1. Introduction: Why AL 4043 Powder Matters in Modern Manufacturing

Aluminum alloy 4043 (AL 4043) powder is a high-silicon aluminum alloy widely used in additive manufacturing (AM), welding, and powder metallurgy (PM) applications. It is known for its excellent corrosion resistance, good fluidity, and compatibility with a wide range of base metals—especially in aerospace, automotive, and general engineering industries.

As the demand for lightweight and high-performance components increases, industrial buyers, OEMs, and contract manufacturers are turning to AL 4043 powder for its proven performance in metal Impresión 3d and PM parts production. For B2B buyers, sourcing the right AL 4043 powder with consistent particle size distribution, purity, and flowability is critical for achieving optimal production outcomes.

Key B2B Use Cases Include:

- Additive manufacturing (Selective Laser Melting & Electron Beam Melting)

- Welding filler materials

- Powder metallurgy parts for lightweight applications

- Automotive engine components

- Aerospace structural parts

Why it Matters for Buyers:

- Supports lean manufacturing and lightweight design

- Enhances corrosion resistance in critical environments

- Ideal para la producción de grandes volúmenes con calidad constante

🧠 Did You Know? Shanghai Truer Technology Co., Ltd offers high-quality AL 4043 and other aluminum alloy powders tailored for additive manufacturing and powder metallurgy. Learn more about our company profile here.

2. Industrial Applications of AL 4043 Alloy Powder

AL 4043 alloy powder is a preferred material choice across multiple industries due to its compatibility with aluminum substrates and its high silicon content (~5%), which improves fluidity and reduces cracking during welding or printing.

Aplicaciones industriales clave

| Industria | Área de aplicación | Benefits of AL 4043 Powder |

|---|---|---|

| Aeroespacial | Componentes estructurales, soportes | Ligero, resistente a la corrosión |

| Automotor | Transmission parts, engine components | Heat resistance, smooth surface finish |

| Electrónica | Housings, casings | Excellent conductivity, fine detail printing |

| General Manufacturing | Metal 3D printing, welding consumables | Good fusion, consistent flowability |

Additive Manufacturing Use Cases

- Fusión selectiva por láser (SLM)

- Sinterización directa de metales por láser (DMLS)

- Binder Jetting (with post-processing)

- Fusión por haz de electrones (EBM)

Welding Applications:

- Used as a filler metal for welding 6xxx series aluminum alloys

- Reduces hot cracking susceptibility

- Produces smooth bead profile with minimal porosity

Powder Metallurgy Use Cases:

- Suitable for press-and-sinter applications

- Used in hybrid assemblies with dissimilar metals

- Integration into multi-metal parts using advanced sintering

🌐 Explore Shanghai Truer’s full range of PM powders including aluminum alloys here.

3. Key Properties and Specifications of AL 4043 Powder

For industrial buyers, understanding the technical properties of AL 4043 powder is essential to ensure compatibility with production environments and quality standards.

Chemical Composition of AL 4043

| Elemento | Composition (wt.%) |

|---|---|

| Silicio (Si) | 4.5 – 6.0 |

| Hierro (Fe) | ≤ 0.8 |

| Cobre (Cu) | ≤ 0.30 |

| Manganeso (Mn) | ≤ 0.05 |

| Magnesio (Mg) | ≤ 0.05 |

| Zinc (Zn) | ≤ 0.10 |

| Aluminio (Al) | Resto |

Propiedades físicas y mecánicas

- Punto de fusión: ~573°C to 582°C

- Densidad: 2.67 g/cm³

- Dureza: ~60 BHN (Brinell Hardness)

- Conductividad térmica: ~170 W/m·K

- Resistencia a la corrosión: Excellent, especially in marine and automotive environments

