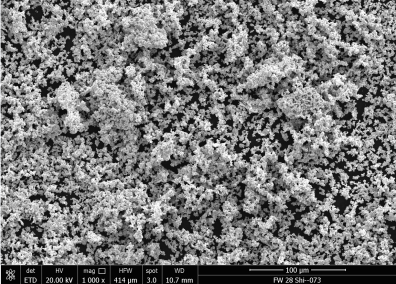

مساحيق الكوبالت والكرومالتي يُشار إليها غالبًا باسم مساحيق CoCr، هي مواد محورية في مجموعة متنوعة من عمليات التصنيع المتقدمة، خاصة في صناعات مثل الفضاء والزراعات الطبية والسيارات. ولكن ما الذي يجعل هذه المساحيق مميزة للغاية؟ ولماذا يشيع استخدامها في التطبيقات عالية الأداء؟ دعونا نتعمق في عالم مساحيق الكوبالت والكروم الرائع، ونستكشف خصائصها وتطبيقاتها وكل ما بينهما.

نظرة عامة على مساحيق الكوبالت والكروم

مساحيق الكوبالت والكروم عبارة عن سبائك تتكون في المقام الأول من الكوبالت (Co) والكروم (Cr)، وغالبًا ما تكون مع إضافات صغيرة من عناصر أخرى مثل الموليبدينوم أو التنجستن أو الكربون. وتحظى هذه المساحيق بالتبجيل بسبب مقاومتها الاستثنائية للتآكل ومقاومتها للتآكل وقوتها في درجات الحرارة العالية. هذه الخصائص تجعلها مثالية للبيئات التي تتعرض فيها المواد لظروف قاسية، مثل الفم (غرسات الأسنان)، أو في المحرك (شفرات التوربينات)، أو حتى في جسم الإنسان (بدائل الورك).

تكوين مساحيق الكوبالت والكروم

يمكن أن تختلف تركيبة مساحيق الكوبالت والكروم اعتمادًا على المتطلبات المحددة للتطبيق. وتشمل التركيبة النموذجية ما يلي:

| العنصر | المحتوى (%) |

|---|---|

| الكوبالت (Co) | 50-70% |

| الكروم (Cr) | 20-30% |

| الموليبدينوم (Mo) | 5-10% |

| التنجستن (W) | 0-5% |

| الكربون (C) | 0.5-2% |

| أخرى (ني، في، إلخ) | 0-5% |

خواص مساحيق الكوبالت والكروم وخصائصها

تتميز مساحيق الكوبالت والكروم بمجموعة فريدة من الخصائص التي تجعلها لا غنى عنها في التطبيقات عالية الأداء. وتشمل بعض الخصائص الرئيسية ما يلي:

- قوة عالية في درجات الحرارة المرتفعة: تحافظ هذه المساحيق على قوتها الميكانيكية حتى في درجات الحرارة العالية، مما يجعلها مثالية للاستخدام في التوربينات والمحركات.

- مقاومة ممتازة للتآكل والتآكل: ويوفر وجود الكروم مقاومة استثنائية للتآكل، بينما تضمن صلابة مصفوفة الكوبالت مقاومة التآكل، مما يجعلها مثالية لغرسات الأسنان وتقويم العظام.

- التوافق الحيوي: سبائك CoCr متوافقة حيوياً، مما يعني أن جسم الإنسان لا يرفضها. وهذا مهم بشكل خاص للغرسات الطبية.

- مقاومة التعب والإجهاد: يمكن لسبائك الكروم والكوبالت والكروم تحمل الإجهاد المتكرر دون حدوث كسر، مما يجعلها مناسبة للأجزاء المعرضة لأحمال دورية.

