Introduction: Why Amorphous Powder Matters in Advanced Manufacturing

Amorphous powder, also known as metallic glass powder or amorphous alloy powder, has become a cornerstone material in sectors such as aerospace, electronics, medical devices, and additive manufacturing. Its unique atomic structure—lacking the long-range order of crystalline materials—gives it exceptional mechanical, magnetic, and thermal properties.

Why B2B Buyers Are Investing in Amorphous Powder

For B2B buyers such as OEMs, distributors, and industrial procurement managers, amorphous powder offers several advantages:

- Superior hardness and wear resistance

- Alta resistencia a la corrosión

- Excellent magnetic permeability

- Ideal for high-frequency electrical applications

- Lower melting points for energy-efficient processing

These properties make it a prime candidate for companies looking to innovate their product lines or improve performance in harsh environments.

| Propiedad | Amorphous Powder | Crystalline Powder |

|---|---|---|

| Atomic Structure | Disordered (non-crystalline) | Ordered (crystalline lattice) |

| Resistencia a la corrosión | Alta | Moderado |

| Magnetic Softness | Excelente | Average |

| Punto de fusión | Baja | Más alto |

| Maquinabilidad | Bien | Varies by material |

Key Industrial Applications of Amorphous Powder

Amorphous powders are used across diverse industries, making them highly sought-after by B2B buyers and industrial suppliers.

1. Additive Manufacturing (3D Printing)

Amorphous metal powders are increasingly used in Impresión 3d applications due to their:

- Lower thermal conductivity (ideal for rapid cooling)

- Elevada relación resistencia/peso

- Smooth surface finish post-print

These features are crucial for aerospace and biomedical applications.

2. Electronics & Magnetic Components

Soft magnetic amorphous powders are used in:

- Transformers

- Inductors

- Núcleos de motor

They help reduce core losses, enabling higher efficiency in electrical devices.

3. Medical Devices

In the medical field, amorphous materials are valued for:

- Biocompatibilidad

- Resistencia a la corrosión

- Non-magnetic properties (ideal for MRI compatibility)

4. Wear-Resistant Coatings

Amorphous powders can be plasma sprayed or thermally sprayed onto surfaces to create:

- Anti-corrosion coatings

- Hard-wearing surfaces in mining, oil & gas, and marine industries

5. Sintered Parts and Powder Metallurgy

In powder metallurgy, amorphous alloys are used to increase:

- Part density

- Resistencia mecánica

- Rendimiento magnético

Types of Amorphous Powders and Their Unique Properties

Amorphous powders are typically categorized based on their base metal or alloy type. Understanding the types helps B2B buyers choose the right material for specific industrial use cases.

Common Types of Amorphous Powders

| Tipo de aleación | Base Elements | Propiedades clave | Aplicaciones |

|---|---|---|---|

| Fe-Based | Fe, Co, B, Si | High magnetic permeability, wear resistance | Transformers, motor cores |

| Ni-Based | Ni, P, B | Corrosion resistance, bio-compatibility | Medical devices, coatings |

| Co-Based | Co, B, Si | Estabilidad a altas temperaturas | Aerospace, chemical industries |

| Zr-Based | Zr, Cu, Al | High strength, glass-forming ability | Structural parts, electronics |

| Cu-Based | Cu, Zr, Ti | Low cost, good formability | Consumer goods, electronics |

Unique Features of Amorphous Powders

- Glass Transition Temperature (Tg): Offers temperature control during processing

- High Elastic Limit: Ideal for load-bearing applications

- Isotropic Properties: Uniform properties in all directions

- High Surface Area: Enhances sintering and coating efficiency

These features make amorphous powders an excellent choice for high-performance industrial parts and components.

Looking to source high-quality amorphous or materiales pulvimetalúrgicos? Consider Shanghai Truer Technology Co., Ltd—a trusted supplier with extensive experience since 2009. They offer a wide range of PM and 3D printing powders suitable for B2B applications in automotive, aerospace, and electronics industries.

Top Global Suppliers of Amorphous Powder for Industrial Buyers

Selecting the right supplier is critical for B2B buyers looking to ensure consistency, quality, and long-term reliability in their supply chain. The amorphous powder market is still relatively niche, so partnering with experienced and well-established manufacturers is key.

Below are some of the leading global suppliers of amorphous powder, known for their technological capabilities, production scale, and compliance with international standards.

