1. Introduction: Why Inconel 713 Rods Matter in High-Performance Industries

Inconel 713 is a nickel-based superalloy known for its exceptional high-temperature strength, corrosion resistance, and oxidation resistance. As one of the most desirable materials used in aerospace, gas turbines, and high-performance engineering applications, Inconel 713 rods are often the material of choice for critical components subjected to extreme environments.

With the rise of additive manufacturing and powder metallurgy (PM), the demand for high-quality Inconel 713 rods has surged among B2B buyers, including:

- Aerospace manufacturers

- Gas turbine OEMs

- Fabricantes de piezas de alto rendimiento para automóviles

- Empresas de hornos industriales y utillaje

- Additive manufacturing powder suppliers

Key Features of Inconel 713 Rods:

| Propiedad | Value / Description |

|---|---|

| Composición básica | Nickel-based with aluminum, chromium, and niobium |

| Temperatura de funcionamiento | Up to 980°C (1800°F) |

| Resistencia a la corrosión | Excellent in oxidizing and reducing environments |

| Límite elástico | High yield strength at elevated temperatures |

| Maquinabilidad | Fair; requires specialized cutting tools |

2. Industrial Applications of Inconel 713 Rods

Inconel 713 rods are widely used in industries that demand excellent mechanical performance at elevated temperatures. Below are the most common application sectors:

✅ Aerospace Industry

- Palas y álabes de turbina

- Combustor components

- Sistemas de escape

✅ Automotive Industry

- Componentes del turbocompresor

- High-performance exhaust manifolds

✅ Power Generation

- Gas turbine rotors

- Protectores térmicos

- Burner nozzles

✅ Metal and Glass Processing

- Furnace components

- Molds and dies for glass forming

✅ Additive Manufacturing and PM

- Precursor material for 3D printing powders

- Raw material for alloyed powder metallurgy applications

Inconel 713’s strength and resistance to creep and fatigue make it ideal for applications where failure is not an option. For example, in aerospace turbine engines, Inconel 713 rods can withstand prolonged exposure to combustion gases without deforming.

3. Properties and Manufacturing Methods of Inconel 713

Key Mechanical and Thermal Properties

| Propiedad | Valor típico |

|---|---|

| Resistencia a la tracción | ~965 MPa at room temperature |

| Creep Rupture Strength | Excellent at 870–980°C |

| Dureza (Rockwell C) | 30–35 HRC |

| Conductividad térmica | 11.4 W/m·K |

| Coeficiente de dilatación | ~13.6 µm/m°C (at 20–1000°C) |

Composición química (% en peso)

| Elemento | Contenido (%) |

|---|---|

| Níquel (Ni) | Balance (Base metal) |

| Cromo (Cr) | 12.5 – 14.5 |

| Aluminio (Al) | 5.5 – 6.5 |

| Titanio (Ti) | 0.5 – 1.0 |

| Carbono (C) | 0.08 – 0.12 |

| Circonio (Zr) | 0.03 – 0.08 |

Common Manufacturing Methods

- Fusión por inducción en vacío (VIM)

Ensures purity and consistency of alloy composition. - Prensado isostático en caliente (HIP)

