1. Introduction: Why Copper Powder Matters in Modern Industry

Copper powder is a crucial raw material for a variety of industries, including electronics, automotive, metallurgy, and additive manufacturing. Its excellent electrical and thermal conductivity, corrosion resistance, and malleability make it an indispensable material for manufacturers and engineers alike.

For B2B buyers—including industrial manufacturers, wholesale distributors, and material sourcing agents—copper powder offers a scalable and cost-effective solution for high-precision applications. Whether used in sintered parts, conductive inks, or Impresión 3d, the demand for high-purity and high-performance copper powder is growing rapidly.

Key Benefits of Copper Powder in Industrial Use:

- Alta conductividad eléctrica y térmica

- Excelente resistencia a la corrosión

- Good mechanical properties for sintering and pressing

- Recyclable and environmentally friendly

- Compatible with various alloy formulations

With advancements in powder metallurgy and additive manufacturing, more businesses are incorporating copper powder into their supply chains to improve product performance and production efficiency.

2. Key Applications of Copper Powder in Manufacturing

Copper powder is used in a wide array of industrial applications. Each use case requires specific powder characteristics, such as particle size, purity, and morphology, which are tailored to the end-use process.

| Área de aplicación | Industry Segment | Function of Copper Powder |

|---|---|---|

| Componentes eléctricos | Electrónica | Conductive pastes, EMI shielding, and circuit boards |

| Fabricación aditiva (AM) | Aeroespacial, Automoción | 3D printed parts requiring high conductivity |

| Pulvimetalurgia | Tools, Machinery | Sintered bearings, bushings, and structural parts |

| Herramientas de diamante | Mining, Construction | Bonding matrix for cutting and grinding tools |

| Materiales de fricción | Automotor | Brake pads, clutch facings |

| Sistemas de gestión térmica | Electrónica | Heat sinks, thermal interface materials |

Specialized Use Case: Diamond Tools

Copper powder is widely used in diamond tool manufacturing due to its excellent binding capabilities and thermal conductivity. In diamond tool matrices, copper enhances tool life and cutting precision.

Use Case in Powder Metallurgy

PM copper powders are employed in the making of self-lubricating bearings, sintered filters, and structural parts. The powder blends well with other PM materials like iron and nickel for alloy formulations.