1. Shanghai Truer Technology Co., Ltd (China)

Established in 2009, Shanghai Truer Technology has become a premium supplier in the powder metallurgy (PM) and additive manufacturing space. Truer entered the 3D printing powder market in 2019 and offers a wide range of high-quality powders including:

- PM bronze, PM brass, PM steel, PM stainless steel

- Amorphous and pre-alloyed powders for sintered parts

- Customizable powder production using water atomization, gas atomization, carbonyl, and reduction methods

Their commitment to innovation and quality makes them a preferred supplier for global B2B buyers seeking reliable material sourcing for:

- Fabricación aditiva

- Sintered components

- Revestimientos resistentes al desgaste

- Soft magnetic applications

👉 Learn more about the company and its capabilities

2. Heraeus (Germany)

Heraeus is a global technology group with deep expertise in advanced materials. Their amorphous alloy powder solutions are mainly focused on:

- Soft magnetic applications

- Biomedical devices

- Energy-efficient motors

They have a strong presence in Europe and North America and are known for high-purity, application-specific solutions.

3. Materion (USA)

Materion is a leader in engineered materials and offers a range of amorphous metal powders for:

- Electrónica

- Aeroespacial

- Medical applications

Their powders are engineered with precision and come with full technical support, making them ideal for OEMs and Tier 1 suppliers.

4. Hitachi Metals (Japan)

Hitachi Metals develops advanced amorphous magnetic materials, especially for:

- Transformers

- High-frequency devices

- Automotive electronics

Their Metglas® line is one of the most recognized brands in the magnetic alloy segment.

5. Advanced Powder Products, Inc. (USA)

APP focuses on custom metal powders for additive manufacturing and powder metallurgy. They offer:

- Amorphous and semi-crystalline powders

- Rapid prototyping services

- Desarrollo de aleaciones personalizadas

Their flexibility and engineering support are particularly appealing to startups and R&D-focused companies.

Why More Buyers Are Sourcing Amorphous Powder from China

Over the past decade, China has rapidly advanced its capabilities in powder metallurgy and additive manufacturing. B2B buyers increasingly look to Chinese suppliers for high-value amorphous powders due to several key advantages.

Benefits of Sourcing from Chinese Manufacturers

| Ventaja | Descripción |

|---|---|

| Relación coste-eficacia | Lower labor and production costs allow for competitive pricing. |

| Producción escalable | Chinese suppliers can handle bulk orders for global distribution. |

| Personalización | More flexible in developing tailor-made alloy compositions. |

| Inversión en I+D | Significant investment in research to match global quality standards. |

| Entrega rápida | Shorter lead times due to efficient logistics and manufacturing cycles. |

Notably, companies like Shanghai Truer Technology Co., Ltd have positioned themselves as reliable partners by offering:

- In-house R&D and testing labs

- ISO-certified quality control

- A wide range of available stock and made-to-order options

- Technical support for sintering, coating, or additive manufacturing applications

For distributors and importers, sourcing from China not only reduces cost but also enhances supply chain flexibility and resilience.

Why Choose Shanghai Truer Technology Co., Ltd as Your Trusted Supplier

Shanghai Truer Technology is more than just a raw material supplier—it is a complete solutions provider for the powder metallurgy and additive manufacturing industries. Here’s why leading OEMs and B2B buyers trust Truer:

1. Wide Product Portfolio

Truer offers an extensive range of PM and amorphous powders:

- PM steel, stainless steel, bronze, brass

- Soft magnetic powders, hybrid alloys

- Gas and water atomized options

- Custom blends for advanced industrial applications

2. In-House Expertise & Technical Support

With over a decade of experience and a dedicated R&D team, Truer provides:

- Technical consultation on material selection

- Sintering process optimization

- Additive manufacturing compatibility checks

3. Quality Assurance

Truer uses advanced testing methods to ensure consistency and purity:

