Introducción a FL-4205 Polvo en pulvimetalurgia

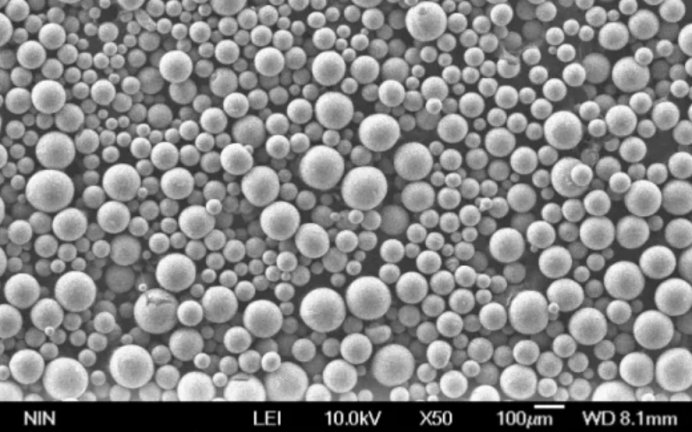

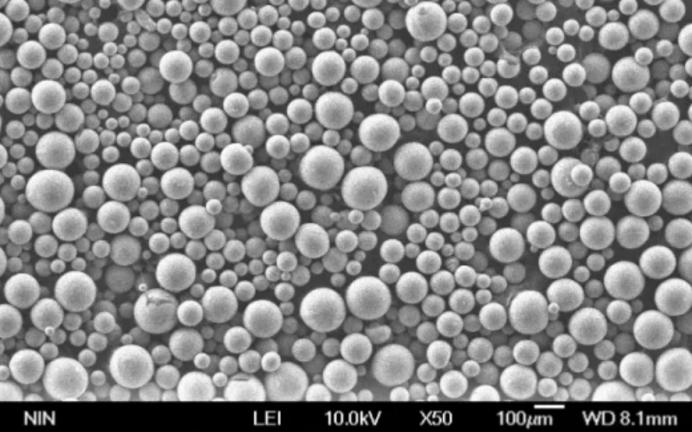

El FL-4205 es un grado de acero pulvimetalúrgico híbrido de baja aleación (PM), ampliamente utilizado en aplicaciones estructurales que requieren un equilibrio entre resistencia, dureza y resistencia al desgaste. Como polvo premezclado que contiene hierro, cobre y carbono, el FL-4205 está diseñado para cumplir normas de alto rendimiento en sectores industriales exigentes.

¿Qué es el polvo FL-4205?

FL-4205 es una designación definida por las normas MPIF (Metal Powder Industries Federation). Normalmente incluye:

- Base metálica: Hierro

- Elementos de aleación: Cobre (~2%), Carbono (~0,5%)

- Método de tratamiento: Atomizado con agua o aleación por difusión

Por qué el FL-4205 es popular en pulvimetalurgia

El FL-4205 está optimizado para el proceso de prensado y sinterizado, ofreciendo una alta resistencia en verde, un buen control dimensional y excelentes propiedades mecánicas tras el sinterizado. Estas características lo hacen ideal para la fabricación de grandes volúmenes de componentes estructurales.

| Propiedad | Especificación FL-4205 (Sinterizado) |

|---|---|

| Densidad | 6.8 - 7,2 g/cm³ |

| Resistencia a la tracción | Hasta 700 MPa |

| Límite elástico | Hasta 500 MPa |

| Dureza (HRB) | 80 - 95 |

| Alargamiento | 1 - 3% |

Aplicaciones industriales del polvo FL-4205

La resistencia mecánica y al desgaste del FL-4205 lo convierten en un material versátil en diversos campos industriales. A continuación se indican los sectores clave que utilizan esta calidad en polvo.

