Introducción: Qué es el polvo FC-1000 y por qué es importante en pulvimetalurgia

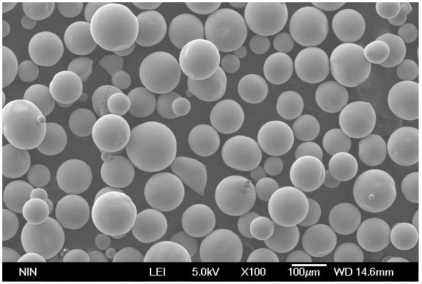

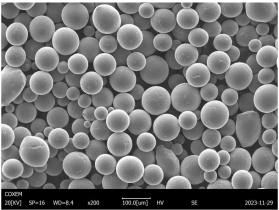

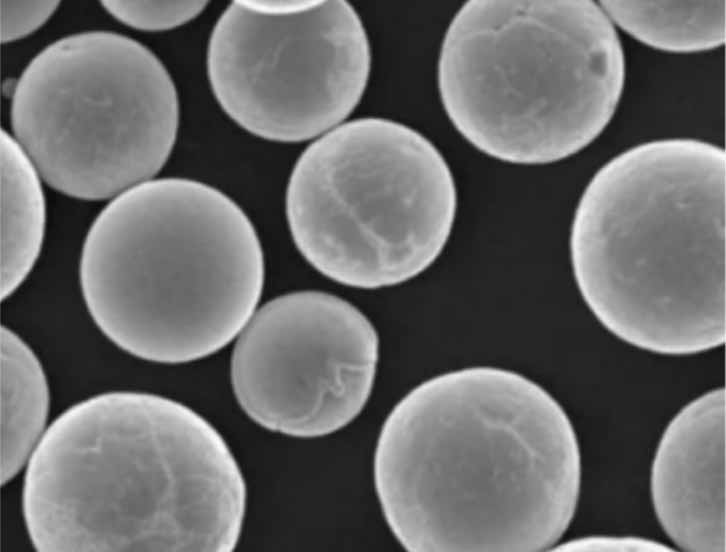

El polvo FC-1000 es un polvo de hierro prealeado ampliamente utilizado que se produce mediante atomización con agua. Está diseñado para ofrecer propiedades mecánicas equilibradas y una excelente compresibilidad en aplicaciones pulvimetalúrgicas (PM). Para los compradores B2B de sectores como la automoción, la maquinaria pesada y los componentes industriales, el FC-1000 ofrece una solución rentable para crear piezas metálicas complejas de alto rendimiento.

¿Qué es FC-1000?

- Tipo: Polvo de hierro prealeado

- Método de producción: Atomización del agua

- Uso típico: Piezas estructurales, engranajes, ruedas dentadas y otros componentes PM de precisión

- Grado Estándar: Compatible con MPIF e ISO

Por qué es importante para los compradores B2B

- Fabricación de gran volumen: Ideal para la producción en serie

- Excelente estabilidad dimensional: Reduce los costes de postprocesado

- Rentabilidad: Precios competitivos con un rendimiento mecánico fiable

- Compatibilidad: Funciona bien con aditivos como grafito, cobre y lubricantes

Para las empresas que buscan polvos ferrosos de alto rendimiento, el FC-1000 representa una opción de material fiable y escalable.

Aplicaciones industriales del polvo FC-1000 en la fabricación

El polvo FC-1000 es un material versátil utilizado en diversos sectores de fabricación que requieren resistencia, maquinabilidad y consistencia. A continuación se indican algunas de las principales aplicaciones industriales:

