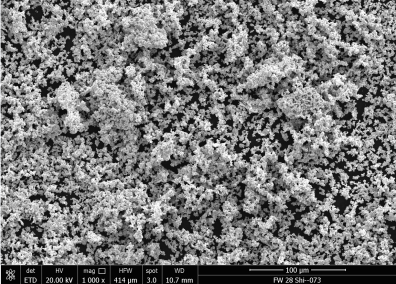

نظرة عامة على مسحوق المسحوق ل الطباعة بالليزر المتعدد

في عالم التصنيع الذي يتطور باستمرار، برزت الطباعة بالليزر المتعدد كتقنية متطورة تدفع حدود ما هو ممكن في مجال التصنيع المضاف. ولكن ما الذي يشغّل هذه التقنية؟ تكمن الإجابة في المساحيق المعدنية المستخدمة في هذه الماكينات المتطورة. هذه المساحيق المصممة والمصنوعة بدقة متناهية هي الأساس الذي تُبنى عليه المكونات المعقدة والمتينة وعالية الدقة.

تعتمد الطباعة متعددة الليزر، خاصةً في مجال تصنيع المواد المضافة للمعادن، اعتمادًا كبيرًا على جودة المساحيق المستخدمة وخصائصها. تتعمق هذه المقالة في الجوانب المختلفة للمساحيق المعدنية للطباعة بالليزر المتعدد، وتستكشف الأنواع والتركيبات والخصائص والتطبيقات المختلفة. سنرشدك خلال التعقيدات التقنية ونقدم لك مقارنات لمساعدتك على اتخاذ قرارات مستنيرة سواء كنت محترفًا متمرسًا أو مبتدئًا فضوليًا.

تركيبة المسحوق للطباعة بالليزر المتعدد

عند مناقشة مساحيق المعادن للطباعة بالليزر المتعددة، يكون التركيب أمرًا بالغ الأهمية. فالتركيب العنصري للمسحوق يحدد مدى ملاءمته لتطبيقات محددة، وسلوك انصهاره، وفي النهاية جودة الجزء المطبوع. فيما يلي تفصيل لتركيبات المساحيق المعدنية الشائعة المستخدمة في الطباعة بالليزر المتعدد:

| نوع المسحوق | التركيب الأساسي | العناصر الثانوية | الخصائص البارزة |

|---|---|---|---|

| فولاذ مقاوم للصدأ 316L | الحديد، الكروم، النيكل، المونيوم | C، Si، Mn | مقاومة عالية للتآكل، ليونة ممتازة |

| سبائك الألومنيوم AlSi10Mg | Al، Si، Mg | الحديد، النحاس، النحاس، المنغنيز | خفيفة الوزن، وخصائص حرارية جيدة، ونسبة قوة إلى وزن عالية |

| سبيكة التيتانيوم Ti-6Al-4V | Ti، Al، V | و، في | متانة عالية، وتوافق حيوي، ومقاومة للتآكل |

| انكونيل 718 | النيكل، والكروم، والحديد، والروبيان | مو، تي، آل، كو | مقاومة درجات الحرارة العالية والقوة والمتانة |

| الكوبالت والكروم (CoCr) | كولورادو، كروم، مو | و، سي | مقاومة ممتازة للتآكل والتوافق الحيوي |

| فولاذ مصهور (18Ni300) | الحديد، النيكل، الكوكس، المونيوم | تي، آل | قوة عالية، وصلابة جيدة، وقابلية للتشغيل الآلي بسهولة |

| سبائك النحاس (CuCrZr) | النحاس، الكروم، الزر | الحديد، الرصاص | موصلية حرارية وكهربائية عالية |

| هاستيلوي إكس | النيكل، الكروم، الحديد، الحديد، المونيوم | كو ، دبليو ، سيليكون | مقاومة الأكسدة والزحف في درجات الحرارة العالية |

| فولاذ الأدوات (H13) | الحديد، الكروم، المونيوم، V | C، Si، Mn | مقاومة عالية للتآكل، صلابة ممتازة |

| سبائك النيكل (Ni625) | النيكل، الكروم، المونيوم، النحاس الأصفر | في، آل، تي آي | مقاومة عالية للتآكل والأكسدة |

يتم ضبط هذه التركيبات بدقة لتوفير خصائص محددة ضرورية لتطبيقات متنوعة، بدءًا من الفضاء الجوي إلى الغرسات الطبية الحيوية.

