1. Introducción: Por qué es importante el polvo de acero inoxidable atomizado en la fabricación moderna

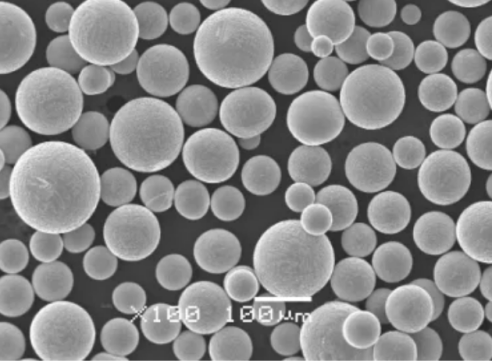

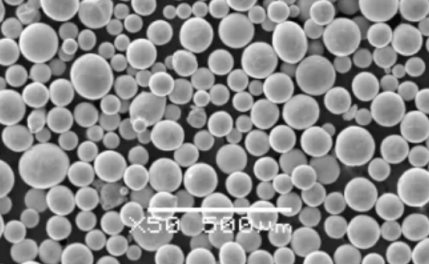

Atomizado acero inoxidable se ha convertido en un material fundamental en diversas industrias, desde la automoción y la aeroespacial hasta la fabricación aditiva y la pulvimetalurgia. Producido mediante un proceso de atomización a alta presión -ya sea gas o agua-, el polvo presenta una fluidez superior, alta pureza y excelentes propiedades de sinterización.

Para los compradores B2B, incluidos los fabricantes OEM, los productores de piezas pulvimetalúrgicas y los revendedores de materiales de impresión 3D, los polvos atomizados de acero inoxidable ofrecen:

- Alta resistencia a la corrosión

- Excelente resistencia mecánica

- Distribución uniforme del tamaño de las partículas

- Excelente compatibilidad con los procesos de sinterización y fabricación aditiva

A medida que las industrias adoptan cada vez más soluciones basadas en polvo metálico para el diseño de piezas complejas y la eficiencia de la producción, aumenta la demanda de polvos de acero inoxidable de alta calidad, especialmente en Asia, Norteamérica y Europa.

2. Aplicaciones industriales del polvo de acero inoxidable atomizado

El polvo de acero inoxidable atomizado se utiliza ampliamente en un amplio espectro de industrias debido a sus versátiles propiedades. He aquí un desglose de las principales aplicaciones:

✅ Componentes de pulvimetalurgia (PM)

- Se utiliza en la producción de engranajes, bujes y piezas estructurales

- Común en maquinaria de automoción e industrial

- Permite la fabricación con forma casi de red

✅ Fabricación aditiva (impresión 3D)

- Ideal para sinterizado láser (SLM) y deposición directa de energía (DED)

- Gran precisión dimensional y excelentes propiedades mecánicas

- Popular en aplicaciones aeroespaciales, médicas y de herramientas

moldeo por inyección de metales (MIM)

- Alta precisión para componentes complejos a pequeña escala

- Excelente para electrónica de consumo e instrumentos médicos

✅ Pulverización térmica y revestimientos

- Crea revestimientos resistentes a la corrosión para tuberías y turbinas

- Mejora la resistencia al desgaste y la resistencia superficial

sistemas de filtración

- Se utiliza en la fabricación de filtros metálicos porosos

- El acero inoxidable ofrece resistencia química y térmica

✅ Matrices de herramientas de diamante

- Los polvos de acero inoxidable se utilizan como agentes aglutinantes en herramientas diamantadas

- Facilita la sinterización y aumenta la durabilidad de las herramientas

Tabla de aplicación:

| Área de aplicación | Ventajas del polvo de acero inoxidable | Industrias objetivo |

|---|---|---|

| Pulvimetalurgia | Alta resistencia, uniformidad y rentabilidad | Automoción, Maquinaria |

| Fabricación aditiva | Precisión, solidez, resistencia a la corrosión | Aeroespacial, Medicina, Defensa |

| Moldeo por inyección de metales | Formas complejas, miniaturización | Electrónica, Sanidad |

| Revestimientos por pulverización térmica | Resistencia a la corrosión y al desgaste | Petróleo y gas, generación de energía |

| Sistemas de filtración | Control de la porosidad, resistencia química | Química, Tratamiento del agua |

| Matrices de herramientas de diamante | Compatibilidad de sinterización, fuerza de adhesión | Construcción, minería |

3. Tipos de polvos de acero inoxidable atomizados & Sus propiedades

Seleccionar el grado adecuado de polvo de acero inoxidable es crucial para conseguir un rendimiento óptimo en su aplicación. Los métodos de atomización -gas y agua- también influyen en las características del polvo.

