1. Introducción: Importancia del polvo CM247LC en aplicaciones de alta temperatura

CM247LC es un polvo de superaleación con base de níquel diseñado para entornos de temperaturas extremas. Se utiliza ampliamente en la industria aeroespacial, los motores de turbina y la fabricación aditiva (AM) debido a su excepcional resistencia, resistencia a la oxidación y estabilidad microestructural a temperaturas elevadas.

Este polvo de alto rendimiento se utiliza principalmente en pulvimetalurgia (PM) y Impresión 3d como la fusión selectiva por láser (SLM) y la fusión por haz de electrones (EBM). A medida que las industrias se orientan hacia componentes de alta temperatura más eficientes y ligeros, la demanda de polvo CM247LC sigue creciendo en todo el mundo, especialmente entre fabricantes de equipos originales, proveedores aeroespaciales, fabricantes de turbinas y proveedores de servicios de impresión 3D.

Palabras clave de SEO B2B de alta intensidad:

- Proveedor de polvo CM247LC

- Polvo de superaleación a base de níquel para AM

- Comprar polvo CM247LC al por mayor

- Polvo de aleación de alta temperatura para turbinas

- Distribuidor de polvo metálico CM247LC

2. Aplicaciones industriales del polvo CM247LC

El polvo CM247LC se utiliza principalmente en:

Aeroespacial & Aviación

- Álabes de turbina

- Toberas del motor

- Cámaras de combustión

- Protectores térmicos

Generación de energía

- Componentes de turbinas de gas

- Piezas de sección caliente en motores a reacción

- Piezas fijas y giratorias de las turbinas eléctricas

Fabricación aditiva

- componentes de motor impresos en 3D

- Piezas a medida para altas temperaturas

- Prototipos que requieren resistencia a la oxidación

Automoción y deportes de motor

- Componentes del turbocompresor

- Válvulas de escape

- Colectores resistentes al calor

Herramientas y equipos industriales

- Moldes de alto rendimiento

- Herramientas resistentes al desgaste que funcionan a temperaturas elevadas

Ventajas:

- Excelente resistencia a la fluencia hasta 1000-1100°C

- Resistencia superior a la fatiga y la corrosión

- Excelente soldabilidad y estabilidad microestructural

| Industria | Solicitud | CM247LC Polvo Beneficio |

|---|---|---|

| Aeroespacial | Álabes de turbina | Resiste la fatiga térmica extrema |

| Generación de energía | Turbinas de gas | Mantiene la resistencia mecánica bajo tensión |

| AM | Piezas de motores a reacción | Permite geometrías ligeras y complejas |

| Automotor | Turbocompresores | Resiste el calor y la oxidación hasta 1100°C |

| Herramientas | Moldes de inyección | Gran resistencia térmica y al desgaste |

3. Características principales y composición de la aleación CM247LC

CM247LC (Low Carbon) es un derivado de la aleación CM247 convencional con un contenido reducido de carbono. Esto mejora la soldabilidad, por lo que resulta ideal para la fabricación aditiva y la pulvimetalurgia.

Composición química (Típica en wt%):

| Elemento | Contenido (%) |

|---|---|

| Níquel (Ni) | Saldo |

| Cromo (Cr) | 8.0 |

| Cobalto (Co) | 9.5 |

| Aluminio (Al) | 5.6 |

| Titanio (Ti) | 0.7 |

| Tántalo (Ta) | 3.2 |

| Tungsteno (W) | 10.0 |

| Molibdeno (Mo) | 0.5 |

| Hafnio (Hf) | 1.4 |

| Carbono (C) | ≤ 0.07 |

| Boro (B) | 0.015 |

| Circonio (Zr) | 0.015 |

Propiedades físicas:

- Densidad: ~8,9 g/cm³

- Punto de fusión: ~1320-1390 °C

- Resistencia a la tracción: >1000 MPa a temperatura ambiente

- Resistencia a la rotura por fluencia: Superior a 1000°C+

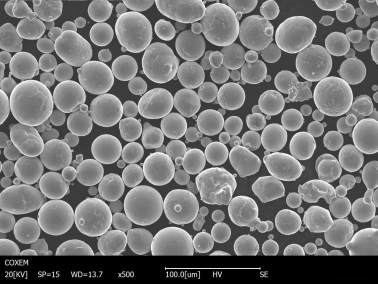

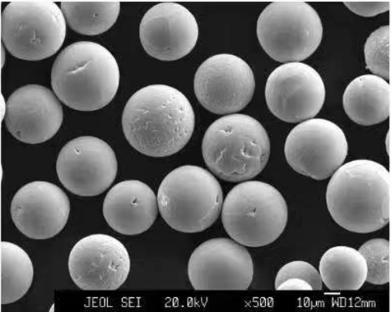

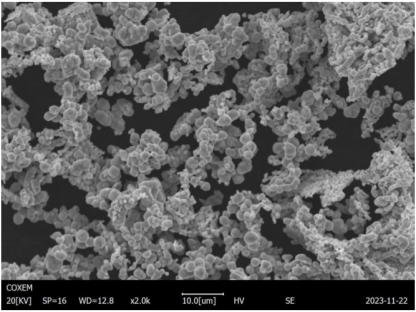

Características del polvo (para AM & PM):

