1. Introduction to FeCo Powder in Industrial Applications

FeCo powder, an iron-cobalt alloy powder, plays a critical role in high-performance applications that require high saturation magnetization, excellent permeability, and thermal stability. It is widely used in the manufacturing of soft magnetic components, sensor systems, and aerospace parts due to its superior magnetic and mechanical properties.

In B2B markets, FeCo powder is increasingly in demand among:

- Fabricantes de componentes aeroespaciales

- Medical imaging equipment producers

- Defense and military contractors

- Electric motor and generator OEMs

- Impresión 3d and additive manufacturing companies

The global push for miniaturization and energy efficiency is pushing enterprises to adopt advanced materials like FeCo alloy powder. Its high Curie temperature and saturation magnetization make it ideal for high-frequency or high-temperature environments.

Palabras clave B2B de alta intensidad:

- Wholesale FeCo powder

- FeCo powder suppliers

- Soft magnetic alloy powder

- Iron cobalt powder manufacturer

- FeCo alloy for aerospace

2. Key Applications of FeCo Powder in B2B Markets

FeCo alloy powders are engineered for high-performance magnetic applications. Below are key industries and use cases:

Aeroespacial y aviación

- Magnetic shielding materials

- Lightweight, high-strength magnetic components

- High-frequency sensors

Automotive and EV

- Electric motor cores

- Magnetic sensors for autonomous systems

- Inductive charging systems

Medical Technology

- MRI machines (magnetic cores and shielding)

- Precision instrumentation

Electronics & Telecommunications

- High-frequency transformers

- Inductors and magnetic sensors

- Wireless charging components

Fabricación aditiva

FeCo powder is suitable for 3D printing complex geometries for custom inductive components or high-performance aerospace parts.

| Industria | Caso práctico | Beneficio |

|---|---|---|

| Aeroespacial | Magnetic shielding, sensors | High saturation magnetization |

| Automotor | Motor cores, inductive components | Lightweight, energy-efficient |