🔍 Grados comunes disponibles:

- 304L - Acero inoxidable de uso general con excelente resistencia a la corrosión

- 316L - Alta resistencia a la corrosión, especialmente en ambientes clorados

- 410L - Martensítica, utilizada en aplicaciones resistentes al desgaste

- 430L - Ferrítico, ideal para aplicaciones magnéticas

- 17-4PH - Endurecido por precipitación para una mayor resistencia

Técnicas de atomización:

| Método | Caracteristicas | Casos de uso ideales |

|---|---|---|

| Atomización de gases | Partículas esféricas, alta pureza, bajo contenido en oxígeno | impresión 3D, MIM, componentes aeroespaciales |

| Atomización del agua | Formas irregulares, rentables, mayor oxígeno | Piezas PM, aplicaciones estructurales |

| Atomización combinada | Rendimiento optimizado y equilibrio de costes | Aplicaciones generales, sistemas híbridos |

🔬 Propiedades clave del polvo:

- Distribución del tamaño de las partículas (PSD): Influye en la fluidez y la densidad de empaquetamiento

- Densidad aparente y de grifo: Influencia en el llenado de la matriz y en el comportamiento de sinterización

- Oxígeno y humedad; Contenido de carbono: Crucial para las propiedades mecánicas y la resistencia a la corrosión

- Caudal: Afecta a la eficiencia del proceso en AM y PM

Shanghai Truer Technology Co., Ltd ofrece una amplia gama de Polvos de acero inoxidable PM producidos mediante técnicas de atomización con agua, gas e híbridas. Las calidades clave incluyen CT-1000, CZ-1000, F-0000, FC-0208, FN-0205, FL-4605 y otras más, adaptadas para satisfacer diversos requisitos industriales.

4. Demanda del mercado, tendencias y amortiguación; potencial de crecimiento en el sector B2B

El mercado mundial de polvo de acero inoxidable atomizado ha experimentado un crecimiento significativo en la última década, impulsado por la expansión de la pulvimetalurgia, la fabricación aditiva (AM) y las industrias de moldeo por inyección de metales (MIM). Para los compradores B2B, comprender estas tendencias es crucial para anticiparse a la demanda, asegurar el suministro y seguir siendo competitivos.

📈 Tendencias clave del mercado:

- Aceleración de la fabricación aditiva: Los sectores aeroespacial, médico y de defensa utilizan cada vez más polvos de acero inoxidable para componentes ligeros y de alto rendimiento.

- Cambio hacia Asia-Pacífico: China e India se están convirtiendo en centros de fabricación clave que ofrecen materiales de PM rentables y de alta calidad.

- Sostenibilidad & Reciclaje: El polvo de acero inoxidable puede reciclarse, en consonancia con los movimientos mundiales hacia la fabricación circular.

- Personalización yamp; Desarrollo de aleaciones: Aumenta la demanda de formulaciones en polvo a medida para usos finales específicos.

🌍 Tamaño y previsión del mercado:

| Año | Valor del mercado mundial (miles de millones de USD) | CAGR (2023-2028) |

|---|---|---|

| 2023 | $2.1 | - |

| 2024 (Est.) | $2.4 | 7.1% |

| 2028 (Proj.) | $3.3 | 7.1% |

🔎 Oportunidades B2B:

- Fabricantes OEM: Garantizar contratos de polvo a largo plazo a precios competitivos.

- Distribuidores y revendedores: Aprovechar la creciente demanda para ampliar el inventario y los catálogos de productos.

- Vendedores de comercio electrónico: Ofrecer polvos de acero inoxidable en envases más pequeños para empresas de MIM e impresión 3D.

5. Elección del proveedor de polvo de acero inoxidable adecuado para su empresa

Seleccionar un proveedor fiable y orientado a la calidad es esencial para mantener unos resultados de producción constantes, cumplir los requisitos de los clientes y proteger su reputación. Tenga en cuenta estos factores clave a la hora de evaluar un proveedor de polvo de acero inoxidable:

🧩 Criterios de evaluación:

| Criterios | Importancia para los compradores B2B | En qué fijarse |

|---|---|---|

| Capacidad de fabricación | Garantiza un suministro constante y de gran volumen | Atomización interna, certificaciones de calidad (ISO, etc.) |

| Personalización del polvo | Adapta las propiedades a las necesidades de la aplicación | Admite aleaciones y tamaños personalizados |

| Asistencia técnica | Ayuda a la ingeniería de aplicaciones | I+D in situ, experiencia metalúrgica |

| Entrega y logística | Minimiza los tiempos de inactividad y los retrasos | Envío mundial, embalaje a granel, entrega rápida |

| Precio y valor | Impacto en la rentabilidad | Precios competitivos sin sacrificar la calidad |

| Certificaciones y conformidad | Obligatorio para los sectores regulados | REACH, RoHS, ASTM, ISO 9001 |

consejo recomendado:

Solicite un Certificado de Análisis (COA) y realice pruebas en lotes pequeños antes de comprometerse con grandes contratos.