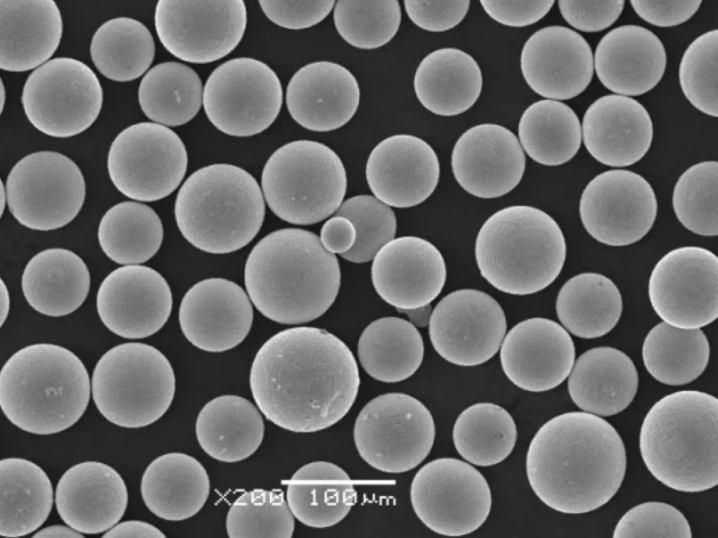

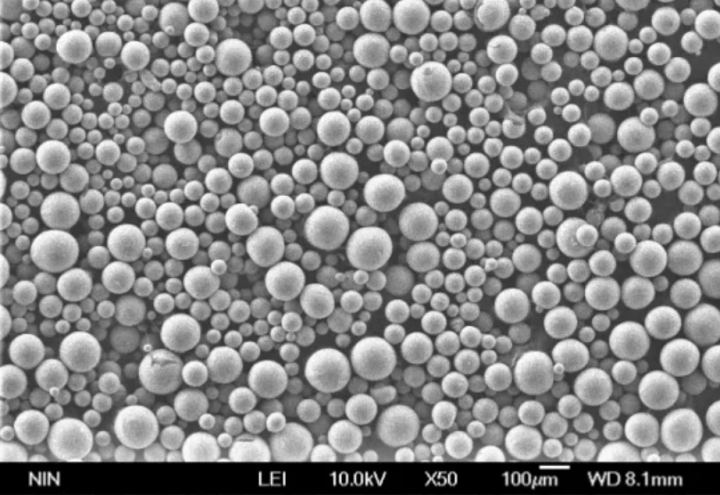

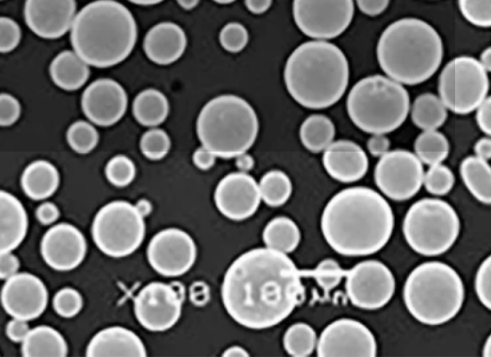

- Particle size distribution control

- Verificación de la composición química

- ISO standard certifications

4. Flexible Order Quantities

Whether you’re a small-batch buyer or a high-volume OEM, Truer can accommodate:

- Sample orders for R&D

- Pilot production batches

- Long-term supply agreements

5. Global Reach and Logistics

Truer supports international shipping with efficient logistics and documentation, making them a reliable partner for:

- Distribuidores

- E-commerce sellers

- Industrial procurement departments

📩 Interested in sourcing amorphous powder? Contact the Truer sales team directly

In addition to amorphous powders, Truer’s División de Aditivos Pulvimetalúrgicos offers specialized additives like:

- Cutting agents: manganese sulfide, SME-100

- Lubricants: Lube-W, SUW-8000

- Graphite powders: TBC-1000, QHP-330

- Aditivos magnéticos blandos: QH-150

This makes Truer a one-stop solution provider for both raw materials and value-added additives, reducing your supplier complexity.

How to Order Wholesale Amorphous Powder from Trusted Suppliers

For B2B buyers, OEMs, and procurement professionals, a streamlined and transparent ordering process is essential when sourcing high-performance materials like amorphous powder. Whether you’re sourcing for additive manufacturing, powder metallurgy, or magnetic applications, understanding the wholesale procurement flow helps reduce lead times and avoid quality issues.

Below is a step-by-step guide to ordering amorphous powder in bulk from reliable suppliers such as Shanghai Truer Technology Co., Ltd.

Proceso de pedido al por mayor paso a paso

1. Define Your Specifications

Before reaching out to a supplier, clearly define your material requirements:

- Alloy type (Fe-based, Ni-based, Zr-based, etc.)

- Nivel de pureza

- Particle size distribution (e.g., D50, D90)

- Atomization method (water, gas, carbonyl, reduction)

- Quantity required (sample, pilot batch, or regular supply)

- Application details (e.g., 3D printing, sintering, coating)

2. Request a Quotation (RFQ)

Send your specifications to the supplier’s sales or technical department. When working with Shanghai Truer, you can use their Página de contacto for fast communication.

Information to include in your RFQ:

- Company name and industry

- Annual volume requirement

- Specification sheet or technical drawing (if applicable)

- Shipping destination and preferred Incoterms (FOB, CIF, etc.)