| Medical Equipment | MRI components | Non-reactive and biocompatible |

| Electrónica | Transformers, sensors | High permeability at high frequency |

| Impresión 3d | Custom magnetic parts | Fabricación en red |

3. Properties and Use Cases of FeCo Alloy Powder

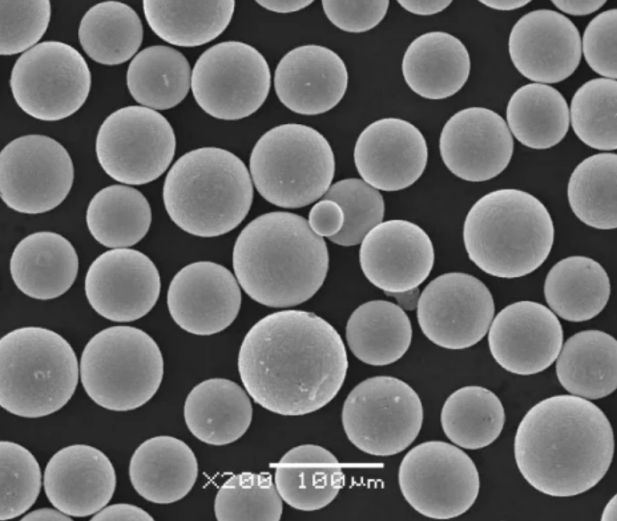

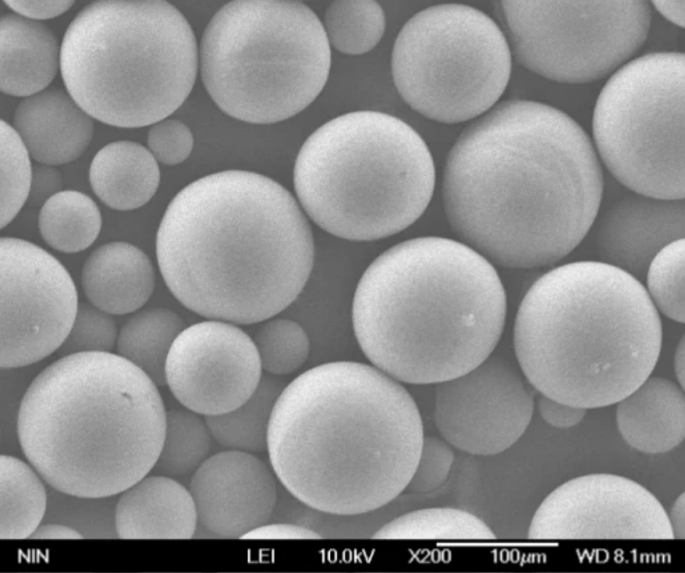

FeCo alloys typically contain 49–50% cobalt and balance iron, with optional trace alloying elements to enhance performance. These powders are often produced by gas atomization, which ensures spherical morphology, low oxygen content, and high flowability — crucial for powder metallurgy and additive manufacturing.

Key Properties of FeCo Powder:

- High saturation magnetization: ~2.4 Tesla

- High Curie temperature: ~950°C

- Excellent soft magnetic properties

- Buena resistencia a la corrosión

- High thermal stability and conductivity

Common Grades:

- FeCo 49/49: Standard for soft magnetics

- FeCo-V (Vanadium alloyed): Improved ductility and corrosion resistance

- FeCo-Ni: Higher electrical resistivity

Applications Table:

| Grado | Composición típica | Área de aplicación | Método de fabricación |

|---|---|---|---|

| FeCo 49/49 | 49% Co, 49% Fe, 2% trace elements | Núcleos magnéticos, blindaje EMI | Gas atomizado |

| FeCo-V | Fe-Co-V alloy | Aerospace, defense, sensors | Gas atomizado |

| FeCo-Ni | Fe-Co-Ni alloy | High-frequency electrical equipment | Gas or water atomized |

For more technical specifications and available grades, you can visit the FeCo powder product page.

4. Market Trends and Global Demand for FeCo Powder

The global FeCo powder market is expanding rapidly, driven by the increasing demand for high-efficiency motors, renewable energy systems, and advanced medical imaging technologies. As industries shift toward miniaturization, electrification, and high-performance components, FeCo alloy powder has become a preferred material choice among OEMs and Tier 1 suppliers.

Principales impulsores del mercado:

- 🌍 Electrification of Transportation: Electric vehicles (EVs) require high-efficiency motors where FeCo plays a role in improving power density.

- 🛰 Aerospace Innovations: Lightweight magnetic shielding and sensor components are essential for satellites and aircraft.

- 🏥 Growth in Medical Devices: MRI and other diagnostic tools depend on magnetic materials with high saturation magnetization.

- 🔧 Fabricación aditiva: 3D printing of magnetic components requires powders with excellent flowability and thermal stability—qualities found in gas-atomized FeCo powders.

FeCo Powder Market Trends

| Tendencia | Impacto en los compradores B2B |

|---|---|

| Increase in gas atomized FeCo demand | Higher quality requirements for 3D printing |

| Rising cobalt prices | Push toward efficient sourcing and hybrid alloys |

| Localization of supply chain | Preference for reliable regional suppliers |

| Customization of alloy grades | Need for flexible suppliers with R&D capabilities |

Major industries are securing long-term contracts with reputable FeCo powder suppliers to mitigate cobalt price volatility and ensure a consistent supply. Strategic partnerships with suppliers like Shanghai Truer ensure technical support, custom alloy development, and on-time delivery.

5. Choosing a Reliable FeCo Powder Supplier

When sourcing FeCo alloy powder for critical applications, selecting the right supplier is paramount. Here are the essential factors that B2B buyers, procurement managers, and distributors should consider:

Criterios clave de evaluación:

- ✅ Método de producción: Gas atomized powders offer superior sphericity and flowability.

- ✅ Purity and Consistency: Low oxygen content and tight particle size distribution are critical.

- ✅ Certificación de materiales: ISO, RoHS, and REACH certifications ensure compliance.

- ✅ Capacidad de personalización: Ability to tailor alloy composition and particle size.

- ✅ Asistencia técnica: Engineering consultation, R&D collaboration, and prototyping services.

- ✅ Logística y plazos de entrega: Reliable delivery schedules and global logistics support.