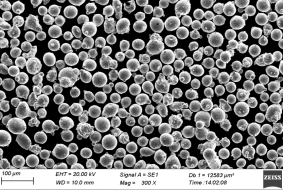

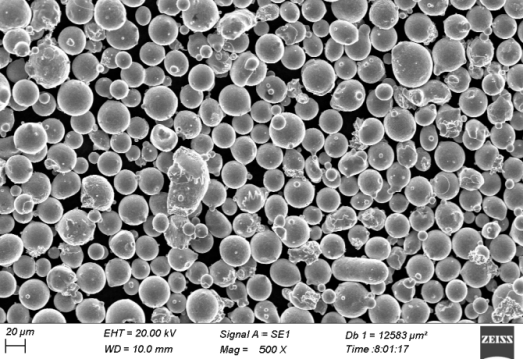

Distribución del tamaño de las partículas

| Solicitud | Gama de tamaños de partículas (µm) |

|---|---|

| Additive Manufacturing (SLM) | 15 – 45 µm |

| Chorro aglomerante | 20 – 50 µm |

| Powder Metallurgy (Press & Sinter) | 45 – 106 µm |

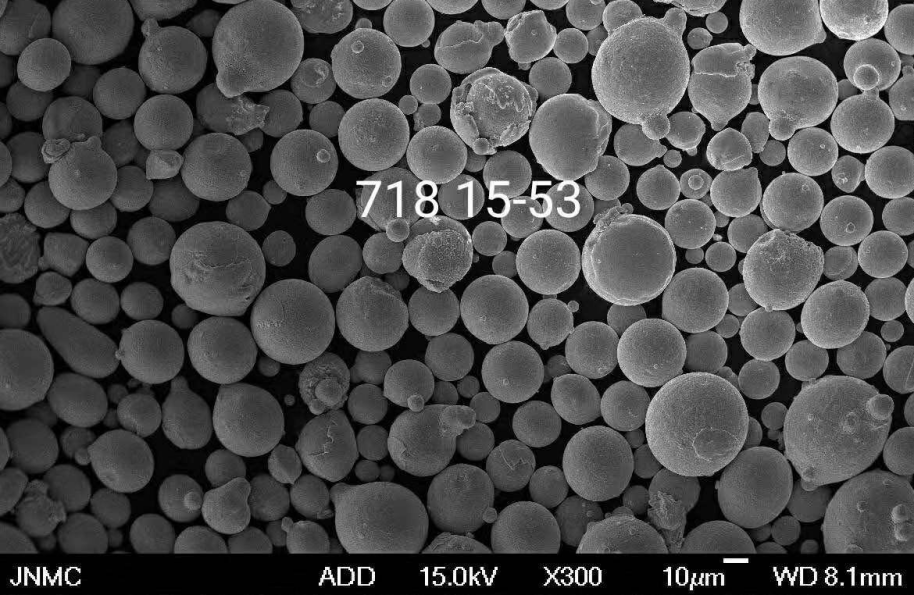

Powder Morphology and Flowability

- Spherical morphology for consistent powder flow

- High tap density and low oxygen content

- Excellent spreadability for layer-by-layer printing

🔍 Looking for custom particle sizes or tailored properties? Contact us today to discuss your AL 4043 powder requirements.

4. Global Market Trends and Demand for AL 4043 Powder

As advanced manufacturing technologies like metal 3D printing and powder metallurgy continue to evolve, the global demand for AL 4043 powder is accelerating. Industries across aerospace, automotive, marine, and consumer electronics are actively integrating lightweight aluminum alloys into their designs to reduce weight, improve fuel efficiency, and enhance corrosion resistance.

Principales impulsores del mercado

- Auge de la fabricación aditiva: The global metal 3D printing market is projected to surpass USD 10 billion by 2030, with aluminum alloys like AL 4043 playing a central role in lightweight component manufacturing.

- Electrificación del automóvil: EV components require lightweight, thermally conductive materials like AL 4043 for battery housings and structural elements.

- Fabricación sostenible: More manufacturers are seeking recyclable, energy-efficient materials like aluminum alloys.

Regional Demand Insights

| Región | Primary Demand Sectors | Growth Outlook |

|---|---|---|

| Norteamérica | Aerospace, defense, automotive | Strong due to AM adoption |

| Europa | Automoción, maquinaria industrial | Driven by EV growth |

| Asia-Pacífico | Electronics, general manufacturing | Fastest growth region |

Market Challenges

- Consistent powder quality across batches

- Reliable supply chains for high-purity powders

- Cost competitiveness with alternative alloys

💡 Tip: Partnering with a reliable supplier like Shanghái Truer helps mitigate supply chain risks and ensures premium powder quality tailored to your application.

5. Choosing the Right AL 4043 Powder Supplier for Your Business

Choosing the right supplier goes beyond just price. For B2B buyers, especially those in additive manufacturing and powder metallurgy, it’s essential to consider several technical and commercial factors when sourcing AL 4043 powder.