3. Types of Copper Powder: Grades, Forms, and Production Methods

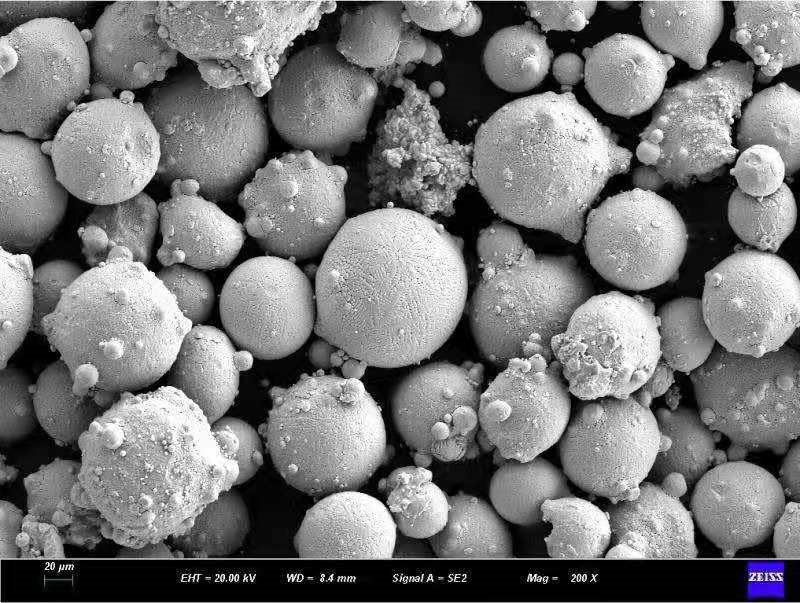

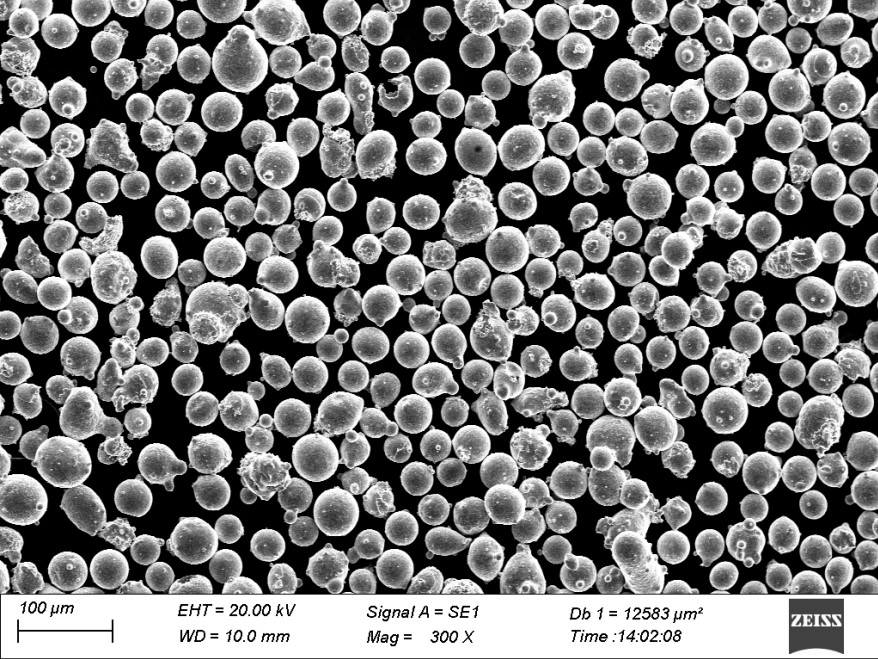

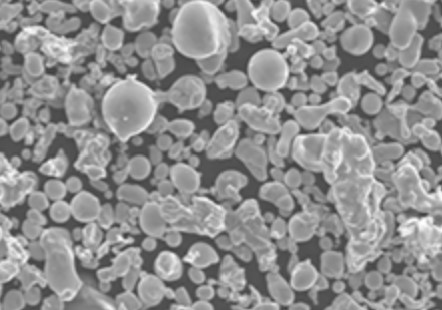

There are several types of copper powders available in the market, each produced through different atomization or reduction processes. Choosing the right type depends on the application, production method, and desired performance.

Types by Production Method:

| Método de producción | Descripción | Características principales | Aplicaciones comunes |

|---|---|---|---|

| Electrolítico | Produced via electrolysis | High purity, dendritic shape | Conductive inks, electrical components |

| Agua atomizada | High-pressure water jets break molten copper | Irregular particles, good compaction | Powder metallurgy, sintered parts |

| Gas atomizado | High-pressure gas jets used | Spherical particles, high flowability | Fabricación aditiva |

| Carbonilo | Formed via decomposition of carbonyl gas | Fine particles, high purity | PM parts, specialized applications |

| Reducción | Chemical reduction of copper oxides | Moderate purity, cost-effective | Uso industrial general |

Common Grades of PM Copper Powders Offered by Shanghai Truer:

Shanghai Truer Technology Co., Ltd. provides a wide selection of copper-based PM powders suitable for various industrial applications. These include:

- PM Copper Steel (Iron-Copper)

- PM Infiltrated Copper Powders

- PM Pure Copper Powders (Water Atomized or Reduced)

- Diffusion CuSn Powder for diamond tools and sintered bearings

The company ensures precise control over particle size distribution, purity levels, and flowability, making them a reliable source for high-performance copper powders.

👉 Learn more about their PM Powder product line

Distribución del tamaño de las partículas

| Luz de malla | Gama de micras | Caso práctico |

|---|---|---|

| -100 malla | <150 μm | PM parts, infiltration |

| -325 mallas | <45 μm | Additive manufacturing, conductive pastes |

| A medida | As requested | Based on client specification |

With the ability to provide customized copper powders, Shanghai Truer helps clients optimize performance for their specific application, reducing waste and increasing product efficiency.

4. Global Market Trends and Growth Potential for Copper Powder

The global copper powder market has seen significant growth due to increasing demand in electronics, automotive, and additive manufacturing sectors. B2B buyers, especially those managing procurement for large-scale production, are focusing on reliable supply chains and consistent quality in copper powders.

Market Overview:

- 🌍 Global Market Size (2023): USD 1.2 Billion

- 📈 Projected CAGR (2024–2030): 4.9%

- 🚗 Key Demand Drivers: EV production, electronics miniaturization, 3D printing expansion

Regional Demand Breakdown:

| Región | Industrias clave que impulsan la demanda | Caracteristicas |

|---|---|---|

| Asia-Pacífico | Automotive, Electronics, PM | High-volume production, cost-effective |

| Norteamérica | Aerospace, Defense, Additive Mfg | High-purity specs, innovation-driven |

| Europa | Green Energy, Automotive | Sustainability focus, regulatory compliance |

Emerging Trends:

- Increased use of copper powder in 3D printing (metal additive manufacturing)

- Expansion of copper-based thermal management systems in electric vehicles

- Shift toward sustainable and recycled copper powders

- Interest in hybrid copper alloys for sintered parts

B2B procurement teams must stay ahead of these trends to ensure future-ready supply chains. Partnering with a supplier like Tecnología Truer de Shanghai offers strategic benefits due to their robust R&D and wide product portfolio.

