Introducción: El creciente papel del polvo de acero inoxidable en la fabricación

El polvo de acero inoxidable se está convirtiendo en la piedra angular de la fabricación industrial avanzada por su versatilidad, durabilidad y compatibilidad con los procesos de fabricación aditiva y pulvimetalurgia (PM). A medida que las industrias mundiales se orientan hacia componentes de ingeniería de precisión y métodos de producción sostenibles, el polvo de acero inoxidable desempeña un papel fundamental a la hora de ofrecer soluciones rentables y de alto rendimiento para sectores como:

- Automotor

- Aeroespacial

- Productos sanitarios

- Electrónica de consumo

- Energía y maquinaria pesada

Para compradores B2B, distribuidores y vendedores de comercio electrónico, el polvo de acero inoxidable ofrece oportunidades escalables en la fabricación aditiva de metales, el moldeo por inyección de metales (MIM) y la producción de piezas sinterizadas. La demanda de polvo de acero inoxidable a granel y a medida está creciendo, y las empresas buscan proveedores fiables que puedan ofrecer calidad, consistencia y experiencia técnica.

¿Qué hace que el polvo de acero inoxidable sea tan valioso?

| Característica | Ventajas para los compradores industriales |

|---|---|

| Resistencia a la corrosión | Ideal para entornos difíciles (marinos, químicos, etc.) |

| Resistencia mecánica | Admite aplicaciones de carga y críticas |

| Estabilidad térmica | Funciona a altas temperaturas |

| Compatibilidad con AM/PM | Permite geometrías de piezas complejas con un desperdicio mínimo |

| Reciclabilidad | Sostenible y rentable |

Con estas ventajas, el polvo de acero inoxidable abre nuevas puertas a la innovación en el diseño de productos y la escalabilidad de la fabricación.

Aplicaciones del polvo de acero inoxidable en las industrias B2B

El polvo de acero inoxidable tiene aplicaciones muy extendidas en diversos sectores industriales. Para los clientes B2B, entender estos casos de uso puede ayudar a identificar dónde encaja el material en su cadena de suministro y modelos de producción.

1. Industria del automóvil

Para su fabricación se utiliza polvo de acero inoxidable:

- Engranajes y bujes sinterizados

- Componentes del sistema de escape

- Piezas del inyector de combustible

- Piezas de transmisión

Estas piezas requieren solidez, resistencia a la corrosión y precisión dimensional, todas ellas alcanzables con piezas PM de acero inoxidable.

2. Aeroespacial y Defensa

En el sector aeroespacial, donde el alto rendimiento y la ligereza son esenciales, se utiliza polvo de acero inoxidable:

- Componentes de turbina

- Boquillas de combustible

- Soportes estructurales

- Prototipos y piezas finales de fabricación aditiva

El polvo es compatible con los procesos de sinterizado directo de metal por láser (DMLS) y de inyección de aglutinante, lo que permite la creación rápida de prototipos y la producción de bajo volumen de piezas complejas.

3. Dispositivos médicos y dentales

Por su biocompatibilidad y resistencia a los procesos de esterilización, el polvo de acero inoxidable se utiliza en:

- Instrumental quirúrgico

- Implantes ortopédicos

- Prótesis dentales

- Implantes a medida mediante Impresión 3d

4. Electrónica de consumo

La miniaturización y la alta precisión son fundamentales en la electrónica. El polvo de acero inoxidable se utiliza en:

- Carcasas para dispositivos móviles

- Componentes tecnológicos portátiles

- Piezas de blindaje EMI

5. Petróleo y Gas

Para aplicaciones de fondo de pozo y alta presión:

- Filtros y componentes de válvulas

- Conectores

- Piezas resistentes al desgaste

Estas aplicaciones demuestran cómo el polvo de acero inoxidable ayuda a los fabricantes a cumplir rigurosas normas de rendimiento en entornos exigentes.

