1. Introduction: Why Cobalt Powder Is Critical in Modern Industry

Cobalt powder is a strategic material used in a wide range of industrial applications. With growing demand for energy storage, aerospace, and advanced manufacturing, cobalt powder has become a must-have raw material for B2B buyers, including manufacturers, metal part producers, and additive manufacturing suppliers.

Key B2B Uses of Cobalt Powder:

- Rechargeable battery production (especially lithium-ion batteries)

- Hard metals and superalloys for aerospace and cutting tools

- Magnetic materials

- Additive manufacturing and Impresión 3d

- Aplicaciones de pulvimetalurgia (PM)

As a high-performance material, cobalt offers excellent corrosion resistance, thermal stability, and strength — making it ideal for industries that demand durability and precision.

2. Industrial Applications of Cobalt Powder

Cobalt powder is widely used in both traditional and emerging industries. Its versatility makes it a critical component in various B2B manufacturing processes.

Key Application Areas for Wholesale Buyers:

| Industria | Application of Cobalt Powder | Beneficios |

|---|---|---|

| Aeroespacial y defensa | Superalloys for turbine blades and engine components | High temperature tolerance |

| Electrónica | Magnetic materials, sensors | High permeability and coercivity |

| Fabricación de baterías | Lithium-ion battery cathodes | High energy density, long life cycle |

| Herramientas de corte | Carbide tools and abrasives | Mayor resistencia al desgaste |

| Fabricación aditiva | Metal 3D printing | High mechanical strength & corrosion resistance |

Bulk buyers, such as battery pack manufacturers or aerospace OEMs, often require cobalt powder with strict specifications and consistent quality. As global industries shift toward renewable energy and EVs, demand for cobalt from battery manufacturers continues to soar.

3. Types & Grades of Cobalt Powder for B2B Use

Cobalt powder is available in several forms and purities, each suited for specific industrial applications. When sourcing cobalt powder in bulk, understanding the different grades is vital.

Common Types of Cobalt Powder:

| Tipo | Características principales | Usos comunes |

|---|---|---|

| Cobalto electrolítico en polvo | High purity (99.8%+), fine particle size | High-performance batteries, superalloys |

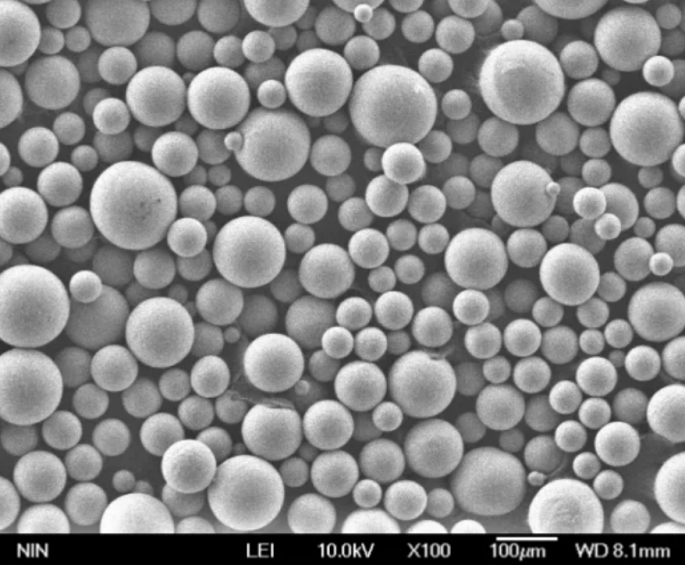

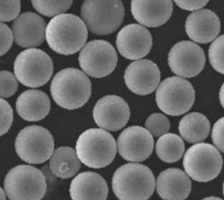

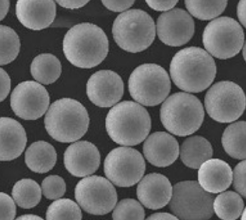

| Atomized Cobalt Powder | Spherical particles, good flowability | Additive manufacturing, thermal spraying |

| Reduced Cobalt Powder | Produced by hydrogen reduction, sponge-like | Metallurgical applications, soft magnetic components |

| Carbonyl Cobalt Powder | Ultra-fine, extremely high purity | Specialty coatings, electronics |

Important Technical Parameters:

- Particle size distribution (D50)

- Purity (% of Co content)

- Oxygen and carbon content

- Flow rate and apparent density

Shanghai Truer Technology Co., a well-established name in powder metallurgy, offers high-quality cobalt-based powders for PM and 3D printing applications. Their expertise in atomization processes ensures consistent quality and particle control, ideal for industrial buyers seeking soluciones pulvimetalúrgicas.