Criterios clave de evaluación

| Factor | Por qué es importante |

|---|---|

| Pureza del polvo | Affects print quality and mechanical properties |

| Distribución del tamaño de las partículas | Influences layer uniformity and sintering |

| Embalaje y logística | Impacts powder stability and shelf life |

| Método de producción | Atomization method affects morphology |

| Asistencia técnica | Vital for application-specific optimization |

| Certificaciones | ISO, RoHS, REACH, etc., ensure compliance |

Questions to Ask Your Supplier

- What is the powder’s oxygen content?

- Can you provide a Certificate of Analysis (COA) for every batch?

- Do you offer custom blends or particle size distributions?

- ¿Cuál es su plazo de entrega para pedidos al por mayor?

- Do you offer application support for additive manufacturing?

Recommended Sourcing Formats

- 10kg, 25kg, and 100kg sealed packaging in inert atmosphere

- Bulk orders with moisture-resistant containers

- Batch traceability with COA and MSDS included

🔗 For a supplier checklist and sourcing guide, download our AL 4043 datasheet from our PM powder section here.

6. Top AL 4043 Powder Manufacturers and Distributors Worldwide

Here’s a comparative overview of some of the leading AL 4043 powder manufacturers serving industrial and wholesale buyers globally:

| Nombre del proveedor | País | Especialidad | Puntos fuertes |

|---|---|---|---|

| Tecnología Truer de Shanghai | China | Additive & PM powders | High customization, B2B focus |

| Ecka Gránulos | Alemania | Aluminum and copper powders | High purity, EU distribution |

| Valimet Inc. | EE.UU. | Atomized aluminum powders | Materiales de calidad aeroespacial |

| Kymera Internacional | EE.UU. | Specialty metal powders | Global reach, diverse alloys |

| TLS Técnica | Alemania | AM-grade metal powders | Spherical powders, R&D focus |

Por qué destaca Shanghai Truer

- Offers both gas and water atomized AL 4043 powder options

- Available in multiple size distributions for AM, welding, and PM

- In-house metallurgy expertise to support custom formulations

- Strategic location in China with global shipping capabilities

- Extensive inventory for rapid fulfillment of bulk orders

🏭 Want to see how Shanghai Truer supports premium AL 4043 sourcing? Visit our homepage to explore our product categories and services.

7. Why More Buyers Are Sourcing AL 4043 Powder from China

Global buyers are increasingly turning to China for sourcing AL 4043 powder due to its cost-effectiveness, scalable production, and technological advancements in atomization equipment.

Ventajas de abastecerse en China

- Precios competitivos: Lower manufacturing and labor costs without compromising quality

- Fabricación avanzada: Modern atomization systems ensure spherical morphology and low oxygen content

- MOQs flexibles: Accommodates both small-batch prototyping and large-scale production

- Strong Logistics Networks: Efficient international shipping and export documentation

Chinese Suppliers vs. Western Suppliers

| Criterios | Proveedores chinos (por ejemplo, Truer) | Proveedores occidentales |

|---|---|---|

| Eficiencia de costes | ✅ Alta | ❌ Higher cost |

| Plazos de entrega | ✅ Shorter (bulk stock) | ❌ Longer (custom orders) |

| Opciones de personalización | ✅ Flexible | ⚠️ Limited in some cases |

| Asistencia técnica | ✅ Metallurgical support | ✅ Disponible |

| Experiencia en exportación | ✅ Full documentation | ✅ Standard |

🌍 Ready to scale your production with reliable bulk supply? Contact Shanghai Truer today for custom quotes and technical consultation.

8. Why Choose Shanghai Truer as Your AL 4043 Powder Partner

Shanghai Truer Technology Co., Ltd has established itself as one of the most professional and trusted manufacturers and suppliers in China’s powder metallurgy and additive manufacturing sectors. Since launching its additive manufacturing division in 2019, Truer has become a go-to source for high-quality metal powders—including gas atomized AL 4043 powder—for industrial buyers, distributors, and OEMs worldwide.

What Makes Truer a Trusted B2B Supplier?

