1. Introduction: What is Reduced Iron Powder and Why It Matters in Industry

Reduced iron powder is a form of elemental iron produced through the reduction of iron oxides using hydrogen or carbon monoxide as reducing agents. Known for its high purity, controlled particle size, and excellent compressibility, reduced iron powder is widely used in:

- Powder metallurgy (PM)

- مكونات مغناطيسية ناعمة

- Welding electrodes

- Friction materials

- Chemical catalysts

In contrast to water atomized or gas atomized iron powders, reduced iron powder is typically produced via the hydrogen or carbon reduction method, making it especially suited for high-purity applications.

Key Characteristics of Reduced Iron Powder:

| الممتلكات | الوصف |

|---|---|

| النقاء | Typically >97% Fe |

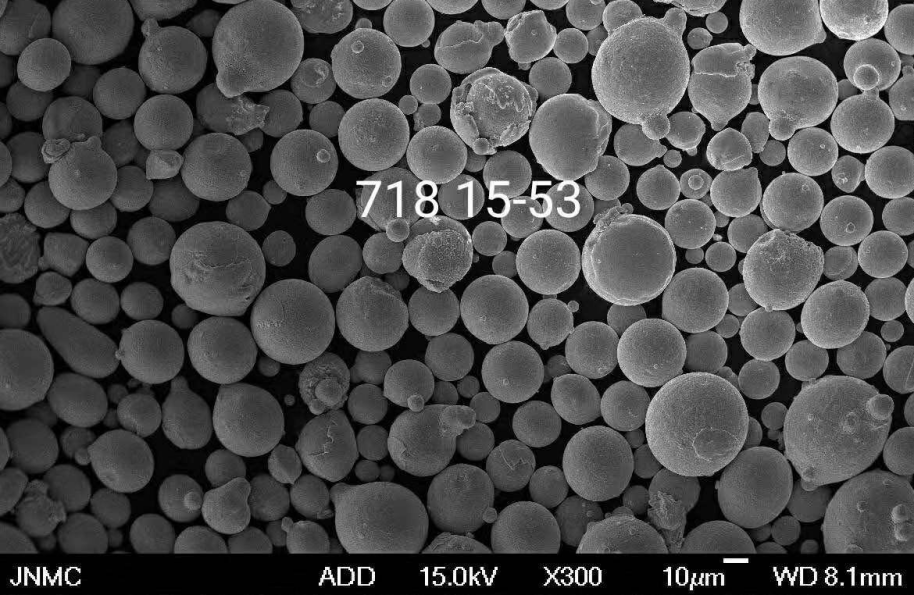

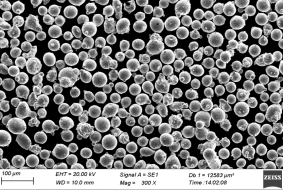

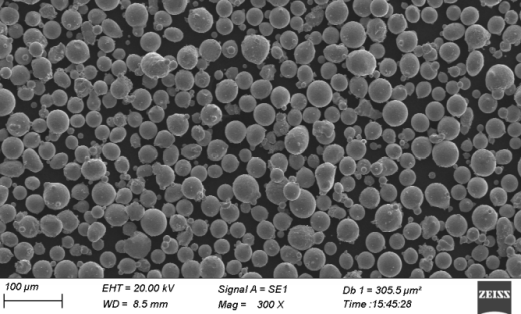

| شكل الجسيمات | Irregular, sponge-like |

| طريقة الإنتاج | Hydrogen/carbon reduction |

| قابلية الانضغاط | ممتاز |

| التطبيقات | PM parts, magnetic parts, catalysts |

For industrial buyers, reduced iron powder offers excellent value due to its cost-effectiveness, performance, and adaptability across multiple applications.

2. Industrial Applications of Reduced Iron Powder

Reduced iron powder is a versatile raw material used in various sectors, including automotive, electronics, metallurgy, and chemical processing. Below are the primary industrial applications:

a. Powder Metallurgy (PM)

- Used to manufacture structural PM parts like gears, bushings, and bearings.

- Offers excellent sintering properties and green strength.

b. Magnetic Applications

- Reduced iron powder is essential in producing soft magnetic cores used in transformers, inductors, and sensors.

- High magnetic permeability and low coercivity make it ideal for electromagnetic applications.

c. Welding Electrodes

- Acts as a key filler material in welding electrodes.

