1. Introducción: Por qué el polvo FD-0408 cambia las reglas del juego de la pulvimetalurgia

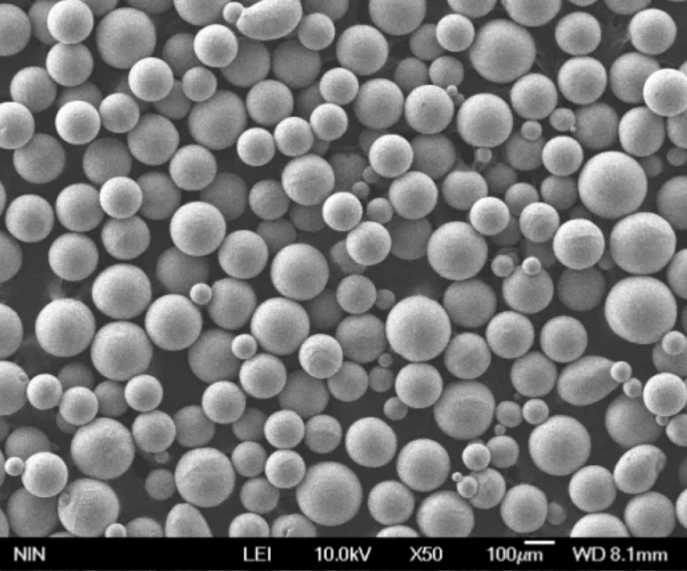

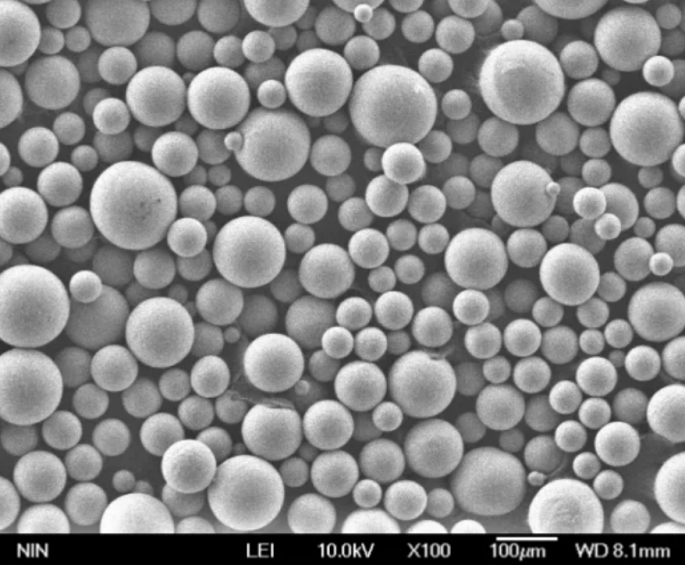

El polvo FD-0408 es un polvo de acero aleado por difusión ampliamente utilizado en pulvimetalurgia (PM) para la producción de componentes estructurales. Combina hierro, carbono y cobre para ofrecer un perfil equilibrado de resistencia, maquinabilidad y rentabilidad. A medida que las industrias avanzan hacia componentes metálicos rentables y de alto rendimiento, el polvo FD-0408 se ha convertido en la opción preferida para aplicaciones de automoción, industriales y de maquinaria.

Principales ventajas para los compradores B2B:

- Alta compresibilidad para una compactación eficaz

- Mayor resistencia tras la sinterización

- Excelente estabilidad dimensional

- Compatible con los equipos PM estándar

- Rentable para grandes volúmenes de producción

El FD-0408 es especialmente adecuado para entornos de producción a gran escala en los que la consistencia, el rendimiento y la asequibilidad son fundamentales, lo que lo hace muy atractivo para compradores mayoristas, fabricantes de equipos originales y distribuidores.

2. Aplicaciones industriales del polvo FD-0408

La fuerza mecánica y la resistencia al desgaste del polvo FD-0408 lo hacen ideal para varias industrias de uso final. A continuación se presenta un desglose de sus aplicaciones más comunes:

| Industria | Componentes comunes | Por qué se utiliza el FD-0408 |

|---|---|---|

| Automotor | Engranajes, piñones, bujes, componentes del árbol de levas | Gran solidez y excelente resistencia al desgaste |

| Maquinaria industrial | Piezas estructurales, actuadores | Buena precisión dimensional y resistencia a la fatiga |

| Herramientas y herrajes | Herramientas manuales, piezas de herramientas eléctricas | Maquinabilidad y resistencia |

| Electrodomésticos | Soportes, bisagras | Producción en serie rentable |

Ventajas para fabricantes y distribuidores:

- Permite fabricar formas casi netas

- Reduce la necesidad de mecanizado secundario

- Proporciona un rendimiento fiable bajo tensión mecánica

Para los equipos de ingeniería y los responsables de compras, el FD-0408 ayuda a agilizar la fabricación a la vez que satisface las exigencias mecánicas de los ensamblajes complejos.