خصائص المسحوق للطباعة متعددة الليزر

إن خصائص المساحيق المعدنية لا تقل أهمية عن تركيباتها. وتؤثر هذه الخصائص على عملية الطباعة والخصائص الميكانيكية للأجزاء المطبوعة والنجاح الكلي لعملية الطباعة بالليزر المتعدد.

| الخصائص | الوصف |

|---|---|

| توزيع حجم الجسيمات | يضمن التوزيع المنتظم لحجم الجسيمات اتساق قابلية التدفق وكثافة التعبئة، وهو أمر ضروري للطباعة طبقة تلو الأخرى. |

| الكروية | تعمل الجسيمات الكروية على تعزيز قابلية التدفق والتعبئة بشكل أفضل، مما يقلل من احتمالية حدوث عيوب في الجزء المطبوع. |

| النقاء | يقلل النقاء العالي من التلوث، الذي يمكن أن يؤدي إلى عيوب أو انخفاض الأداء في الجزء النهائي. |

| الكثافة الظاهرة | يمكن أن تؤدي الكثافة الظاهرية الأعلى إلى تحسين الخواص الميكانيكية للجزء النهائي، حيث تؤدي إلى تقليل الفراغات والعيوب. |

| قابلية التدفق | تُعد قابلية التدفق الجيدة ضرورية لتوزيع المسحوق بشكل متسق أثناء عملية الطباعة، مما يؤثر على جودة البناء والموثوقية. |

| محتوى الرطوبة | يعد المحتوى المنخفض من الرطوبة أمرًا بالغ الأهمية لمنع الأكسدة أو التفاعلات الأخرى التي يمكن أن تضر بأداء المسحوق. |

| محتوى الأكسجين | يعد التحكم في مستويات الأكسجين أمرًا حيويًا، خاصةً في المواد التفاعلية مثل التيتانيوم، حيث يمكن أن يؤدي ارتفاع الأكسجين إلى التقصف. |

| التجانس الكيميائي | يضمن خواص ميكانيكية موحدة في جميع أنحاء الجزء المطبوع، مما يمنع وجود نقاط ضعف أو تناقضات. |

| نسيج السطح | يقلل نسيج السطح الأملس من الاحتكاك بين الجسيمات، مما يعزز قابلية التدفق وتماسك الطبقات أثناء الطباعة. |

يعد فهم هذه الخصائص أمرًا أساسيًا لاختيار المسحوق المناسب لاستخدامك المحدد، مما يضمن الأداء والجودة المثلى.

أنواع المساحيق المعدنية لـ الطباعة بالليزر المتعدد

تتطلب التطبيقات المختلفة أنواعًا مختلفة من مساحيق المعادن. إليك نظرة مفصلة على بعض المساحيق المعدنية الأكثر استخدامًا في الطباعة بالليزر المتعدد:

| نوع المسحوق المعدني | التطبيقات | مزايا | سلبيات |

|---|---|---|---|

| فولاذ مقاوم للصدأ 316L | الأجهزة الطبية ومعدات تجهيز الأغذية | مقاومة عالية للتآكل، متوافقة حيوياً | قوة أقل مقارنة بالسبائك الأخرى |

| سبائك الألومنيوم AlSi10Mg | صناعة الطيران، قطع غيار السيارات | خفيفة الوزن ونسبة قوة إلى الوزن عالية | قوة إجهاد محدودة |

| سبيكة التيتانيوم Ti-6Al-4V | الفضاء، والغرسات الطبية | قوة عالية، وتوافق حيوي | باهظة الثمن وصعبة المعالجة |

| انكونيل 718 | شفرات التوربينات، والمكونات عالية الحرارة | مقاومة ممتازة للحرارة والقوة | يصعب تشغيلها آلياً |

| الكوبالت والكروم (CoCr) | زراعة الأسنان وزراعة الأسنان وزراعة العظام | مقاومة التآكل، ومقاومة التآكل، والتوافق الحيوي | تكلفة عالية |

