1. Introducción al polvo de FeCu18 y su relevancia industrial

El polvo FeCu18 es un polvo prealeado de hierro-cobre que contiene aproximadamente un 18% de cobre en peso. Esta composición ofrece una combinación única de resistencia mecánica, conductividad térmica y excelente comportamiento de sinterización, lo que convierte al FeCu18 en un material ideal para la fabricación de componentes pulvimetalúrgicos.

Las piezas PM de alto rendimiento, como casquillos, engranajes, componentes de árboles de levas y piezas estructurales, requieren a menudo la durabilidad y maquinabilidad que proporciona el FeCu18. Gracias a sus sólidas propiedades metalúrgicas y a su rentabilidad, el FeCu18 es ampliamente utilizado por:

- OEM de automoción y proveedores de primer nivel

- Fabricantes de equipos industriales

- Productores de componentes de conductividad eléctrica y térmica

- Los compradores B2B de comercio electrónico se abastecen de piezas PM

Por qué el FeCu18 está ganando adeptos en el mercado B2B

- ✅ Excelente resistencia al desgaste y solidez

- ✅ Alta resistencia en verde para una mayor eficacia de prensado

- ✅ Compatible con los métodos de atomización por agua y por gas

- ✅ Rentable frente a otros sistemas de aleación

- ✅ Ideal para la producción de grandes volúmenes con una calidad constante

2. Aplicaciones del polvo FeCu18 en pulvimetalurgia

El perfil de material único del polvo de FeCu18 lo hace adecuado para una amplia gama de aplicaciones en industrias que exigen tanto resistencia mecánica como rendimiento térmico.

Industria del automóvil

- Cubos sincronizadores

- Bujes de transmisión

- Componentes deslizantes

- Tapas de cojinete del árbol de levas

Eléctrico & Aplicaciones térmicas

- Conectores eléctricos

- Disipadores térmicos e interfaces térmicas

- Componentes PM conductivos

Industrial & Piezas estructurales

- Componentes de la cerradura

- Ruedas dentadas

- Piezas de maquinaria agrícola

| Área de aplicación | Pieza PM típica | Principales ventajas del FeCu18 |

|---|---|---|

| Automotor | Bujes, engranajes | Resistencia al desgaste, maquinabilidad |

| Eléctrico | Conectores | Alta conductividad |

| Industrial | Piezas estructurales | Fuerza, rendimiento |

3. Propiedades del material y especificaciones técnicas del FeCu18

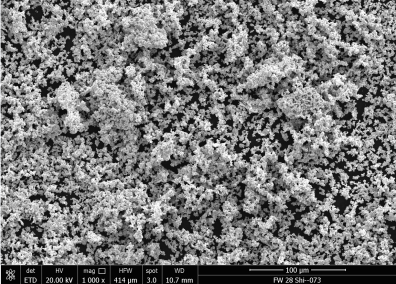

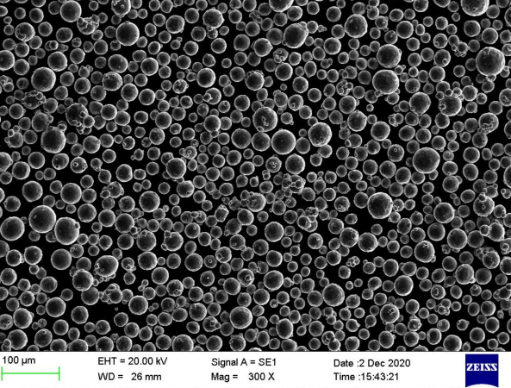

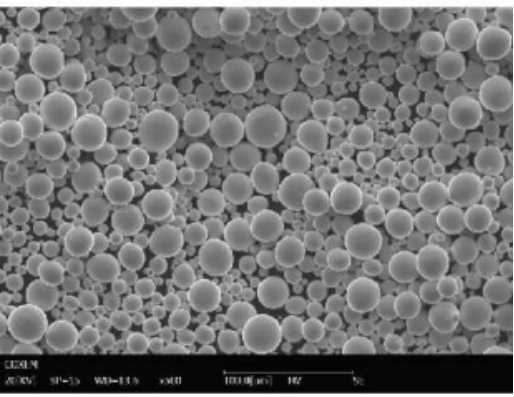

El polvo de FeCu18 está diseñado para equilibrar resistencia, ductilidad, conductividad térmica y sinterizabilidad. El polvo puede prepararse mediante atomización con agua o con gas, en función de los requisitos específicos de la aplicación.