Improves mechanical strength and removes porosity. - Casting and Forging

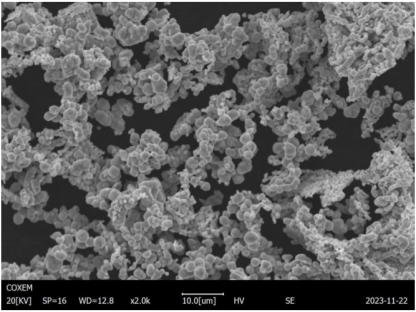

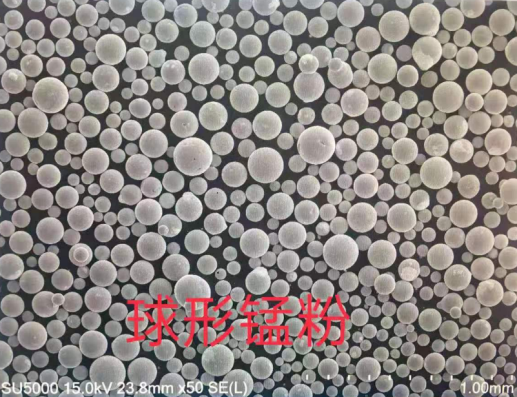

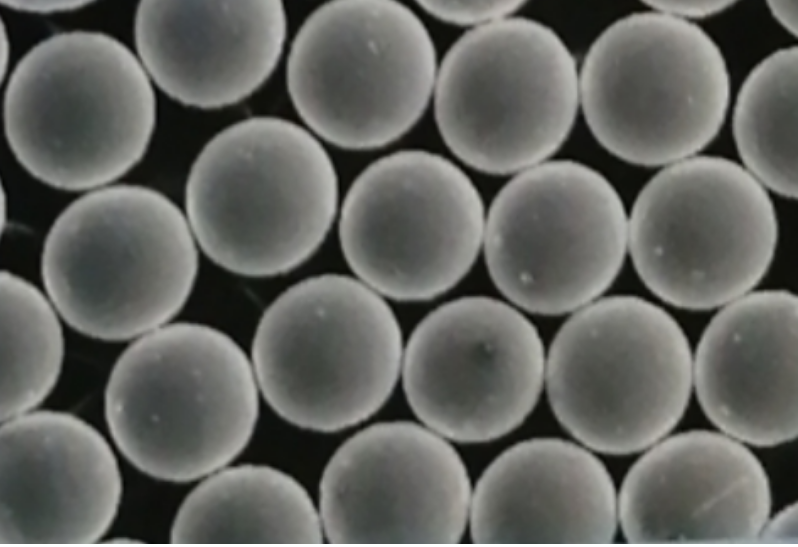

Suitable for producing rods in various diameters and lengths. - Pulvimetalurgia (PM)

Used for producing fine powders for 3D printing or compacted rods.

Learn more about our PM capabilities here

Advantages of PM and Additive Manufacturing

- Enhanced microstructural control

- Near-net shape production

- Reducción de los residuos de material

- Formulación de aleaciones a medida

Shanghai Truer Technology Co., Ltd has deep expertise in powder metallurgy and additive manufacturing. Established in 2009, Truer began its Impresión 3d powder division in 2019 and now offers a full portfolio of PM and AM-grade materials. The company produces high-quality Inconel and other nickel-based alloy powders via gas and water atomization, making it a reliable supplier for industries demanding precision-engineered components.

4. Global Market Trends and Demand for Inconel 713 Alloys

The demand for Inconel 713 rods is growing rapidly, driven by the expansion of high-temperature applications in aerospace, defense, energy, and industrial manufacturing. B2B buyers are increasingly seeking reliable suppliers of nickel-based alloy rods to fulfill high-performance requirements for extreme environments.

🌐 Key Market Drivers:

- Aerospace modernization: Increased production of jet engines and turbine systems

- Energy sector growth: Expansion of gas turbine power plants and renewable energy infrastructure

- Automotive innovation: Development of turbocharged systems and electric vehicle components

- Fabricación aditiva (AM): Rising demand for superalloy powders and rods for 3D printing

📈 Market Size & Forecast (Inconel Alloy Rods)

| Región | 2023 Market Size (USD) | CAGR (2024-2029) | Industrias clave |

|---|---|---|---|

| Norteamérica | $650 Million | 6.5% | Aeroespacial, Defensa |

| Europa | 520 millones de dólares | 5.8% | Energy, Automotive |

| Asia-Pacífico | $470 Million | 7.2% | Manufacturing, AM |

| Oriente Medio | $180 Million | 6.0% | Oil & Gas, Power |

🔥 Industry Trends:

- Shift toward powder-based production: Powder metallurgy and AM methods are gaining traction for producing Inconel 713 parts.

