1. Introduction: Why 310S Powder is Vital in Industrial Manufacturing

310S stainless steel powder is a high-temperature, oxidation-resistant alloy widely used in powder metallurgy (PM) and additive manufacturing (AM). Known for its excellent corrosion resistance, durability, and workability, 310S powder is a preferred material in industries like aerospace, automotive, petrochemical, and energy.

For B2B buyers, especially distributors, OEMs, and component manufacturers, sourcing high-quality 310S stainless steel powder is critical for achieving cost-efficiency and production reliability.

Key Characteristics of 310S Stainless Steel Powder:

- High chromium (24-26%) and nickel (19-22%) content

- Excellent resistance to oxidation and sulfidation

- High-temperature strength (up to 1100°C)

- Buena soldabilidad y conformabilidad

- Low carbon content reduces carbide precipitation

B2B Buyers Who Benefit from 310S Powder:

| Industria | Solicitud | B2B Buyer Profile |

|---|---|---|

| Aeroespacial | Componentes de turbina | OEM manufacturers, Tier 1 suppliers |

| Automotor | Sistemas de escape | Distributors, component fabricators |

| Petroquímica | Intercambiadores de calor | Plant equipment suppliers |

| Metal Fabrication | High-temp fixtures | Steel part manufacturers |

| Energía | Burner nozzles | Power plant contractors |

For buyers seeking long-term cost savings through superior material performance and reliability, 310S powder offers an optimal solution.

2. Key Applications of 310S Stainless Steel Powder in B2B Sectors

310S stainless steel powder is highly versatile and serves various industrial applications through powder metallurgy and additive manufacturing. Its high-temperature strength and corrosion resistance make it indispensable in extreme environments.

Common Applications in PM and AM Manufacturing:

- High-Temperature Components:

Used in aerospace and energy sectors for parts that operate under thermal stress. - Sintered Filters and Porous Components:

Ideal for fluid and gas filtration in chemical processing and oil & gas industries. - Automotive Exhaust and Manifold Parts:

Withstands high exhaust temperatures while resisting oxidation. - 3D Printed Heat-Resistant Structures:

Used in laser powder bed fusion (LPBF) and directed energy deposition (DED) for customized high-temp components.

Benefits for B2B Manufacturers:

- Lower material wastage through near-net-shape manufacturing

- Shorter lead times via additive manufacturing

- Improved component performance in extreme environments

Key Sectors Using 310S Powder:

| Sector | Componente | Método de fabricación |

|---|---|---|

| Aeroespacial | Jet engine nozzles | Fabricación aditiva |

| Automotor | Turbocharger housings | Pulvimetalurgia |

| Energía | Furnace linings | Sinterización |

| Química | Recipientes de reactores | Prensa & Sinterización |

Más información 310S powder applications and specifications on our dedicated product page.

3. Properties and Grades of 310S Stainless Steel Powder

Understanding the physical, mechanical, and chemical properties of 310S powder helps B2B buyers make informed procurement decisions. Shanghai Truer offers multiple grade options to meet different industrial needs.

Composición química (típica)

| Elemento | Contenido (%) |

|---|---|

| Cromo (Cr) | 24.0–26.0 |

| Níquel (Ni) | 19.0–22.0 |

| Carbono (C) | ≤ 0.08 |

| Manganeso (Mn) | ≤ 2.0 |

| Silicio (Si) | ≤ 1.5 |

| Fósforo (P) | ≤ 0.045 |

| Azufre (S) | ≤ 0.03 |

| Hierro (Fe) | Saldo |

Key Mechanical Properties

| Propiedad | Valor |

|---|---|

| Resistencia a la tracción | > 515 MPa |

| Límite elástico | > 205 MPa |

| Alargamiento | > 40% |

| Dureza | 170–215 HB |

| Densidad | ~7.98 g/cm³ |

| Punto de fusión | ~1400°C |

Available Grades from Shanghai Truer:

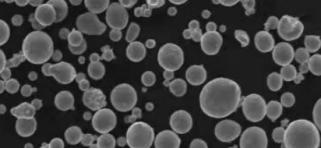

- Gas Atomized 310S Powder: Ideal for additive manufacturing processes like SLM and DED

- Water Atomized 310S Powder: Best suited for press & sinter and MIM applications

- Custom Blends: Tailored for specific density, flowability, or particle size distribution

Shanghai Truer provides 310S powder in various particle sizes (15–45μm, 45–105μm, etc.), optimized for different B2B manufacturing processes. Visit our Quiénes somos to learn more about our powder metallurgy capabilities.