Tipos de polvo de acero inoxidable y sus propiedades

Los diferentes grados y métodos de procesamiento de los polvos de acero inoxidable satisfacen las distintas necesidades industriales. En Shanghai Truer Technology Co., Ltd, suministramos una amplia gama de polvos de acero inoxidable adaptados a la pulvimetalurgia y la fabricación aditiva.

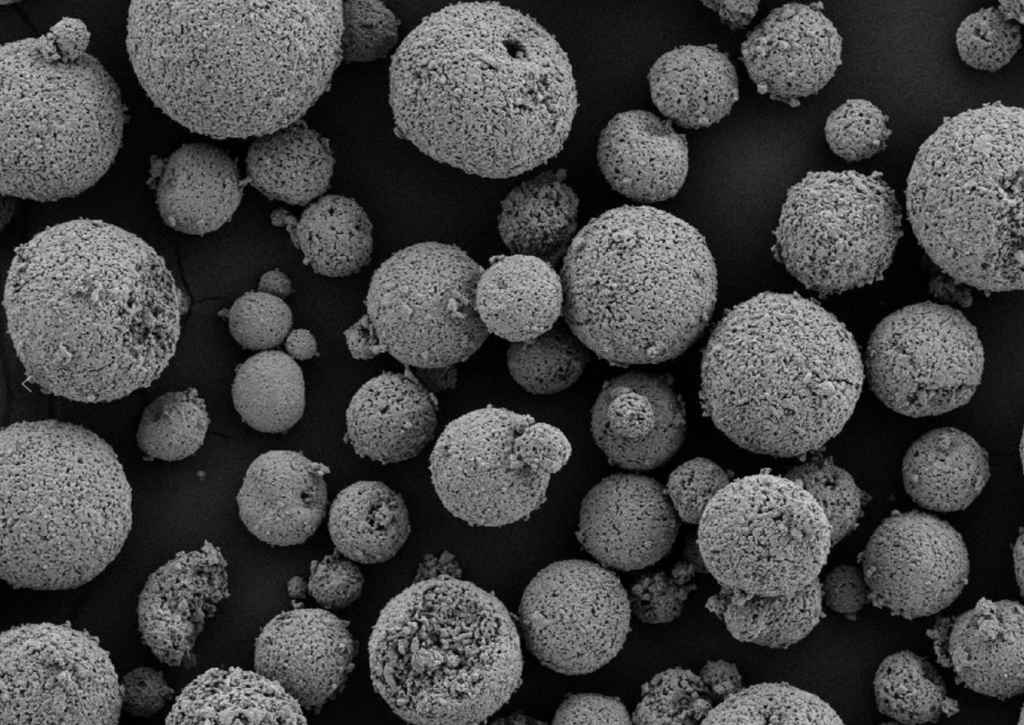

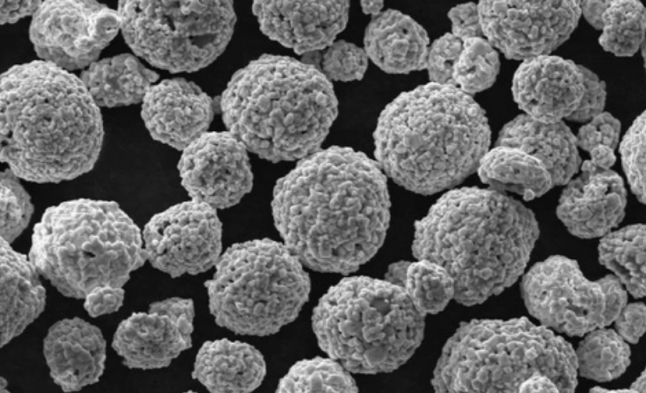

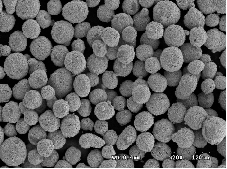

1. Métodos de fabricación

| Método | Descripción |

|---|---|

| Atomización del agua | Rentable; buena para piezas PM con densidad y resistencia moderadas |

| Atomización de gases | Produce partículas esféricas; ideal para la fabricación aditiva |

| Atomización combinada | Método híbrido para adaptar la morfología de las partículas y el rendimiento del flujo |