- Rise of hybrid manufacturing: Combining casting and machining with PM for optimized product performance.

- Sustainability initiatives: OEMs are shifting to suppliers with greener, waste-reducing production processes.

- Digital procurement platforms: Buyers are increasingly using B2B marketplaces and supplier websites to compare and source metals.

Shanghai Truer Technology is at the forefront of these trends. Leveraging its advanced powder metallurgy production lines and AM-compatible materials, Truer enables global buyers to access high-quality Inconel and other superalloy powders and rods. Visit the about us page to explore their capabilities.

5. Key Considerations When Choosing Inconel 713 Rod Suppliers

Choosing the right supplier is critical for material consistency, lead time, and overall project success. B2B buyers should assess suppliers on the following parameters:

📝 Evaluation Criteria for Inconel 713 Rod Suppliers

| Criterios | Importancia | En qué fijarse |

|---|---|---|

| Certificación de materiales | ✅ Critical | ASTM, ISO, AMS-compliant certifications |

| Método de fabricación | ✅ Critical | VIM, PM, Gas Atomized, HIP |

| Supply Chain Capabilities | ✅ Critical | Global delivery, custom sizing, MOQ flexibility |

| Garantía de calidad | ✅ Alta | 100% traceability, in-house testing labs |

| Asistencia técnica | ✅ Alta | Engineering consultation, application guidance |

| Lead Time & Inventory | ✅ Alta | Readily available stock, fast production cycles |

| Transparencia de precios | ✅ Medium | Clear quotations, bulk discount structures |

📌 Tips for B2B Buyers:

- Request a sample batch or material test report (MTR)

- Confirm alloy batch traceability and production lot size

- Ask about post-processing options (annealing, cutting, etc.)

- Ensure conflict-free and RoHS compliance for global export

Shanghai Truer Technology Co., Ltd meets all these criteria with a strong reputation in the Chinese powder metallurgy sector. Their full-service approach includes material customization, technical support, and global delivery—making them a preferred partner for international buyers.

6. Top Inconel 713 Rod Manufacturers and Distributors Globally

To support your procurement strategy, here are some of the leading Inconel 713 rod manufacturers and distributors operating in global markets:

🌍 Leading Inconel 713 Rod Suppliers

| Nombre del proveedor | Ubicación | Especialidad | Puntos fuertes |

|---|---|---|---|

| Special Metals Corporation | EE.UU. | Inconel castings and rods | Inventor of Inconel alloys, global network |

| Shanghai Truer Technology Co., Ltd | China | PM & AM nickel-based powders and rods | Customization, fast delivery, R&D support |

| Haynes Internacional | EE.UU. | Aleaciones de alta temperatura | Strong aerospace presence |

| VDM Metales | Alemania | Superalloy sheets, bars, rods | European market leader |

| All Metals & Forge Group | EE.UU. | Forged rods and discs | Custom sizes, ISO certified |

| Tecnología Carpenter | EE.UU. | High-performance specialty alloys | Aerospace-grade material, R&D driven |

🧭 For international buyers seeking cost-effective and high-quality alternatives, Chinese suppliers like Shanghai Truer offer competitive pricing, flexible MOQs, and advanced PM production capabilities. Their Inconel 713 rods are manufactured with strict quality control and can be customized for AM or traditional applications.

To explore Truer’s full material range, visit the main product page.

7. Why More Buyers Are Turning to Chinese Suppliers

In recent years, B2B purchasers in aerospace, defense, and industrial manufacturing have increasingly turned to Chinese suppliers for high-performance alloys like Inconel 713 rods. This shift isn’t just about cost—Chinese manufacturers are investing heavily in technology, quality control, and global logistics.