Industria del automóvil

- Engranajes sinterizados

- Poleas del árbol de levas

- Bielas

- Piezas de amortiguador

Electricidad y Maquinaria

- Núcleos de motor

- Componentes magnéticos

- Piezas de carcasa para maquinaria industrial

Electrodomésticos

- Componentes de la cerradura

- Pequeñas conexiones mecánicas

- Piezas resistentes al desgaste

| Industria | Ejemplo de aplicación | Ventajas del FC-1000 |

|---|---|---|

| Automotor | Engranajes de transmisión | Gran solidez y resistencia a la fatiga |

| Maquinaria industrial | Carcasas de bombas | Excelente precisión dimensional |

| Material eléctrico | Núcleos magnéticos | Permeabilidad magnética y consistencia mejoradas |

| Bienes de consumo | Mecanismos de cierre | Alta resistencia al desgaste y calidad del acabado superficial |

Ventajas B2B

- Tasas de desguace más bajas: Gracias a la capacidad de conformado de precisión

- Altas velocidades de producción: Compatible con líneas PM automatizadas

- Integración con aditivos: Se mezcla fácilmente con cobre, grafito y lubricantes como Lube-W y SUW-5000B para mejorar sus propiedades

Propiedades clave y ventajas de rendimiento del polvo FC-1000 PM

Conocer las propiedades técnicas del polvo FC-1000 ayuda a los compradores B2B a tomar decisiones de compra bien fundadas. El FC-1000 está diseñado para ofrecer un rendimiento superior en aplicaciones exigentes.

Propiedades mecánicas

- Fuerza Verde: Alta densidad verde para una manipulación fiable antes de la sinterización

- Fuerza sinterizada: Excelente integridad estructural tras la sinterización

- Dureza: Puede ajustarse con aditivos y parámetros de sinterización

Características físicas

| Propiedad | Gama de especificaciones |

|---|---|

| Tamaño de partícula | 45-150 µm |

| Densidad aparente | 2.90-3,10 g/cm³ |

| Caudal | ≤ 28 s/50g |

| Compresibilidad a 600 MPa | ≥ 7,00 g/cm³ |

Ventajas de rendimiento

- Excelente prensabilidad: Baja fricción durante la compactación

- Alta densidad verde: Reduce los defectos en estado verde

- Buena sinterabilidad: Microestructura uniforme tras la sinterización

- Adaptabilidad: Puede utilizarse con diversos sistemas de aditivos, incluidos agentes de corte como SME-100 y TD-8

Potencial de personalización

El FC-1000 se utiliza a menudo como polvo base en formulaciones híbridas o aleadas por difusión, lo que permite a los fabricantes adaptar propiedades como:

- Resistencia al desgaste

- Resistencia a la corrosión

- Rendimiento magnético

Para obtener más información sobre FC-1000 y otros polvos PM, visite nuestro Productos pulvimetalúrgicos página.

Evaluación de proveedores de FC-1000: Lo que deben saber los compradores B2B

Elegir al proveedor de polvo FC-1000 adecuado es crucial para los fabricantes que confían en una calidad constante, una logística fiable y unos precios competitivos. Para los compradores B2B, especialmente en los sectores de la pulvimetalurgia y la fabricación aditiva, la evaluación de los proveedores va más allá de las propiedades de los materiales: se trata de una colaboración a largo plazo y de eficiencia operativa.

Criterios clave para evaluar a los proveedores de FC-1000

| Criterios de evaluación | Por qué es importante para los compradores B2B |

|---|---|

| Consistencia del producto | Garantiza un rendimiento repetible en todos los ciclos de producción |

| Capacidad de producción | Soporta pedidos de gran volumen y minimiza los retrasos |

| Garantía de calidad | Procesos, trazabilidad y pruebas por lotes con certificación ISO |

| Asistencia técnica | Consultas in situ, asistencia en la selección de polvos, I+D |

| Estructura de precios | Precios al por mayor competitivos con descuentos por volumen |

| Logística de entrega | Capacidad de envío mundial, transparencia en los plazos de entrega |

Preguntas que deben hacerse los compradores B2B

- ¿Cuál es el plazo de entrega habitual para los pedidos a granel de FC-1000 en polvo?

- ¿Existen servicios personalizados de mezcla o integración de aditivos?