Composición típica

| Elemento | Contenido (% en peso) |

|---|---|

| Hierro (Fe) | Saldo |

| Cobre (Cu) | 18% ± 1 |

| Carbono (C) | ≤ 0.02 |

| Oxígeno (O) | ≤ 0.3 |

Propiedades físicas

| Propiedad | Valor |

|---|---|

| Densidad aparente | 2.5 - 3,2 g/cm³ |

| Caudal (Hall) | 30 s/50g |

| Temperatura de sinterización | 1120-1150°C |

| Tamaño de partícula | 75-150 μm (personalizable) |

Características principales

- ✅ Excelente compresibilidad

- ✅ Contracción de sinterización uniforme

- ✅ Resistente a la oxidación durante la sinterización

- ✅ Propiedades mecánicas adecuadas para cargas dinámicas

Shanghai Truer Technology Co., Ltd ofrece Polvo de FeCu18 en múltiples especificaciones adecuados para aplicaciones de automoción, térmicas e industriales. Sus polvos se producen mediante atomización con agua y cumplen estrictas normas de calidad, lo que garantiza un rendimiento constante en la producción en serie.

4. Tendencias del mercado mundial y demanda de FeCu18

La demanda de polvo de FeCu18 se ha disparado en los últimos años, impulsada por la creciente adopción de la pulvimetalurgia (PM) en los sectores automovilístico, industrial y eléctrico. Dado que los fabricantes siguen buscando materiales rentables y de alto rendimiento, el FeCu18 destaca por su equilibrio entre resistencia, mecanizabilidad y conductividad.

Principales impulsores del mercado

- Electrificación del automóvil: Aumento del uso de piezas PM en VE y vehículos híbridos.

- Objetivos de sostenibilidad: La eficiencia de la fabricación PM’cercana a la forma neta reduce el desperdicio de material.

- Diversificación de la cadena mundial de suministro: Los compradores están diversificando sus fuentes de aprovisionamiento para incluir a proveedores asiáticos por las ventajas de coste y disponibilidad.

- Avances tecnológicos: El perfeccionamiento de las tecnologías de atomización y mezcla de polvos ha mejorado la calidad y consistencia del FeCu18.

Previsiones de mercado

| Región | CAGR (2024-2029) | Segmento de aplicación principal |

|---|---|---|

| Norteamérica | 5.1% | Automoción, Maquinaria industrial |

| Europa | 4.6% | Eléctrico, Automoción |

| Asia-Pacífico | 6.3% | Automoción, Comercio electrónico Piezas PM |

El FeCu18 es especialmente importante en los mercados en desarrollo, donde existe una gran necesidad de componentes PM asequibles y duraderos. Los compradores de estas regiones recurren cada vez más a proveedores fiables con capacidad de integración vertical, como Shanghai Truer Technology Co.

5. Consideraciones clave al seleccionar un proveedor de polvo de FeCu18

Elegir al proveedor de FeCu18 adecuado es esencial para mantener la calidad del producto, los plazos de producción y la rentabilidad. A continuación se enumeran los factores críticos que deben evaluarse al abastecerse de polvo de FeCu18 a granel:

1. Consistencia del polvo y control de calidad

- ¿Proporciona el proveedor coherencia entre lotes?

- ¿Se comprueba el tamaño de las partículas, la fluidez y la sinterabilidad del polvo?

2. Método de atomización

- La atomización con agua ofrece ventajas económicas y es adecuada para piezas estructurales.

- La atomización con gas proporciona una morfología del polvo superior para aplicaciones de precisión.

3. Asistencia técnica y personalización

- ¿Puede el proveedor adaptar el contenido de cobre o el tamaño de las partículas?

- ¿Ofrecen mezclas para aplicaciones específicas?

4. Conformidad y certificaciones

- ISO 9001 o normas específicas del sector (por ejemplo, IATF 16949 para automoción)

- Conformidad con REACH y RoHS para distribución mundial

5. Cadena de suministro y logística

- ¿Almacenes regionales o envíos rápidos a todo el mundo?

- Opciones de embalaje para pedidos al por mayor o personalizados

| Factor de evaluación | Por qué es importante | Shanghai Truer’s Advantage |

|---|---|---|

| Calidad del polvo | Garantiza la fiabilidad del producto | Protocolos estrictos de control de calidad y pruebas de laboratorio |

| Personalización | Adaptado a las aplicaciones del cliente | Especificaciones y métodos de procesamiento flexibles |

| Asistencia técnica | Integración fluida en la producción | Consultores profesionales en aditivos PM |

| Logística | Reduce los plazos de entrega y los gastos de envío | Red mundial de distribución |

Para obtener más información sobre las capacidades de aditivos de Truer, visite su Acerca de la página.