6. Principales proveedores mundiales y chinos de polvo de acero inoxidable atomizado

El mercado B2B del polvo de acero inoxidable está atendido por numerosos actores nacionales e internacionales. A continuación encontrará una lista de los principales proveedores con capacidades demostradas en tecnologías de atomización y suministro a granel.

🌐 Principales proveedores mundiales:

| Nombre de la empresa | Ubicación | Especialidad |

|---|---|---|

| Höganäs AB | Suecia | Polvos PM, materiales AM, sostenibilidad |

| Sandvik Osprey | Reino Unido | Polvos atomizados con gas para AM y MIM |

| Aditivo para carpinteros | EE.UU. | polvos de impresión 3D de calidad aeroespacial |

| Erasteel | Francia | Polvos de acero rápido, MIM |

🇨🇳 Principales proveedores chinos:

| Nombre de la empresa | Ofertas clave | Puntos fuertes |

|---|---|---|

| Shanghai Truer Technology Co., Ltd | Amplia gama de polvos de acero inoxidable PM y AM, incluidos CT-1000, FC-0208 | Atomización híbrida, servicio completo de aditivos |

| CNPC Polvo | Polvos atomizados con agua/gas | Centrado en la exportación, rentable |

| Polvo Jinlong de Changsha Hunan | Acero inoxidable y polvos a base de hierro | Experiencia con MIM y herramientas diamantadas |

| Materiales Sino-Euro | Acero inoxidable esférico para AM | Líneas de atomización avanzadas |

🏆 En el punto de mira: Shanghai Truer Technology Co., Ltd

Shanghai Truer es una empresa de confianza en el campo de la pulvimetalurgia desde 2009, y en 2019 se incorporó a la fabricación aditiva. La empresa ofrece una amplia cartera de polvos de acero inoxidable fabricados mediante métodos de atomización con agua, gas e híbridos. El compromiso de Truer con la innovación y la calidad la convierte en la opción preferida para aplicaciones de alto rendimiento en los sectores de automoción, aeroespacial y de herramientas.

Aspectos destacados del producto:

- Polvos de las series CT-1000, CZ-1000, FC-0208, FN-0205

- Water & polvos inoxidables atomizados con gas de 15μm a 200μm

- Producción con certificación ISO y laboratorio interno de I+D

Ventajas B2B:

- Coherencia en grandes volúmenes

- Desarrollo de aleaciones personalizadas

- Asesoramiento técnico y entrega global

Explore el catálogo completo de polvo de acero inoxidable de Truer en su Página de polvos PM.

7. Ventajas de comprar acero inoxidable en polvo en China

A medida que crece la demanda mundial de acero inoxidable en polvo, muchos compradores B2B, distribuidores y fabricantes recurren a China para abastecerse. Este cambio está impulsado por una combinación estratégica de rentabilidad, escalabilidad de la producción e innovación continua.

🌟 Principales ventajas de los proveedores chinos:

| Ventaja | Qué significa para los compradores B2B |

|---|---|

| Precios competitivos | Los menores costes de fabricación ofrecen mejores márgenes a los distribuidores |

| Alta capacidad de producción | Admite pedidos de gran volumen y suministro OEM a largo plazo |

| Avances tecnológicos | Técnicas modernas de atomización comparables a las normas mundiales |

| Amplia gama de productos | Múltiples grados y formas disponibles para diversas aplicaciones |

| Experiencia y conformidad en materia de exportación | Amplia experiencia con el transporte marítimo y las normas internacionales |

🇨🇳 Por qué China es líder mundial en polvos PM & AM:

- Rápidas inversiones en fabricación avanzada e I+D

- La fuerte demanda interna estimula la innovación

- Apoyo gubernamental a las exportaciones de manufacturas de gama alta

- Experiencia demostrada en el suministro a las industrias automovilística, médica y aeroespacial

🔍 ¿Desea obtener polvo de acero inoxidable de alta calidad de China? Empiece por trabajar con fabricantes certificados como Shanghai Truer Technology Co., Ltdque combina experiencia técnica con capacidad de servicio internacional.

8. Por qué elegir Shanghai Truer Technology Co., Ltd como su socio de polvo

Shanghai Truer Technology Co., Ltd es uno de los proveedores más fiables del sector chino de la pulvimetalurgia y la fabricación aditiva. Con más de una década de experiencia y un enfoque láser en la innovación, Truer ofrece polvos de acero inoxidable de primera calidad y soluciones aditivas a medida para compradores B2B de todo el mundo.

