1. مقدمة: ما هو مسحوق SS-316L المنحل؟

مسحوق SS-316L المنحل هو مسحوق مطحون بدقة الفولاذ المقاوم للصدأ مسحوق مصنوع باستخدام تقنيات الانحلال الغازي أو المائي. إنه مشتق من سبيكة SS-316L - وهي فولاذ مقاوم للصدأ أُوستني معروف بمقاومته المتميزة للتآكل وقوته وقابليته للتشغيل. يرمز الحرف "L" في 316L إلى "الكربون المنخفض"، مما يعزز قابلية اللحام ويقلل من خطر ترسب الكربيد.

في قطاعات التصنيع بين الشركات مثل التصنيع الإضافي (AM) وتعدين المسحوق (PM) وقولبة حقن المعادن (MIM)، أصبح مسحوق SS-316L المنحل مادة مفضلة لإنتاج أجزاء معقدة بأقل قدر من النفايات.

ما الذي يجعل SS-316L متميزًا؟

| الميزة | الفائدة لمشتري B2B |

|---|---|

| مقاومة التآكل | مثالي للصناعات البحرية والكيميائية والغذائية |

| ليونة عالية | يتيح الطباعة ثلاثية الأبعاد للهندسات المعقدة |

| محتوى منخفض من الكربون | يمنع ترسب الكربيد أثناء اللحام |

| بنية مجهرية متسقة | مناسب لعمليات AM و PM و MIM |

| التوافق الحيوي | يستخدم في تطبيقات زراعة الأسنان والطبية |

لفهم أعمق لمواد تعدين المسحوق، يمكنك استكشاف كتالوج منتجاتنا الكامل هنا.

2. التطبيقات الصناعية الرئيسية لمسحوق SS-316L

يستخدم مسحوق SS-316L المنحل في مجموعة واسعة من القطاعات. إن تعدد استخداماته، جنبًا إلى جنب مع استقراره الميكانيكي والكيميائي، يجعله الخيار الأفضل للمصنعين الذين يبحثون عن مواد موثوقة وعالية الأداء.

حالات الاستخدام الرئيسية في الصناعة

- التصنيع المضاف (الطباعة ثلاثية الأبعاد)

- مكونات الفضاء الجوي

- الغرسات الطبية

- الأدوات الصناعية

- تعدين المسحوق (PM)

- قطع غيار السيارات

- المكونات الهيكلية

- التجميعات المغناطيسية

- قولبة حقن المعادن (MIM)

- أغلفة إلكترونية عالية الدقة

- أجزاء الساعات والمجوهرات

- مكونات من الدرجة العسكرية

جدول مقارن للتطبيقات

| الصناعة | مثال على التطبيق | فائدة مسحوق SS-316L |

|---|---|---|

| الفضاء | شفرات التوربينات، الأقواس | يتحمل الضغط ودرجات الحرارة العالية |

| الطبية | الأدوات الجراحية، الغرسات | متوافق حيويًا ومقاوم للتآكل |

| السيارات | التروس والبطانات | متين ومقاوم للاهتراء |

| تجهيز الأغذية | الناقلات والصمامات | يقاوم المحاليل الحمضية والمالحة |

| المعالجة الكيميائية | المضخات والخزانات | متانة كيميائية ممتازة |

3. خصائص ومزايا SS-316L لـ AM و PM

ينبع أداء مسحوق SS-316L المنحل من تركيبه الكيميائي وطريقة الانحلال. تقدم شركة شنغهاي تروير كلاً من المتغيرات المنحلة بالماء والغاز، مما يضمن المرونة بناءً على احتياجات التطبيق.

التركيب الكيميائي لمسحوق SS-316L

| العنصر | المحتوى النموذجي (%) |

|---|---|

| الكروم (Cr) | 16.0 – 18.0 |

| النيكل (ني) | 10.0 – 14.0 |

| الموليبدينوم (Mo) | 2.0 – 3.0 |

| المنجنيز (Mn) | ≤ 2.0 |

| السيليكون (Si) | ≤ 1.0 |

| الكربون (C) | ≤ 0.03 |

| الحديد (Fe) | الرصيد |

الخصائص الفنية الرئيسية

- توزيع حجم الجسيمات: تقدم Truer PSD مخصصًا يتم التحكم فيه من 15 ميكرومتر إلى 150 ميكرومتر.