| Propiedad | Especificación |

|---|---|

| Distribución del tamaño de las partículas | 15-45µm (SLM), 45-105µm (EBM/PM) |

| Fluidez | Excelente |

| Densidad del grifo | Alta |

| Morfología | Esférica (atomizada con gas) |

| Contenido de oxígeno | ≤ 200 ppm |

Shanghai Truer Technology Co., Ltd ofrece CM247LC polvo con excelente esfericidad, fluidez y niveles de oxígeno controlados, garantizando la consistencia tanto para fabricación aditiva y aplicaciones pulvimetalúrgicas. Sus polvos se fabrican utilizando tecnologías de atomización con gas y atomización híbrida para cumplir los más altos estándares de calidad exigidos por las industrias aeroespacial y de generación de energía.

El polvo CM247LC de Truer está diseñado para:

- Fusión por láser y haz de electrones

- Prensado isostático en caliente (HIP)

- Moldeo por inyección de metales (MIM)

- Procesos de prensado y sinterización

4. Tendencias del mercado y crecimiento de la demanda de CM247LC en polvo

La demanda mundial de polvo CM247LC se está acelerando debido a la rápida adopción de la fabricación aditiva y a la creciente necesidad de materiales de alta temperatura en los sectores aeroespacial y energético. A medida que los motores de turbina se vuelven más compactos y eficientes, aumenta la demanda de superaleaciones con base de níquel como la CM247LC.

Principales tendencias del mercado que impulsan el crecimiento

- Expansión de la fabricación aditiva

A medida que la impresión 3D se generaliza en el sector aeroespacial y de defensa, el CM247LC es uno de los materiales preferidos para imprimir componentes metálicos que deben soportar entornos extremos. - Programas de modernización de turbinas de gas

Las centrales eléctricas de todo el mundo están actualizando sus turbinas de gas a modelos más nuevos, que requieren materiales de alto rendimiento como el CM247LC. - Iniciativas de aligeramiento

Los fabricantes de equipos originales están sometidos a presiones para reducir el peso de las piezas de aviación y automoción, lo que convierte al CM247LC en el material preferido por su relación resistencia-peso. - Aumento de la producción aeroespacial

El repunte de la aviación comercial tras la pandemia está impulsando la demanda de aleaciones de alta temperatura para los nuevos motores aeronáuticos.

Tamaño y previsión del mercado mundial (2024-2030)

| Región | 2024 Valor del mercado (millones de USD) | CAGR (2024-2030) |

|---|---|---|

| Norteamérica | $68.5 | 6.8% |

| Europa | $54.3 | 6.1% |

| Asia-Pacífico | $77.2 | 7.5% |

| Resto del mundo | $23.1 | 5.9% |

| Total mundial | $223.1 | 6.8% |

Palabras clave B2B de alta intensidad:

- Polvo CM247LC para impresión 3D aeroespacial

- Tendencias del mercado de polvos de aleaciones de alta temperatura

- Polvo esférico CM247LC para AM

- Polvo de superaleación de níquel para turbinas

A medida que el mercado madura, los compradores también se vuelven más informados y selectivos sobre las características del polvo, la fiabilidad del suministro y la credibilidad del proveedor, factores que convierten a empresas como Shanghai Truer Technology en socios destacados.

5. Cómo seleccionar un proveedor de polvo CM247LC fiable

Elegir al proveedor adecuado es fundamental para garantizar la calidad constante de las piezas, reducir los tiempos de inactividad y cumplir los requisitos de certificación, especialmente en sectores regulados como el aeroespacial y el energético.

Factores clave a tener en cuenta:

| Criterios | En qué fijarse |

|---|---|

| Calidad del polvo | Morfología esférica, PSD estrecha, bajo contenido de oxígeno |

| Método de producción | Atomización con gas o atomización híbrida gas-agua |

| Certificaciones | ISO 9001, AS9100, trazabilidad de materiales |

| Consistencia de los lotes | Misma PSD y química en todos los lotes |

| Fiabilidad de la entrega | Estabilidad de la cadena de suministro y control del plazo de entrega |

| Asistencia técnica | Ingeniería de aplicaciones, integración de procesos, I+D |

Preguntas para su proveedor:

- ¿Qué método de atomización se utiliza para producir el polvo?

