1. Introducción: Qué es el polvo de FeCu10 y por qué es importante

El polvo FeCu10 es un polvo prealeado de hierro-cobre que contiene aproximadamente un 10% de cobre en peso. Se utiliza mucho en aplicaciones de pulvimetalurgia debido a sus excelentes propiedades mecánicas, su mayor sinterizabilidad y su rentabilidad. Este material es una buena opción en sectores como la automoción, la maquinaria y la electrónica de consumo, donde la fuerza, la resistencia al desgaste y la conductividad térmica son fundamentales.

Por qué FeCu10 es importante para los compradores B2B

- Gran demanda en la producción de piezas estructurales de PM

- Excelente maquinabilidad y estabilidad dimensional tras la sinterización

- Rentable alternativa a los aceros de mayor aleación

- Ideal para componentes de automoción como cubos sincronizadores, engranajes y bujes

Industrias que utilizan FeCu10 en polvo:

| Industria | Ejemplos de aplicación |

|---|---|

| Automotor | Engranajes, sincronizadores, cubos de embrague |

| Maquinaria | Rodamientos, componentes estructurales |

| Electrónica de consumo | Disipadores térmicos, conectores |

| Equipamiento industrial | Bujes, espaciadores, piezas deslizantes |

2. Aplicaciones industriales del FeCu10 en pulvimetalurgia

El polvo de FeCu10 es especialmente apreciado en la industria pulvimetalúrgica por su adaptabilidad a diversos entornos de sinterización y su capacidad para mejorar el rendimiento de los componentes.

Aplicaciones clave

- Sector del automóvil: Se utiliza en la producción en serie de componentes de alto desgaste.

- Bienes de consumo: Adecuado para aplicaciones que requieren una buena conductividad térmica.

- Maquinaria industrial: Ofrece buena solidez y resistencia a la fatiga.

- Herramientas y herrajes: A menudo se utiliza en piñones, poleas y levas.

Ventajas en pulvimetalurgia:

- Mayor resistencia de la sinterización debido a la difusión del cobre

- Porosidad reducida y densidad mejorada

- Mayor resistencia a la corrosión en comparación con el polvo de hierro puro

Ejemplo de uso de la pulvimetalurgia:

| Componente | Ventajas del uso de polvo de FeCu10 |

|---|---|

| Engranaje | Gran resistencia al desgaste y gran solidez |

| Casquillo | Buena maquinabilidad y conductividad térmica |

| Anillo sincronizador | Gran consistencia dimensional y durabilidad |

El polvo FeCu10 ofrece un rendimiento superior en piezas sinterizadas que requieren tanto resistencia como conductividad.

3. Propiedades y ventajas del polvo de FeCu10

El polvo FeCu10 está diseñado para cumplir las exigentes normas de la fabricación industrial. Combina la resistencia mecánica del hierro con las propiedades térmicas y eléctricas del cobre.

Composición química (típica)

| Elemento | Contenido (%) |

|---|---|

| Hierro | 89.0 - 90.0 |

| Cobre | 9.5 - 10.5 |

| Otros | <0.5 |

Propiedades físicas

| Propiedad | Valor |

|---|---|

| Densidad aparente | 2.5-3,0 g/cm³ |

| Caudal (Hall) | ≤40 s/50g |

| Compresibilidad | Alta, dependiendo de la compactación |

| Temperatura de sinterización | 1120-1150 °C |

Ventajas del uso de polvo de FeCu10:

- ✅ Excelente estabilidad dimensional tras la sinterización

- ✅ Alta resistencia en verde y resistencia sinterizada

- ✅ Bueno corrosión resistencia

- ✅ Rentable para la producción de grandes volúmenes

Idoneidad para diversos métodos de procesamiento:

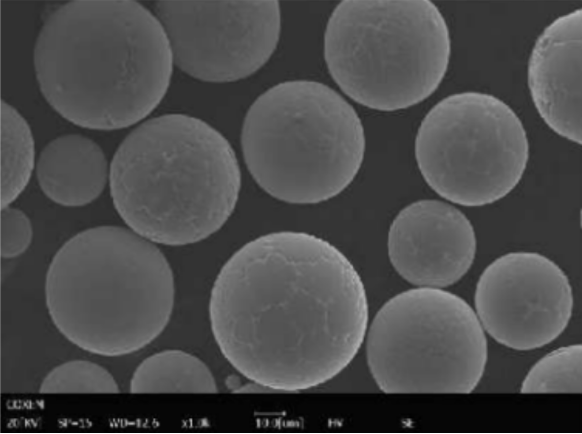

- El polvo de FeCu10 atomizado con agua es ideal para:

- Prensa & sinterización

- Compactación en caliente

- Técnicas de infiltración

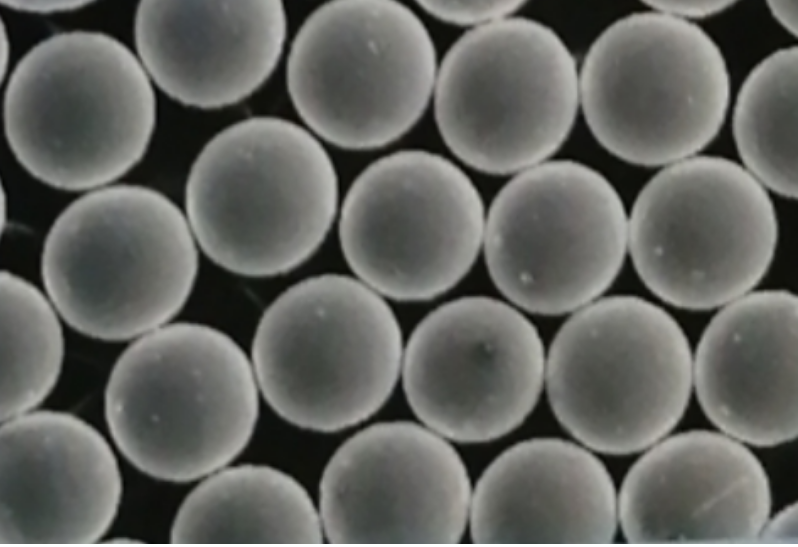

Shanghai Truer Technology Co., Ltd ofrece polvos de hierro-cobre FeCu10 de alta calidad producido mediante atomización con agua, lo que garantiza un tamaño uniforme de las partículas y una excelente fluidez. Puede obtener más información sobre su Productos en polvo PM para obtener especificaciones detalladas.

4. Tendencias del mercado del polvo de FeCu10 y previsión de la demanda

El polvo de FeCu10 está experimentando una creciente demanda en múltiples segmentos industriales, impulsada por el cambio global hacia componentes ligeros, rentables y de alto rendimiento. La pulvimetalurgia (PM) sigue aumentando como proceso de fabricación preferido, especialmente en los sectores de la automoción y la maquinaria.

Principales impulsores del mercado

- Electrificación del automóvil: Los materiales ligeros y termoconductores como el FeCu10 son esenciales en los componentes de los vehículos eléctricos.

- Automatización industrial: Aumento de la demanda de piezas PM en robótica y maquinaria de precisión.

- Optimización de costes: El FeCu10 ofrece una solución económica con propiedades mecánicas fiables, por lo que es ideal para la producción en serie.

Perspectivas del mercado mundial

| Región | Previsión de crecimiento (2024-2028) | Principales impulsores de la demanda |

|---|---|---|

| Asia-Pacífico | TACC 6,5 | Automoción, electrónica de consumo, herramientas industriales |

| Norteamérica | TACC 5,8 | Aeroespacial, defensa, componentes para vehículos eléctricos |

| Europa | TACC 4,9 | Energía verde, maquinaria de alto rendimiento |

| Oriente Medio | Emergentes | Infraestructuras, petróleo y gas |

Oportunidades de futuro

- Impresión 3d Integración: El FeCu10 se está estudiando en la fabricación aditiva basada en la extrusión de metales y el chorro de aglutinante.

- Fabricación ecológica: La reducción de los residuos y del consumo de energía en los procesos de PM hacen que el FeCu10 resulte atractivo para la producción sostenible.

Shanghai Truer Technology está estratégicamente posicionada para satisfacer esta creciente demanda mundial con su división especializada en pulvimetalurgia y su amplia línea de productos. Más información sobre la empresa aquí.

5. Elección del proveedor adecuado de polvo de FeCu10

Seleccionar al proveedor adecuado es esencial para mantener la calidad, la uniformidad y la rentabilidad en su línea de producción. Ya sea distribuidor, fabricante u OEM, estos son los criterios clave para evaluar a un proveedor de FeCu10.

Factores clave a tener en cuenta:

- Calidad y pureza del polvo: Busque proveedores que utilicen métodos de atomización fiables (por ejemplo, atomización con agua o gas).

- Distribución uniforme del tamaño de las partículas: Garantiza un comportamiento uniforme de compactación y sinterización.

- Opciones de personalización: Posibilidad de adaptar el polvo para aplicaciones específicas o requisitos de densidad.

- Escalabilidad del volumen: ¿Puede el proveedor gestionar pedidos al por mayor de forma coherente?

- Certificaciones: ISO 9001, REACH y otras normas de calidad pertinentes.

- Asistencia técnica: Asistencia en la optimización y resolución de problemas del proceso PM.