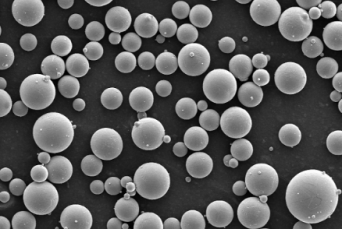

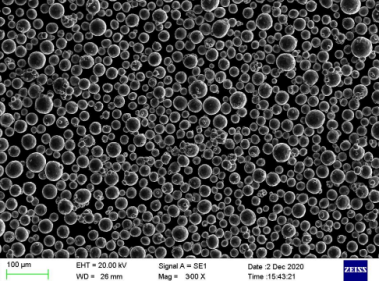

- علم الصرف: جزيئات كروية (منحلة بالغاز) أو غير منتظمة (منحلة بالماء) بناءً على عملية التصنيع.

- الكثافة:

- الكثافة الظاهرية: 2.5–4.0 جم/سم³

- كثافة النقر: 4.5–5.0 جم/سم³

- قابلية التدفق: ممتاز لآلات الضغط AM و PM نظرًا للشكل والـ PSD المتحكم فيهما.

مزايا لمشتري الشركات

- إمكانية إعادة إنتاج عالية عبر الدُفعات

- متوافق مع ISO و ASTM للاستخدام الصناعي العالمي

- متوفر بكميات كبيرة لمصنعي المعدات الأصلية والموزعين والمصنعين

- متوافق مع تقنيات SLM و EBM و Binder Jetting

تم تصميم مساحيق SS-316L من الدرجة الإضافية من شركة شنغهاي تروير لتحقيق أفضل أداء للتدفق والتلبيد. تعرف على المزيد حول شركة شنغهاي تروير ورسالتنا لدعم التصنيع الحديث.

4. اتجاهات السوق والطلب على مسحوق SS-316L في الشركات

مع استمرار الصناعات في اعتماد التصنيع الإضافي (AM) وتعدين المسحوق (PM) على نطاق واسع، يتسارع الطلب العالمي على مساحيق الفولاذ المقاوم للصدأ عالية الجودة - وخاصة SS-316L - بسرعة.

نظرة عامة على السوق العالمية

وفقًا لتقارير الصناعة الحديثة، من المتوقع أن يتجاوز سوق مسحوق المعادن 10 مليارات دولار أمريكي بحلول عام 2030، حيث تمثل مساحيق الفولاذ المقاوم للصدأ جزءًا كبيرًا من هذا النمو. يكتسب مسحوق SS-316L المنحل، على وجه الخصوص، زخمًا في الصناعات عالية الدقة مثل الفضاء والطب والطاقة نظرًا لسلامته الميكانيكية ومقاومته للتآكل.

محركات النمو الرئيسية

- الزيادة في اعتماد الطباعة ثلاثية الأبعاد في الفضاء والرعاية الصحية

- زيادة الطلب على المواد خفيفة الوزن وعالية القوة

- زيادة الاستثمار في التصنيع المحلي، عند الطلب

- مبادرات الحكومة دعم الصناعة 4.0 والإنتاج المستدام

اتجاهات البحث بين الشركات والكلمات الرئيسية ذات النية العالية

يبحث المشترون بالجملة ومصنعو المعدات الأصلية والموزعون بشكل متزايد عن:

- "شراء مسحوق SS-316L بكميات كبيرة"

- "موردي مسحوق الفولاذ المقاوم للصدأ المنحل"

- "مسح

- "مسحوق المعادن بالجملة لعملية التشكيل بالضغط"

- "مصنّعو مسحوق SS-316L في الصين"

ونتيجة لذلك، يبحث مديرو التوريد بنشاط عن موردين موثوقين يتمتعون بجودة ثابتة وقدرات لوجستية ودعم فني.

5. كيفية اختيار مورد موثوق لمسحوق SS-316L

يعد اختيار المورد المناسب لمسحوق SS-316L الذري أمرًا بالغ الأهمية لأداء المنتج وفعالية التكلفة واستقرار سلسلة التوريد على المدى الطويل. سواء كنت مصنعًا للمعدات الأصلية أو مصنعًا متعاقدًا أو موزعًا، يجب أن تضع في اعتبارك العوامل الرئيسية التالية:

قائمة مراجعة اختيار المورد

| المعايير | ما أهمية ذلك |

|---|---|

| طريقة الإنتاج | تحدد شكل الجسيمات وقابليتها للتدفق والنقاء |

| شهادات الجودة | ابحث عن الامتثال لمعايير ISO 9001 و ASTM و CE و ROHS |

| اتساق الدُفعات | يضمن أداءً موحدًا للأجزاء في عمليات التصنيع بالإضافة إلى عملية التشكيل بالضغط |

| قابلية التوسع | يدعم المشتريات طويلة الأجل وعالية الحجم |

| الدعم الفني | ضروري لتحسين المواد واستكشاف الأخطاء وإصلاحها |

| مهل التسليم والخدمات اللوجستية | يؤثر على تخطيط الإنتاج والتزامات التسليم |

| حجم الجسيمات القابل للتخصيص والتعبئة والتغليف | يوفر المرونة لمختلف التطبيقات |