4. Global and Regional Market Trends for 310S Powder

The global demand for 310S stainless steel powder is on the rise due to the increased adoption of powder metallurgy (PM) and additive manufacturing (AM) techniques across industries. The push for lightweight, corrosion-resistant, and high-temperature materials is driving growth in both developed and emerging markets.

Principales impulsores del mercado

- Growth of Additive Manufacturing (AM):

The rapid expansion of Impresión 3d applications in aerospace, energy, and medical sectors is increasing demand for gas-atomized 310S powder. - Electrificación del automóvil:

Components for EVs and hybrid vehicles require higher durability and corrosion resistance, making 310S a preferred choice. - Energy Sector Revamp:

Investments in renewable and nuclear energy infrastructure are boosting the need for high-temperature steel parts. - Environmental Regulations:

Stricter emissions and safety standards are pushing manufacturers toward high-performance materials like 310S.

Global Demand Outlook (2024–2030)

| Región | CAGR (2024-2030) | Key Demand Sectors |

|---|---|---|

| Norteamérica | 6.2% | Aeroespacial, petróleo y gas |

| Europa | 5.8% | Automotive, Energy |

| Asia-Pacífico | 8.5% | Manufacturing, Infrastructure |

| Oriente Medio | 4.9% | Petroquímica |

| América Latina | 4.3% | Mining, Construction |

Market Opportunity for B2B Buyers

- OEMs and Contract Manufacturers: Benefit from increased material availability and customization options.

- Distributors and Resellers: Can capitalize on growing demand by stocking high-grade 310S powder.

- Component Producers: Gain competitive advantage through high-performance, durable materials.

For more information on our full line of PM powders and metal blends, visit our comprehensive product catalog.

5. Top Factors When Choosing a 310S Powder Supplier

Selecting the right supplier is critical for B2B buyers sourcing 310S stainless steel powder. Material consistency, technical expertise, and scalability are essential to ensure quality and cost-efficiency throughout the supply chain.

Consideraciones clave para la contratación B2B:

- Purity and Composition Consistency

- Look for guaranteed chemical composition with low inclusions and impurities.

- Ensure batch-to-batch consistency for manufacturing reliability.

- Tecnología de producción

- Gas atomization for AM applications (SLM, DED)

- Water atomization for PM applications (press & sinter, MIM)

- Combined atomization options for tailored properties

- Certifications and Standards Compliance

- ISO 9001, ASTM, and relevant industry-specific certifications

- Fiabilidad de la cadena de suministro

- Ability to fulfill large-volume orders with consistent lead times

- On-time shipping and global logistics support

- Technical Support and R&D

- Access to powder metallurgy experts for application guidance

- Custom blends based on your specific use case

- Pricing Flexibility

- Tiered pricing for bulk purchases

- Transparent cost structures and long-term contracts

Lista de comprobación para la evaluación de proveedores

| Criterios | Importancia | Shanghái Truer |

|---|---|---|

| Composition Accuracy | ★★★★★ | ✅ Sí |

| Tecnología de atomización | ★★★★★ | ✅ Water, Gas, Combined |

| Bulk Supply Capability | ★★★★☆ | ✅ 10+ tons/month |

| Custom Powder Blends | ★★★★☆ | ✅ Disponible |

| Technical Assistance | ★★★★★ | ✅ Expert R&D Team |

| Envíos internacionales | ★★★★☆ | ✅ Export-Ready Logistics |

6. Leading 310S Stainless Steel Powder Suppliers in Asia

Asia is home to some of the most reliable and cost-effective suppliers of 310S stainless steel powder. For B2B buyers, especially those targeting high production volumes, these manufacturers offer competitive pricing and robust quality assurance.

