1. Introduction to CuNi2SiCr Powder in Manufacturing

CuNi2SiCr powder is a high-performance copper-based alloy known for its excellent mechanical strength, corrosion resistance, and electrical conductivity. This powder is widely used in powder metallurgy (PM) and additive manufacturing (AM) sectors, especially in industries requiring high-temperature resistance and wear resilience.

For B2B buyers—including aerospace component manufacturers, automotive part OEMs, precision electronics producers, and industrial mold makers—CuNi2SiCr offers a unique blend of properties essential for high-demand applications. Its composition typically includes:

| Elemento | Composición (%) |

|---|---|

| Cu | Saldo |

| Ni | 1.5–2.5 |

| Si | 0.4–0.8 |

| Cr | 0.1–0.4 |

Key reasons why CuNi2SiCr is gaining popularity in the B2B materials market:

- Elevada relación resistencia/peso

- Superior resistance to corrosion and oxidation

- Excellent conductivity with good thermal stability

- Easy machinability and sinterability in PM processes

As industries aim to reduce weight while maintaining performance, CuNi2SiCr powder has become a strategic material across global manufacturing chains.

2. Industrial Applications of CuNi2SiCr Alloy Powder

CuNi2SiCr powder is versatile in its application across multiple industries. Distributors, OEMs, and e-commerce sellers servicing the following sectors can benefit from stocking this alloy:

A. Aerospace & Defense

- Used in aircraft structural components, bushings, and connectors

- High corrosion resistance in extreme environments

B. Automotive & Transportation

- Applied in high-performance engine parts, brake systems, and transmission components

- Offers wear resistance and strength under dynamic loads

C. Electrical & Electronics

- Ideal for connectors, terminals, and switchgear requiring high conductivity

- Maintains performance over long lifecycle usage

D. Tooling & Molding

- Used in molds requiring rapid heat dissipation and wear resistance

- Perfect for plastic injection molds and die-casting components

E. Additive Manufacturing (Impresión 3d)

- CuNi2SiCr’s fine granularity and flowability make it ideal for laser and binder jet fusion techniques

- Uniform microstructure ensures consistent part quality

| Industria | Área de aplicación | Key Benefit |

|---|---|---|

| Aeroespacial | Connectors, landing gear, bushings | High strength & corrosion resistance |

| Automotor | Engine parts, gears, sensors | Durability & conductivity |

| Electrónica | Switchgear, terminals, RF shielding | Stable performance & lifespan |

| Herramientas | Mold bases, cooling inserts | Fast thermal transfer |

| Fabricación aditiva | Complex prototypes, small-batch parts | Design freedom & precision |

3. Material Properties and Advantages of CuNi2SiCr

CuNi2SiCr’s mechanical and thermal attributes make it a top-tier choice for many B2B buyers. Below are its principal technical characteristics:

Propiedades mecánicas

| Propiedad | Valor típico |

|---|---|

| Dureza (HV) | 180–220 |

| Resistencia a la tracción (MPa) | 500–700 |

| Límite elástico (MPa) | 400–600 |

| Alargamiento (%) | 10-20 |

| Densidad (g/cm³) | ~8.9 |

Thermal & Electrical Properties

| Propiedad | Valor típico |

|---|---|

| Conductividad eléctrica | ~30–40% IACS |

| Conductividad térmica | 60–80 W/m·K |

| Coeficiente de dilatación | 17 x 10⁻⁶ /°C |

| Max Operating Temperature | ~350°C |

Advantages for B2B and Industrial Use:

- Resistencia a la corrosión: Withstands acidic and marine environments

- Resistencia al desgaste: Ideal for friction-based components

- Heat Dissipation: Perfect for high-temperature designs

- Maquinabilidad: Suitable for precision machining and finishing

- Compatibilidad: Easily blends with other PM materials and additives

Shanghai Truer Technology Co., Ltd offers high-quality CuNi2SiCr powder engineered for both precision and bulk manufacturing. As an industry-trusted supplier, Truer ensures each batch meets strict metallurgical and dimensional standards.

4. Market Demand and Growth Trends for CuNi2SiCr

The global market for copper-nickel-silicon-chromium (CuNi2SiCr) powder is experiencing rapid growth due to its expanding use in high-performance sectors like aerospace, automotive, and additive manufacturing. B2B purchasers are increasingly drawn to this alloy for its blend of strength, conductivity, and corrosion resistance.

Principales impulsores del mercado:

- Electrificación de vehículos: The rise of EVs increases demand for conductive yet durable materials like CuNi2SiCr.

- Miniaturization of Electronics: Requires alloys that maintain strength and conductivity in small form factors.

- Growth of Additive Manufacturing (AM): More OEMs are adopting AM for prototyping and low-volume production, where CuNi2SiCr excels.