النماذج الرئيسية لـ مساحيق الكوبالت والكروم

هناك العديد من الدرجات والنماذج المحددة من مساحيق الكوبالت والكروم المتوفرة في السوق، كل منها مصمم لتطبيقات مختلفة. فيما يلي نظرة فاحصة على عشرة نماذج بارزة:

- CoCrMo (ASTM F75)

- الوصف: هذه السبيكة هي سبيكة الكوبالت والكروم والموليبدينوم الأكثر استخدامًا في الغرسات الطبية، خاصةً في تطبيقات تقويم العظام والأسنان.

- الخصائص: توافق حيوي عالٍ، ومقاومة عالية للتآكل، ومقاومة ممتازة للتآكل.

- CoCrW (الساتل 21)

- الوصف: تُستخدم هذه السبيكة، المعروفة بمقاومتها الاستثنائية للتآكل، في مقاعد الصمامات والمحامل وأدوات القطع.

- الخصائص: صلابة عالية، وقوة ممتازة في درجات الحرارة العالية، ومقاومة جيدة للتآكل.

- CoCrNiMo (ASTM F562)

- الوصف: تستخدم في المقام الأول في الأدوات الجراحية والمكونات عالية القوة.

- الخصائص: قوة عالية، وليونة جيدة، ومقاومة للتآكل.

- CoCrMoC (ASTM F90)

- الوصف: متغير مع إضافات الكربون لتحسين الصلابة.

- الخصائص: زيادة مقاومة التآكل، ومناسبة للتطبيقات عالية الإجهاد.

- CoCrAlY (AMS 5894)

- الوصف: تستخدم في التطبيقات الفضائية، وخاصة في شفرات التوربينات.

- الخصائص: مقاومة عالية للأكسدة في درجات الحرارة المرتفعة، وخصائص ميكانيكية جيدة.

- CoCrCrFeFeMniNi (سبيكة عالية الانتروبيا)

- الوصف: سبيكة أحدث تُستخدم في التطبيقات البحثية المتقدمة لخصائصها الفريدة.

- الخصائص: ليونة وقوة ومقاومة جيدة للتآكل.

- CoCrMoTi

- الوصف: تعمل إضافة التيتانيوم على تحسين التوافق الحيوي وتقليل الكثافة.

- الخصائص: خفيفة الوزن، ومقاومة عالية للتآكل، ومناسبة للغرسات الطبية.

- CoCrSiW

- الوصف: تُستخدم هذه السبيكة في الطلاءات المقاومة للتآكل في التطبيقات الصناعية.

- الخصائص: صلابة عالية، ومقاومة ممتازة للتآكل، وثبات جيد في درجات الحرارة العالية.

- CoCrMoNb

- الوصف: تعزز إضافة النيوبيوم من القوة ومقاومة التعب.

- الخصائص: خصائص ميكانيكية محسّنة ومناسبة للمكونات الفضائية.

- CoCrZr

- الوصف: تعمل إضافة الزركونيوم على تحسين التوافق الحيوي ومقاومة التآكل.

- الخصائص: مقاومة عالية للتآكل، ومناسبة لغرسات الأسنان وتقويم العظام.

تطبيقات مساحيق الكوبالت والكروم

مساحيق الكوبالت والكروم مواد متعددة الاستخدامات تستخدم في مختلف الصناعات. وفيما يلي نظرة على بعض تطبيقاتها الأكثر شيوعًا:

| طلب | الصناعة | التفاصيل |

|---|---|---|

| زراعة الأسنان | الطبية | تُستخدم سبائك CoCr في التيجان والجسور وأطر الأسنان. |

| زراعة الورك والركبة | الطبية | ونظراً لتوافقها الحيوي ومقاومتها للتآكل، تُستخدم سبائك CoCr في استبدال المفاصل. |

| شفرات التوربينات | الفضاء | تُستخدم مساحيق CoCr في المحركات النفاثة نظرًا لقوتها في درجات الحرارة العالية. |

| مقاعد الصمامات والمحامل | السيارات | مقاومة التآكل العالية تجعلها مثالية لهذه المكونات. |

| أدوات القطع | صناعي | تُستخدم سبائك CoCr في الأدوات لصلابتها ومتانتها. |

| مكونات الفضاء الجوي | الفضاء | تستخدم في المكونات الحرجة عالية الإجهاد بسبب مقاومتها للإجهاد. |

| الأطراف الصناعية | الطبية | تُستخدم سبائك CoCr في إنتاج الأطراف الصناعية المتينة والمتوافقة حيوياً. |

| الطلاءات المقاومة للاهتراء | صناعي | يستخدم في الطلاءات لإطالة عمر المعدات المعرضة للظروف القاسية. |