- Enhances arc stability and improves mechanical strength of the weld.

d. Friction Materials

- Used in brake pads and clutch plates due to its wear resistance and thermal conductivity.

e. Chemical and Catalytic Applications

- Serves as a reducing agent and catalyst carrier in chemical industry.

- Used in processes like hydrogenation and desulfurization.

Summary Table: Applications vs. Benefits

| مجال التطبيق | Benefits of Reduced Iron Powder |

|---|---|

| تعدين المساحيق | High compressibility, low oxygen content |

| المكونات المغناطيسية | Good magnetic properties, cost-effective |

| أقطاب اللحام الكهربائية | Enhances arc stability, weld strength |

| مواد الاحتكاك | Thermal conductivity, wear resistance |

| الصناعة الكيميائية | Effective catalyst support, high surface area |

3. Types and Grades of Reduced Iron Powder for Manufacturing

There are multiple grades and forms of reduced iron powder tailored for specific applications. Shanghai Truer Technology Co., Ltd, a leading supplier in China, offers a wide selection of reduced iron powders through various production techniques to meet diverse industrial needs.

a. Classification by Production Method

- Hydrogen-Reduced Iron Powder

- High purity, suitable for magnetic and chemical uses.

- Carbon-Reduced Iron Powder

- Cost-effective, used in structural PM parts.

b. Grade-Specific Options from Shanghai Truer

Shanghai Truer provides a variety of reduced and pre-alloyed iron powders, including:

- PM iron

- PM copper steel (Fe-Cu)

- PM nickel steel (Fe-Ni)

- PM phosphorus iron

- PM infiltrated iron and steel

These powders are available in grades such as F-0000, FC-0208, FN-0205, FD-0200, FD-0208, FX-2008, and FN-5000, suitable for both standard and advanced PM applications.

Sample Table: Shanghai Truer Powder Grades

| الصف | التركيب | مجال التطبيق |

|---|---|---|

| F-0000 | حديد نقي | Magnetic parts, PM components |

| FC-0208 | Fe-Cu | الأجزاء الهيكلية |

| FN-0205 | Fe-Ni | High-strength PM parts |

| FD-0200 | سبائك الانتشار | مكونات السيارات |

| FN-5000 | Fe-Ni (high nickel) | Magnetic applications |

You can explore more about these powder types on the صفحة منتج مسحوق مسحوق PM of Shanghai Truer.

4. Global Market Trends and Growth Potential for Reduced Iron Powder

Reduced iron powder is experiencing significant growth, driven by the expansion of the automotive, electronics, and additive manufacturing sectors. The global powder metallurgy market is projected to surpass USD 10 billion by 2030, with reduced iron powder playing a central role in structural and magnetic component manufacturing.

محركات السوق الرئيسية:

- تخفيف وزن السيارات: Automakers are increasingly using powder metallurgy to reduce vehicle weight and improve fuel efficiency. Reduced iron powder is crucial in producing lightweight gears, cams, and pulleys.

- Electrification and Magnetic Applications: The rise of electric vehicles (EVs) and renewable energy systems is boosting demand for soft magnetic materials, where reduced iron powders are a critical input.

- Additive Manufacturing (طباعة ثلاثية الأبعاد): Powder-based additive manufacturing is on the rise. While gas atomized powders dominate, reduced iron powder is being explored for cost-effective prototyping and binder jetting.

رؤى السوق الإقليمية:

| المنطقة | Market Trend |

|---|---|

| آسيا والمحيط الهادئ | Largest producer and consumer, driven by China and India’s automotive sector |

| أوروبا | Strong demand in EV and high-precision manufacturing |

| أمريكا الشمالية | Growing use in aerospace and defense industries |

Growth Sectors:

- EV motors and sensors

- Hydraulic and pneumatic tools

- Sintered mechanical parts

- Catalysts and chemical reactors

As the demand for high-performance, cost-effective materials grows, reduced iron powder is well-positioned to meet industry needs across multiple sectors.