| فولاذ مصهور (18Ni300) | الأدوات، والمكونات عالية القوة | قوة وصلابة عالية وسهولة في التشغيل الآلي | باهظة الثمن |

| سبائك النحاس (CuCrZr) | المبادلات الحرارية، والمكونات الكهربائية | توصيل حراري وكهربائي ممتاز | عرضة للأكسدة |

| هاستيلوي إكس | المعالجة الكيميائية والفضاء الجوي | مقاومة درجات الحرارة العالية، ومقاومة الأكسدة | مكلفة للغاية وصعبة اللحام |

| فولاذ الأدوات (H13) | قوالب الحقن والصب بالقالب | مقاومة عالية للتآكل والمتانة | عرضة للتشقق أثناء المعالجة الحرارية |

| سبائك النيكل (Ni625) | المعالجة البحرية والكيميائية | مقاومة التآكل، قابلية لحام جيدة | تكلفة عالية، وتوافر محدود |

لكل من هذه المساحيق نقاط قوة ونقاط ضعف فريدة من نوعها، مما يجعلها مناسبة لتطبيقات محددة ولكنها قد تكون إشكالية بالنسبة لتطبيقات أخرى. على سبيل المثال، في حين أن سبيكة التيتانيوم Ti-6Al-4V يوفر قوة وتوافقًا حيويًا لا مثيل لهما، كما أنه أكثر تكلفة وأصعب في المعالجة مقارنةً ب فولاذ مقاوم للصدأ 316L.

تطبيقات المسحوق للطباعة متعددة الليزر

تُستخدم الطباعة بالليزر المتعدد في مختلف الصناعات، ويتطلب كل منها مساحيق معدنية محددة تلبي متطلباتها الفريدة. فيما يلي نظرة تفصيلية على بعض التطبيقات:

| الصناعة | التطبيقات | المساحيق المعدنية المفضلة |

|---|---|---|

| الفضاء | شفرات التوربينات، والمكونات الهيكلية | إينكونيل 718، سبائك التيتانيوم Ti-6Al-4V، سبائك الألومنيوم AlSi10Mg |

| الطبية | الغرسات والأدوات الجراحية | الفولاذ المقاوم للصدأ 316L، الكوبالت-الكروم (CoCr)، سبائك التيتانيوم Ti-6Al-4V |

| السيارات | مكونات خفيفة الوزن وأجزاء المحرك | سبائك الألومنيوم AlSi10Mg، فولاذ مغلف (18Ni300)، فولاذ مقاوم للصدأ 316L |

| الأدوات | القوالب والقوالب والمكونات عالية القوة | فولاذ الأدوات (H13)، الفولاذ الصلب (18Ni300)، إنكونيل 718 |

| الطاقة | المبادلات الحرارية، ومكونات توليد الطاقة | سبائك النحاس (CuCrZr)، سبائك النيكل (Ni625)، Hastelloy X |

| البحرية | مكونات مقاومة للتآكل، أجزاء هيكلية مقاومة للتآكل | سبائك النيكل (Ni625)، الفولاذ المقاوم للصدأ 316L، إنكونيل 718 |

لكل صناعة متطلبات متميزة، مما يجعل اختيار المسحوق المعدني المناسب أمرًا بالغ الأهمية لضمان الأداء الأمثل والفعالية من حيث التكلفة.

المواصفات والأحجام والدرجات والمعايير

عند اختيار مساحيق المعادن للطباعة بالليزر المتعددة، من المهم مراعاة المواصفات والأحجام والدرجات والمعايير المطلوبة لتطبيقك المحدد. إليك جدول مفصل يلخص هذه الجوانب:

| نوع المسحوق المعدني | نطاق حجم الجسيمات (ميكرومتر) | الصف | المعايير | النقاء |

|---|---|---|---|---|

| فولاذ مقاوم للصدأ 316L | 15-45 | سلسلة AM | أستم F3184، أيزو 5832-1 | 99.9% |

| سبائك الألومنيوم AlSi10Mg | 20-63 | سلسلة AM | ISO 9001 وSTM F3318 وISO 9001 | 99.8% |