Industria del automóvil

- Piezas de transmisióncomo cubos y engranajes sincronizadores

- Componentes del chasis: brazos de torsión, soportes de control

- Piezas de motor: guías de válvulas, balancines

Maquinaria industrial

- Bombas y compresoressuperficies de apoyo resistentes al desgaste

- Conjuntos de engranajes utilizados en robótica y automatización

- Ejes y acoplamientos de alta carga

Herramientas eléctricas y manuales

- Componentes del martillo perforador

- Discos de embrague

- Elementos de herramientas rotativas

Maquinaria agrícola y de construcción

- Casquillos y espaciadores utilizados en entornos difíciles

- Soportes estructurales que requieren una gran capacidad de carga

| Sector industrial | Aplicaciones típicas del FL-4205 |

|---|---|

| Automotor | Cubos sincronizadores, componentes del tren de válvulas |

| Maquinaria industrial | Carcasas de engranajes, ejes, portaherramientas |

| Construcción | Soportes de montaje, casquillos |

| Herramientas y herrajes | Componentes de taladro, piezas de embrague |

Propiedades del material y características de rendimiento

FL-4205 está diseñado para ofrecer una combinación equilibrada de resistencia, compresibilidad y densidad sinterizada. Su rendimiento puede mejorarse aún más con operaciones secundarias como el endurecimiento por sinterización, el tratamiento con vapor o la impregnación con aceite.

Principales características mecánicas

- Alta resistencia en verde: Permite diseños de piezas complejos y reduce los daños por expulsión.

- Buena densidad sinterizada: Garantiza la precisión dimensional y la fiabilidad mecánica.

- Excelente maquinabilidad: Especialmente cuando se combina con aditivos como el sulfuro de manganeso (MnS).

Compatibilidad con aditivos

Para optimizar aún más el rendimiento de FL-4205, Truer ofrece una variedad de aditivos pulvimetalúrgicos:

- Lubricantes: SUW-5000B y SUW-8000 para mejorar la compactación.

- Agentes de corte: SME-100 (sin azufre), TD-8 (compuesto).

- Aditivos magnéticos blandos: QH-150 para piezas electromagnéticamente activas.

- Aditivos de grafito: TBC-400 y TBC-1000 para ajustar el contenido de carbono.

Estas opciones permiten a ingenieros y fabricantes personalizar las propiedades finales de los componentes FL-4205, adaptándolos a aplicaciones específicas.

| Tipo de aditivo | Nombre del producto | Beneficio |

|---|---|---|

| Lubricantes | SUW-5000B | Mejora de la compactación y la expulsión |

| Agentes de corte | PYME-100 | Maquinabilidad mejorada |

| Aditivos magnéticos | QH-150 | Mejores propiedades magnéticas blandas |

| Aditivos de grafito | TBC-400 | Control del contenido de carbono |

Para más información sobre FL-4205 y otros Opciones de polvo PMvisite el catálogo de productos de Truer.

Tendencias del mercado mundial y previsión de la demanda

La demanda de componentes pulvimetalúrgicos, especialmente los fabricados con polvo FL-4205, sigue creciendo en todo el mundo debido a la creciente adopción de la fabricación ligera y rentable en todas las industrias. Esta sección explora el panorama actual del mercado, las proyecciones de crecimiento y lo que significa para los compradores y distribuidores.

Panorama mundial de la industria PM

El mercado mundial de la pulvimetalurgia se valoró en aproximadamente 28 000 millones de USD en 2023 y se prevé que alcance los 40 000 millones de USD en 2030, creciendo a una TCAC del 5,2%. El polvo FL-4205 contribuye de forma decisiva a este crecimiento gracias a su:

- Versatilidad en aplicaciones estructurales

- Rentabilidad para la producción a gran escala

- Compatibilidad con los procesos modernos de endurecimiento por sinterización

Impulsores del mercado para FL-4205

- Aligeramiento en automoción: Cada vez más fabricantes de automóviles recurren a piezas de PM para reducir el peso de los vehículos y mejorar la eficiencia del combustible.

- Electrificación de equipos: La demanda de piezas PM ligeras y conductoras de la electricidad está creciendo en los vehículos eléctricos y la automatización industrial.

- Presión sobre la sostenibilidad: FL-4205 admite la fabricación casi en forma de red, lo que minimiza los residuos y reduce la huella de carbono.

| Motor del mercado | Impacto en la demanda de FL-4205 |

|---|---|

| Crecimiento de la industria del automóvil | Alta - Piezas estructurales de automóviles |

| Electrificación y automatización | Medio - Gear & demanda de rodamientos |

| Iniciativas de fabricación ecológica | Alta - Producción energéticamente eficiente |

| Auge del sector manufacturero en Asia-Pacífico | Muy alta - Producción de PM a granel |

Desglose regional de la demanda

| Región | Industrias clave que utilizan FL-4205 | Cuota de mercado (%) |

|---|---|---|

| Asia-Pacífico | Automoción, Maquinaria | 45% |

| Norteamérica | Herramientas, Aeroespacial | 30% |

| Europa | Automoción, Robótica | 20% |

| Resto del mundo | Equipamiento industrial | 5% |

Este aumento de la demanda sitúa al FL-4205 como un material estratégico para compradores y distribuidores que deseen ampliar sus carteras.