📈 Key Reasons Why Global Buyers Choose Chinese Manufacturers:

| Factor | Competitive Advantage for Chinese Suppliers |

|---|---|

| Eficiencia de costes | Menores costes laborales y operativos |

| Advanced PM Capabilities | Sophisticated water/gas atomization lines |

| Plazos de entrega más cortos | High production capacity and inventory stock |

| Material Customization | Flexibility in sizing, composition, and packaging |

| Experiencia en exportación | Proven track record in serving global markets |

| Inversión en I+D | Partnerships with universities and R&D labs |

🇨🇳 China’s Role in the Superalloy Market

- Leading producer of powder metallurgy (PM) materials

- Competitive in gas atomized and diffusion alloyed powders

- Expanding global footprint via e-commerce and direct exports

Companies like Shanghai Truer Technology Co., Ltd exemplify this shift. Since launching its additive manufacturing division in 2019, Truer has become a top-tier supplier of custom-engineered 3D printing powders, nickel-based alloys, and performance rods—including Inconel 713.

Thanks to Truer’s vertically integrated production model and strict quality assurance, international B2B clients benefit from lower costs without compromising performance or compliance. Learn more about their company mission and innovation aquí.

8. Why Choose Shanghai Truer Technology for Inconel 713 Rods

Shanghai Truer Technology is not just a manufacturer—it is a strategic partner for B2B buyers looking for long-term quality, reliability, and innovation in powder metallurgy and additive manufacturing.

🏆 What Sets Truer Apart?

| Característica | Detalles |

|---|---|

| Experiencia acreditada | Founded in 2009, expanded into additive manufacturing in 2019 |

| Wide Alloy Portfolio | Inconel 713, PM bronze, PM stainless steel, PM brass, and more |

| Tecnología de atomización avanzada | Water, gas, and hybrid atomization for high-purity powder production |

| Custom Engineering Support | Tailored alloy development and material testing for client applications |

| Full Compliance | ISO-certified, RoHS-compliant, and export-ready |

| Logística mundial | Fast delivery and custom packaging for international orders |

| Soluciones llave en mano | From powder to finished rod, with optional machining and finishing |

🧪 Powder Metallurgy & Additive Manufacturing Capabilities

Truer offers a wide selection of PM powders and additives, including:

- PM 4600 Steel, PM Infiltrated Iron, y Acero inoxidable PM

- Lube-W, SUW-5000B, SME-100 agentes de corte sin azufre

- Soft magnetic additives (QH-150) y Graphite TBC-400

These materials are suitable for advanced applications such as:

- Aerospace-grade structural parts

- Diamond tool binders

- Oil-impregnated sintered bearings

- 3D-printed industrial components

Explore Truer’s full product selection on the Página de polvos PM.

9. FAQs: Buying Inconel 713 Rods in Bulk

❓ What is the MOQ (Minimum Order Quantity) for Inconel 713 rods?

At Shanghai Truer, the MOQ is flexible based on project requirements. Small batches are available for prototyping and R&D, while bulk discounts apply for large-scale orders.

❓ Do you offer material certifications?

Yes. All Inconel 713 rods come with full Material Test Reports (MTRs), including chemical composition, mechanical properties, and compliance with international standards like ASTM and AMS.

❓ Can you customize rod dimensions?

Absolutely. Truer offers a range of diameters and lengths, as well as custom cutting and finishing services to meet your specifications.

❓ What is the typical lead time for delivery?

For in-stock items, lead time is typically 5–10 business days. Custom production orders may take 2–4 weeks depending on complexity and volume.

❓ Do you ship internationally?

Yes. Truer ships to North America, Europe, Southeast Asia, and the Middle East via air, sea, or express courier. All export documentation is handled in-house.

❓ ¿Cómo hago un pedido?

Puede ponerse en contacto directamente a través de página de contacto to get a custom quote, sample request, or technical consultation.

🔚 Ready to Source Premium Inconel 713 Rods?

Shanghai Truer Technology Co., Ltd is your trusted partner for high-performance alloy solutions. With advanced manufacturing capabilities, a global logistics network, and full engineering support, Truer empowers your business to stay ahead in demanding industries.

✅ Whether you’re in aerospace, energy, automotive, or additive manufacturing, Truer delivers the quality and precision your application requires.

👉 Contact us now to request a quote or speak with a materials engineer.