Lista de comprobación para la evaluación de proveedores:

| Criterios | Nivel de importancia | Tecnología Truer de Shanghai |

|---|---|---|

| Certificación ISO | ✅✅✅ | ✅✅✅ |

| Grados de polvo personalizados | ✅✅✅ | ✅✅✅ |

| I+D y asistencia técnica | ✅✅✅ | ✅✅✅ |

| Flexibilidad MOQ | ✅✅ | ✅✅✅ |

| Plazo de entrega | ✅✅✅ | ✅✅✅ |

| Experiencia mundial en exportación | ✅✅✅ | ✅✅✅ |

Shanghai Truer Technology destaca en todas estas áreas, ofreciendo soluciones de aditivos a medida y una línea completa de FeCu10 y polvos PM relacionados para la adquisición B2B a gran escala.

6. Principales proveedores mundiales y chinos de FeCu10 en polvo

Para ayudarle a tomar una decisión informada sobre su aprovisionamiento, aquí tiene un desglose de algunos de los principales proveedores de polvo de FeCu10 a nivel mundial, con especial atención a los fabricantes chinos, que están ganando rápidamente cuota de mercado gracias a la rentabilidad y las mejoras de calidad.

Principales proveedores mundiales de FeCu10 en polvo

| Nombre de la empresa | País | Puntos fuertes |

|---|---|---|

| Höganäs AB | Suecia | Líder mundial en polvos PM, amplia cartera |

| GKN Hoeganaes | EE.UU. | Fuerte orientación hacia la automoción y la I+D |

| Polvos metálicos de Río Tinto | Canadá | Producción de gran volumen, calidad constante |

Principales proveedores chinos de FeCu10 en polvo

| Nombre de la empresa | Puntos fuertes |

|---|---|

| Shanghai Truer Technology Co., Ltd | División PM establecida, diversos tipos de polvo, asistencia técnica, certificación ISO |

| CNPC Polvo | Producción a gran escala, amplia red de distribución |

| Maquinaria Changsha Tianjiu | Centrado en polvos de baja aleación y a base de hierro |

Por qué Shanghái es líder en China

- ✅ Fundada en 2009 con una división especializada en fabricación aditiva lanzada en 2019

- ✅ Ofrece ambos calidades de polvo estándar y personalizadas (por ejemplo, FeCu10, F0008, FD-0208)

- ✅ Métodos de atomización avanzados: agua, gas e híbridos

- ✅ Contactar con el equipo directamente para asistencia técnica o consultas sobre precios

Al asociarse con Shanghai Truer, los distribuidores y fabricantes de equipos originales obtienen acceso a un proveedor fiable y de gran capacidad que puedan satisfacer las necesidades cambiantes del mercado.

7. Por qué cada vez más compradores recurren a fuentes chinas de polvo de FeCu10

En los últimos años, las estrategias globales de adquisición han cambiado, y cada vez más compradores B2B, OEM y distribuidores eligen proveedores chinos para el polvo de FeCu10. Este cambio se debe a una combinación de rentabilidad, normas de calidad mejoradas y una sólida infraestructura de fabricación.

Razones clave del cambio:

- Ventaja de costes: Los polvos FeCu10 chinos suelen tener un precio entre un 20 y un 30% inferior al de sus homólogos occidentales sin comprometer la calidad.

- MOQs flexibles: Ideal tanto para compradores a pequeña escala como para grandes volúmenes.

- Capacidades de producción avanzadas: Muchos fabricantes utilizan atomización de agua y gas, produciendo polvos que cumplen las normas internacionales.

- Plazos de entrega más cortos: El aprovisionamiento local en Asia o el envío mundial rápido desde China reducen los ciclos de aprovisionamiento.

Comparación: Proveedores occidentales frente a chinos

| Característica | Proveedores occidentales | Proveedores chinos (por ejemplo, Shanghai Truer) |

|---|---|---|

| Precio por Kg | Más alto | Más competitivos |

| MOQ | Alta | Flexible (pequeños & grandes pedidos) |

| Personalización del polvo | Disponible | Gran flexibilidad |

| Asistencia técnica | Regional | Asistencia mundial con servicio en inglés |

| Plazos de entrega | 4-8 semanas | 1-3 semanas |

| Red logística | Maduro | En rápida expansión |

Para los compradores internacionales que buscan optimizar su cadena de suministro, abastecerse de polvo de FeCu10 de China -especialmente de proveedores de confianza como Tecnología Truer de Shanghai-pueden ofrecer una ventaja estratégica sin sacrificar la fiabilidad ni la calidad.

8. Por qué elegir Shanghai Truer Technology para el polvo de FeCu10

Shanghai Truer Technology Co., Ltd es un nombre líder en la industria pulvimetalúrgica china, conocida por su polvos de FeCu10 de gran purezala empresa cuenta con instalaciones de producción avanzadas y soluciones de aditivos de amplio espectro.