| سبيكة التيتانيوم Ti-6Al-4V | 15-45 | سلسلة AM | معيار الفلك القياسي F2924، ISO 5832-3 | 99.5% |

| انكونيل 718 | 15-53 | سلسلة AM | astm B637، ISO 6362 | 99.8% |

الكوبالت والكروم (CoCr) | 20-45 | سلسلة AM | أستم f75، أيزو 5832-12 | 99.5% |

| فولاذ مصهور (18Ni300) | 15-53 | سلسلة AM | A709، أيزو 683-17، أستم A709، أيزو 683-17 | 99.9% |

| سبائك النحاس (CuCrZr) | 10-45 | سلسلة AM | أستم ب 192، أيزو 5414 | 99.9% |

| هاستيلوي إكس | 15-53 | سلسلة AM | astm B333، ISO 18286 | 99.8% |

| فولاذ الأدوات (H13) | 15-45 | سلسلة AM | A681 astm A681، ISO 4957 | 99.7% |

| سبائك النيكل (Ni625) | 15-53 | سلسلة AM | astm B443، ISO 6206 | 99.8% |

تضمن هذه المواصفات أن المساحيق تفي بمعايير الصناعة من حيث الأداء والجودة، مما يوفر الاتساق في المكونات المطبوعة النهائية.

تفاصيل الموردين والأسعار

اختيار المورد المناسب لا يقل أهمية عن اختيار المسحوق المناسب. فيما يلي ملخص للموردين ذوي السمعة الطيبة وتفاصيل الأسعار العامة لمختلف مساحيق المعادن:

| المورد | نوع المسحوق المعدني | السعر التقريبي (لكل كيلوغرام) | الموقع | موقع إلكتروني |

|---|---|---|---|---|

| ساندفيك للتصنيع الإضافي | فولاذ مقاوم للصدأ 316L | $150 – $250 | السويد | sandvik.com |

| EOS | سبائك الألومنيوم AlSi10Mg | $200 – $300 | ألمانيا | eos.info |

| أركام (GE Additive) | سبيكة التيتانيوم Ti-6Al-4V | $400 – $600 | السويد | arcam.com |

| كيناميتال | انكونيل 718 | $350 – $500 | الولايات المتحدة الأمريكية | kennametal.com |

| معدن مكتبي | الكوبالت والكروم (CoCr) | $500 – $700 | الولايات المتحدة الأمريكية | desktopmetal.com |

| تقنية LPW | فولاذ مصهور (18Ni300) | $300 – $450 | المملكة المتحدة | lpwtechnology.com |

| مضافات GKN | سبائك النحاس (CuCrZr) | $250 – $350 | ألمانيا | gknpowder.com |

| هاستيلوي® من هاينز | هاستيلوي إكس | $600 – $800 | الولايات المتحدة الأمريكية | haynesintl.com |

| سيسما | فولاذ الأدوات (H13) | $220 – $320 | ايطاليا | sisma.com |

| فيلو3د | سبائك النيكل (Ni625) | $500 – $700 | الولايات المتحدة الأمريكية | velo3d.com |

قد تختلف الأسعار بناءً على كمية الطلب وتكاليف الشحن وتقلبات السوق. استشر دائمًا الموردين لمعرفة أحدث الأسعار والتوافر.

مزايا وقيود مساحيق المعادن من أجل الطباعة بالليزر المتعدد

يتضمن اختيار المسحوق المعدني المناسب الموازنة بين مزاياه وحدوده. وفيما يلي نظرة عامة مقارنة:

| نوع المسحوق | مزايا | محددات |

|---|---|---|

| فولاذ مقاوم للصدأ 316L | مقاومة للتآكل، وخصائص ميكانيكية جيدة | قوة أقل مقارنة ببعض السبائك |

| سبائك الألومنيوم AlSi10Mg | خفيفة الوزن ونسبة قوة إلى الوزن عالية | قوة إجهاد أقل، وتكلفة أعلى للمعالجة |

| سبيكة التيتانيوم Ti-6Al-4V | متانة عالية، مقاومة ممتازة للتآكل، متوافقة حيوياً | باهظة الثمن وصعبة المعالجة |