- ¿Cuáles son los modelos logísticos disponibles (FOB, CIF, DDP)?

- ¿Puede el proveedor facilitar hojas de datos técnicos y muestras de COA?

Señales de advertencia que hay que evitar

- Propiedades de lote incoherentes

- Falta de documentación técnica

- Comunicación deficiente o respuestas tardías

- No hay clientes de referencia ni casos prácticos

Un buen socio proveedor de FC-1000 debe comportarse más como un proveedor de soluciones que como un simple vendedor. Cuando se abastezca en China o Asia, asegúrese de que el proveedor tiene experiencia y certificaciones internacionales.

Los 5 principales fabricantes de polvo FC-1000 en Asia

Asia se ha convertido en una potencia para la pulvimetalurgia, con varios fabricantes que producen polvo FC-1000 de alta calidad utilizando tecnologías de atomización avanzadas. Estos son los 5 principales proveedores a tener en cuenta:

| Compañía | País | Especialidades |

|---|---|---|

| Tecnología Truer de Shanghai | China | Ofrece una gama completa de soluciones de PM, desde polvo hasta aditivos y equipos |

| Höganäs China | China | Marca mundial, fabricación local, amplia red de distribución |

| Acero JFE | Japón | Polvo de hierro de gran pureza, fuerte en productos de automoción |

| Kobelco (Kobe Steel) | Japón | Polvos avanzados aleados por difusión para piezas de alta resistencia |

| PMT Co., Ltd. | Corea del Sur | Polvo ferroso de alta calidad y soluciones para piezas compactadas |

Mirada detallada: Shanghai Truer Technology Co., Ltd.

Shanghai Truer Technology ha destacado en la industria pulvimetalúrgica china. Desde que entró en el espacio de la fabricación aditiva en 2019, Truer se ha centrado en la integración de equipos, polvo y servicios aditivos.

Por qué destaca Truer:

- ✅ Gama completa de FC-1000 y polvos PM relacionados

- ✅ Formulaciones de aditivos a medida (grafito, lubricantes, agentes de corte)

- ✅ Métodos de atomización avanzados: agua, gas y combinados

- ✅ Soporte de ingeniería in situ y asociaciones de I+D

- ✅ Con la confianza de cientos de fabricantes de PM de todo el mundo

Para saber más sobre la misión y las capacidades de la empresa, visite la página Sobre nosotros en su sitio web oficial.

Por qué cada vez más compradores compran FC-1000 a fabricantes chinos

En los últimos años, se ha producido un cambio en el aprovisionamiento global, ya que cada vez más compradores B2B recurren a proveedores chinos de materiales pulvimetalúrgicos como el FC-1000. Esta tendencia se debe a las ventajas competitivas en costes, escala de producción e innovación.

Principales razones del cambio

1. Eficiencia de costes

- Menores costes laborales y operativos

- Descuentos por volumen para pedidos al por mayor

- Reducción de los gastos generales de los contratos a largo plazo

2. Avances tecnológicos

- Instalaciones avanzadas de atomización de agua y gas

- Mezcla de aditivos y personalización internas

- Capacidad para cumplir las normas PM internacionales

3. Integración de la cadena de suministro

- Integración vertical desde la materia prima hasta la entrega

- Soluciones logísticas flexibles (FOB, DDU, DDP)

- Proximidad a centros clave de electrónica y automoción

| Factor | Proveedores occidentales | Proveedores chinos (por ejemplo, Truer) |

|---|---|---|

| Precio por kg (a granel) | $4.50 - $6.00 | $2.80 - $3.70 |

| Integración de aditivos a medida | Limitado | Ampliamente disponible |

| MOQ (Cantidad mínima de pedido) | 1-2 toneladas | 500 kg o menos en algunos casos |

| Plazos de entrega | 6-8 semanas | 2-4 semanas (para pedidos estándar) |

Impacto real para los compradores B2B

- Menor tiempo de comercialización para nuevas piezas PM

- Mayor ROI gracias a la reducción de los costes de material

- Cadenas de suministro escalables para las crecientes necesidades de producción

Explore toda la gama de materiales PM disponibles de fabricantes chinos como Truer visitando la página página oficial del producto.