6. Top FeCu18 Polvo Proveedores y Distribuidores en el Mundo

A continuación encontrará una lista de algunos de los proveedores de FeCu18 en polvo más reconocidos en el mercado global B2B:

| Nombre del proveedor | Región | Aspectos destacados y capacidades |

|---|---|---|

| Shanghai Truer Technology Co., Ltd | China | Amplia gama de polvos PM, atomización personalizada, experiencia en aditivos |

| Höganäs AB | Suecia | Líder mundial en PM, amplia I+D, polvos de hierro de alta calidad |

| Polvos metálicos de Río Tinto | Canadá | Integración vertical, fuerte presencia norteamericana |

| GKN Hoeganaes | EE.UU. | Polvos PM para automoción, distribución mundial |

| CNPC Polvo | China | Precios competitivos, volúmenes flexibles, gran capacidad de exportación |

Por qué destaca Shanghai Truer

Shanghai Truer Technology Co., Ltd es uno de los proveedores de polvo de FeCu18 más fiables de China. Con más de una década de experiencia en materiales PM y un fuerte enfoque en la integración aditiva y la personalización, Truer ofrece un valor excepcional a los compradores B2B de todo el mundo.

Puntos fuertes:

- ✅ Creada en 2009, la división de aditivos se puso en marcha en 2019

- ✅ Ofrece FeCu18 atomizado tanto en agua como en gas

- ✅ Gama completa de aditivos para MP, incluidos lubricantes, grafito y agentes de corte

- ✅ Distribución granulométrica personalizada, envasado y asistencia técnica

- ✅ Sólida cartera de clientes nacionales e internacionales

Puede consultar toda la gama de productos Truer’ aquí.

7. Por qué los compradores recurren a los fabricantes chinos de FeCu18

Los compradores mundiales, incluidos fabricantes de equipos originales, distribuidores y mayoristas de comercio electrónico, se abastecen cada vez más de FeCu18 de fabricantes chinos. Esta tendencia está impulsada por varias ventajas competitivas:

Ahorro de costes

- Los menores costes de producción y mano de obra en China permiten precios más competitivos.

Escala de fabricación

- Los proveedores chinos de PM, como Truer, operan en grandes instalaciones, lo que permite una producción de gran volumen y plazos de entrega más cortos.

Personalización y flexibilidad

- Las fórmulas en polvo a medida y los plazos de entrega son más fáciles de negociar.

Avances en calidad

- Las modernas tecnologías de atomización, el estricto control de calidad y los procesos con certificación ISO han elevado la calidad del polvo de PM chino a niveles mundiales.

| Motivo del cambio | Ventajas para los compradores B2B |

|---|---|

| Eficiencia de costes | entre un 15 y un 40% más barato que los proveedores occidentales |

| Plazos de entrega más cortos | Entrega puntual para grandes volúmenes |

| Personalización de productos | Granulometría específica de la aplicación & mezclas |

| Certificaciones mundiales | Cumplimiento de las normas ISO, RoHS y REACH |

Shanghai Truer es un ejemplo destacado de este cambio, ya que ofrece contactar con el servicio de asistencia y asesoramiento técnico a clientes de todo el mundo.

8. Cómo pedir polvo de FeCu18 al por mayor a Shanghai Truer

Shanghai Truer Technology Co., Ltd ha agilizado el proceso de pedido para los clientes B2B globales. Tanto si compra por primera vez como si es un socio a largo plazo, Truer proporciona un flujo de trabajo de aprovisionamiento fluido, transparente y eficiente.

Proceso de pedido paso a paso

| Paso | Descripción |

|---|---|

| 1. Consulta sobre el producto | Visite el FeCu18 polvo página y envíe una solicitud con sus requisitos específicos: cantidad, tamaño de partícula, método de atomización, especificaciones técnicas y plazo de entrega. |

| 2. Consulta técnica | Un especialista de Truer PM se pondrá en contacto con usted para confirmar las especificaciones técnicas y ofrecerle recomendaciones basadas en su aplicación (por ejemplo, automoción, electricidad, estructuras). |

| 3. Presupuesto y muestras | Reciba un presupuesto formal y, si lo desea, muestras de material para pruebas y validación. Truer puede realizar pruebas de pequeños lotes para OEM y equipos de I+D. |

| 4. Contrato y pago | Finalizar los términos del contrato, incluido el pago (T/T, L/C disponible), los Incoterms y el método de entrega (FOB, CIF, DDP). |

| 5. Producción & Control de calidad | Tras la confirmación del pedido, Truer inicia la fabricación y realiza inspecciones de calidad durante el proceso. En cada lote se comprueba la composición, el caudal y la distribución granulométrica. |

| 6. Embalaje y envío | Los polvos se envasan en bidones o bolsas sellados, antiestáticos y a prueba de humedad (etiquetado personalizado disponible). Documentos de exportación y MSDS incluidos. |

| 7. Asistencia posventa | Truer proporciona asistencia posterior a la entrega, que incluye asistencia técnica, nuevos pedidos y resolución de problemas de aplicación. |