2. Calidades comunes de acero inoxidable

| Grado | Composición | Ámbitos de aplicación |

|---|---|---|

| 316L | Bajo contenido en carbono, molibdeno | Medicina, marina, procesamiento de alimentos |

| 304L | Bajo contenido en carbono, cromo-níquel | Automoción, electrodomésticos, arquitectura |

| 410 | Martensítico, alta resistencia | Herramientas, cuchillería, piezas resistentes al desgaste |

| 17-4PH | Endurecimiento por precipitación | Aeroespacial, componentes estructurales |

3. Especificaciones disponibles en Shanghai Truer

Shanghai Truer suministra polvos de acero inoxidable con propiedades personalizables como:

- Distribución del tamaño de las partículas (10-100 micras)

- Fluidez y densidad aparente

- Bajos niveles de oxígeno e impurezas

- Alta esfericidad para polvos de grado AM

Nuestros clientes utilizan nuestros polvos de acero inoxidable en el moldeo por inyección de metales, el sinterizado por láser, el chorro de aglutinante y la PM convencional.

🔗 Obtenga más información sobre nuestras ofertas de polvo de acero inoxidable en nuestro PM Polvo Página de producto.

Tendencias del mercado mundial y oportunidades de crecimiento del polvo de acero inoxidable

El mercado mundial de polvo de acero inoxidable está experimentando un rápido crecimiento, impulsado por la creciente demanda de fabricación aditiva, aligeramiento de automóviles y prácticas de producción sostenibles. Para los compradores B2B, esto representa una oportunidad lucrativa para capitalizar las tendencias emergentes y asegurar ventajas a largo plazo en la cadena de suministro.

Panorama del mercado

Según un reciente estudio de mercado:

- Se prevé que el mercado mundial del polvo de acero inoxidable alcance los 1.000 millones de euros en 2009 6 900 millones de dólares en 2030creciendo a una TCAC del 5.8% de 2023 a 2030.

- Asia-Pacífico tiene la mayor cuota de mercado, con China, Japón y Corea del Sur líder en adopción de pulvimetalurgia y fabricación aditiva.

- En automoción, aeroespacial, y médico sectores son los mayores consumidores de polvo de acero inoxidable.

Principales factores de crecimiento

| Factor | Repercusiones para los compradores y distribuidores mayoristas |

|---|---|

| Adopción de la fabricación aditiva | Impulsa la demanda de polvos esféricos de gran pureza |

| Cambio hacia una fabricación sostenible | Fomenta el uso de materiales reciclables y de bajo contenido en residuos, como los polvos metálicos |

| Aligeramiento en automoción | Aumenta el uso de componentes inoxidables sinterizados |

| Aumento de las piezas metálicas a medida | Impulsa la demanda de aplicaciones de alta precisión en lotes pequeños |

| Ayudas públicas & Incentivos | Promueve las capacidades nacionales de PM y AM en los mercados clave |

Para los distribuidores B2B y los vendedores de comercio electrónico, estas tendencias apuntan a una creciente demanda de polvo de acero inoxidable a granella calidad, la fiabilidad de las cadenas de suministro y el valor añadido de las fuentes de abastecimiento.

Oportunidades para compradores mayoristas

- Ampliar los catálogos de productos para incluir polvos inoxidables a medida.

- Oferta envases de marca blanca para nichos de mercado industriales.

- Asociarse con Fabricantes chinos para lograr competitividad de costes y escalabilidad de volúmenes.