العلامات الحمراء التي يجب تجنبها

- عدم وجود إمكانية التتبع أو شهادة المواد

- شكل جسيمات أو حجم جسيمات غير متسق

- لا توجد خبرة مع عملاء التصنيع الإضافي

- دعم العملاء المحدود أو خدمة ما بعد البيع

💡 تبرز شركة Shanghai Truer Technology Co., Ltd. من خلال تقديم إمكانية تتبع كاملة وشهادات من جهات خارجية واستشارات فنية مع كل شحنة. تم تصميم مساحيقهم للتطبيقات الصناعية المتطورة وتم اختبارها بدقة لتلبية المعايير العالمية.

6. أفضل موردي مسحوق SS-316L في آسيا والعالم

عند تقييم الموردين، من المفيد مقارنة رواد الصناعة من حيث القدرة والموثوقية. فيما يلي قائمة منسقة بأفضل الموردين الذين يقدمون مسحوق SS-316L الذري لعملاء B2B.

جدول مقارنة لموردي مسحوق SS-316L الرائدين

| اسم المورد | المنطقة | طريقة الانحلال | التركيز المتخصص | الحد الأدنى لكمية الطلب وخيارات الكميات الكبيرة |

|---|---|---|---|---|

| شركة Shanghai Truer Technology Co. | الصين | الماء والغاز | عملية التشكيل بالضغط، والتصنيع الإضافي، وقولبة الحقن المعدنية، والسبائك المخصصة | الحد الأدنى لكمية الطلب مرن |

| هوغاناس إيه بي | السويد | المياه | أجزاء عملية التشكيل بالضغط، والمواد المغناطيسية اللينة | نطاق صناعي |

| مضافات النجار | الولايات المتحدة الأمريكية | الغاز | مساحيق التصنيع الإضافي المستخدمة في صناعة الطيران والفضاء والأجهزة الطبية | حجم كبير |

| ساندفيك للتصنيع الإضافي | السويد | الغاز | مساحيق التصنيع الإضافي عالية الدقة | حجم كبير |

| شركة CNPC لمواد المسحوق المحدودة. | الصين | الغاز والبلازما | مساحيق المعادن المخصصة | حجم متوسط إلى مرتفع |

لماذا تتصدر شركة شنغهاي تروير في الصين

- تأسست عام 2009، مع التركيز على التصنيع الإضافي منذ عام 2019

- تقدم درجات مسحوق SS-316L القياسية والممتازة

- قدرة إنتاج مرنة للطلبات الصغيرة إلى الكبيرة

- تكامل عميق مع صناعات عملية التشكيل بالضغط والتصنيع الإضافي

- متخصصة في طرق الذرة المائية والذرة الهجينة

استكشف مجموعة منتجات عملية التشكيل بالضغط الكاملة من Truer للحصول على المواصفات الفنية وصحائف البيانات القابلة للتنزيل.

7. لماذا يتحول المزيد من المشترين إلى الموردين الصينيين

أصبحت الشركات المصنعة الصينية مثل Shanghai Truer تحظى بشعبية متزايدة بين الشركات المصنعة للمعدات الأصلية والموزعين وموردي التجارة الإلكترونية العالميين. إليك السبب:

المزايا الرئيسية للتوريد من الصين

- تسعير فعال من حيث التكلفة: أسعار تنافسية للكيلوغرام الواحد بسبب التصنيع المحلي المتقدم

- مهلة زمنية أقصر: خاصة بالنسبة لأسواق آسيا وآسيان

- الحد الأدنى المرن لكمية الطلب: مثالي للمؤسسات الصغيرة والمتوسطة الحجم

- خيارات التخصيص: حجم الجسيمات المخصص والتعبئة والتغليف وتركيبة السبائك

- الجودة المثبتة: عدد متزايد من المصانع المعتمدة من ISO والمجهزة للتصدير

دراسة حالة: مورد مكونات السيارات الدولي

حول مورد سيارات من الدرجة الأولى توريده لمسحوق SS-316L من مورد أوروبي إلى Shanghai Truer. النتيجة:

- انخفاض بنسبة 18% في تكلفة المواد

- دورة تسليم أسرع بنسبة 30%

- تحسين التشطيب السطحي في الأجزاء النهائية الملبدة

- استشارة في الموقع ودعم تخصيص المسحوق

يكتشف المزيد من المشترين الدوليين قيمة العمل مع الموردين الصينيين ذوي الخبرة والمدفوعين بالابتكار.