3. Sample Evaluation (Optional but Recommended)

For first-time buyers or new materials, request a sample:

- Truer provides small samples for lab testing and sintering trials

- Evaluate powder morphology, flowability, and purity

- Conduct application-specific performance testing

4. Technical Confirmation and Customization

If needed, Shanghai Truer’s R&D team can assist with:

- Desarrollo de aleaciones personalizadas

- Powder blending for hybrid applications

- Coating compatibility checks

- Magnetic property verification

5. Purchase Order & Payment Terms

Once you’re satisfied with the quality and pricing:

- Place a formal Purchase Order (PO)

- Confirm payment terms (TT, LC, etc.)

- Lead time is typically 7–15 days depending on order size and material type

6. Packaging and Shipping

Truer uses industrial-grade packaging to ensure product integrity:

- Double-sealed bags in vacuum-packed drums

- Optional nitrogen packaging for oxidation-sensitive powders

- Export-compliant labeling and documentation

They offer global logistics and export support to North America, Europe, and Southeast Asia.

FAQs: Common Questions About Buying Amorphous Powder in Bulk

To assist B2B buyers and procurement officers, here are answers to frequently asked questions about sourcing amorphous powder.

1. What is the minimum order quantity (MOQ)?

The MOQ varies depending on the material type, but for most amorphous powders:

- MOQ: 10 kg for standard products

- Custom alloys may require 25–50 kg minimum due to production setup

2. Can I request a custom alloy composition?

Yes. Shanghai Truer offers custom alloy development for specific applications such as:

- High-frequency magnetic components

- Revestimientos resistentes a la corrosión

- Biocompatible medical parts

Their additive manufacturing division is equipped to create tailored powder blends.

3. What are the available particle size ranges?

Particle size options depend on the atomization method:

| Método | Tamaños |

|---|---|

| Gas atomizado | 5 – 100 μm |

| Agua atomizada | 25 – 200 μm |

| Carbonilo | <10 μm |

| Atomización combinada | 10 – 80 μm |

Truer can provide size fractions according to your process requirements.

4. What testing certifications are provided?

Each batch comes with a Certificate of Analysis (COA), detailing:

- Composición química

- Distribución granulométrica

- Morphology analysis (optional)

- Magnetic properties (for Fe-based amorphous)

ISO 9001 and material-specific certifications are available upon request.

5. How long is the lead time for large bulk orders?

Standard lead times:

- In-stock items: 5–7 working days

- Custom production: 10–15 working days

- Large volume or custom alloys: May require 20–25 days

Shipping time depends on your destination. Truer supports air, sea, and express courier options.

6. What industries benefit most from amorphous powder?

Industries that commonly use amorphous powders include:

- Aeroespacial

- Electronics (transformers, inductors)

- Automotive (motor cores, sensors)

- Medical (implants, surgical tools)

- Oil & gas (wear-resistant coatings)

- Additive manufacturing (3D metal printing)

7. Does Shanghai Truer offer technical support?

Yes. Truer has a dedicated engineering team that provides:

- Material selection guidance

- Process optimization for sintering or AM

- Technical documentation and MSDS

- Application-specific consultation

Their team works closely with global B2B partners to ensure performance and reliability.

8. Can I visit the production site?

Yes. Truer welcomes international clients to visit their production and R&D facilities in Shanghai, China. A virtual tour or video call can also be arranged.

9. Are there bulk discounts for large purchases?

Yes. Truer provides tiered pricing based on volume:

| Cantidad (kg) | Discount Rate |

|---|---|

| 100 – 500 kg | 5% off |

| 500 – 1000 kg | 10% off |

| 1000 kg | Custom quote |

10. Do you offer private labeling or OEM services?

Yes, Truer can package powders under your brand name and offer OEM support for distributors and resellers.

By working with a seasoned supplier like Shanghai Truer Technology Co., Ltd, you gain access to a full spectrum of powder metallurgy solutions, from raw materials to technical support and global logistics.

Internal Anchor Text Summary (5 Internal Links Used)

- Company and its capabilities

- División de Aditivos Pulvimetalúrgicos

- Contact the Truer sales team directly

- Additive manufacturing division

- Shanghai Truer Technology Co., Ltd

With its strong production capabilities, R&D excellence, and global supply chain support, Shanghai Truer is a leading choice for B2B buyers seeking high-quality amorphous powders. Whether you’re in need of standard materials or custom-engineered solutions, Truer offers the professionalism and flexibility to support your growth.

👉 Ready to streamline your supply chain with premium amorphous powder? Get in touch today for a personalized quote or technical consultation.