5. Key Factors When Choosing a Reliable Iron Powder Supplier

Selecting the right supplier is critical for consistency, quality control, and long-term reliability. For B2B buyers such as manufacturers, distributors, and R&D companies, here are the key considerations when evaluating a reduced iron powder supplier:

a. Product Quality & Certification

- ISO and RoHS compliance

- Particle size control and chemical composition accuracy

- High purity and low oxygen content for critical applications

b. Production Capabilities

- Ability to produce large volumes consistently

- Multiple production methods (reduction, water atomization, gas atomization)

- In-house R&D for customized grades

c. Supply Chain and Logistics

- Timely delivery and inventory management

- قدرات الشحن العالمية

- Ability to handle bulk/wholesale orders

d. Technical Support and Customization

- Engineering support to optimize powder selection

- Custom blends based on application needs

- On-site consultation and process integration

e. Pricing and Value

- أسعار تنافسية لطلبات الشراء بالجملة

- Volume-based discounts

- Transparent quotation and ordering process

Checklist for Buyers:

| المعايير | الميزات التي يجب توفرها |

|---|---|

| جودة متسقة | Verified particle size, purity standards |

| Flexible Supply Capacity | Scalable production for large or custom orders |

| الدعم الفني | Application-specific advice and guidance |

| الشهادات | ISO, RoHS, REACH, etc. |

| الخدمات اللوجستية والمهلة الزمنية | Global delivery & short turnaround |

6. Top 5 Reduced Iron Powder Suppliers in Asia

Here are five of the most reliable manufacturers and wholesalers of reduced iron powder in Asia, based on supply capacity, product range, and global reach:

| اسم الشركة | البلد | نقاط القوة الرئيسية |

|---|---|---|

| شركة شنغهاي تروير تكنولوجي المحدودة (Shanghai Truer Technology Co., Ltd.) | الصين | Wide range of PM powders, technical support, customization |

| شركة JFE للصلب | اليابان | High-purity powders, strong R&D |

| Hoganas AB (Asia Division) | Sweden/Japan | Global network, premium quality |

| Pometon S.p.A (Asian Branch) | Italy/India | Diverse metal powder portfolio |

| شركة CNPC لمواد المسحوق المحدودة. | الصين | Scale production, competitive pricing |

تسليط الضوء: شركة Shanghai Truer Technology Co., Ltd

Founded in 2009, شركة شنغهاي تروير تكنولوجي المحدودة (Shanghai Truer Technology Co., Ltd.) has become one of China’s most professional suppliers in the powder metallurgy industry. Since launching its additive manufacturing division in 2019, Truer has expanded its offerings to include:

- Reduced iron and steel powders

- Prealloyed and diffusion alloyed PM powders

- Magnetic and structural powder grades

- Additives, lubricants, and cutting agents for PM processing

Truer stands out for its integrated approach—providing both powder production equipment and high-quality powders, supported by an expert engineering team.

7. Why More Buyers Are Sourcing from China for Reduced Iron Powder

China has become a global hub for powder metallurgy materials due to its production capacity, pricing advantages, and technological innovation. For international buyers, sourcing reduced iron powder from Chinese manufacturers like Shanghai Truer offers several strategic benefits:

a. Cost Efficiency

- Lower manufacturing and labor costs

- أسعار تنافسية لطلبات الشراء بالجملة

- High-quality products at reduced costs

b. Advanced Manufacturing Infrastructure

- Access to modern reduction and atomization technologies

- Ability to scale production quickly

- Continuous R&D and material innovation

c. Product Range and Customization

- Variety of PM grades (Fe, Fe-Cu, Fe-Ni, diffusion alloys)

- Custom particle size and morphology

- Application-specific powder blends

d. Streamlined Export Processes

- Mature logistics and export documentation systems

- Experience with international compliance and standards

- دعم مبيعات وفني متعدد اللغات

e. Supplier Diversity & Options

- Multiple verified suppliers for risk reduction

- Ability to source additives, powders, and equipment from one partner

Buyer Tip: For those exploring sourcing opportunities, صفحة الاتصال الخاصة بشركة شنغهاي Truer is an excellent starting point to request custom quotations or technical guidance.

8. How to Order Wholesale Reduced Iron Powder from China

For B2B buyers looking to source reduced iron powder in bulk, a smooth and transparent ordering process is essential. Shanghai Truer Technology Co., Ltd has designed a buyer-friendly workflow that ensures fast quoting, customization, and reliable delivery worldwide.