Por qué elegir Shanghai Truer como su proveedor de polvo FC-1000

Shanghai Truer Technology Co., Ltd. ha desarrollado una sólida reputación entre los compradores B2B como proveedor fiable e innovador de polvo FC-1000 y materiales pulvimetalúrgicos relacionados. Con un modelo de servicio completo que incluye el desarrollo de polvos, la integración de aditivos y la consultoría técnica, Truer ofrece una ventaja competitiva a fabricantes y distribuidores de todo el mundo.

1. Amplia cartera de productos

Truer no sólo suministra FC-1000, sino que ofrece una completa gama de materiales pulvimetalúrgicos y aditivos para una amplia variedad de aplicaciones.

Grados de polvo disponibles:

- FC-0208 - Hierro-cobre aleado por difusión

- FD-0208 - Piezas sinterizadas de alta densidad

- FL-4605 - Acero PM híbrido de baja aleación

- FN-0205 - Aceros PM hierro-níquel

- FD-20Cu, FN-5000, CT-1000 - Varios grados de rendimiento para aplicaciones personalizadas

Aditivos especiales:

- Grafito: TBC-400, TBC-1000

- Lubricantes: Lube-W, SUW-5000B, SUW-8000

- Agentes de corte: SME-100 (sin azufre), TD-8

- Aditivos magnéticos blandos: QH-150, QHP-330

2. Experiencia en tecnología de atomización

Shanghai Truer utiliza múltiples métodos de atomización para garantizar las características óptimas del polvo para cada aplicación:

| Tipo de atomización | Características | Aplicaciones |

|---|---|---|

| Agua atomizada | Rentable, alta compresibilidad | Piezas estructurales PM |

| Gas atomizado | Alta esfericidad, bajo contenido de oxígeno | Fabricación aditiva y polvos AM |

| Atomización combinada | Equilibrio entre fluidez y rendimiento mecánico | Piezas especiales e híbridas PM |

3. Ingeniería y asistencia técnica

El equipo técnico de Truer colabora con los clientes para:

- Optimizar las combinaciones polvo-aditivo

- Diseñar nuevas formulaciones para mejorar la maquinabilidad o el magnetismo

- Ofrecer asistencia in situ para líneas de producción pulvimetalúrgicas

- Proporcionar documentación completa, incluyendo MSDS, COA y TDS

Puede póngase en contacto con el equipo técnico de Truer para obtener asistencia personalizada, personalizar productos o solicitar una muestra.

4. Cadena de suministro global escalable

Si usted es un OEM, distribuidor o fabricante por contrato, el equipo de logística de Truer garantiza:

- Plazos de entrega rápidos (de 2 a 4 semanas como norma)

- Cumplimiento de las normas mundiales de expedición (REACH, RoHS, ISO9001)

- Cantidades de pedido flexibles (de 500 kg a más de 100 toneladas)

- Embalaje y documentación listos para la exportación

Cómo pedir polvo FC-1000 al por mayor a Truer

Hacer un pedido de FC-1000 PM en polvo a Shanghai Truer es un proceso ágil y optimizado para B2B. Tanto si necesita unas pocas toneladas para una nueva línea de productos como contenedores regulares para la producción en curso, Truer ofrece una interfaz de adquisición flexible y receptiva.