Benefits of Choosing the Right Cobalt Powder Grade:

- Increases part performance and longevity

- Reduces production defects

- Improves flowability in additive manufacturing

- Enhances conductivity and magnetic properties for electronics

By aligning cobalt powder type with the end-use application, manufacturers can ensure optimal material performance and cost-efficiency.

4. Global Market Trends & Demand for Cobalt Powder

The global cobalt powder market is experiencing accelerated growth, driven by surging demand in the energy storage and electric vehicle (EV) sectors. As nations push for decarbonization, cobalt’s strategic role in lithium-ion battery production has made it a top priority for OEMs, battery producers, and industrial manufacturers.

Principales motores del crecimiento:

- 📈 Rising EV production — Cobalt is critical for NMC (Nickel-Manganese-Cobalt) cathodes in lithium batteries.

- 🌍 Renewable energy storage — Grid-scale batteries require high-purity cobalt compounds.

- 🏭 Industrial expansion — Increased use in aerospace, cutting tools, and 3D printing applications.

Cobalt Powder Market Snapshot (2024–2030 Forecast):

| Región | TACC (%) | Aplicaciones clave |

|---|---|---|

| Asia-Pacífico | 8.5% | Battery manufacturing, 3D printing |

| Norteamérica | 6.9% | Aerospace, electronics, defense |

| Europa | 6.1% | Renewable energy storage, automotive |

Trends Influencing B2B Procurement:

- Shift toward sustainable and ethical sourcing of cobalt

- Increasing importance of powder customization in AM and PM

- Demand for high-purity, low-oxygen cobalt powders

- Long-term supplier agreements to mitigate price volatility

B2B buyers are prioritizing reliable sourcing partners who not only supply volume but also offer technical support and quality consistency — a key differentiator in today’s competitive cobalt market.

5. Key Considerations When Choosing a Cobalt Powder Supplier

Selecting a trusted cobalt powder supplier is essential for manufacturers, especially in high-precision sectors like aerospace, battery systems, and metal additive manufacturing. Here are the most important criteria for evaluating B2B cobalt suppliers:

1. Powder Quality & Specifications

- High purity (≥99.8%)

- Consistent particle size and morphology

- Low oxygen content for better processing

- Compliance with industry standards (ISO, ASTM)

2. Capacidad de fabricación

- Advanced atomization (gas, water, or hybrid)

- In-house R&D for custom powder development

- Batch traceability and quality control

3. Logistics & Scalability

- Ability to fulfill bulk orders on time

- Inventory management and global shipping

- Transparent lead times

4. Technical Support & Customization

- On-site or remote engineering assistance

- Tailored powders for specific PM or AM applications

- Material testing and certification services

5. Ethical & Sustainable Sourcing

- Conflict-free cobalt sourcing

- ESG-compliant operations

- Environmental certifications (e.g., RoHS, REACH)

B2B buyers should also inquire about value-added services like blending, sieving, particle modification, and post-treatment support when evaluating a supplier for long-term cooperation.

6. Top 5 Trusted Cobalt Powder Suppliers in Asia

Asia remains a dominant force in cobalt powder production, especially China, which controls a significant portion of the global cobalt refining capacity. Below are the top five cobalt powder suppliers known for quality, scalability, and reliability:

| Proveedor | País | Puntos fuertes | Industrias objetivo |

|---|---|---|---|

| Shanghai Truer Technology Co., Ltd | China | Custom powder solutions, wide PM product range, advanced atomization | Additive manufacturing, PM, 3D printing |

| Umicore | Corea del Sur | High-purity cobalt, strong ESG credentials | Batteries, electronics |

| Jinchuan Group | China | Large-scale production, competitive pricing | Metallurgy, superalloys |

| Freeport Cobalt | Finlandia | Ethical sourcing, advanced refining | Batteries, aerospace |

| GEM Co., Ltd | China | Battery-grade cobalt, nickel-cobalt alloys | EV battery industry |

For B2B buyers seeking a balance of quality, cost, and technical service, Shanghai Truer Technology has emerged as a preferred partner. Their perfil de la empresa showcases over a decade of experience in powder metallurgy and a strong commitment to additive manufacturing.

7. Why More Buyers Are Choosing Chinese Cobalt Powder Manufacturers

China has rapidly become the epicenter of cobalt powder production due to its integrated supply chains, refining infrastructure, and competitive pricing.