| انكونيل 718 | مقاومة ممتازة للحرارة وقوة عالية | صعوبة في التشغيل الآلي، وتكلفة أعلى |

| الكوبالت والكروم (CoCr) | مقاومة التآكل، والتوافق الحيوي | التكلفة العالية ومتطلبات المعالجة المعقدة |

| فولاذ مصهور (18Ni300) | قوة عالية وصلابة جيدة | باهظة الثمن، وتتطلب معالجة حرارية دقيقة |

| سبائك النحاس (CuCrZr) | توصيل حراري وكهربائي ممتاز | عرضة للأكسدة، ومعقدة في المعالجة |

| هاستيلوي إكس | مقاومة درجات الحرارة العالية، ومقاومة الأكسدة | مكلفة للغاية وصعبة اللحام |

| فولاذ الأدوات (H13) | مقاومة عالية للتآكل، صلابة ممتازة | عرضة للتشقق أثناء المعالجة الحرارية |

| سبائك النيكل (Ni625) | مقاومة التآكل، قابلية لحام جيدة | تكلفة عالية، وتوافر محدود |

يقدم كل نوع من أنواع المسحوق مجموعة فريدة من الفوائد المناسبة لتطبيقات محددة، ولكنه يأتي أيضًا مع مجموعة من التحديات الخاصة به. على سبيل المثال، في حين أن سبيكة التيتانيوم Ti-6Al-4V مرغوب فيه بشدة لقوته وتوافقه الحيوي، إلا أن تكلفته العالية واحتياجات معالجته المعقدة قد لا تجعله مناسبًا لكل مشروع.

التعليمات

| سؤال | الإجابة |

|---|---|

| ما هو دور المساحيق المعدنية في الطباعة بالليزر المتعدد؟ | تُستخدم المساحيق المعدنية كمادة وسيطة في الطباعة بالليزر المتعددة، مما يتيح إنشاء أجزاء معقدة طبقة تلو الأخرى. |

| كيف تؤثر المساحيق المعدنية المختلفة على المنتج النهائي؟ | ويؤثر اختيار المسحوق على الخواص الميكانيكية للجزء المطبوع النهائي ومظهره وأدائه، بما في ذلك القوة والمتانة ومقاومة الظروف المختلفة. |

| ما أهمية حجم الجسيمات في مساحيق المعادن؟ | يؤثر حجم الجسيمات على قابلية المسحوق للتدفق وكثافة التعبئة، مما يؤثر بدوره على اتساق الطبقات المطبوعة وجودتها. |

| هل يمكن إعادة تدوير المساحيق المعدنية؟ | نعم، يمكن إعادة تدوير العديد من مساحيق المعادن، على الرغم من أن العملية والكفاءة يمكن أن تختلف اعتمادًا على المسحوق وتقنية إعادة التدوير المستخدمة. |

| ما هي التكاليف النموذجية للمساحيق المعدنية للطباعة بالليزر المتعدد؟ | تختلف التكاليف بشكل كبير حسب نوع المسحوق ونقائه والمورد. وتتراوح الأسعار بشكل عام من $150 إلى $800 للكيلوغرام الواحد. |

| كيف يؤثر النقاء على مساحيق المعادن؟ | ينتج عن المساحيق عالية النقاء عدد أقل من الملوثات، مما يؤدي إلى خصائص ميكانيكية أفضل وموثوقية أفضل للجزء المطبوع النهائي. |

| هل هناك أي مخاوف بيئية بشأن المساحيق المعدنية؟ | يمكن أن تشكل المساحيق المعدنية مخاوف بيئية إذا لم يتم التعامل معها بشكل صحيح، بما في ذلك مخاطر الغبار والتلوث. تعتبر تدابير السلامة السليمة وممارسات التخلص منها أمرًا بالغ الأهمية. |

| ما المعايير التي يجب أن تفي بها المساحيق المعدنية للطباعة بالليزر المتعدد؟ | تشمل المعايير الشائعة مواصفات ASTM وISO، والتي تضمن الجودة والاتساق في المساحيق المستخدمة في التصنيع الإضافي. |