Consideraciones clave a la hora de comprar polvo de acero inoxidable a los proveedores

Elegir al proveedor de polvo de acero inoxidable adecuado es fundamental para garantizar una calidad constante del producto, cumplir las normas de conformidad y mantener la eficiencia de la producción. Estos son los factores más importantes que deben evaluar los compradores B2B:

1. Calidad y pureza del polvo

Asegúrese de que el proveedor ofrece:

- Distribución homogénea del tamaño de las partículas

- Bajos niveles de oxígeno e impurezas

- Composiciones personalizadas (por ejemplo, 316L, 304, 17-4PH)

- Morfología esférica para aplicaciones AM

2. Capacidad de fabricación

Evaluar los métodos de producción de polvo:

| Método | Caso de uso ideal |

|---|---|

| Atomización de gases | Fabricación aditiva & binder jetting |

| Atomización del agua | Aplicaciones convencionales de PM y press-sinter |

| Atomización combinada | Propiedades físicas a medida |

Shanghai Truer Technology Co., Ltd ofrece los tres métodos, proporcionando flexibilidad en el abastecimiento en función de las necesidades de su aplicación.

3. Certificaciones y normas

Busque el cumplimiento de normas ISO y específicas del sector, como:

- ISO 9001:2015

- Conformidad RoHS/REACH

- Informes de ensayos de materiales (MTR)

- Conformidad personalizada para los sectores aeroespacial o médico

4. Personalización y logística

Un proveedor fiable debe ofrecer:

- Mezclado y tamizado personalizados

- Opciones de envasado a granel (25 kg, 500 kg, 1 tonelada)

- Apoyo logístico global

- Asesoramiento técnico y pruebas de muestras

🔗 Obtenga más información sobre nuestros servicios y capacidades en el Acerca de Truer Technology página.

Los 5 mejores proveedores de polvo de acero inoxidable de Asia

En Asia se encuentran algunos de los fabricantes de polvo de acero inoxidable más avanzados del mundo. He aquí cinco de los proveedores más fiables para los compradores B2B:

| Nombre de la empresa | País | Especialidad | Puntos fuertes |

|---|---|---|---|

| Shanghai Truer Technology Co., Ltd | China | PM & AM polvo de acero inoxidable | Grados personalizados, tecnología de atomización, I+D industrial |

| Pometon S.p.A | India/Italia | Polvos atomizados con agua y gas | Décadas de experiencia en metalurgia |

| Hoganas AB | Japón/Suecia | Polvos metálicos de alto rendimiento | Alcance mundial, I+D avanzada |

| CNPC Powder Material Co., Ltd | China | Polvos de fabricación aditiva | Producción a gran escala, polvos certificados AM |

| Kymera Internacional | Corea del Sur | Polvos de aleaciones especiales | Diversa gama de aleaciones, sólida red de exportación |

Por qué Shanghai Truer es líder en polvo de acero inoxidable

- Más de 14 años de experiencia en el sector

- División de polvo PM y AM dedicada

- Gama completa de calidades y mezclas de acero inoxidable

- Granulometrías personalizadas y envasado a granel

- Plazos de entrega rápidos para pedidos internacionales

🔗 Descubra más sobre nuestra gama de polvos de acero inoxidable en la Página de polvos PM.

Por qué cada vez más compradores recurren a fabricantes chinos de polvo de acero inoxidable

China se ha convertido rápidamente en un centro mundial de producción de acero inoxidable en polvo, gracias a sus precios competitivos, sus avances tecnológicos y su capacidad de fabricación a gran escala. He aquí por qué cada vez más compradores B2B, vendedores de comercio electrónico y fabricantes de equipos originales se abastecen de polvo de acero inoxidable en China:

1. Eficiencia de costes

- Menores costes laborales y operativos

- Aprovisionamiento competitivo de materias primas

- Capacidad de producción de grandes volúmenes

2. Tecnología de fabricación avanzada

- Lo último en tecnología equipo de atomización

- Integración de IA y automatización en control de calidad

- Capacidad de producción polvos esféricos para la fabricación aditiva

3. Cadenas de suministro favorables a la exportación

- Bien establecida redes logísticas mundiales

- Soporte multilingüe y cumplimiento de las normas de exportación

- Personalización para normas regionales (por ejemplo, UE, EE.UU.)

4. Amplia experiencia en aplicaciones

Proveedores chinos como Shanghai Truer prestan apoyo a una amplia gama de industrias:

- Piezas sinterizadas para automóviles

- Impresión 3D aeroespacial

- Prototipos de implantes médicos

- Carcasas y blindajes electrónicos

🔗 ¿Está interesado en abastecerse en China? Póngase en contacto con nosotros a través de nuestro Página de contacto para una consulta gratuita y muestras de apoyo.