Lista de comprobación para la evaluación de proveedores:

| Factor | Por qué es importante | En qué fijarse |

|---|---|---|

| Tecnología de atomización | Determines powder quality | Gas atomized with spherical morphology |

| Inventory & Lead Time | Impacts production timelines | Stock availability and fast shipping |

| Experience in FeCo Alloys | Ensures technical understanding | Years of expertise in magnetic alloys |

| Alcance mundial | Supports multinational operations | Export capabilities, multilingual support |

| Opciones de personalización | Tailors powder to application needs | Particle size control, custom alloy blends |

6. Top Global and Chinese FeCo Powder Distributors

The demand for FeCo powder has led to the emergence of several specialized powder metallurgy companies globally. Below are top suppliers known for their quality and supply capabilities of FeCo alloy powders.

Leading FeCo Powder Suppliers:

| Nombre de la empresa | Región | Puntos fuertes |

|---|---|---|

| Shanghai Truer Technology Co., Ltd | China | Custom alloying, gas/water atomization, excellent R&D |

| Höganäs AB | Europa | Large-scale production, extensive product range |

| Tecnología Carpenter | EE.UU. | High-purity soft magnetic alloys for aerospace |

| Sandvik (Alleima) | Suecia | Advanced metal powders for AM and PM |

| Daido Steel Co. | Japón | Specialty FeCo alloys for magnetic applications |

Entre ellas, Shanghái Truer stands out for its commitment to innovation, customization, and B2B focus. With an extensive portfolio of PM and AM powders, Truer is a reliable supplier for clients seeking consistent quality and technical support.

Más información Shanghai Truer’s company background here.

7. Por qué cada vez más compradores recurren a fabricantes chinos

In recent years, Chinese manufacturers have become increasingly dominant in the global powder metallurgy and additive manufacturing markets. For FeCo powder, buyers are turning to China for several reasons:

Producción rentable

Chinese suppliers offer competitive pricing due to the availability of raw materials and efficient manufacturing infrastructure.

Tecnología avanzada

Companies like Shanghai Truer utilize both water and gas atomization, enabling them to meet diverse customer requirements, from soft magnetic alloys to diffusion-alloyed and hybrid powders.

Personalización y flexibilidad

Chinese suppliers are more flexible in MOQs (minimum order quantities), custom alloy formulations, and delivery timelines.

Servicios integrados

Many Chinese manufacturers offer end-to-end services — from powder development to application testing — which is ideal for startups and R&D-driven enterprises.

| Ventajas para los compradores B2B | Por qué es importante |

|---|---|

| Costes más bajos | Improves profit margins |

| Asistencia técnica | Helps accelerate product development |

| Pedidos a medida | Tailored to application requirements |

| Plazos de entrega más cortos | Faster time to market |

In particular, Shanghai Truer’s ability to supply high-performance FeCo powders at scale has made it a preferred partner for international buyers. Their página de contacto makes it easy for procurement teams to initiate a quote or technical discussion.

8. Why Choose Shanghai Truer as Your FeCo Powder Partner

For enterprises sourcing high-performance magnetic powders, Shanghai Truer Technology Co., Ltd is emerging as one of the most trusted FeCo powder suppliers in China’s powder metallurgy market. Founded in 2009 and active in additive manufacturing since 2019, Truer blends deep technical expertise with modern production capabilities to serve global industrial clients.

¿Qué diferencia a Shanghai Truer?

- 🏭 End-to-End Manufacturing: From powder atomization to quality control, Truer manages the entire value chain.

- ⚙️ Dual Atomization Capability: Offers water, gas, and hybrid atomization to produce a full spectrum of PM and AM powders.

- 🧪 Desarrollo de aleaciones personalizadas: FeCo-V, FeCo-Ni, and other formulations tailored to your magnetic and structural requirements.

- 🌐 Global Shipping & Support: Export-ready with multilingual support and flexible shipping arrangements.

- 🔍 Industry-Ready Grades: Supplies FeCo powders suitable for aerospace, EVs, 3D printing, and medical imaging.