Opciones de envasado

| Tipo de envase | Volumen | Características |

|---|---|---|

| Bolsas de vacío | 5-25 kg | Ideal para uso a pequeña escala o I+D |

| Tambores de fibra | 50-250 kg | Envase a granel, forro antihumedad |

| Palés a medida | 500 kg | Para el transporte en contenedores |

Para más información o para solicitar un presupuesto, visite la página oficial de Truer Página de contacto.

9. Preguntas frecuentes: Compra y uso de polvo de FeCu18 a granel

A continuación figuran las preguntas más frecuentes de los equipos de compras, ingenieros y distribuidores PM que se plantean la compra a gran escala de polvo de FeCu18.

P1: ¿Cuál es la vida útil del polvo de FeCu18?

- Respuesta: Cuando se almacena en un recipiente seco y sellado a temperatura ambiente, el polvo de FeCu18 tiene una vida útil de hasta 12 meses sin degradación de su rendimiento.

P2: ¿Es el polvo de FeCu18 compatible con todos los hornos de sinterización?

- Respuesta: Sí. El FeCu18 puede sinterizarse en hornos de cinta continua estándar o en hornos de sinterización por lotes. La sinterización óptima se consigue a 1120-1150°C en una atmósfera reductora (por ejemplo, hidrógeno o amoníaco disociado).

P3: ¿Puedo solicitar un contenido de cobre o un tamaño de partícula personalizados?

- Respuesta: Absolutamente. Truer ofrece servicios de mezcla personalizada para proporcionar un contenido específico de cobre (±1%) y distribuciones de tamaño de partículas (por ejemplo, D50 = 75 μm) para satisfacer sus necesidades exactas de aplicación.

P4: ¿Cuál es la cantidad mínima de pedido?

- Respuesta: Para pedidos internacionales, el MOQ suele ser de 100 kg. No obstante, se pueden considerar pedidos de prueba más pequeños para nuevos clientes o proyectos de I+D.

P5: ¿Proporciona Truer asistencia técnica para el diseño de piezas o la optimización de la sinterización?

- Respuesta: Sí. La división de aditivos de Truer incluye un equipo de ingenieros expertos en pulvimetalurgia que pueden ayudarle con la selección de materiales, la optimización de procesos y el análisis de propiedades tras la sinterización. Puede obtener más información sobre sus servicios de aditivos PM aquí.

P6: ¿Qué métodos de atomización existen para el FeCu18?

- Respuesta: El polvo de FeCu18 de Truer puede suministrarse a través de:

- Atomización con agua (WA): Rentable, adecuada para aplicaciones estructurales.

- Atomización por gas (GA): Partículas esféricas, ideales para componentes de alta precisión.

- Atomización híbrida: Combina las ventajas de WA y GA para soluciones personalizadas.

Reflexiones finales: Asociación con Shanghai Truer para FeCu18

La demanda de polvo de FeCu18 sigue aumentando en todos los sectores que dependen de componentes PM rentables y de alto rendimiento. Para los compradores, fabricantes de equipos originales y distribuidores que buscan un proveedor de confianza, flexible y técnicamente avanzado, Shanghai Truer Technology Co. ofrece una solución convincente.

Por qué destaca Truer:

- ✅ Más de 15 años de excelencia en pulvimetalurgia

- ✅ Capacidades internas completas de atomización, mezcla y pruebas

- ✅ Aditivos para MP personalizados y asistencia técnica

- ✅ Experiencia demostrada en exportación con clientes B2B globales

- ✅ Precios competitivos y plazos de entrega fiables

Explore la gama completa de soluciones pulvimetalúrgicas de Truer y comience hoy mismo con su pedido de FeCu18 visitando su sitio web oficial.

🔗 Recapitulación de enlaces de anclaje interno (5 enlaces incrustados para SEO)

- FeCu18 polvo página - Detalles y especificaciones del producto

- Página de contacto - Consultas y solicitudes de presupuesto

- Acerca de la página - Antecedentes de la empresa y división de aditivos

- Sitio web oficial - Explorar todos los productos y servicios PM

- FeCu18 polvo página de producto - Opciones de pedido y personalización