Por qué elegir Shanghai Truer Technology como proveedor de confianza

Cuando se trata de abastecerse de polvo de acero inoxidable para pulvimetalurgia (PM) y fabricación aditiva (AM), Shanghai Truer Technology Co., Ltd destaca como uno de los proveedores más fiables y capaces del panorama metalúrgico chino. Con más de una década de experiencia y una división dedicada al polvo, Truer ofrece una calidad de producto, unos conocimientos técnicos y una capacidad de servicio B2B inigualables.

Perfil de la empresa: Shanghai Truer Technology Co., Ltd

- Fundada: 2009

- Se crea la División AM: 2019

- Competencia básica: Fabricación y suministro de polvos de impresión 3D y polvos metálicos de grado PM de alta calidad

- Ubicación: Shanghai, China

- Página web: am-material.com

¿Qué hace que Truer sea la opción preferida de los compradores mayoristas?

| Característica | Valor para los compradores B2B |

|---|---|

| Amplia gama de productos | Desde acero inoxidable hasta bronce, latón, acero al níquel y aleaciones personalizadas |

| Personalización del polvo | Granulometría, fluidez, composición y mezcla adaptadas a las necesidades del cliente |

| Múltiples métodos de atomización | Atomización con agua, gas y combinada para una morfología óptima de las partículas |

| Soluciones aditivas | Lubricantes, agentes de corte, aditivos magnéticos blandos y aleaciones de difusión |

| Asistencia técnica | Consultas de expertos, orientación sobre aplicaciones y servicios de ensayo de muestras |

| Alcance mundial | Logística preparada para la exportación y servicio multilingüe de atención al cliente |

Productos destacados

Shanghai Truer suministra una rica variedad de polvos de acero inoxidable adecuados para:

- Moldeo por inyección de metales (MIM)

- Chorro aglomerante

- Sinterizado láser (SLS, DMLS)

- Piezas PM convencionales

Los grados disponibles incluyen:

- 316L, 304L, 410, 17-4PHy otras variantes de acero inoxidable

- Calidades especiales adaptadas a la resistencia a la corrosión, la solidez o la sinterabilidad

Además, Truer también ofrece PM4200, PM4600, SBF2218, y Serie FX polvos para aplicaciones avanzadas de sinterización.

División de Materiales Aditivos

La División de Materiales Aditivos de Truer es conocida por:

- Lubricantes de alto rendimiento: Lube-W, SUW-5000B, SUW-8000

- Agentes de corte: Sulfuro de manganeso, SME-100 (sin azufre), TD-8 (agente de corte compuesto)

- Aditivos magnéticos: QH-150, QHP-330

- Aditivos de grafito: TBC-400, TBC-1000

🔗 Visita el Acerca de la página de Truer Technology para saber más sobre la historia, la misión y las capacidades de la empresa.

Cómo pedir polvo de acero inoxidable al por mayor a China

Pedir polvo de acero inoxidable a granel a un fabricante chino de renombre como Shanghai Truer es un proceso sencillo. He aquí una guía detallada paso a paso para distribuidores, fabricantes de equipos originales y compradores industriales.

Paso 1: Defina sus requisitos

Antes de ponerse en contacto con el proveedor, determine:

- Grado de polvo o composición del material (por ejemplo, acero inoxidable 316L)

- Método de aplicación (AM, PM, MIM)

- Gama de tamaños de partículas (por ejemplo, 15-45 μm para AM, 45-150 μm para PM)

- Cantidad necesaria (por ejemplo, 500 kg, 1 tonelada, 5 toneladas mensuales, etc.)

- Preferencias de envasado (bidones sellados, bolsas envasadas al vacío, etc.)

Paso 2: Enviar una consulta

Puede iniciar una solicitud de presupuesto a través de:

- Formulario de contacto en línea

- Correo electrónico o WhatsApp

- Llamada telefónica directa con un comercial

🔗 Usa Truer's Página de contacto para enviar directamente su consulta.