FeCo Powder Portfolio at Truer

| Tipo de polvo | Método de atomización | Aplicaciones |

|---|---|---|

| FeCo 49/49 | Gas atomizado | Soft magnetic components, transformers |

| FeCo-V | Gas atomizado | Aerospace, shielding, sensors |

| FeCo-Ni | Atomizado agua/gas | High-frequency electronics, MRI equipment |

In addition to FeCo powders, Truer offers a wide range of Polvos PM including PM bronze, PM steel, PM stainless steel, and prealloyed hybrid low-alloy grades like FL-4605 and FD-0208 — ideal for automotive and structural applications.

Additive and Lubricant Solutions

Truer also provides complementary powder additives and lubricants to optimize the pressing, sintering, and machining of PM components:

- Lube-W, SUW-5000B, SUW-8000 (PM lubricants)

- Cutting agents like SME-100 (sulfur-free)

- Soft magnetic additives QH-150, QHP-330

- Graphite grades TBC-400 and TBC-1000

By consolidating your sourcing through Truer, you reduce supplier fragmentation, ensure material consistency, and simplify your procurement process.

9. How to Order Wholesale FeCo Powder from Shanghai Truer

Ordering FeCo powder for industrial or commercial use is simple and efficient when working with Shanghai Truer. Whether you’re a procurement manager, R&D engineer, or distributor, Truer’s B2B workflow is designed for clarity and speed.

Step-by-Step Wholesale Ordering Guide:

- Enviar una consulta

Visite el página de contacto and fill out the inquiry form with details like powder type, grade, quantity, and delivery timeline. - Consulta técnica

A technical representative will contact you to confirm specs, suggest suitable grades, or discuss custom alloy development. - Presupuesto y plazo de entrega

You’ll receive a detailed quotation including cost, packaging options, Incoterms (EXW, FOB, CIF), and estimated delivery schedule. - Pedido de muestras (opcional)

Request a small batch for internal testing and quality validation. - Confirmación de pedido a granel

Approve the purchase order, finalize payment terms, and receive order confirmation. - Producción y humedad; Garantía de calidad

Truer’s in-house quality control team ensures that all powders meet technical parameters and ISO standards. - Envío y documentación

Orders are shipped with full export documentation including COA (Certificate of Analysis), MSDS, and packing list. - Asistencia posventa

Truer provides ongoing technical support, including post-delivery consultation and application recommendations.

Available Packaging Formats:

| Tamaño del paquete | Tipo de contenedor | Caso práctico |

|---|---|---|

| 1-5 kg | Vacuum-sealed bag | R&D, prototyping, sample testing |

| 25 kg | Steel drum | Medium production runs |

| 500-1000 kg | Bulk container | High-volume manufacturing |

To streamline your request, it’s recommended to include specifications like particle size distribution (e.g., 15–45 µm for AM), required purity levels, and preferred atomization method.

10. FAQs: Common Questions About Buying Wholesale FeCo Powder

Q1: What industries commonly use FeCo powder?

FeCo powder is widely used in aerospace, automotive (especially EVs), electronics, medical imaging, and 3D printing. Its high saturation magnetization and thermal stability make it ideal for high-frequency and high-temperature environments.

Q2: What is the recommended particle size for additive manufacturing?

For most AM applications, a particle size range of 15–45 µm is recommended. Shanghai Truer can tailor the particle size distribution to match your printing technology (SLM, EBM, binder jetting).

Q3: Can Truer provide custom FeCo alloy formulations?

Yes. Truer specializes in alloy customization, including FeCo-V, FeCo-Ni, and hybrid compositions for enhanced corrosion resistance or ductility.

Q4: How are Truer’s powders packaged for international shipping?

Powders are vacuum-sealed, moisture-protected, and shipped in steel drums or bulk containers with full export documentation and COA.

Q5: How do I request a quote or sample?

You can request a quote or sample directly through the Shanghai Truer website, or by visiting the página de contacto.

Embedded Internal Links Recap:

- FeCo powder product page

- Shanghai Truer company introduction

- Contact us to request a quote

- Truer’s PM powder selection

- Official website homepage

By partnering with Shanghai Truer, your business gains access to high-quality FeCo alloy powders, a full suite of additive components, and a trusted supply chain partner with over a decade of industry experience.

Ready to source FeCo powder for your next project? Póngase en contacto con Truer hoy mismo to get a quote or speak with our technical team.