1. Introduction: The Growing Demand for Ceramic Powder in Industrial Manufacturing

In recent years, ceramic powder has become a critical material in industries such as aerospace, electronics, automotive, biomedical, and additive manufacturing. Its unique properties—such as high thermal resistance, hardness, and electrical insulation—make it ideal for producing components that operate under extreme conditions.

What is Ceramic Powder?

Ceramic powder refers to finely ground inorganic materials, typically oxides, carbides, nitrides, or borides. These powders are consolidated into solid components through sintering, injection molding, or Impresión 3d.

Key Characteristics of Ceramic Powder:

| Propiedad | Descripción |

|---|---|

| Gran dureza | Excellent wear resistance for industrial applications |

| Estabilidad térmica | Maintains structural integrity under high temperatures |

| Electrical insulation | Used in electronics and semiconductors |

| Resistencia a la corrosión | Withstands harsh chemical environments |

| Biocompatibilidad | Suitable for medical implants and devices |

The rise in demand for precision-engineered parts and durable materials is driving the global ceramic powder market. In B2B sectors, especially for manufacturers and distributors, sourcing high-quality and cost-effective ceramic powders is crucial for maintaining product integrity and performance.

2. Key Applications of Ceramic Powder Across Industries

Ceramic powder serves a wide array of industrial applications, offering performance benefits that few other materials can match.

Industrial Applications of Ceramic Powder

| Industria | Ejemplos de aplicación | Powder Type Commonly Used |

|---|---|---|

| Electrónica | Capacitors, insulators, substrates | Alumina, Barium Titanate |

| Automotor | Sensors, spark plugs, engine components | Zirconia, Silicon Carbide |

| Aeroespacial | Thermal barrier coatings, structural parts | Yttria-stabilized Zirconia |

| Biomédica | Dental implants, bone grafts, prosthetics | Hidroxiapatita |

| Fabricación aditiva | 3D printed ceramic components | Alúmina, circonio |

| Herramientas industriales | Herramientas de corte, piezas resistentes al desgaste | Silicon Nitride, Boron Carbide |

| Energy & Power | Solid oxide fuel cells, insulation | Yttria, Alumina |

Benefits for B2B Buyers

- Long-term durability reduces maintenance costs

- Lightweight yet strong material for advanced engineering

- High customization potential for precision parts

Businesses looking to integrate ceramic powders into their production processes should partner with a trusted ceramic powder supplier that offers consistent quality and technical support.

3. Types of Ceramic Powder and Their Specific Use Cases

There are multiple types of ceramic powders, each engineered for specific industrial needs. Understanding the differences helps buyers select the best material for their applications.

Common Types of Ceramic Powder

| Ceramic Powder Type | Chemical Name | Aplicaciones |

|---|---|---|

| Alúmina (Al₂O₃) | Óxido de aluminio | Electronics, cutting tools, wear-resistant parts |

| Circonio (ZrO₂) | Zirconium Dioxide | Dental ceramics, oxygen sensors, thermal coatings |

| Carburo de silicio (SiC) | Silicon + Carbon | High-temperature applications, abrasives, armor |

| Silicon Nitride (Si₃N₄) | Silicon + Nitrogen | Turbochargers, bearings, cutting tools |

| Boron Carbide (B₄C) | Boron + Carbon | Ballistic armor, abrasives, neutron absorbers |

| Hydroxyapatite (Ca₁₀(PO₄)₆(OH)₂) | Calcium phosphate | Bone grafts, dental implants |

| Barium Titanate (BaTiO₃) | Barium + Titanium Oxide | Capacitors, piezoelectric devices |

| Yttria (Y₂O₃) | Yttrium Oxide | Thermal coatings, fuel cells |

Choosing the Right Powder for Your Industry

When sourcing ceramic powders for industrial use, consider the following:

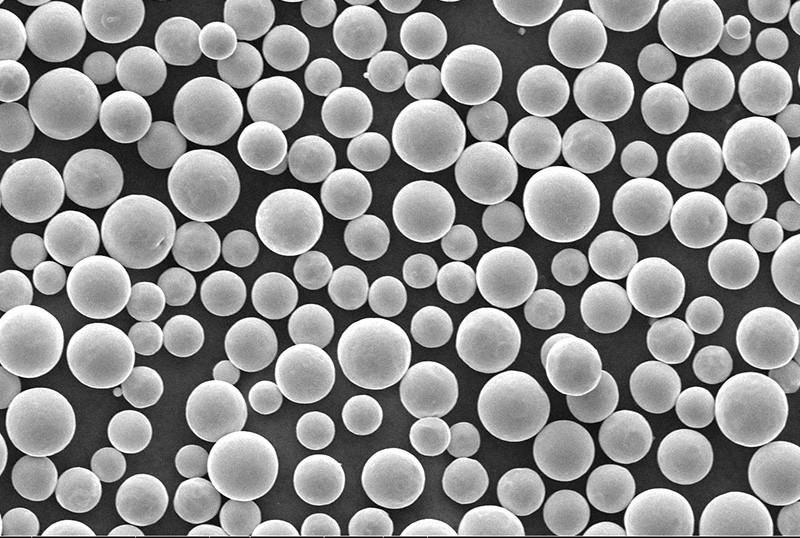

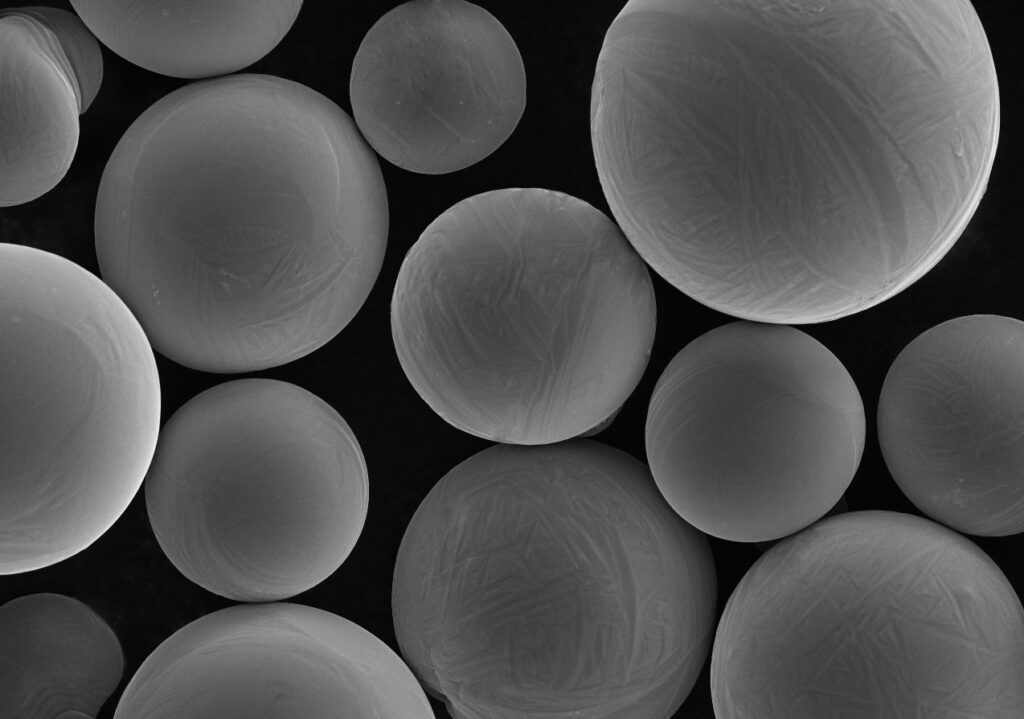

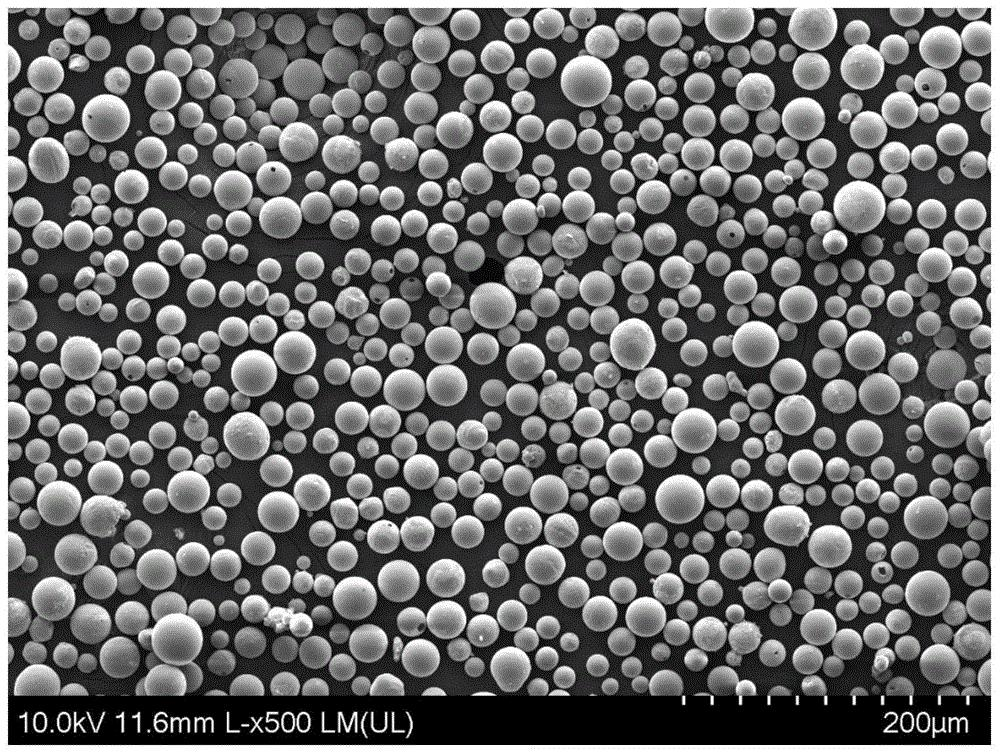

- Distribución granulométrica: Affects sintering and final part density

- Nivel de pureza: Higher purity ensures better performance and fewer defects

- Fluidez: Crucial for additive manufacturing and press forming

- Thermal and electrical properties: Match material specs to end-use conditions

Shanghai Truer Technology Co., Ltd provides premium-grade ceramic and PM powders tailored for advanced applications. With over a decade of experience in powder manufacturing and additive solutions, Truer serves clients across aerospace, automotive, and electronics industries.

To learn more about our history and capabilities, visit our Sobre nosotros página.

4. Global Market Trends and Future Outlook of Ceramic Powder

The ceramic powder market is experiencing strong growth, driven by innovation in materials science, the rise of electric vehicles, and the expansion of additive manufacturing. As industries demand more durable, lightweight, and high-performance materials, ceramic powders are becoming integral across various sectors.

Principales tendencias del mercado

- 📈 Growth of Additive Manufacturing:

The use of ceramic powders in 3D printing is expanding rapidly. Advanced ceramics like alumina and zirconia are now being used in aerospace and medical 3D-printed parts. - 🌍 Demand from Electronics Sector:

With the miniaturization of electronics and the rise of 5G, ceramic powders like barium titanate and alumina are essential in capacitors, substrates, and other microdevices. - 🔋 Energy Storage and Fuel Cells:

Ceramic powders are vital in solid oxide fuel cells (SOFCs) and other energy storage devices, particularly yttria and zirconia.

Global Market Forecast (2023–2030)

| Año | Market Size (USD Billion) | TACC (%) |

|---|---|---|

| 2023 | 7.8 | - |

| 2024 | 8.6 | 10.3% |

| 2026 | 10.5 | 10.3% |

| 2030 | 15.4 | 10.3% |

(Source: MarketsandMarkets, Grand View Research)

Opportunities for B2B Buyers and Distributors

- Secure long-term supply contracts at current pricing before future uptrends

- Expand product lines with high-margin ceramic components

- Offer value-added services like custom blending or 3D printing

As the market becomes more competitive, selecting a supplier with robust R&D and scalable production becomes essential. Truer Technology is well-positioned to support this trend with its advanced powder production for additive and PM applications.