Cómo seleccionar el proveedor de polvo FL-4205 adecuado

Para los responsables de compras, fabricantes de equipos originales y distribuidores, elegir un proveedor fiable de polvo FL-4205 es fundamental para garantizar la calidad del producto y la continuidad de la cadena de suministro. Estos son los factores clave que hay que evaluar para abastecerse de este polvo:

1. Calidad y consistencia del polvo

- Compruebe si tiene la certificación MPIF o ISO.

- Solicite datos sobre la distribución granulométrica (PSD) y la fluidez.

- Verificar los métodos de producción (por ejemplo, atomizado con agua, aleación por difusión).

2. Capacidades de personalización

¿Puede el proveedor ajustar los niveles de carbono, el contenido de cobre u ofrecer aditivos de valor añadido como lubricantes o potenciadores de la maquinabilidad?

3. Estabilidad de la cadena de suministro

- ¿Mantiene el proveedor un inventario constante?

- ¿Son capaces de realizar entregas masivas, puntuales y globales?

4. Asistencia técnica y documentación

- Fichas técnicas

- FDS y certificaciones de conformidad

- Servicios de consultoría en ingeniería

| Criterios de evaluación | Por qué es importante |

|---|---|

| Pureza del polvo & PSD | Impacta en la consistencia de la sinterización |

| Opciones de personalización | Adapta el polvo a la aplicación |

| Certificaciones y normas | Garantiza la calidad y la trazabilidad |

| Capacidad de entrega mundial | Apoya proyectos internacionales |

Principales proveedores de FL-4205 en polvo en Asia

Asia-Pacífico alberga a varios proveedores líderes de polvo FL-4205. La madurez de la cadena de suministro y los bajos costes de producción de la región la convierten en un atractivo destino de abastecimiento para los compradores mundiales.

1. Shanghai Truer Technology Co., Ltd (China)

- Establecido: 2009

- Lanzamiento de PM Business: 2019

- Especialidad: FL-4205 aleado con agua/difusión y aditivos completos

- Certificaciones: Conforme a las normas ISO y MPIF

Ventajas clave:

- Amplia gama de productos que incluye FL-4205, FD-0208 y polvos prealeados

- Soluciones de aditivos a medida (por ejemplo, grafito QHP-330, agentes de corte SME-100)

- Instalaciones propias de producción de polvo e I+D

más información Shanghai Truer’antecedentes y capacidades

2. Hoganas (China y Suecia)

- Líder mundial en polvos PM

- Ofrece FL-4205 bajo nombres propios

- I+D avanzado para aplicaciones de endurecimiento por sinterización

3. GKN Hoeganaes (India)

- Ofrece polvos PM híbridos de baja aleación

- Fuerte apoyo técnico en Asia

- Suministros a fabricantes de equipos originales y de primer nivel del sector de la automoción

| Nombre del proveedor | Puntos fuertes | Ubicación |

|---|---|---|

| Shanghái Truer | Servicio completo de polvos PM + I+D de aditivos | China |

| Hoganas | Líder mundial, amplia cartera de grados | China/Suecia |

| GKN Hoeganaes | Especialización en automoción, alcance mundial | India |

Estos proveedores ofrecen cantidades al por mayor, calidades personalizadas y asistencia técnica, lo que resulta ideal para compradores B2B y fabricantes OEM.