المواصفات والأحجام والدرجات والمعايير

تأتي مساحيق الكوبالت والكروم بمواصفات وأحجام ودرجات مختلفة، كل منها مصمم خصيصًا لتطبيقات محددة. يلخص الجدول أدناه المواصفات الرئيسية:

| المواصفات | الصف | حجم الجسيمات (ميكرومتر) | قياسي |

|---|---|---|---|

| ASTM F75 | الطبية | 15-45 | ASTM F75 |

| AMS 5894 | الفضاء | 10-53 | AMS 5894 |

| ASTM F90 | الطبية | 20-50 | ASTM F90 |

| ستلايت 21 | صناعي | 15-63 | ASME BPVC |

| ASTM F562 | الطبية | 25-45 | ASTM F562 |

| CoCrAlY | الفضاء | 10-50 | AMS 5894 |

| CoCrFeMnNi | الأبحاث | 10-45 | مخصص |

| CoCrMoTi | الطبية | 20-45 | الأيزو 5832-4 ISO 5832-4 |

| CoCrSiW | صناعي | 15-63 | ASME BPVC |

| CoCrMoNb | الفضاء | 10-50 | AMS 5894 |

الموردون والتسعير

تختلف تكلفة مساحيق الكوبالت والكروم حسب الدرجة وحجم الجسيمات والمورد. وفيما يلي تفصيل لبعض الموردين وأسعارهم:

| المورد | الصف | السعر (دولار/كجم) | البلد |

|---|---|---|---|

| تكنولوجيا النجار | ASTM F75 | $250 – $300 | الولايات المتحدة الأمريكية |

| ساندفيك | ستلايت 21 | $200 – $250 | السويد |

| أركام إيه بي (GE Additive) | CoCrMoTi | $300 – $350 | السويد |

| إتش سي ستارك | CoCrAlY | $400 – $450 | ألمانيا |

| معادن ATI | ASTM F90 | $280 – $320 | الولايات المتحدة الأمريكية |

| تقنية LPW | CoCrFeMnNi | $350 – $400 | المملكة المتحدة |

| EOS GmbH | ASTM F562 | $270 – $320 | ألمانيا |

| براكسير للتقنيات السطحية | CoCrSiW | $200 – $260 | الولايات المتحدة الأمريكية |

| هوجاناس | CoCrMoNb | $320 – $380 | السويد |

| كيناميتال | CoCrZr | $250 – $310 | الولايات المتحدة الأمريكية |

مزايا وقيود مساحيق الكوبالت والكروم

مثل أي مادة، فإن مساحيق الكوبالت والكروم لها نقاط قوتها وضعفها. دعونا نستكشفها:

| مزايا | محددات |

|---|---|

| مقاومة عالية للتآكل | التكلفة: الكوبالت والكروم من المواد باهظة الثمن. |

| مقاومة ممتازة للتآكل | الكثافة: أثقل من بعض البدائل مثل سبائك التيتانيوم. |

| القوة في درجات الحرارة العالية | قابلية التشغيل الآلي: يمكن أن تكون سبائك CoCr صعبة في التشغيل الآلي. |

| التوافق الحيوي | التوفر: إمدادات محدودة مقارنةً بالسبائك الأكثر شيوعاً. |

| مقاومة التعب والإجهاد | تعقيد المعالجة: يتطلب تحكمًا دقيقًا أثناء التصنيع. |

| تعدد الاستخدامات في مختلف الصناعات | الأثر البيئي: يمكن أن يكون لتعدين الكوبالت وتكريره عواقب بيئية كبيرة. |

أسئلة وأجوبة

س1: ما هي مساحيق الكوبالت والكروم المستخدمة في المقام الأول؟

A1: تُستخدم مساحيق الكوبالت والكروم بشكل أساسي في التطبيقات عالية الأداء التي تتطلب مواد ذات قوة عالية ومقاومة للتآكل ومقاومة للتآكل. وتستخدم على نطاق واسع في القطاعات الطبية والفضائية والصناعية.