3. Propiedades y características de rendimiento de FD-0408

El FD-0408 es conocido por su equilibrada composición química, que contribuye a su elevada resistencia mecánica y densidad sinterizada. A continuación se ofrece un resumen técnico:

Composición química (típica):

| Elemento | Contenido (%) |

|---|---|

| Fe (Hierro) | Saldo |

| Cu (Cobre) | 2.0 - 4.0 |

| C (Carbono) | 0.3 - 0.6 |

Propiedades mecánicas tras la sinterización:

| Propiedad | Valor (típico) |

|---|---|

| Resistencia a la tracción | Hasta 620 MPa |

| Límite elástico | 400 - 500 MPa |

| Dureza (HRB) | 80 - 95 |

| Alargamiento | 1% - 3% |

| Densidad sinterizada | ~6,8 - 7,1 g/cm³ |

Beneficios clave de rendimiento:

- Diseño aleado por difusión: Proporciona propiedades más uniformes que las mezclas simples

- Buen control dimensional: Ideal para componentes con tolerancias estrechas

- Mayor resistencia en verde: Admite la manipulación automatizada

Estas características hacen que el FD-0408 sea adecuado para los fabricantes que desean optimizar el rendimiento y reducir los costes de postprocesamiento.

👉 Más información Materiales en polvo PM aquí.

4. Tendencias del mercado mundial y potencial de crecimiento del polvo FD-0408

Con el impulso mundial a la fabricación ligera y rentable, el mercado de la pulvimetalurgia (PM) está experimentando un crecimiento significativo, especialmente en los sectores de la automoción y la industria. Entre los materiales más demandados se encuentra el polvo FD-0408, gracias a su estructura aleada por difusión y a sus fiables prestaciones mecánicas.

Principales impulsores del mercado:

- Electrificación del automóvil: Aumento de la demanda de componentes PM de alta resistencia y precisión en las cadenas cinemáticas y transmisiones de los vehículos eléctricos.

- Objetivos de sostenibilidad: El FD-0408 admite la fabricación con forma casi de red, lo que reduce el desperdicio de material.

- Presiones de costes: Los fabricantes buscan alternativas asequibles pero de alto rendimiento a las piezas de fundición o forja.

- Expansión en Asia-Pacífico: La rápida industrialización de países como China e India está impulsando la demanda de piezas PM.

Previsiones de mercado para los polvos de acero PM (2024-2030):

| Región | CAGR | Factores de crecimiento |

|---|---|---|

| Asia-Pacífico | 6.8% | Automoción, electrónica de consumo, maquinaria industrial |

| Europa | 5.2% | Iniciativas ecológicas, innovación en automoción |

| Norteamérica | 4.9% | Aeroespacial y defensa, automatización industrial |

El FD-0408 se ajusta perfectamente a estas tendencias, ofreciendo una solución práctica para la producción de grandes volúmenes con fuertes requisitos mecánicos.

5. Factores clave a tener en cuenta al elegir un proveedor de FD-0408

Los compradores B2B, los responsables de compras y los distribuidores deben evaluar varios factores críticos a la hora de seleccionar un proveedor fiable de FD-0408:

1. Calidad del polvo & Consistencia

- Compruebe si los procesos de fabricación cuentan con la certificación ISO

- Garantizar un control estricto de la distribución granulométrica y la composición química

- Evaluar el rendimiento de las piezas sinterizadas a partir de lotes de prueba

2. Capacidad de producción & Plazo de entrega

- ¿Puede el proveedor gestionar pedidos al por mayor de forma coherente?

- ¿Cuál es su plazo medio de producción?

- ¿Son compatibles con los modelos de entrega justo a tiempo (JIT)?

