonelaje de prensa y densidad objetivo.

9. Preguntas frecuentes: Todo lo que necesita saber sobre el polvo FL-4605

Estas son algunas de las preguntas más frecuentes de los compradores B2B y los ingenieros que compran polvo FL-4605:

P1: ¿Cuál es la diferencia entre FL-4605 y FC-0208?

A: Aunque ambos son polvos de acero de baja aleación, FL-4605 ofrece una mayor resistencia mecánica debido a su estructura de aleación híbrida. Es ideal para piezas sometidas a mayor tensión y desgaste.

P2: ¿Qué temperatura de sinterización es óptima para FL-4605?

A: Normalmente 1120-1150°C en una atmósfera controlada para obtener los mejores resultados. Truer puede proporcionar curvas de sinterización basadas en su tipo de horno.

P3: ¿Se puede mezclar el polvo FL-4605 con lubricantes?

A: Sí. Truer ofrece FL-4605 premezclado con lubricantes como SUW-5000B para mejorar la compactación y la expulsión durante el prensado.

P4: ¿Ofrece Truer asistencia técnica?

A: Absolutamente. Truer proporciona asistencia técnica completa, desde la selección del polvo hasta la optimización de la sinterización. Puede obtener más información sobre sus servicios en página de perfil de la empresa.

P5: ¿Cuál es la cantidad mínima de pedido?

A: Truer ofrece MOQ flexibles a partir de 25 kg para los nuevos clientes y hasta varias toneladas para los compradores habituales a granel.

P6: ¿Es FL-4605 adecuado para piezas de automoción?

A: Sí, se utiliza ampliamente en engranajes, ruedas dentadas, rodamientos y otros componentes de alta carga debido a su resistencia y estabilidad dimensional.

🔗 Enlaces internos de texto ancla utilizados en el artículo:

- División de polvo PM - vinculado en la sección 7

- Contáctenos - vinculados en la sección 8

- página de perfil de la empresa - vinculado en la sección 9

- nuestro catálogo completo de productos - vinculados en la sección 3

- página corporativa - vinculado en la sección 6

Si es usted fabricante, distribuidor o director de compras y busca una fuente fiable de FL-4605 en polvo, Shanghai Truer Technology está a su disposición para satisfacer sus necesidades con productos de alta calidad, asesoramiento experto y entrega en todo el mundo. Para comenzar su viaje de abastecimiento, póngase en contacto con el equipo de Truer hoy mismo y solicite un presupuesto o una muestra.