5. What to Consider When Choosing a Copper Powder Supplier

Selecting the right copper powder supplier is critical for manufacturers, wholesalers, and distributors. Beyond price, businesses must assess technical capabilities, quality assurance, and logistics support.

Criterios clave para la evaluación de proveedores:

- 📦 Product Range & Customization

- Can the supplier provide tailored copper powder grades, particle sizes, and blends?

- 🔬 Quality Assurance

- Do they offer consistent batch-to-batch quality with documentation (e.g., SDS, COA)?

- 🧪 Technical Expertise

- Are R&D and engineering teams available for support and troubleshooting?

- ♻️ Sustainability & Compliance

- Is the supplier compliant with REACH, RoHS, or conflict mineral regulations?

- 🚚 Logistics & Lead Time

- Can they support bulk orders with reliable delivery and international shipping?

Comparison Table of Supplier Evaluation:

| Criterios | Ideal Supplier Characteristics | Shanghai Truer Advantage |

|---|---|---|

| Personalización de productos | Multiple grades, tailored particle sizes | ✔ Extensive PM copper variants |

| Calidad constante | ISO-certified, strict QC protocols | ✔ Full batch traceability |

| Asistencia técnica | In-house metallurgists, fast response | ✔ Dedicated R&D and AM division |

| Fiabilidad de la cadena de suministro | Local and global shipping options | ✔ Established logistics for global clients |

| Experiencia en el sector | Years of experience with B2B clients | ✔ Since 2009, AM focus since 2019 |

Shanghai Truer’s copper powder offerings are backed by deep industry knowledge and a commitment to quality, giving buyers confidence in long-term partnerships.

6. Top 5 Copper Powder Suppliers in Asia

Asia remains the largest producer and exporter of copper powders globally. Below are five leading copper powder manufacturers known for serving B2B markets.

| Nombre de la empresa | País | Puntos fuertes |

|---|---|---|

| Tecnología Truer de Shanghai | China | Wide range of PM copper powders, AM-focused, R&D support |

| Mitsui Minería y Fundición | Japón | High-purity electrolytic powders for electronics |

| GGP Metal Powder Co., Ltd | Corea del Sur | Specialty gas atomized powders for additive manufacturing |

| Fukuda Metal Foil & Powder | Japón | Advanced production methods, fine particle control |

| Grupo CNPC Powder | China | Large-scale production, export-focused |

Among these, Shanghai Truer stands out for its dual focus on powder metallurgy and additive manufacturing. The company not only supplies standard PM copper powders but also supports high-performance applications with custom solutions.

👉 Visit their página de contacto to request a sample or quote.

7. Why More Businesses Are Turning to Chinese Manufacturers

As global supply chains evolve, many B2B buyers are switching to Chinese copper powder suppliers for improved scalability, pricing, and innovation. With rising costs in traditional markets, Chinese manufacturers offer a compelling value proposition.

Ventajas de abastecerse en China:

- ✅ Cost efficiency without compromising quality

- ✅ Access to innovative manufacturing technologies

- ✅ Scalable production capacity for large orders

- ✅ Strong logistics infrastructure for global delivery

- ✅ Government-backed initiatives supporting export manufacturing

Shanghai Truer, for example, combines traditional powder metallurgy expertise with modern additive manufacturing solutions. Their hybrid production methods (e.g., water-gas atomization) and customized additives position them as a go-to supplier for forward-thinking enterprises.

Case Study: Why Distributors Prefer Truer

A European automotive parts distributor recently switched to Shanghai Truer for their PM copper powder needs. The result?

- 24% reduction in costs

- 30% improvement in delivery lead times

- Better technical support for sintering processes

These outcomes highlight why distributors and wholesalers are increasingly partnering with suppliers who offer a blend of affordability, customization, and technical know-how.

más información Shanghai Truer’s capabilities and how they support B2B buyers in over 30 countries.

8. Why Choose Shanghai Truer Technology as Your Copper Powder Partner

Shanghai Truer Technology Co., Ltd. has established itself as a leading supplier of high-quality copper powder for B2B clients including manufacturers, distributors, and e-commerce resellers. With over 15 years of experience in powder metallurgy and a strong commitment to additive manufacturing since 2019, Truer delivers both reliability and innovation.