3. Asistencia técnica y personalización

- Disponibilidad de asesoramiento técnico para el diseño de piezas

- Mezclas o granulometrías personalizadas en función de los requisitos de la aplicación

- Asistencia técnica in situ o virtual

4. Precios y condiciones de pago

- Precios competitivos para pedidos de gran volumen

- Planes de pago flexibles para compradores a largo plazo

- Precios escalonados para distribuidores y revendedores

5. Logística y distribución mundial

- Capacidad de envío internacional

- Almacenamiento local en las regiones objetivo

- Apoyo documental (MSDS, COA, cumplimiento de REACH/RoHS)

📌 Si buscas un proveedor de confianza que cumpla todos estos requisitos, explora Perfil de la empresa Shanghai Truer Technology.

6. Principales proveedores de Polvo FD-0408 en Asia y Europa

Para los profesionales de compras y los mayoristas que buscan fuentes de polvo FD-0408, aquí están algunos de los proveedores con mejores resultados basados en la calidad, la capacidad de producción y el alcance global.

Los 3 mejores proveedores de Asia:

| Compañía | Ubicación | Puntos fuertes |

|---|---|---|

| Shanghai Truer Technology Co. | China | FD-0408 de alta calidad de atomización de agua/reducción/carbonilo, soluciones completas de aditivos, formulaciones a medida |

| JFE Steel Corporation | Japón | Técnicas avanzadas de aleación por difusión, fuertes en PM para automoción |

| Hoganas China | China | Amplia cartera de aceros PM, fuerte apoyo logístico |

Los 3 mejores proveedores de Europa:

| Compañía | País | Puntos fuertes |

|---|---|---|

| Höganäs AB | Suecia | Líder mundial en polvos PM, amplia I+D |

| MIMETE S.r.l. | Italia | Aleaciones personalizadas y polvos finos para aditivos y PM |

| GKN Hoeganaes | Alemania | Producción a gran escala, certificaciones de automoción |

🛒 Para compradores centrados en la calidad, la personalización y la rentabilidad, Tecnología Truer de Shanghai destaca como una opción de primer nivel. Con más de una década en el sector y una división dedicada a la fabricación aditiva, Truer ofrece servicios integrales de pulvimetalurgia.

Por qué los compradores confían en Shanghai Truer:

- Más de 14 años de experiencia en gestión de proyectos (est. 2009)

- Línea completa de producción de FD-0408 con calidad constante

- Mezclas de polvos y granulometría a medida

- Precios competitivos para mayoristas y fabricantes de equipos originales

- Logística rápida y red de distribución mundial

Shanghai Truer también produce otros grados PM relacionados, como FC-0208, FL-4605 y FD-0208, ofreciendo flexibilidad a los compradores con diversas necesidades de aplicación.

✅ ¿Necesita presupuesto o consulta técnica? Póngase en contacto con Truer Technology aquí.

7. Por qué cada vez más compradores compran polvo FD-0408 en China

A medida que evolucionan las cadenas de suministro mundiales, más compradores B2B recurren a fabricantes chinos para abastecerse de materiales pulvimetalúrgicos de alto rendimiento como el FD-0408. Este cambio está impulsado por varias ventajas estratégicas que China ofrece a compradores mayoristas, fabricantes de equipos originales y distribuidores.

Principales razones del aumento de las compras en China:

precios competitivos

- Los proveedores chinos ofrecen precios mucho más bajos sin comprometer la calidad.

- Ideal para fabricantes de gran volumen que desean reducir los costes unitarios.

✅ Capacidades de fabricación avanzadas

- Modernas instalaciones con procesos de atomización del agua, carbonilación y reducción.

- Capacidad para cumplir estrictas especificaciones técnicas y pedidos personalizados.

mOQ flexible y soporte OEM

- Las cantidades mínimas de pedido (MOQ) más bajas facilitan las cosas a las empresas de nueva creación y a los fabricantes de tamaño medio.

- Servicios personalizados de marca, etiquetado y envasado.

producción rápida y logística de exportación

- Plazos de entrega rápidos gracias a líneas de producción optimizadas.

- Infraestructura de exportación bien establecida a Norteamérica, Europa y regiones SEA.

✅ Experiencia integrada en fabricación aditiva

- Muchos proveedores chinos de PM, como Tecnología Truer de Shanghai, también son compatibles con la fabricación aditiva, lo que permite a los compradores acceder a materiales avanzados y soluciones híbridas.