Visión general de la empresa:

- Fundada: 2009

- Se crea la División PM: 2019

- Especialización: Water & polvos metálicos atomizados con gas para aplicaciones de aditivos y PM

- Certificaciones: ISO 9001, producción conforme a la CE

- I+D: Equipo interno de desarrollo y personalización de polvos

FeCu10 Powder Highlights de Truer:

- ✅ Producido a través de atomización controlada del agua

- disponible en varios grados: F0008, FD-0208, FC-0208, FN-5000

- ✅ Excelente compresibilidad y sinterabilidad

- ✅ Distribución homogénea del tamaño de las partículas

- ✅ Pedidos al por mayor con precios competitivos

Cartera de polvos PM más amplia de Truer:

| Tipo de polvo | Ejemplo de notas | Aplicaciones |

|---|---|---|

| Polvos a base de hierro | F-0000, F0008, FD-0208 | Automoción, ferretería industrial |

| Polvos a base de cobre | FeCu10, FD-20Cu | Casquillos, conectores, disipadores de calor |

| Polvos de acero inoxidable | SBF2218, FX-2008 | Piezas y herramientas resistentes a la corrosión |

| Polvos de acero de baja aleación | FL-4605, FX1005 | Componentes de alta resistencia |

Puede consultar el informe completo de Truer Línea de productos en polvo PM para explorar otros materiales además del polvo de FeCu10.

Servicios adicionales de Truer:

- 📦 OEM & Embalaje de marca privada

- 🔬 Asesoramiento técnico para el diseño de piezas PM

- 🧪 Mezcla de polvos a medida para aplicaciones únicas

- 🌐 Logística global y documentación para la exportación

Si usted’está buscando un socio de confianza, experimentado y receptivo para la venta al por mayor de polvo de FeCu10, Truer destaca como una opción de primer nivel.

9. Preguntas frecuentes: Todo lo que debe saber sobre la compra de FeCu10 en polvo al por mayor

Estas son algunas de las preguntas más frecuentes que se hacen los distribuidores, fabricantes y compradores industriales a la hora de comprar FeCu10 en polvo.

P1: ¿Cuál es la cantidad mínima de pedido (MOQ) de FeCu10 en polvo?

A: Shanghai Truer ofrece MOQ flexibles en función de sus necesidades. Para los pedidos de prueba, cantidades más pequeñas (100-500 kg) están disponibles.

P2: ¿Puedo solicitar una mezcla de FeCu10 personalizada?

A: Sí. El equipo de I+D de Truer puede modificar el contenido de cobre, el tamaño de las partículas o las características de flujo para adaptarse a sus necesidades específicas de producción.

P3: ¿Es adecuado el polvo FeCu10 para la impresión 3D?

A: Aunque el FeCu10 se utiliza principalmente en los procesos de prensado y sinterizado, Truer también ofrece versiones para chorro de ligante y AM por extrusión. Póngase en contacto con ellos para estudiar la compatibilidad.

P4: ¿Cómo se envasa el polvo de FeCu10 para envíos internacionales?

A: El polvo se suele envasar al vacío en bidones revestidos de PE o en bolsas de doble capa con protección contra la humedad. También se ofrecen opciones de envasado personalizadas.

P5: ¿Cómo puedo obtener una ficha técnica o una muestra?

A: Puede póngase en contacto con el equipo técnico-comercial de Truer para solicitar una TDS, COA o una muestra gratuita para su evaluación.

Cómo pedir polvo de FeCu10 al por mayor a Shanghai Truer

Hacer un pedido a Truer es muy sencillo, incluso para los compradores extranjeros.

Proceso de pedido paso a paso:

- Consulta sobre el producto

➤ Correo electrónico o enviar una consulta en línea con su grado, volumen y aplicación requeridos. - Consulta técnica (opcional)

➤ Los ingenieros de Truer pueden ayudar a recomendar el mejor grado o mezcla de polvo. - Presupuesto y solicitud de muestras

➤ Reciba precios, opciones de envío y plazos de entrega. Se pueden enviar muestras previa solicitud. - Confirmación de pedido

➤ Asegure su pedido con una factura proforma y el pago. - Producción & amp; Envasado

➤ Su polvo de FeCu10 se fabrica y envasa según sus especificaciones. - Envío y entrega

➤ Entrega mundial por vía aérea, marítima o mensajería urgente. Documentos de exportación facilitados.

Métodos de pago admitidos:

- Transferencia bancaria (T/T)

- PayPal (para muestras o pedidos pequeños)

- Carta de crédito (para contratos a granel)

Al elegir Truer, tendrá acceso a un proveedor integral de polvo PM que respalde sus objetivos de producción desde las pruebas de laboratorio hasta la producción en serie.