✅ Industry Experience

- Over 14 years in powder metallurgy and materials science

- 5+ years dedicated to additive manufacturing powder development

- Recognized for excellence in both domestic and overseas markets

✅ Capacidades de fabricación avanzadas

- Offers both gas atomized and water atomized AL 4043 powder

- Custom particle size ranges available (15–45 μm, 20–53 μm, etc.)

- Controlled oxygen content and high sphericity for AM applications

✅ Full Product Portfolio

In addition to AL 4043 powder, Truer provides a wide array of PM and AM materials:

- PM brass, bronze, iron, steel, copper, and stainless steel powders

- Diffusion alloyed and prealloyed steels (e.g., FD-0208, FL-4605)

- Specialty additives: lubricants, cutting agents, soft magnetic materials

✅ Global B2B Support

- English-speaking sales and technical engineering teams

- Fast shipping with international trade support

- Responsive after-sales service and ongoing R&D collaboration

Customer-Centric Services

| Servicio | Descripción |

|---|---|

| Custom Powder Blends | Tailored compositions for unique applications |

| Consulta técnica | Metallurgical support and process matching |

| Batch Traceability | COAs, MSDS, and quality inspection reports provided with each shipment |

| Scalable Orders | From sample testing (1–5 kg) to bulk orders (1–10 tons/month) |

📦 Looking for consistent, high-performance AL 4043 powder for your AM or PM production? Explore our products and download technical datasheets here.

9. How to Order Wholesale AL 4043 Powder from Shanghai Truer

Ordering AL 4043 powder from Shanghai Truer is a straightforward process designed for B2B efficiency, whether you’re a distributor, 3D printing service bureau, or OEM manufacturer.

Step-by-Step Ordering Guide

🔍 Step 1: Define Your Specifications

- Required particle size (e.g., 15–45 μm for SLM)

- Atomization method (gas atomized preferred for AM)

- Quantity (MOQ starts at 10 kg; discounts available for 500+ kg)

📝 Step 2: Request a Quotation

- Email your RFQ to the sales team

- Include technical requirements, shipping address, and delivery timeline

- You can also fill out the inquiry form directly on our website

🧪 Step 3: Sample Testing (Optional)

- Order a 1–2 kg test batch

- Receive a Certificate of Analysis (COA) with the sample

- Evaluate printability, flowability, and microstructure

📦 Step 4: Place Bulk Order

- Confirm commercial invoice and shipping terms

- Choose packaging: vacuum-sealed bags or nitrogen-filled drums

- Select delivery option: air freight, sea freight, or express (DHL/FedEx)

📄 Step 5: Receive Documentation

- COA, MSDS, and customs paperwork included

- HS codes and export compliance support provided

🚚 Step 6: Delivery and After-Sales Support

- Receive your products in 7–14 days depending on region

- Continuous technical support available for powder performance optimization

💬 Ready to get started? Request a quote or speak to our sales team directly.

10. FAQs: Buying Wholesale AL 4043 Powder – What You Should Know

Here are answers to the most commonly asked questions by B2B buyers looking to source AL 4043 powder:

Q1: What is the typical lead time for bulk AL 4043 powder orders?

A: Standard lead time is 7–14 working days for stocked sizes. Custom batches may take up to 21 days depending on particle size and quantity.

Q2: Is gas atomized AL 4043 better than water atomized?

A: Yes. For additive manufacturing, gas atomized powders offer better sphericity, flowability, and lower oxygen content—ideal for SLM and DMLS processes.

Q3: What packaging formats are available?

A: AL 4043 powders are available in 10kg foil vacuum bags, 25kg nitrogen-filled drums, and 100kg bulk containers. All packaging is moisture-resistant.

Q4: Can Truer provide custom particle sizes?

A: Absolutely. We offer tailored size distributions (e.g., 20–53 μm, 45–106 μm) to meet specific needs in AM, PM, or welding applications.

Q5: How do I ensure shipment compliance for international orders?

A: Truer provides full export documentation including MSDS, COA, and HS codes. We also assist with customs clearance and shipping insurance.

Q6: What standards does your AL 4043 powder meet?

A: Our powder meets or exceeds industry standards for AM (ASTM F3318), welding filler metal (AWS A5.10 ER4043), and powder metallurgy.

Q7: Can I visit Truer’s facility or request video audits?

A: Yes. We welcome factory audits and can schedule a virtual tour or live demo of our production lines.

📘 For more technical questions or to download product specs, visit our About Us page and explore our full capabilities.