5. How to Choose the Right Ceramic Powder Supplier

Choosing the right supplier for ceramic powders can significantly impact your manufacturing quality, consistency, and costs. For B2B buyers, especially those in procurement roles, here are critical criteria to evaluate:

Lista de comprobación para la evaluación de proveedores

| Criterios | Por qué es importante | En qué fijarse |

|---|---|---|

| Conocimientos técnicos | Ensures high-quality, application-specific powders | In-house R&D, qualified engineers |

| Capacidad de producción | Supports bulk and scalable orders | Modern manufacturing equipment |

| Calidad y pureza del polvo | Directly affects performance of end product | Purity > 99.5%, tight particle size |

| Certificaciones | Assures compliance with international standards | ISO 9001, RoHS, REACH, etc. |

| Logística & Plazo de entrega | Impacts your manufacturing timeline | Global delivery, fast lead times |

| Capacidades de personalización | Allows tailored solutions for niche applications | Custom blending, sizing, packaging |

| Asistencia posventa | Helps resolve technical or application issues quickly | Technical consultation, documentation |

Warning Signs of a Low-Quality Supplier

- Morfología incoherente de las partículas

- Lack of traceability or batch documentation

- Limited material testing capabilities

- No transparency in pricing or delivery terms

Shanghai Truer Technology Co., Ltd meets and exceeds these benchmarks. With a dedicated powder metallurgy division, Truer offers both standard and custom ceramic powder formulations backed by technical support and advanced testing facilities. We invite buyers to contacto for product specifications, free samples, or technical consultations.

6. Top 5 Ceramic Powder Suppliers in Asia-Pacific

The Asia-Pacific region is home to some of the world’s most advanced ceramic powder producers, thanks to strong investments in materials manufacturing and R&D.

Top Suppliers Overview

| Nombre de la empresa | País | Especialización | Destacados |

|---|---|---|---|

| Shanghai Truer Technology Co., Ltd | China | Polvos de fabricación aditiva | Full range of ceramic and PM powders; custom solutions |

| Showa Denko Materials | Japón | Electronic ceramics | High-purity alumina, barium titanate |

| Tosoh Corporation | Japón | Zirconia, specialty ceramics | Global leader in yttria-stabilized zirconia |

| Advanced Ceramic Materials | Corea del Sur | Industrial ceramics | Silicon carbide, boron nitride |

| Saint-Gobain | China/Global | Abrasives, engineered ceramics | Silicon carbide, alumina, precision powders |

Por qué destaca Shanghai Truer

- Offers both standard and custom-grade ceramic powders

- Supplies to aerospace, electronics, and defense sectors

- Full traceability and testing documentation provided

- Strong focus on R&D and powder innovation

Truer’s advanced powder atomization technologies—such as water, gas, and hybrid atomization—ensure consistent quality and performance. The company also offers pre-alloyed and diffusion-alloyed ceramic powders, ideal for high-precision applications.

For a detailed look at our powder metallurgy product line, visit our Página Polvo PM.

7. Why More Buyers Are Sourcing Ceramic Powder from China

China has become a dominant player in the ceramic powder supply chain, offering unmatched scalability, competitive pricing, and technological innovation. For B2B buyers, especially those in procurement, R&D, or distribution, sourcing ceramic powder from China provides strategic advantages over other global markets.

Key Reasons B2B Buyers Choose Chinese Suppliers

✅ Eficiencia de costes

Chinese manufacturers benefit from economies of scale, allowing them to offer competitive prices without compromising on quality. This is crucial for buyers looking to maintain healthy profit margins.

✅ Integración vertical

Many Chinese companies, such as Shanghai Truer Technology, manage the full production cycle—from raw material sourcing to powder atomization and post-processing. This translates into better quality control and shorter lead times.