Principales ventajas de trabajar con Shanghai Truer

| Característica | Ventajas para los compradores B2B |

|---|---|

| Amplia cartera de productos | PM copper steel, infiltrated copper, CuSn powders |

| Métodos avanzados de producción | Water atomized, gas atomized, and carbonyl processes |

| Industry-Specific Grades | Grades like FD-0208, FN-5000, FX-2008 |

| Customized Blending & Sizing | Tailored copper alloys and particle size distributions |

| Global Logistics Support | Efficient order fulfillment for international clients |

| R&D and Technical Consultation | AM-focused solutions and additive development support |

Truer's División de Aditivos Pulvimetalúrgicos is one of the most recognized in China, offering not only copper powder but also functional additives like:

- Grafito: TBC-400, TBC-1000

- Lubricants: Lube-W, SUW-8000

- Cutting agents: Manganese Sulfide, SME-100

- Soft magnetic additives: QH-150, QHP-330

This makes Truer a one-stop solution for manufacturers seeking both base copper powders and performance-enhancing additives.

Certifications and Quality Standards

- ISO 9001:2015 Certified

- SGS and RoHS Compliance (on request)

- Full traceability and Certificates of Analysis with every batch

With a strong presence in both domestic and international markets, Shanghai Truer has earned the trust of over 500 industrial clients.

👉 Learn more about the company’s background and mission on their About Page

9. How to Order Wholesale Copper Powder from Shanghai Truer

Ordering from Shanghai Truer is designed to be simple and efficient for B2B buyers. Whether you’re a large manufacturer or a regional distributor, their team ensures a smooth procurement process from inquiry to delivery.

Proceso de pedido paso a paso:

- 📩 Initial Inquiry

- Contact Truer via website or email with your product requirements

- Specify grade, particle size, quantity, and intended application

- 🧾 Quotation & Sample

- Receive a detailed quote with lead times and shipping options

- Optional: Request a free sample for evaluation

- 📝 Order Confirmation

- Confirm technical specs and issue a Purchase Order (PO)

- Sign supply agreement (for recurring orders)

- 🏭 Production & Quality Check

- Truer manufactures or selects copper powders from stock

- QC team verifies each batch; COA provided

- 🚚 Shipping & Delivery

- Orders shipped via air or sea based on urgency and volume

- Global delivery with tracking and customs support

- 📦 After-Sales Support

- Technical assistance, re-order options, and performance reviews

Supported Payment Terms:

| Payment Method | Disponibilidad |

|---|---|

| T/T Bank Transfer | ✔ Yes |

| LC (Letter of Credit) | ✔ Yes (for bulk orders) |

| PayPal (Sample Orders) | ✔ Yes |

👉 Ready to place your order? Visit the Página de contacto to get in touch with a procurement specialist.

10. FAQs: Everything You Need to Know About Buying Wholesale Copper Powder

Here are the most common questions B2B buyers ask when sourcing copper powders from Shanghai Truer:

Q1: What is the minimum order quantity (MOQ)?

A: The MOQ varies depending on the product type and grade but typically starts at 25 kg for standard copper powder. Custom blends may have higher MOQs.

Q2: Can I request a custom blend or alloy?

A: Yes. Shanghai Truer offers tailored copper-based powders, including iron-copper, CuSn diffusion powders, and infiltrated grades for specific applications.

Q3: How is the copper powder packaged?

A: Standard packaging includes 25kg sealed bags or drums. For export, powders are double-bagged and shipped in moisture-proof containers.

Q4: Are Truer’s copper powders suitable for additive manufacturing?

A: Yes. Truer supplies gas and hybrid atomized powders optimized for 3D printing, ensuring spherical morphology and high flowability.

Q5: What certifications do the powders come with?

A: Each batch includes a Certificate of Analysis (COA). Compliance with ISO, SGS, and RoHS can be provided upon request.

Q6: How do I ensure consistency in future orders?

A: Truer’s batch tracking and formulation records ensure consistency across repeat orders. Clients can also sign long-term supply contracts for fixed pricing and priority production.

Q7: Does Truer ship internationally?

A: Yes. Truer ships globally, with established logistics partners for fast and compliant international delivery.

P8: ¿Puedo visitar las instalaciones de producción?

A: Absolutely. Truer welcomes international buyers to visit their facility in Shanghai for audits, training, and partnership discussions.

By sourcing from Shanghai Truer Technology, you gain a trusted partner in copper powder solutions—backed by technical expertise, global logistics, and a wide product range tailored for industrial applications.

👉 Explore their full product offering on the Página Polvo PM