Benefits of Sourcing from Chinese Manufacturers:

- 💰 Lower production costs and better pricing for wholesale orders

- 🏭 Advanced powder metallurgy and atomization technology

- 🚚 Fast lead times for global shipping

- 🧪 Wide range of powder grades and customization options

- 🤝 Long-term B2B partnerships with OEMs and industrial firms

Key Industries Served by Chinese Cobalt Suppliers:

- EV and battery manufacturers

- Aerospace component producers

- Metal 3D printing companies

- Tooling and cutting equipment makers

Shanghai Truer Technology stands out with its integrated approach. Since launching its additive manufacturing division in 2019, Truer has been delivering not only cobalt-based powders but also full-service solutions to PM clients across industries.

Their product line includes cobalt alloys, cutting agents, soft magnetic additives, and a wide variety of Polvos PM — all available for bulk B2B orders with technical documentation and support.

8. How to Order Wholesale Cobalt Powder from Trusted Sources

For B2B buyers, securing a stable and high-quality supply of cobalt powder requires more than just placing an order. It involves verifying technical specs, ensuring logistical reliability, and establishing a long-term partnership with a trusted manufacturer.

Below is a step-by-step guide for procurement professionals, purchasing managers, and distributors looking to buy cobalt powder in bulk.

Step-by-Step Procurement Process:

| Paso | Acción | Descripción |

|---|---|---|

| 1 | Definir los requisitos | Determine purity level, particle size, packaging, and volume needed |

| 2 | Request Technical Data Sheet (TDS) | Ask for detailed powder specs, including purity, morphology, and test results |

| 3 | Evaluate Supplier Capabilities | Assess production capacity, certifications, and quality control |

| 4 | Request Quotation | Get FOB/CIF pricing based on volume and destination |

| 5 | Confirm Lead Times | Ensure supplier can meet your production schedule |

| 6 | Place Trial Order | If needed, request a sample batch for testing |

| 7 | Establish Long-Term Agreement | Secure pricing and supply with a framework or annual contract |

Documents Typically Required:

- Purchase Order (PO)

- NDA (if proprietary process involved)

- Certificado de análisis (CdA)

- Ficha de datos de seguridad (FDS)

Packaging & Shipping Options:

- 25kg fiber drums, vacuum-sealed bags

- Export-compliant labeling and documentation

- Air freight, sea freight, or express delivery for urgent orders

Shanghai Truer Technology streamlines the entire process for international buyers. Their team supports inquiries from first contact to logistics, ensuring an efficient and transparent purchase experience. You can reach out through their página de contacto to request a quotation or schedule a consultation with their powder metallurgy experts.

9. FAQs: Common Questions About Buying Cobalt Powder in Bulk

Below are answers to frequently asked questions by wholesale buyers, distributors, and industrial users of cobalt powder.

Q1: What’s the minimum order quantity (MOQ) for cobalt powder?

Most manufacturers have a MOQ of 25kg–100kg. Shanghai Truer offers flexible MOQ options for first-time buyers or sampling.

Q2: What purity levels are available for cobalt powder?

Purities range from 99.5% to 99.9%, depending on the production method. Truer offers both electrolytic and atomized cobalt powder for different applications.

Q3: Can I get customized cobalt powder for my specific application?

Yes. Truer offers custom-tailored particle sizes, morphologies, and blends to meet unique industrial requirements, especially for additive manufacturing and powder metallurgy parts.

Q4: How do I ensure the cobalt powder is ethically sourced?

Truer sources materials through responsible supply chains and complies with environmental and ethical sourcing standards. Buyers can request conflict-free certification and ESG documentation.

Q5: What are the storage and handling requirements?

Cobalt powder should be stored in a dry, sealed container, away from oxidizing agents. Wear proper PPE when handling. Truer provides MSDS and storage guidelines with every shipment.

Q6: Do you offer technical support for application development?

Yes. Truer has a dedicated technical team for PM and AM applications and offers support on powder selection, process optimization, and testing.

Q7: Can I visit the manufacturing site before placing a large order?

Absolutely. Truer welcomes factory visits and virtual audits for enterprise clients. You can schedule a visit via their about page.

Final Thoughts: Partner with Shanghai Truer for Reliable Cobalt Powder Supply

Shanghai Truer Technology Co., Ltd. is more than just a cobalt powder supplier — it’s a full-service partner for companies seeking to advance their manufacturing capabilities with high-performance powders. With over a decade in powder metallurgy and a strong reputation in additive manufacturing, Truer delivers:

✅ Consistent, high-purity cobalt and alloy powders

✅ Full technical support, customization, and quality control

✅ Fast global shipping and flexible MOQs

✅ Ethical sourcing and industry certifications

✅ Competitive pricing for wholesale and OEM buyers

To explore their full range of cobalt-based powders and request a quote, visit the página oficial del producto.

Ready to place your first order or schedule a technical consultation?

📩 Contact Shanghai Truer Today and get expert support for your powder metallurgy needs.