8. لماذا تختار شركة Shanghai Truer Technology Co., Ltd.

برزت شركة Shanghai Truer Technology Co., Ltd. كشركة رائدة في أسواق تعدين المساحيق والتصنيع الإضافي في الصين. يتم اعتماد مسحوق SS-316L الذري على نطاق واسع من قبل العملاء في صناعات الفضاء والسيارات والأجهزة الطبية والأدوات الصناعية.

أبرز ملامح ملف تعريف الشركة

- تأسست: 2009

- التخصص: مساحيق التصنيع الإضافي، إضافات تعدين المساحيق

- قدرات المصنع:

- ترذيذ الغاز

- ترذيذ الماء

- التكنولوجيا الهجينة للغاز والماء

- الشهادات: مواد متوافقة مع ISO و ASTM

منتجات مسحوق SS-316L المميزة

| رمز المنتج | طريقة الانحلال | نطاق حجم الجسيمات | التركيز على التطبيق |

|---|---|---|---|

| SS316L-GA | الغاز المرذاذ | 15–45 ميكرومتر | SLM، EBM، Binder Jet |

| SS316L-WA | رذاذ الماء | 45–150 ميكرومتر | عملية التشكيل بالضغط والتلحيم، MIM |

| SS316L-HY | هجين | قابل للتخصيص | عملية التشكيل بالضغط عالية الأداء |

لماذا تختار Truer؟

- مختبرات البحث والتطوير ومراقبة الجودة الداخلية

- استشارة ودعم خاص بالتطبيقات

- أسعار تنافسية وخيارات شحن عالمية

- سجل حافل مع عملاء Fortune 500

- مجموعة واسعة من الإضافات ومواد السبائك

📞 هل أنت مهتم بالحلول المخصصة؟ اتصل بفريق Truer هنا لمناقشة احتياجات التوريد الخاصة بك.

9. كيفية طلب مسحوق SS-316L بالجملة من Truer

عند شراء مسحوق SS-316L الذري بكميات كبيرة، يحتاج المصنعون والموزعون ووكلاء التوريد إلى عملية شراء مبسطة وشفافة. تقدم شركة Shanghai Truer Technology Co., Ltd. نظام طلب فعالًا مصممًا لتلبية احتياجات مشتري B2B عبر مختلف الصناعات.

عملية الطلب خطوة بخطوة

| الخطوة | الوصف |

|---|---|

| 1 | الاستفسار الأولي – أرسل طلبك عبر نموذج الاتصال الخاص بـ Truer أو البريد الإلكتروني |

| 2 | مراجعة مواصفات المنتج – حدد حجم الجسيمات المطلوبة وطريقة الذرة والكمية |

| 3 | عرض أسعار والمهلة الزمنية – احصل على عرض أسعار مفصل بما في ذلك الشحن والحد الأدنى لكمية الطلب |

| 4 | أخذ العينات (اختياري) – اطلب دفعة تجريبية للاختبار (قد يتم تطبيق رسوم) |

| 5 | اتفاقية الشراء – الانتهاء من شروط العقد بما في ذلك التسليم والدفع واحتياجات الشهادات |

| 6 | الإنتاج ومراقبة الجودة – يتم تصنيع المسحوق واختباره من حيث الجودة وتعبئته |

| 7 | الشحن والتسليم – تدعم Truer النقل الجوي والبحري والسريع في جميع أنحاء العالم |

خيارات التخصيص للطلبات المجمعة

- خيارات التغليف: أسطوانات 10 كجم، 25 كجم، 100 كجم؛ مختومة بتفريغ الهواء؛ أكياس مملوءة بالنيتروجين

- تخصيص حجم الجسيمات: توزيع حجم الجسيمات المصمم خصيصًا من 15 ميكرومتر إلى 150 ميكرومتر

- المعالجات السطحية: عوامل مضادة للتكتل، التخميل، إلخ.

- التوثيق: شهادة المطابقة، صحائف بيانات سلامة المواد، تقارير الاختبار، RoHS، REACH متوفرة عند الطلب

الدفع والخدمات اللوجستية

- المدفوعات المقبولة: T/T، L/C، PayPal (للعينات)، يوان صيني

- شروط التجارة الدولية: متوفرة على أساس تسليم ظهر السفينة، والتأمين على التكلفة والشحن، والتسليم مع دفع الرسوم

- الشحن: من الباب إلى الباب عالميًا عبر DHL أو FedEx أو وكيل الشحن

💬 هل تحتاج إلى عرض أسعار مخصص اليوم؟ قم بزيارة صفحتنا الرئيسية وابدأ رحلة التوريد الخاصة بك مع Truer الآن.