Top 5 310S Powder Suppliers in Asia

| Proveedor | País | Puntos fuertes | Método de producción |

|---|---|---|---|

| Shanghai Truer Technology Co., Ltd | China | Custom blends, bulk supply, R&D support | Gas & Water Atomized |

| Sandvik Asia | India | High-grade AM powders | Gas atomizado |

| Acero Daido | Japón | Specialty steel grades | Gas atomizado |

| POSCO PowderTech | Corea del Sur | Advanced metallurgy | Agua atomizada |

| Acero JFE | Japón | High precision steel powders | Atomización combinada |

Lo que diferencia a Shanghai Truer:

- Established in 2009, with a dedicated PM division since 2019

- Full integration of 3D printing powder equipment and materials

- Offers both high-purity gas atomized and cost-effective water atomized powders

- Specializes in custom powder solutions for AM and PM processes

Shanghai Truer isn’t just a material supplier—it’s a strategic partner in powder metallurgy. Learn more about our company background and mission on our Quiénes somos.

7. Por qué cada vez más compradores recurren a fabricantes chinos

China has rapidly emerged as a global leader in the production of powder metallurgy materials, offering scalable production, competitive pricing, and increasing quality standards. B2B buyers worldwide are benefiting from this shift.

Principales ventajas de abastecerse en China:

- Rentabilidad:

Lower operational costs allow Chinese suppliers to offer highly competitive rates, especially for bulk orders. - Advanced Manufacturing:

Many Chinese manufacturers, including Shanghai Truer, now operate advanced atomization facilities rivaling Western standards. - Personalización y flexibilidad:

Fast turnaround on custom blends, particle sizes, and packaging options. - R&D Support:

Integrated R&D departments offer formulation advice and prototyping capabilities.

Common Concerns Addressed:

| Concern | Solution from Shanghai Truer |

|---|---|

| Garantía de calidad | ISO-certified, strict QC testing |

| Language Barrier | Multilingual sales and tech team |

| Logística | Global shipping with full documentation |

| Asistencia técnica | Application-specific guidance and support |

As a trusted supplier in the Chinese powder metallurgy industry, Shanghai Truer delivers not just material—but value at every step. Ready to speak with a sales engineer? Póngase en contacto con nosotros.

8. Why Choose Shanghai Truer as Your 310S Powder Supplier

Shanghai Truer Technology Co., Ltd stands out as one of the most trusted and innovative powder metallurgy suppliers in China. With over a decade of experience and a specialized division for additive manufacturing launched in 2019, Truer has positioned itself as a reliable B2B partner for high-performance stainless steel powders, including 310S.

¿Qué diferencia a Shanghai Truer?

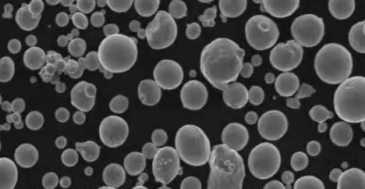

✅ Fabricación integrada

Truer is one of the few companies capable of delivering both powder production equipment and high-quality powders. This vertical integration ensures quality control from atomization to packaging.

✅ Flexible Atomization Technologies

Whether your business requires gas atomized 310S for additive manufacturing or water atomized powder for PM parts, Truer offers both — including combined methods for unique application needs.

✅ Amplia gama de productos

Truer supplies a broad spectrum of PM powders beyond 310S, including:

- PM stainless steels: 316L, 304L, 410L, and more

- PM tool steels: FL-4605, FD-0208

- Prealloyed and hybrid steels: FX1005, FX-2008

- Copper and bronze-based powders

- Diffusion alloyed and lubricated powders

✅ B2B-Focused Services

Truer understands the complexities of B2B procurement. Services include:

- Custom material development

- Batch traceability and quality documentation

- Logistic support for global shipping

- Dedicated customer service and technical consultation

✅ Established Industry Trust

Recognized as a professional additive supplier in the Chinese PM industry, Truer has long-standing partnerships with domestic and international manufacturers, R&D institutions, and distributors.