- ¿Proporcionan un certificado de análisis (CoA) completo con cada lote?

- ¿Pueden admitir rangos de tamaño de partícula personalizados para mi proceso (por ejemplo, SLM frente a EBM)?

- ¿Qué industrias utilizan actualmente su polvo CM247LC?

- ¿Dispone de pruebas internas (caudal, densidad del grifo, contenido de oxígeno)?

Shanghai Truer Technology no sólo cumple estas expectativas, sino que las supera. Su equipo técnico ayuda a los clientes a optimizar sus procesos AM y PM, ofreciendo una trazabilidad completa y una logística fiable para compradores B2B globales.

💡 Más información Capacidades y certificaciones de Shanghai Truer para suministros de pulvimetalurgia y fabricación aditiva.

6. Principales proveedores de Polvo CM247LC en Asia-Pacífico

La región Asia-Pacífico se ha convertido en un centro estratégico para los polvos metálicos de alta precisión, con China, Japón y Corea del Sur a la cabeza en I+D y producción. A continuación se comparan algunos de los principales proveedores de polvo CM247LC de la región.

Principales proveedores de polvo CM247LC de APAC

| Proveedor | País | Puntos fuertes | ¿Compatible con AM? | Clientes OEM |

|---|---|---|---|---|

| Shanghai Truer Technology Co., Ltd | China | Atomización híbrida gas-agua, gama completa de aleaciones, fuerte soporte PM/AM | ✅ | Aeroespacial, Herramientas, Energía |

| Grupo Toyal | Japón | Aleaciones de níquel de calidad aeroespacial, control de calidad avanzado | ✅ | Fabricantes de motores a reacción |

| Polvo POSCO | Corea del Sur | Producción de gran volumen, PSD consistente | ✅ | Power & Auto |

| Sandvik APAC | China | Polvos atomizados con gas de primera calidad | ✅ | Aeroespacial y médica |

| CNPC Polvo | China | Producción a gran escala, rentable | ✅ | Industria general |

Por qué destaca Shanghai Truer:

- Ofrece polvos CM247LC atomizados tanto con agua como con gas

- I+D interno para el desarrollo de aleaciones personalizadas

- Asistencia técnica para sinterización, HIP y procesamiento AM

- Producción y pruebas de materiales con certificación ISO

- Precios competitivos para pedidos al por mayor y OEM

Shanghai Truer no es un mero proveedor, sino un socio de servicios integrales que ofrece asistencia de principio a fin, desde la selección del polvo hasta su aplicación. Para consultas a granel, puede póngase en contacto directamente con su equipo.

7. Por qué más compradores eligen fabricantes chinos de polvo CM247LC

En la última década, China se ha convertido en líder mundial en la producción de polvo metálico, especialmente de aleaciones de alto rendimiento como la CM247LC. Gracias a los avances en tecnología de atomización, control de calidad y certificaciones internacionales, los proveedores chinos compiten ahora directamente con las marcas occidentales, a menudo con precios más competitivos y plazos de entrega más rápidos.

Principales ventajas de los proveedores chinos de polvo CM247LC

| Ventaja | Descripción |

|---|---|

| Eficiencia de costes | Los menores costes de producción y mano de obra permiten fijar precios competitivos al por mayor. |

| Atomización avanzada | La adopción de tecnologías de atomización con gas e híbridas permite la producción de polvos de calidad aeroespacial. |

| Escalabilidad | La capacidad de producción de grandes volúmenes garantiza un suministro fiable para fabricantes de equipos originales y de primer nivel. |

| Apoyo a la exportación | Muchos proveedores ofrecen envíos internacionales, documentación y asistencia multilingüe. |

| Innovación | Los laboratorios chinos de I+D están invirtiendo en el desarrollo de nuevas aleaciones y en la mejora de los procesos. |

Por qué los compradores de CM247LC se decantan por proveedores chinos:

- Calidad comparable o superior a las opciones occidentales

- Plazos de producción y entrega más rápidos

- Voluntad de personalizar los polvos para procesos AM/PM específicos

- Apoyo tanto a la creación de prototipos en lotes pequeños como a la producción a gran escala

En este mercado destaca Shanghai Truer Technology Co., Ltdque se ha convertido en un nombre de confianza entre los compradores B2B mundiales por su calidad constante del polvo CM247LC y sus servicios técnicos integrados.

Puede consultar más información sobre sus gama de productos pulvimetalúrgicos.

8. Por qué elegir Shanghai Truer Technology como su proveedor de CM247LC

Presentación de la empresa

Fundada en 2009 y entrando en el espacio de fabricación aditiva en 2019, Shanghai Truer Technology Co., Ltd se ha forjado una reputación como uno de los proveedores de polvos de alto rendimiento más profesionales y fiables de China. Su polvo CM247LC está diseñado específicamente para aplicaciones AM y PM exigentes.