10. الأسئلة الشائعة: شراء مسحوق SS-316L بكميات كبيرة للاستخدام الصناعي

لمساعدة مديري التوريد والمتخصصين في المشتريات على اتخاذ قرارات مستنيرة، إليك إجابات على الأسئلة الأكثر شيوعًا حول شراء مسحوق SS-316L الذري من Shanghai Truer.

أسئلة عامة حول المنتج

س1: ما الفرق بين مسحوق SS-316L الذري بالغاز والماء؟

A1: مساحيق الذرة بالغاز كروية ومثالية للطباعة ثلاثية الأبعاد نظرًا لقابليتها الممتازة للتدفق. مساحيق الذرة المائية ذات شكل غير منتظم أكثر ومناسبة لعملية التشكيل بالضغط والتلحيم.

س2: ما هي الصناعات التي تستخدم مسحوق SS-316L بشكل عام؟

A2: تعد صناعات الفضاء والسيارات والأجهزة الطبية والطاقة والمجوهرات والمعالجة الكيميائية من المستهلكين الرئيسيين.

س3: هل يمكنني طلب توزيع حجم جسيمات معين (PSD)؟

A3: نعم. تقدم Truer أحجام جسيمات مخصصة تتراوح من 15 ميكرومتر إلى 150 ميكرومتر اعتمادًا على تطبيقك.

أسئلة حول الخدمات اللوجستية والحد الأدنى لكمية الطلب

س4: ما هو الحد الأدنى لكمية الطلب (MOQ)؟

A4: تختلف الحد الأدنى لكمية الطلب من 10 كجم للعينة إلى 100 كجم أو أكثر لطلبات الإنتاج. اتصل بـ Truer للحصول على الحد الأدنى لكمية الطلب المحددة بناءً على نوع المنتج.

س5: كم من الوقت يستغرق شحن المسحوق؟

A5: المهلة الزمنية القياسية هي 7-14 يوم عمل، اعتمادًا على حجم الطلب والتخصيص.

س6: هل تشحن دوليًا؟

A6: نعم. تشحن Truer إلى أمريكا الشمالية وأوروبا وجنوب شرق آسيا والشرق الأوسط مع وثائق تصدير كاملة.

الجودة والامتثال

س7: هل مساحيقك معتمدة؟

A7: نعم. توفر Truer مساحيق متوافقة مع ISO و ASTM مع وثائق كاملة بما في ذلك شهادة المطابقة و SDS وتقارير التتبع.

س8: كيف تتحكم في جودة المسحوق واتساقه؟

A8: تتضمن بروتوكولات ضمان الجودة الصارمة تحليل حجم الجسيمات بالليزر، وفحوصات شكل SEM، واختبار الكثافة، والتحقق من التركيب الكيميائي.

س9: هل يمكنني زيارة منشأتك أو تدقيق المصنع؟

A9: نعم. ترحب Truer بعمليات تدقيق المصنع والجولات الافتراضية. حدد موعدًا للزيارة عبر صفحة اتصل بنا.

11. الخلاصة والدعوة النهائية إلى العمل

يعد مسحوق SS-316L الذري مادة خام حاسمة عبر قطاعات التصنيع الإضافي وتعدين المساحيق وقولبة الحقن المعدنية. مع ارتفاع الطلب العالمي وأصبحت معايير التطبيقات أكثر صرامة، أصبح الحصول على مسحوق عالي الجودة ومتسق أكثر أهمية من أي وقت مضى.

تقدم شركة Shanghai Truer Technology Co., Ltd. قيمة استثنائية لمشتري B2B الذين يبحثون عن:

- 💡 جودة مسحوق موثوقة ومعتمدة من ISO

- 🔧 التخصيص في حجم الجسيمات والتعبئة والتغليف وتركيبة السبائك

- 🌍 دعم الشحن والخدمات اللوجستية العالميين

- 🤝 الدعم الفني والخبرة الخاصة بالصناعة

- 💰 أسعار تنافسية وحدود دنيا لكمية الطلب مرنة

سواء كنت مو

👉 هل أنت مستعد لتقديم طلبك الأول أو طلب عينة؟

قم بزيارة الموقع الرسمي لشركة Shanghai Truer أو تحقق من كتالوج مسحوق PM للبدء