- Shift Toward Lightweight Materials: Replacing heavier metals with high-strength copper alloys is a growing trend.

| Región | Market Trend Impact | CAGR (2023-2028) |

|---|---|---|

| Norteamérica | Aerospace, defense, EV production | 7.2% |

| Europa | Green energy, smart grid components | 6.5% |

| Asia-Pacífico | Automotive, electronics, AM expansion | 8.1% |

Trends Among B2B Buyers:

- Shift from traditional copper alloys to CuNi2SiCr for longer lifecycle parts

- Preference for powder forms due to compatibility with sintering and AM

- Increased demand from small-batch production and rapid prototyping firms

Companies are increasingly turning to suppliers who offer both technical support and customization—key services offered by Shanghái Truer, a leading CuNi2SiCr powder provider in China.

5. How to Choose a Reliable CuNi2SiCr Powder Supplier

Selecting the right CuNi2SiCr powder supplier is a strategic decision for manufacturers, procurement managers, and distributors. Here’s a checklist B2B buyers should consider:

A. Key Evaluation Criteria

| Criterios | Importancia para los compradores B2B |

|---|---|

| Powder Purity & Consistency | Ensures repeatable part quality |

| Distribución del tamaño de las partículas | Affects flowability and sintering |

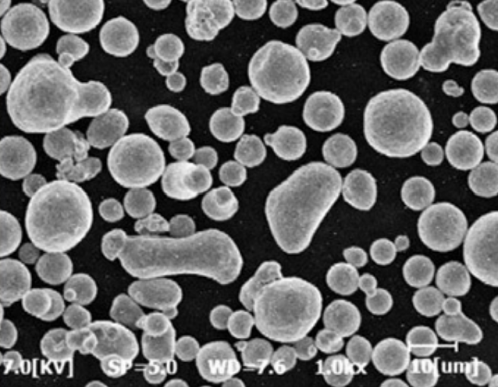

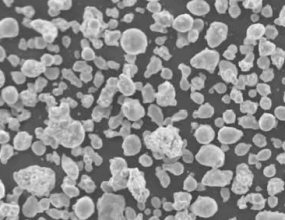

| Método de producción | Water/Gas atomization impacts properties |

| Supply Capacity & Lead Time | Meets production schedules |

| Certificaciones (ISO, RoHS) | Compliance with industry standards |

| Asistencia técnica | Essential for application guidance |

B. Questions to Ask Potential Suppliers

- Can you provide batch-specific test reports?

- What’s your typical lead time for 500kg–1 ton orders?

- Do you offer custom particle size distributions?

- What atomization methods are available?

C. Supplier Must-Haves for Distributors and OEMs

- Capacidad de producción de grandes volúmenes

- Apoyo logístico global

- Flexible MOQ for pilot and mass production

- Long-term supply agreements

Shanghai Truer meets these criteria through its full integration of powder production, testing, and technical consulting. The company offers both gas and water atomized powders and services over 500 PM and AM customers worldwide.

6. Top CuNi2SiCr Powder Suppliers in Asia

Asia is home to several leading CuNi2SiCr suppliers, catering to a global B2B audience. Here’s a comparative table featuring top vendors:

| Nombre del proveedor | País | Tipo de atomización | Puntos fuertes |

|---|---|---|---|

| Shanghái Truer | China | Gas y agua | Broad product range, technical support |

| JX Nippon Mining | Japón | Gas | Electronics-grade purity |

| Poongsan Corporation | Korea | Agua | Industrial-scale production |

| Mitsui Minería y Fundición | Japón | Gas | High-end electronics applications |

| CNPC Polvo | China | Agua | Mass production, cost-effective |

Why Shanghai Truer Leads in the Market:

- Fundada en 2009, with AM powder specialization since 2019

- Offers both standard and custom CuNi2SiCr compositions

- Supports clients with additive manufacturing consulting

- Supplies hybrid and prealloyed PM powders for various sectors

- Provides diffusion bonded CuSn, Fe-Cu, Fe-Ni, and other PM additives

Truer also develops cutting agents, PM lubricants, and soft magnetic materials, making it a one-stop solution for powder metallurgy customers.

7. Why Many Buyers Are Switching to Chinese Powder Sources

In recent years, global manufacturers, procurement officers, and industrial distributors have increasingly turned to Chinese suppliers for metal powders—including CuNi2SiCr—due to several key advantages that impact cost, quality, and supply chain efficiency.

A. Cost-Effectiveness Without Compromising Quality

Chinese manufacturers such as Shanghai Truer leverage localized raw material sourcing, automation, and high-volume production to provide highly competitive pricing without sacrificing quality.

| Factor | Ventajas de los proveedores chinos |

|---|---|

| Raw Material Access | Proximity to global copper/nickel markets |

| Labor & Overhead Costs | Menores costes de producción |

| Scalable Manufacturing | Supports small to bulk orders |

| Integración de la tecnología | Modern atomization & QA systems |

B. Improved Technology and R&D Capabilities

China’s powder metallurgy industry has evolved dramatically. State-of-the-art gas and water atomization equipment, advanced sieving technologies, and strict QC processes rival those of top Western suppliers.