✅ Advanced Manufacturing Technologies

Modern Chinese suppliers leverage state-of-the-art production methods, including:

- Atomización del agua

- Atomización de gas

- Hybrid atomization

- Carbonyl and reduction processing

✅ Diversa cartera de productos

From alumina and zirconia to silicon carbide and boron nitride, Chinese suppliers often cater to a wide range of industries and applications, including:

- Aeroespacial

- Productos sanitarios

- Automotor

- Industrial tooling

- Fabricación aditiva

✅ Global Distribution Capabilities

Many Chinese suppliers have international logistics partners and export licenses, ensuring reliable delivery to North America, Europe, Southeast Asia, and beyond.

🔍 To explore a full range of ceramic and PM powders from a leading Chinese supplier, visit the AM-Material homepage.

8. Why Choose Shanghai Truer Technology as Your Ceramic Powder Supplier

Shanghai Truer Technology Co., Ltd is a trusted name in the powder metallurgy and additive manufacturing sectors. Since 2009, Truer has been delivering high-performance powders to global B2B clients, including OEM manufacturers, distributors, and research institutions.

What Makes Truer a Preferred Partner

🌐 Full-Service Solutions

Truer doesn’t just sell powder—it delivers end-to-end solutions including powder selection, custom formulations, and additive manufacturing consulting.

🔬 Wide Product Portfolio

In addition to ceramic powders, Truer offers:

- PM Bronze, Brass, Iron, Steel, Nickel Silver powders

- Stainless steel powders via water and gas atomization

- Lubricants, cutting agents, and graphite additives

🧪 Advanced R&D Support

Truer’s in-house lab supports material testing, prototyping, and performance optimization. This makes it easier for B2B clients to develop new products or enhance existing ones.

💼 Industry Certifications

Truer meets international standards and offers full compliance documentation for export and technical audits.

🎯 Custom Sourcing and Blending

Need a specific particle size, morphology, or binder system? Truer can develop custom blends to match your application needs.

Example Product Grades Available

| Tipo de polvo | Grados disponibles | Método de producción |

|---|---|---|

| Alúmina | Alpha-phase, high purity | Spray drying, calcination |

| Zirconia | Yttria-stabilized, monoclinic | Spray drying, hydrothermal |

| Carburo de silicio | Alpha/beta phase, micro/nano sizes | Reaction bonded, sintered |

| PM Iron/Steel Powders | FD-0200, FD-0208, FL-4605, FN-0205 | Water/Gas/Hybrid atomization |

| Aditivos de grafito | TBC-400, TBC-1000 | Synthetic and natural blends |

Whether you’re looking to prototype new ceramic components or source bulk powders for mass production, Truer is ready to support you.

📞 Have a technical question or need a quote? Reach out through our Contáctenos página.

9. FAQs: Common Questions About Buying Wholesale Ceramic Powder

Here are some of the most frequently asked questions by B2B buyers exploring ceramic powder suppliers:

Q1: What’s the MOQ (Minimum Order Quantity) for ceramic powders?

Most suppliers, including Shanghai Truer, offer flexible MOQs depending on the powder type and application. For standard grades, MOQ can start from 25 kg. Customized formulations may require higher volumes.

Q2: Can I request custom particle sizes or morphologies?

Yes. Truer offers custom sizing and post-processing services to meet specific requirements for sintering, 3D printing, or injection molding applications.

Q3: Do you provide technical data sheets (TDS) and MSDS?

Absolutely. Every powder batch from Truer is accompanied by a full technical data sheet and Material Safety Data Sheet for compliance and quality assurance.

Q4: Can I get free samples before placing a bulk order?

Yes, free samples (typically 200–500g) are available for qualified industrial buyers. Contact our team to request a sample tailored to your application.

Q5: How can I ensure consistent quality in repeat orders?

Truer uses strict quality control protocols, including batch testing, in-house lab analysis, and traceable production records. Repeat clients can also request pre-shipment inspections.

Q6: Which industries do you primarily serve?

Truer serves a broad range of industries including:

- Aeroespacial y defensa

- Automotor

- Electrónica

- Biomédica

- Energía

- Fabricación aditiva

Q7: Do you support international shipping?

Yes. Truer ships globally with full export documentation and works with trusted logistics partners to ensure timely delivery.