Puntos fuertes de Shanghai Truer:

✅ Capacidades avanzadas de atomización

- Atomización de gas para morfología esférica

- Atomización híbrida gas-agua para una distribución del tamaño de partícula a medida

- Control estricto del oxígeno, el nitrógeno y otras impurezas

✅ Completa cartera de polvos

Además de CM247LC, Truer también ofrece:

- PM Bronce, PM Acero inoxidable, PM Aceros para herramientas

- Polvos aleados por difusión como FD-0208, FX-2008

- Polvos especiales para herramientas diamantadas y cojinetes sinterizados

- Aditivos magnéticos y de corte como QH-150, SME-100

✅ Apoyo técnico y logístico

- Recomendaciones específicas para cada aplicación

- Tamaño de polvo personalizado (por ejemplo, 15-45 µm, 45-105 µm)

- Pruebas de laboratorio internas de fluidez, densidad de toma, PSD

- Documentación global de envío y exportación

certificaciones y garantía de calidad

- Certificación ISO9001

- Trazabilidad completa y documentación de los lotes

- Calidad constante entre lotes

✅ Clientes B2B de todo el mundo confían en nosotros

Entre las industrias a las que servimos se incluyen:

- OEM del sector aeroespacial

- Fabricantes de turbinas de gas

- proveedores de servicios de impresión 3D

- Proveedores de automoción de primer nivel

- Fabricantes de herramientas y moldes

Testimonio de un cliente:

"Shanghai Truer nos ha ayudado a escalar nuestras operaciones de fabricación aditiva con una calidad constante del polvo CM247LC y un excelente soporte técnico." - Fabricante de piezas aeroespaciales, Alemania

🔗 Más información sobre la historia y la misión de Truer.

9. Preguntas frecuentes: Compra de polvo CM247LC a granel para uso industrial

P1: ¿Cuál es el plazo de entrega habitual para los pedidos de polvo CM247LC a granel?

A: Para distribuciones de tamaño de partícula estándar (por ejemplo, 15-45 µm para AM), el plazo de entrega suele ser de 2-3 semanas. Las PSD personalizadas pueden requerir de 3 a 4 semanas. Truer ofrece producción acelerada para necesidades urgentes.

P2: ¿Cómo se envasa el polvo CM247LC para envíos internacionales?

A: Los polvos se envasan al vacío en recipientes antiestáticos a prueba de humedad. El embalaje estándar incluye bidones de 5 kg, 10 kg y 25 kg. Todos los envíos cumplen la normativa internacional sobre transporte de materiales peligrosos.

P3: ¿Puede Shanghai Truer proporcionar polvo CM247LC tanto para AM como para PM?

A: Sí. Truer adapta las propiedades del polvo a diferentes aplicaciones, entre ellas:

- SLM/EBM: 15-45 µm, excelente fluidez

- MIM y HIP: 45-105 µm, densidad de toma controlada

- Prensar y sinterizar: Mezclas personalizadas con aditivos

P4: ¿Proporciona Truer documentación técnica y CoA?

A: Sí. Cada lote incluye un Certificado de Análisis (CoA) con composición química, PSD, morfología, caudal y contenido de oxígeno/nitrógeno. La trazabilidad del material se mantiene en todas las etapas.

P5: ¿Cómo puedo hacer un pedido al por mayor de polvo CM247LC?

A: Puede iniciar una consulta o hacer un pedido:

- Visitar la página de contacto

- Envíe un correo electrónico al equipo de ventas de Truer con sus especificaciones

- Solicitud de una muestra para cualificación antes del pedido a gran escala

🧲 Recapitulación de enlaces internos

Para mejorar el SEO de los contenidos y la navegación de los usuarios, he aquí cinco enlaces internos incrustados utilizados a lo largo de este blog:

| Texto de anclaje | URL |

|---|---|

| fabricación aditiva y aplicaciones pulvimetalúrgicas | https://am-material.com/pm-powder/ |

| Capacidades y certificaciones de Shanghai Truer | https://am-material.com/about/ |

| gama de productos pulvimetalúrgicos | https://am-material.com/pm-powder/ |

| Más información sobre la historia y la misión de Truer | https://am-material.com/about/ |

| página de contacto | https://am-material.com/contact-us/ |

✅ ¿Está listo para obtener polvo CM247LC de alta calidad para sus necesidades aeroespaciales, energéticas o de fabricación aditiva?

Póngase en contacto con Shanghai Truer Technology hoy mismo para obtener soluciones a medida, conocimientos técnicos y un suministro global fiable.

📩 Póngase en contacto con el equipo de Truer para solicitar un presupuesto o una muestra.