🏢 Descripción general de la empresa:

- Fundada: 2009

- Se crea la División de Fabricación Aditiva: 2019

- Actividad principal: equipos de producción de polvos de impresión 3D, acero inoxidable & polvos de aleación, aditivos PM

- Sitio web: am-material.com

🔧 Oferta de productos:

| Categoría de productos | Ejemplos & Calificaciones |

|---|---|

| Polvos de acero inoxidable PM | CT-1000, CZ-1000, FC-0208, FN-0205, FL-4605 |

| Métodos de atomización | Atomizado de gas, atomizado de agua, atomizado combinado |

| Aditivos específicos para cada aplicación | Lube-W, SUW-8000, QH-150, SME-100, TBC-1000 |

| Desarrollo de aleaciones personalizadas | Disponible previa petición |

📦 Beneficios del servicio B2B:

- I+D interno y apoyo a la ingeniería de aplicaciones

- Distribuciones granulométricas y composiciones de aleación personalizadas

- Flexibilidad de la cadena de suministro para fabricantes de equipos originales y distribuidores de todo el mundo

- Calidad con certificación ISO y rendimiento constante de los lotes

🤝 De confianza:

- OEM de automoción

- Fabricantes de componentes aeroespaciales

- distribuidores de material de impresión 3D

- Fabricantes de piezas MIM y PM

📌 ¿Listo para escalar su adquisición de polvo de acero inoxidable? Póngase en contacto con el equipo Truer hoy mismo para solicitar un presupuesto o una consulta técnica.

9. Preguntas frecuentes: Compra de polvo de acero inoxidable atomizado a granel

Para ayudarle a racionalizar sus decisiones de compra, aquí tiene las respuestas a las preguntas más frecuentes sobre el suministro de polvo de acero inoxidable atomizado para uso industrial:

❓ ¿Cuál es la cantidad mínima de pedido (MOQ) para la venta al por mayor?

La mayoría de los proveedores, incluido Truer, ofrecen cantidades mínimas flexibles a partir de 25 kg para muestras personalizadas y 500 kg para pedidos al por mayor. Para pedidos superiores a 1 tonelada se aplican descuentos por volumen.

❓ ¿Puedo solicitar distribuciones granulométricas personalizadas?

Sí. Truer ofrece personalización para PSD basada en su aplicación específica, ya sea para impresión 3D (15-45μm), piezas PM (45-150μm) o MIM (5-25μm).

❓ ¿Sus polvos cumplen las normas internacionales?

Absolutamente. Los polvos de acero inoxidable de Truer cumplen las normas ASTM, ISO y GB. COAs (Certificados de Análisis) y SDS (Hojas de Datos de Seguridad) están disponibles con todos los envíos.

❓ ¿Cómo se envasan los polvos para envíos internacionales?

El embalaje estándar incluye:

- bidones sellados de 25 kg (con purga de nitrógeno si es necesario)

- palés de 1000 kg para pedidos a granel

- Embalaje personalizado disponible previa solicitud

❓ ¿Cuál es el plazo de entrega de los pedidos al por mayor?

- Grados estándar: 7-10 días laborables

- Grados personalizados: 15-20 días laborables

- Envío urgente disponible en todo el mundo

❓ ¿Ofrecen asistencia técnica para nuevas aplicaciones?

Sí. El equipo de metalúrgicos e ingenieros de Truer ofrece asistencia técnica completa, desde la selección de materiales hasta la orientación para la sinterización.

❓ ¿Cómo puedo hacer un pedido?

Puede enviar una consulta o solicitar un presupuesto directamente a través de Truer's página de contacto. Nuestro equipo le responderá en 24 horas con precios, plazos de entrega y documentación técnica.

🧭 Enlaces internos de anclaje utilizados en este blog:

- Acerca de Shanghai Truer Technology Co., Ltd

- Catálogo de productos PM Powder

- Página principal

- Página de contacto para pedidos al por mayor

- Más soluciones PM

Al combinar una calidad de producto superior, precios competitivos y un servicio de atención al cliente receptivo, Shanghai Truer Technology Co., Ltd es su socio estratégico B2B para polvo de acero inoxidable atomizado. Tanto si está ampliando sus operaciones de impresión 3D como si está expandiendo su línea de productos PM, Truer le ofrece la fiabilidad y la experiencia que su empresa necesita.

¿Listo para empezar? Póngase en contacto con nosotros y descubra cómo podemos contribuir a su éxito con polvos metálicos de alto rendimiento.

adelántese al mercado. Asóciese con Truer: donde el polvo de precisión se une a la potencia de producción.