Por qué cada vez más compradores se abastecen de polvos PM en China

China se ha convertido en un centro mundial de abastecimiento de materiales pulvimetalúrgicos, incluido el FL-4205, debido a su:

Ventajas competitivas

- Menores costes de producción

- Tecnologías avanzadas de atomización y aleación

- Producción constante a gran escala

- Apoyo gubernamental a la fabricación de gama alta

Infraestructura logística y de la cadena de suministro

- Sólidas redes de transporte marítimo y ferroviario

- Apoyo al comercio electrónico transfronterizo

- Plazos de entrega cortos y servicio de atención al cliente ágil

| Razones para abastecerse en China | Beneficio empresarial |

|---|---|

| Economías de escala | Menor coste por kg |

| Innovación tecnológica | Calidad y pureza constantes |

| Canales de exportación establecidos | Entrega mundial fiable |

| Diversa base de proveedores | Más opciones de personalización |

Shanghai Truer, por ejemplo, aprovecha estas ventajas para ofrecer a los compradores industriales una solución de abastecimiento de FL-4205 fiable y rentable. Puede explorar su gama completa de materiales pulvimetalúrgicos aquí.

Por qué elegir Shanghai Truer como su proveedor de polvo FL-4205

A medida que aumenta la demanda mundial de materiales pulvimetalúrgicos de alto rendimiento, los compradores y los responsables de compras dan cada vez más prioridad a la fiabilidad, la experiencia técnica y la capacidad de personalización de los proveedores. Shanghai Truer Technology Co., Ltd. destaca como socio B2B de confianza para la venta al por mayor de polvo FL-4205 y otros materiales de grado PM.

Presentación de la empresa

Shanghai Truer Technology Co, Ltd se fundó en 2009 y entró formalmente en la industria de la fabricación aditiva y la pulvimetalurgia en 2019. Con más de una década de experiencia en el procesamiento de polvo y un fuerte enfoque en la innovación, Truer se ha forjado una reputación como uno de los proveedores de aditivos más profesionales de China.

| Atributo | Detalles |

|---|---|

| Fundada | 2009 |

| Inicio de la actividad PM | 2019 |

| Especialización | Polvos PM, aditivos, polvos de impresión 3D |

| Métodos de producción | Atomizado con agua, atomizado con gas, carbonilo, aleado por difusión |

| Certificaciones | Cumplimiento del grado MPIF, normas de fabricación ISO |

| Experiencia en exportación | Atiende a clientes de Asia, Europa y Norteamérica |

Por qué los compradores B2B confían en Truer

- Cartera completa de polvos

Truer no sólo ofrece FL-4205, sino también una amplia gama de calidades PM, como FD-0208, FX-2008, FN-0205, FC-0208 y muchas más. Tanto si necesita polvos de acero híbridos de baja aleación, prealeados o aleados por difusión, Truer le tiene cubierto. - Soluciones aditivas integradas

La División de Aditivos de Truer ofrece productos patentados como:- Lubricantes: Lube-W, SUW-5000B, SUW-8000

- Agentes de corte: SME-100 (sin azufre), TD-8

- Aditivos de grafito: TBC-400, TBC-1000

- Aditivos magnéticos blandos: QH-150, QHP-330

- Personalización y asistencia técnica

Truer colabora estrechamente con fabricantes de equipos originales y distribuidores para desarrollar composiciones de polvo y mezclas de aditivos a medida para aplicaciones específicas, garantizando la calidad desde la creación de prototipos hasta la producción a gran escala. - Logística mundial eficiente

Con una red de exportación bien establecida y asistencia multilingüe, Truer garantiza a sus clientes internacionales una entrega puntual y una comunicación fluida.

👉 Más información sobre Truer's perfil y capacidades de la empresa

Cómo hacer un pedido al por mayor de FL-4205 en polvo

Para los compradores B2B, pedir polvo FL-4205 a granel requiere evaluar las especificaciones técnicas, los plazos de entrega y las estructuras de precios. He aquí una guía paso a paso para ayudar a los compradores a abastecerse de Shanghai Truer de manera eficiente.

Proceso de pedido paso a paso

- Enviar consulta

- Visite Truer's página de contacto

- Indique sus especificaciones: cantidad, grado (FL-4205), granulometría y lugar de entrega.

- Consulta técnica

- El equipo técnico de Truer confirmará las características del polvo y sugerirá aditivos opcionales para mejorar el rendimiento.

- Presupuesto y plazo de entrega

- Recibirá un presupuesto detallado con precios FOB/EXW, plazos de entrega y opciones de embalaje.