Step-by-Step Ordering Process from Shanghai Truer

| الخطوة | الوصف |

|---|---|

| 1. Inquiry & Consultation | Contact Truer with specifications (grade, quantity, application) |

| 2. Technical Evaluation | Engineers recommend suitable powder or custom formulation |

| 3. Sample & Quotation | Sample shipment arranged; formal quote provided with lead time and terms |

| 4. Order Confirmation | Agreement signed; production begins |

| 5. الإنتاج ومراقبة الجودة | Powder produced and quality-checked per ISO standards |

| 6. Packaging & Logistics | Vacuum-sealed or bagged; exported with full documentation |

| 7. دعم ما بعد البيع | Ongoing application support and reorder assistance |

الوثائق المقدمة

- شهادة تحليل (COA)

- صحيفة بيانات سلامة المواد (MSDS)

- Export documents (invoice, packing list, customs forms)

- Technical data sheets

خيارات التخصيص

- Particle size distribution (20μm–250μm)

- Chemical composition (Fe-Cu, Fe-Ni, etc.)

- Packaging (20kg, 25kg, 500kg super sacks)

- Additive blending (graphite, lubricants, etc.)

Minimum Order Quantity (MOQ):

Generally starts from 500kg for standard grades; lower MOQs are available for R&D or trial batches.

📌 For a quick start, visit the صفحة اتصل بنا to request a sample or quote.

9. FAQs: Common Questions About Buying Reduced Iron Powder Wholesale

Below are some frequently asked questions from manufacturers, distributors, and OEMs interested in sourcing reduced iron powder:

Q1: What is the difference between reduced iron powder and atomized iron powder?

A: Reduced iron powder is produced via chemical reduction (hydrogen or carbon), yielding irregular, sponge-like particles ideal for sintering and magnetic applications. Atomized iron powder (water/gas) has spherical particles and is often used in 3D printing or high-strength parts.

Q2: Is reduced iron powder suitable for automotive part manufacturing?

A: Yes. It’s widely used in producing sintered gears, bushings, clutch plates, and timing components due to its compressibility and consistency.

Q3: How can I ensure the reduction powder meets my application requirements?

A: Shanghai Truer provides technical consultations to match powder grades (e.g., F-0000, FC-0208, FN-5000) with your specific needs. You can also request a PM powder sample before placing a bulk order.

Q4: What testing and quality control standards do you follow?

A: Truer adheres to ISO 9001 quality management, with full lab testing for particle size, chemical composition, and sintering behavior.

Q5: What is the lead time for wholesale orders?

A: Standard lead time is 10–15 business days. Custom grades may take 20–25 days depending on complexity and volume.

Q6: Can I request a non-standard iron powder blend (e.g., with lubricants or cutting agents)?

A: Absolutely. Truer offers integrated solutions including lubricants (Lube-W, SUW-8000), cutting agents (SME-100), and magnetic additives, all blended with your base PM powder.

Q7: Do you ship internationally?

A: Yes, Truer exports globally with experience handling customs clearance and logistics for North America, Europe, Southeast Asia, and the Middle East.

Q8: What types of industries typically buy reduced iron powder from Truer?

A: Automotive, electronics, appliance manufacturing, PM part producers, diamond tool manufacturers, and soft magnetic component makers.

Q9: Can I visit your facility or get a virtual tour?

A: Yes, Shanghai Truer welcomes on-site visits and offers virtual tours. Reach out via the : الانحلال المائي أو الاختزال for scheduling.

✅ Internal Links Used Across the Blog

| نص الارتباط | عنوان URL المضمن |

|---|---|

| صفحة منتج مسحوق مسحوق PM | https://am-material.com/pm-powder/ |

| شركة شنغهاي تروير تكنولوجي المحدودة (Shanghai Truer Technology Co., Ltd.) | https://am-material.com/about/ |

| صفحة اتصل بنا | https://am-material.com/contact-us/ |

| sample or quote | https://am-material.com/contact-us/ |

| : الانحلال المائي أو الاختزال | https://am-material.com/about/ |

By sourcing from reliable suppliers like Shanghai Truer Technology Co., Ltd, manufacturers gain access to high-performance powders, custom solutions, and global support—all essential elements for scaling production in today’s competitive industrial landscape.

If you’re ready to elevate your material sourcing, connect with our team today and explore how reduced iron powder can transform your manufacturing process.

👉 Get a Free Consultation or Sample Now

📌 Need more technical data or want to explore additives, lubricants, and sintering enhancers? Visit our full product catalog on the Truer PM Powder Page.