Proceso de pedido al por mayor paso a paso

Paso 1: Solicitud de información & correspondencia de especificaciones

- Póngase en contacto con Truer a través del formulario de contacto o por correo electrónico

- Proporcionar especificaciones (grado, granulometría, cantidad, necesidades de envasado)

- Solicite fichas técnicas o muestras si lo necesita

Paso 2: Oferta y confirmación técnica

- Reciba un presupuesto detallado con plazo de entrega, MOQ, condiciones de pago

- Confirmar cualquier integración de aditivos o formatos de envasado personalizados

Paso 3: Prueba de muestras (opcional)

- Solicite una muestra de 5-10 kg de FC-1000 en polvo

- Realización de pruebas internas o envío a laboratorios de validación externos

Paso 4: Orden de compra & Producción

- Hacer un pedido con las condiciones acordadas (FOB Shanghai u otros Incoterms)

- Horarios más precisos de producción o expedición a partir del inventario

Paso 5: Envío y entrega

- Truer se encarga de la documentación, el despacho de aduanas y la logística

- Reciba actualizaciones de seguimiento y entrega de envíos

| Pedidos | Opciones disponibles |

|---|---|

| MOQ | 500 kg |

| Embalaje | sacos de 25 kg, sacos jumbo de 1 tonelada, a medida |

| Condiciones de pago | T/T, L/C, negociable |

| Métodos de entrega | Carga marítima, Carga aérea, Express (muestras) |

| Certificaciones proporcionadas | ISO9001, MSDS, COA, TDS |

El equipo especializado de ventas y logística de Truer garantiza una experiencia sin problemas tanto para los compradores que compran por primera vez como para los que repiten, ya sean nacionales o internacionales.

Preguntas frecuentes: Todo lo que preguntan los compradores B2B sobre el polvo FC-1000

A continuación encontrará algunas de las preguntas más frecuentes de compradores mayoristas, distribuidores y fabricantes a la hora de abastecerse de polvo FC-1000.

1. ¿Cuál es la distribución típica del tamaño de las partículas del polvo FC-1000?

El FC-1000 suele tener un rango de tamaños de partícula de 45-150 μmoptimizado para una excelente compresibilidad y fluidez en aplicaciones pulvimetalúrgicas.

2. ¿Se puede mezclar el FC-1000 con aditivos como cobre o grafito?

Sí. FC-1000 se utiliza a menudo como polvo base en formulaciones híbridas. Truer ofrece soluciones premezcladas con cobre, grafito y lubricantes para satisfacer las necesidades específicas de la aplicación.

3. ¿Cuál es la diferencia entre FC-1000 y FC-0208?

El FC-0208 es una versión aleada por difusión del FC-1000 con cobre añadido. Proporciona mayor resistencia mecánica y densidad sinterizada para aplicaciones exigentes.

4. ¿Es adecuado el FC-1000 para piezas estructurales sinterizadas?

Absolutamente. Se utiliza mucho en piezas estructurales por su resistencia mecánica, densidad verde y rentabilidad.

5. ¿Cómo garantiza Truer la calidad del polvo?

Usos más verdaderos equipo de atomización automática, estrictos protocolos de control de calidad, y sistemas de trazabilidad de lotes. Todos los polvos son inspeccionados para:

- Distribución granulométrica

- Caudal

- Composición química

- Densidad aparente y de toma

Para más información técnica sobre el producto, visite la página Sección del producto FC-1000 del sitio web Truer.

Resumen de enlaces internos:

| Texto de anclaje | URL de destino |

|---|---|

| Productos pulvimetalúrgicos | https://am-material.com/pm-powder/ |

| Sobre nosotros | https://am-material.com/about/ |

| Póngase en contacto con el equipo técnico de Truer | https://am-material.com/contact-us/ |

| Sección del producto FC-1000 | https://am-material.com/pm-powder/ |

| Formulario de contacto | https://am-material.com/contact-us/ |

Al proporcionar polvo FC-1000 de alta calidad, soluciones aditivas avanzadas y asistencia de primera clase, Shanghai Truer es su socio estratégico en pulvimetalurgia. Tanto si lanza un nuevo producto de PM como si aumenta la producción, Truer le ofrece los materiales y la experiencia que necesita para tener éxito.

¿Está listo para hacer un pedido o solicitar una muestra? Contacte con Truer hoy mismo y habla con un experto en PM.