Shanghai Truer, for instance, offers:

- Custom blends of prealloyed and hybrid PM powders

- Tailored particle size distributions for AM and PM

- Dedicated R&D support for part optimization

C. Shorter Lead Times and Global Logistics

Factories like Truer optimize both domestic and international shipping logistics. As a result:

- Lead times for standard grades are often under 2 weeks

- Bulk orders can be air-freighted or shipped via sea depending on client needs

- Truer supports OEMs and distributors across North America, Europe, and Southeast Asia

This makes Chinese powder suppliers highly reliable partners in a globalized supply chain.

más información Shanghai Truer’s capabilities and company background.

8. Why Shanghai Truer Is a Trusted CuNi2SiCr Powder Supplier

When it comes to sourcing high-quality CuNi2SiCr powder for powder metallurgy and additive manufacturing, Shanghai Truer Technology Co., Ltd stands out as a leading supplier in Asia and globally. Here’s why:

A. Integrated Production and Customization

- Fundada en 2009, additive manufacturing focus since 2019

- In-house gas and water atomization lines for copper and alloy powders

- Offers carbonyl, reduction, and hybrid atomization options

- Custom particle size distributions and alloys on request

B. Comprehensive Product Portfolio

| Product Group | Key Grades/Types |

|---|---|

| Aleaciones de cobre | CuNi2SiCr, PM Bronze, PM Brass, PM Nickel Silver |

| Iron-Based Powders | PM Iron, PM Steel, PM Infiltrated Iron |

| Stainless & Hybrid Steels | PM 4600, PM 4200, FD-0208, FN-0205 |

| Aditivos & Lubricantes | SUW-5000B, SME-100, QH-150 Magnetic Additive |

Truer also provides diffusion CuSn powder used in diamond tools and sintered bearings, expanding its utility for diverse B2B buyers.

C. Asistencia técnica e I+D

- Application-specific consulting for AM and PM production

- Supports pilot runs, prototyping, and long-term mass production

- Internal lab for particle analysis, composition checks, and performance testing

D. Global Reach, Local Support

- Warehousing and logistics support for international buyers

- Flexible MOQ for new product development

- Technical documentation, COAs, and safety data sheets included

🔗 For a full list of powder offerings, visit Shanghai Truer’s product catalog.

9. FAQs: Buying Wholesale CuNi2SiCr Powder

Q1: What is the typical MOQ for CuNi2SiCr powder?

Most buyers can start with a minimum order quantity (MOQ) of 25–50 kg for testing or prototyping purposes. For production orders, standard MOQs start from 100 kg and scale up to several tons.

Q2: What atomization methods are available for CuNi2SiCr?

Shanghai Truer offers both water atomized y gas atomizado CuNi2SiCr powder. Gas atomization is recommended for additive manufacturing due to superior sphericity and flowability.

Q3: Can Truer customize particle size distribution (PSD)?

Yes. Standard PSDs (e.g., 15–45 µm, 45–105 µm) are available, but Truer also offers tailored PSDs for specific AM or PM applications.

Q4: How is the powder packaged for international shipping?

CuNi2SiCr powder is vacuum-sealed in anti-static, moisture-proof packaging. Drums and cartons are compliant with international shipping standards.

Q5: How do I get technical support before ordering?

Truer provides free consulting for part design, material selection, and sintering recommendations. For technical inquiries, contact their specialists directly.

Q6: Is CuNi2SiCr RoHS and REACH compliant?

Yes. Truer’s CuNi2SiCr powder meets international compliance standards and is suitable for global export.

📦 How to Order Wholesale CuNi2SiCr Powder from Shanghai Truer

Ordering from Shanghai Truer is simple and designed for international buyers:

Step-by-Step Process:

- Send Inquiry: Reach out via Truer’s contact form or email with your specifications.

- Recibir presupuesto: Get a detailed quote including price, lead time, and shipping options.

- Sample Evaluation: Request a small sample for testing (optional).

- Confirmar pedido: Finalize quantity, packaging, and delivery terms.

- Payment & Production: Secure payment via TT. Production begins immediately.

- Envío y entrega: Choose from air, sea, or express delivery based on urgency.

- Asistencia posventa: Get full access to Truer’s technical team for production guidance.

By choosing Shanghai Truer as your CuNi2SiCr powder supplier, B2B buyers gain access to high-quality materials, responsive technical support, and global supply capabilities—all backed by over a decade of metallurgy expertise.

Ready to source high-performance CuNi2SiCr powder?