Paso 3: Recibir asesoramiento técnico

Truer asigna un consultor técnico dedicado a:

- Revise sus necesidades de aplicación y volumen

- Recomendar grados y especificaciones de polvo adecuados

- Facilite una ficha de datos técnicos (TDS) y una ficha de datos de seguridad de los materiales (MSDS)

- Sugerir muestras de prueba si es necesario

Paso 4: Recibir presupuesto y confirmar pedido

Tras la alineación técnica, recibirá:

- Oferta con precio FOB/CIF incluido

- Estimación de plazos

- Opciones de envío

- Condiciones de pago (T/T, LC, etc.)

Una vez confirmada, se emite una factura proforma (PI).

Etapa 5: Producción y expedición

- Truer inicia la producción o prepara el inventario

- El polvo se envasa en recipientes resistentes a la humedad, aptos para la exportación

- Un transportista o transportista asociado organiza la entrega en su lugar de residencia

- Se facilitan documentos de seguimiento y envío

Paso 6: Asistencia postventa

- Reciba asistencia técnica sobre el rendimiento del polvo

- Opciones personalizadas de reabastecimiento y suministro periódico

- Certificaciones de productos y documentación de conformidad

| Hito del pedido | Plazo (Est.) |

|---|---|

| Respuesta a la consulta | En 24 horas |

| Ejemplo de envío | 3-7 días laborables |

| Producción de pedidos a granel | 10-25 días laborables |

| Envíos internacionales | 7-20 días laborables |

Preguntas frecuentes: Preguntas frecuentes sobre la compra de polvo de acero inoxidable al por mayor

1. ¿Cuál es la cantidad mínima de pedido (MOQ) para el polvo de acero inoxidable?

La mayoría de las calidades tienen una MOQ de 25 kgpero los descuentos por volumen empiezan en 500 kg y más.

2. ¿Puedo solicitar mezclas o granulometrías personalizadas?

Sí. Truer se especializa en formulaciones personalizadasincluidas las mezclas de acero inoxidable con cobre, níquel u otros metales, así como distribuciones granulométricas a medida para las necesidades AM y PM.

3. ¿Qué certificaciones cumplen sus polvos?

Los polvos de Truer cumplen ISO 9001, RoHS, y Normativa REACHy pueden facilitarse certificaciones previa solicitud.

4. ¿Ofrecen muestras para pruebas?

Sí. Muestras en pequeñas cantidades (500 g-5 kg) pueden enviarse para pruebas, según el tipo de polvo y la aplicación.

5. ¿Cómo se garantiza la calidad de los pedidos recurrentes?

- Control de calidad lote a lote

- Pruebas de laboratorio internas

- Documentación específica del cliente y hojas de especificaciones

6. ¿Puedo utilizar sus polvos para aplicaciones de impresión 3D?

Absolutamente. Truer’s polvos de acero inoxidable atomizados por gas son adecuados para DMLS, SLM y chorro de ligante con alta fluidez y morfología esférica.

7. ¿Exporta a todo el mundo?

Sí, Truer exporta a Europa, Norteamérica, Sudeste Asiático y Oriente Mediocon pleno apoyo logístico y documental.

8. ¿Cuáles son sus condiciones de pago?

Las cláusulas estándar incluyen T/T (transferencia telegráfica) y Carta de crédito para grandes pedidos.

9. ¿Cómo puedo ponerme en contacto con ustedes para recibir asistencia técnica?

Puede ponerse en contacto con el equipo técnico y comercial de Truer’ a través de la dirección Página de contacto o por correo electrónico para obtener ayuda inmediata.

Al abastecerse de polvo de acero inoxidable de un proveedor especializado como Shanghai Truer Technology, los compradores B2B acceden a una cadena de suministro fiable, escalable y de calidad garantizada para aplicaciones de fabricación avanzadas.

🔗 Explore toda nuestra gama de polvos metálicos y materiales aditivos en la página oficial de Página del producto.