Estudio de caso del comprador: Compra de FD-0408 a Shanghai Truer

| Tipo de comprador | Región | Solicitud | Resultados |

|---|---|---|---|

| OEM de automoción | Alemania | Casquillos del árbol de levas | Reducción de costes en un 18% y mejora del plazo de suministro en un 30% |

| Distribuidor de piezas industriales | EE.UU. | Piezas estructurales PM | Calidad constante con un índice de cumplimiento de pedidos del 98 |

| Fabricante de herramientas | India | Engranajes para herramientas eléctricas | La mezcla personalizada FD-0408 mejoró la dureza en un 12% |

8. Por qué elegir Shanghai Truer Technology como su proveedor de FD-0408

Shanghai Truer Technology Co., Ltd. es un proveedor y fabricante de confianza de polvo FD-0408 y otros polvos de acero aleados por difusión. Desde su fundación en 2009, Truer ha construido una reputación de materiales de alta calidad, experiencia técnica y servicio centrado en el cliente en las industrias de pulvimetalurgia y fabricación aditiva.

¿Qué diferencia a Shanghai Truer?

✅ Capacidades de fabricación de gama completa

- Ofrece FD-0408, FD-0208, FN-0205, FL-4605 y muchos polvos híbridos y aleados por difusión.

- Admite procesos de atomización con agua, atomización con gas, carbonilo y reducción.

✅ Conocimientos técnicos

- División especializada en aditivos para aplicaciones PM avanzadas.

- Ofrece agentes de corte, lubricantesgrafito y aditivos magnéticos blandos.

certificaciones de calidad

- Certificación ISO 9001:2015

- Documentación completa que incluye COA, MSDS y conformidad con RoHS/REACH

soluciones personalizadas

- Granulometría, fluidez y composición adaptadas a las necesidades del cliente.

- Equipos de ingenieros disponibles para colaborar en el diseño y la optimización.

✅ Distribución mundial y asistencia

- Envío rápido a Asia, Europa y Norteamérica

- Atención al cliente y asesores técnicos multilingües

Muestra FD-0408 Especificación de Truer:

| Propiedad | Valor |

|---|---|

| Contenido en cobre | 2.0 - 4.0% |

| Contenido de carbono | 0.3 - 0.6% |

| Densidad sinterizada | 6.8-7,1 g/cm³ |

| Presión | 600-800 MPa |

| Fuerza Verde | Excelente para la manipulación automatizada |

🔍 ¿Quieres explorar más opciones en polvo? Explora toda la Catálogo de polvos PM aquí.

9. FAQs: Compra al por mayor de FD-0408 en polvo para la fabricación

P1: ¿Cuál es la cantidad mínima de pedido (MOQ) para el polvo FD-0408?

R: Shanghai Truer ofrece MOQ flexibles a partir de 100 kg, ideales tanto para series piloto como para producción a gran escala.

P2: ¿Puede personalizarse el polvo FD-0408 para obtener propiedades mecánicas específicas?

R: Sí. El equipo de ingeniería de Truer puede ajustar el contenido de carbono y cobre, el tamaño de las partículas y la fluidez según las necesidades de su aplicación.

P3: ¿Es el FD-0408 adecuado para piezas mecánicas de alto desgaste?

R: Por supuesto. Su estructura aleada por difusión proporciona una gran resistencia a la tracción y al desgaste, por lo que es ideal para engranajes, bujes y piezas estructurales.

P4: ¿Realiza Truer Technology envíos internacionales?

R: Sí. Truer realiza envíos a todo el mundo con documentación completa, incluidos COA, MSDS y asistencia para el despacho de aduanas.

P5: ¿Cómo hago un pedido al por mayor?

R: Puede ponerse en contacto directamente con el equipo de ventas de Truer a través del página de contacto o envíe una consulta a través de su formulario en línea.

🔚 Reflexiones finales

El polvo FD-0408 es un material esencial para los fabricantes que buscan optimizar el rendimiento y el coste en una amplia gama de aplicaciones industriales. Gracias a sus excelentes propiedades mecánicas, su compatibilidad con los procesos PM estándar y su amplia disponibilidad, no es de extrañar que los compradores mundiales recurran cada vez más a proveedores chinos de confianza como Shanghai Truer Technology.

Al asociarse con Truer, usted obtiene acceso no sólo al polvo FD-0408 de primera calidad, sino también a una completa cartera de soluciones que incluye aditivos PM, asistencia técnica y logística global.

👉 ¿Listo para agilizar su abastecimiento de FD-0408? Visite Página de inicio de Shanghai Truer Technology para empezar.