- Aprobación de muestras (opcional)

- Solicite muestras de polvo para probarlas en su proceso antes de comprometerse a comprar a granel.

- Confirmación de pedido a granel

- Finalizar el pedido con las condiciones contractuales y el acuerdo de pago.

- Producción & Envío

- Truer fabrica su pedido, realiza controles de calidad y lo envía por vía marítima, aérea o terrestre.

Opciones de envasado disponibles

| Tamaño del envase | Descripción | Caso práctico |

|---|---|---|

| sacos de 25 KG | Bolsas estándar de PE con forro Kraft | Producción piloto, I+D |

| bidones de 500 KG | Bidones de acero sellados con camisas | Fabricación de volumen medio |

| palés de 1000 KG | Paletizados para facilitar su manipulación | Aprovisionamiento de grandes volúmenes de OEM |

Opciones de personalización

Los compradores pueden solicitarlo:

- Distribución granulométrica específica (por ejemplo, <150µm)

- Aditivos en polvo premezclados

- Relaciones de aleación únicas basadas en los requisitos de carga de la aplicación

🔗 Explora Truer al completo Catálogo de polvos PM para comparar las calidades disponibles a granel.

Preguntas frecuentes sobre la compra de FL-4205 en polvo al por mayor

Para ayudar a los profesionales de las compras y a los distribuidores, hemos recopilado las respuestas a las preguntas más frecuentes sobre el abastecimiento de FL-4205 de Shanghai Truer.

P1: ¿Cuál es la cantidad mínima de pedido (MOQ) para el polvo FL-4205?

A: La cantidad mínima de referencia (MOQ) habitual es de 500 kg para pedidos al por mayor. Sin embargo, pueden acordarse cantidades menores para series piloto o fines de I+D.

P2: ¿Puedo solicitar mezclas de aditivos personalizadas con mi polvo FL-4205?

A: Sí. Truer se especializa en la personalización de aditivos. Los compradores pueden solicitar mezclas con grafito, lubricantes, agentes de corte o modificadores magnéticos.

P3: ¿Qué documentación técnica se proporciona?

A: Cada envío incluye:

- Certificado de análisis (COA)

- Ficha de datos de seguridad (FDS)

- Informe sobre la distribución granulométrica

- TDS y asesoramiento técnico, si es necesario

P4: ¿Cuánto se tarda en recibir un pedido?

A: Los plazos de entrega suelen oscilar entre 2 y 4 semanas, dependiendo del volumen del pedido y de la personalización. Se pueden negociar pedidos rápidos.

P5: ¿Es compatible el polvo FL-4205 con los procesos de endurecimiento por sinterización?

A: Sí. FL-4205 es adecuado para procesos de endurecimiento por sinterización e impregnación de aceite, y Truer puede ajustar la química del polvo para optimizar la dureza y la tenacidad.

P6: ¿Realiza Truer envíos internacionales?

A: Absolutamente. Truer tiene una amplia experiencia en exportación y realiza envíos a Norteamérica, Europa, Sudeste Asiático y Oriente Medio con un completo apoyo logístico.

P7: ¿Cómo empiezo?

A: Visite el Contáctenos para solicitar un presupuesto o hablar con un asesor técnico.

Resumen de enlaces internos incrustados

Estos son los enlaces internos de anclaje añadidos a lo largo del artículo para mejorar el SEO y la navegación de los usuarios:

| Texto de anclaje utilizado | URL incrustada |

|---|---|

| Opciones de polvo PM | https://am-material.com/pm-powder/ |

| Shanghai Truer’antecedentes y capacidades | https://am-material.com/about/ |

| Materiales pulvimetalúrgicos | https://am-material.com/pm-powder/ |

| Perfil de la empresa y capacidades | https://am-material.com/about/ |

| Contáctenos | https://am-material.com/contact-us/ |

Al elegir Shanghai Truer como su proveedor de polvo FL-4205, se está asociando con una empresa técnicamente avanzada y centrada en el cliente que entiende las necesidades de la fabricación moderna. Si usted es un OEM, distribuidor o comprador de alto volumen, Truer ofrece la calidad del producto, soporte técnico y escalabilidad necesaria para tener éxito en un mercado competitivo.

👉 ¿Listo para solicitar un presupuesto o una consulta técnica? Visite Página de contacto de Truer hoy.