س2: هل سبائك الكوبالت والكروم آمنة للغرسات الطبية؟

A2: نعم، إن سبائك الكوبالت والكروم متوافقة حيويًا، مما يجعلها آمنة للاستخدام في الغرسات الطبية مثل تيجان الأسنان واستبدال مفصل الورك والركبة.

س3: كيف تقارن مساحيق الكوبالت والكروم بمساحيق سبائك التيتانيوم؟

A3: توفر مساحيق الكوبالت والكروم مقاومة أفضل للتآكل وقوة أعلى في درجات الحرارة المرتفعة مقارنةً بسبائك التيتانيوم. ومع ذلك، فإن التيتانيوم أخف وزنًا وغالبًا ما يكون أسهل في التشغيل الآلي.

س4: ما هي التكلفة النموذجية لمساحيق الكوبالت والكروم؟

A4: وتختلف التكلفة حسب الدرجة والمورّد، ولكنها تتراوح بشكل عام من $200 إلى $450 للكيلوغرام الواحد.

السؤال 5: ما هي التحديات التي تواجه معالجة مساحيق الكوبالت والكروم؟

A5: تشمل تحديات المعالجة التكلفة العالية للمواد الخام، وتعقيد التصنيع الآلي، والحاجة إلى التحكم الدقيق أثناء التصنيع لتجنب العيوب.

السؤال 6: ما هي الصناعات الأكثر استفادة من مساحيق الكوبالت والكروم؟

A6: تستفيد الصناعات الطبية والفضائية بشكل كبير من استخدام مساحيق الكوبالت والكروم بسبب متطلباتها الصعبة لأداء المواد.

السؤال 7: هل هناك مخاوف بيئية مرتبطة بمساحيق الكوبالت والكروم؟

A7: نعم، يمكن أن يكون لاستخراج الكوبالت والكروم ومعالجتهما تأثيرات بيئية، لا سيما في مناطق التعدين حيث يتم الحصول على هذه المعادن.

السؤال 8: هل يمكن استخدام مساحيق الكوبالت والكروم في الطباعة ثلاثية الأبعاد؟

A8: بالتأكيد! تُستخدم مساحيق CoCr بشكل شائع في التصنيع الإضافي لإنتاج مكونات معقدة وعالية الأداء.

السؤال 9: كيف تعمل مساحيق الكوبالت والكروم على تحسين أداء أدوات القطع؟

A9: إن المقاومة العالية للتآكل والصلابة العالية لسبائك CoCr تجعلها مثالية لأدوات القطع، مما يسمح بعمر أطول للأداة وقطع أكثر دقة.

Q10: ما هو مستقبل مساحيق الكوبالت والكروم في التصنيع؟

A10: مع التقدم المستمر في علوم المواد، من المتوقع أن تظل مساحيق الكوبالت والكروم ذات أهمية حاسمة في التطبيقات المتطورة، لا سيما في التصنيع الإضافي والهندسة الطبية الحيوية.

خاتمة

تعد مساحيق الكوبالت والكروم أكثر من مجرد مزيج من المعادن؛ فهي حجر الزاوية في التطورات الهندسية والطبية الحديثة. وسواء كان ذلك في محرك طائرة نفاثة أو داخل جسم المريض، فإن الخصائص الفريدة لهذه المساحيق تضمن تلبية المتطلبات الصارمة للتطبيقات عالية الأداء.