Truer’s 310S Powder Capabilities

| Característica | Detalle |

|---|---|

| Tamaño de las partículas | 15–45μm, 45–105μm, custom available |

| Atomization Types | Gas, Water, Combined |

| Embalaje | 5kg, 25kg, 100kg drums or custom |

| Monthly Capacity | 10+ tons |

| Regiones exportadoras | América del Norte, Europa, Sudeste Asiático |

| Ayuda | Application evaluation, prototyping, bulk pricing |

Ready to explore Truer’s full line of stainless steel and custom PM powders? Visit our product catalog for PM powder specifications and grades.

9. How to Order Wholesale 310S Powder from Shanghai Truer

Ordering 310S stainless steel powder in bulk from Truer is a streamlined process designed for B2B buyers who prioritize quality, logistics efficiency, and responsive support.

Proceso de pedido paso a paso

- Submit Your Inquiry

Contact our sales team through the online form or email us directly with your application details, required quantity, and desired particle size. - Technical Evaluation

Our metallurgical experts will review your use case and recommend the best grade and atomization method (gas, water, or combined). - Presupuesto y muestra

Receive a formal quotation with lead time, shipping options, and pricing tiers. Sample shipments are available for validation before bulk orders. - Customize Your Order

Choose packaging, shipping logistics (FOB, CIF, DDP), and any required documentation (RoHS, REACH, MSDS, etc.). - Producción & Control de calidad

Once confirmed, your order is moved to production. Every batch undergoes strict quality testing including chemical analysis, particle size distribution, and flowability. - Envío y entrega

Orders can be shipped globally via sea, air, or courier. Truer works with reliable logistics partners to ensure timely delivery with proper export documentation. - Asistencia posventa

Our team provides ongoing technical support, reordering assistance, and feedback collection to ensure long-term satisfaction.

Wholesale Pricing Benefits

| Volumen del pedido | Discount Tier | Plazos de entrega |

|---|---|---|

| 100-500 kg | 5% | 10–14 days |

| 500-1000 kg | 8% | 14–18 days |

| 1000+ kg | 12–15% | 18-25 días |

For a custom quote tailored to your project, please get in touch with us.

10. FAQs: Everything B2B Buyers Need to Know About 310S Powder

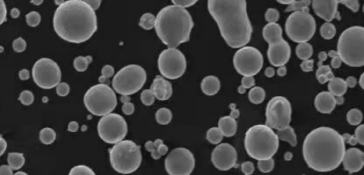

Q1: What is the difference between gas atomized and water atomized 310S powder?

A: Gas atomized powder has superior sphericity and flowability, ideal for 3D printing and AM. Water atomized powder is more cost-efficient and is suitable for press & sinter or MIM applications.

Q2: Can Truer provide technical data sheets and MSDS for 310S powder?

A: Yes. Every shipment includes a full technical specification sheet, MSDS, and test reports (chemical composition, PSD, etc.).

Q3: Is customization available for particle size and packaging?

A: Absolutely. Truer offers tailored solutions including particle sizes from 15μm up to 150μm and packaging in sealed containers or anti-static drums as per your needs.

Q4: How does Truer ensure batch-to-batch quality consistency?

A: All powder batches are manufactured with controlled atomization parameters, followed by multi-point quality testing before dispatch.

Q5: Do you ship internationally?

A: Yes, Truer exports globally and handles all required export documentation and logistics coordination.

P6: ¿Hay muestras disponibles para las pruebas?

A: Yes. Sample quantities (1–5 kg) can be shipped for qualification before placing a bulk order.

Q7: What is the lead time for bulk orders?

A: Depending on volume and customization, typical lead times range from 10 to 25 days.

Q8: Where can I learn more about Truer’s full capabilities?

A: Visit our Acerca de Truer page for an overview of our history, technology, and mission.

📌 Ready to source high-quality 310S stainless steel powder at wholesale prices?

🔗 Contact Shanghai Truer now to request a quote or technical consultation for your next project.