1. Introduction: The Growing Demand for FeSiAl Powder in Industry

FeSiAl powder—a ferroalloy composed of iron (Fe), silicon (Si), and aluminum (Al)—is gaining momentum in the global manufacturing and metallurgy sectors. This alloyed powder is particularly valued for its magnetic properties, corrosion resistance, and thermal stability, making it an essential material in the production of magnetic cores, electronic components, and sintered parts.

As industries move toward lightweight, high-performance, and cost-effective materials, FeSiAl powder is becoming a key player in powder metallurgy (PM) processes, soft magnetic composites (SMCs), and additive manufacturing.

What’s Driving the Demand?

- Rapid growth in electric vehicle (EV) manufacturing

- Expansion of renewable energy sectors requiring efficient magnetic materials

- Increased adoption of طباعة ثلاثية الأبعاد and PM in industrial applications

- Cost advantages over traditional FeSi or FeAl materials

| Market Segment | Typical Use of FeSiAl Powder | المزايا |

|---|---|---|

| السيارات | Motor cores, sensors, sintered gears | Reduced weight, improved efficiency |

| الإلكترونيات | EMI shielding, inductors | High magnetic permeability |

| التصنيع الإضافي | Metal 3D printing components | Tailored magnetic performance |

| الآلات الصناعية | Wear-resistant parts, magnetic clamps | مقاومة التآكل، قابلية التشغيل |

FeSiAl powder is experiencing a surge in B2B demand, particularly from wholesale buyers, distributors, and OEM manufacturers looking to optimize performance and cost.

2. Industrial Applications of FeSiAl Powder

FeSiAl powder is widely recognized for its use in high-frequency, low-loss magnetic applications. As industries prioritize energy efficiency and miniaturization of components, the alloy’s versatile properties make it suitable across multiple sectors.

التطبيقات الرئيسية:

- 📌 Soft Magnetic Components (SMC): Used in electric motors, inductors, and transformers for high frequency and low energy loss.

- 📌 Additive Manufacturing: Used in 3D printing to manufacture customized magnetic parts.

- 📌 Sintered Components: Ideal for gears, bushings, and structural PM parts due to good compressibility and mechanical strength.

- 📌 EMI Shielding: Effective in shielding equipment from electromagnetic interference in automotive and aerospace industries.

Specific Industry Examples:

| القطاع | طلب | FeSiAl Benefit |

|---|---|---|

| السيارات | EV motors, gear components | High saturation magnetization |

| الطاقة المتجددة | Wind turbine sensors, power electronics | Stable performance in harsh conditions |

| الفضاء | Avionics EMI shielding | خفيف الوزن ومتين |

| الإلكترونيات الاستهلاكية | Inductor cores, transformers | Low core loss, high frequency support |

FeSiAl is especially popular for applications where magnetic efficiency and heat resistance are critical. These benefits are driving its use in next-gen technologies.

3. Properties and Benefits of FeSiAl Powder

FeSiAl powder offers a unique combination of magnetic, structural, and processing advantages. Compared to traditional iron-based powders, it delivers significantly improved soft magnetic performance and mechanical properties.

الخصائص الرئيسية:

- ✅ High Magnetic Permeability

- ✅ Low Core Loss in High-Frequency Applications

- ✅ Excellent Thermal Stability

- ✅ Corrosion Resistance

- ✅ Good Compressibility for PM Applications

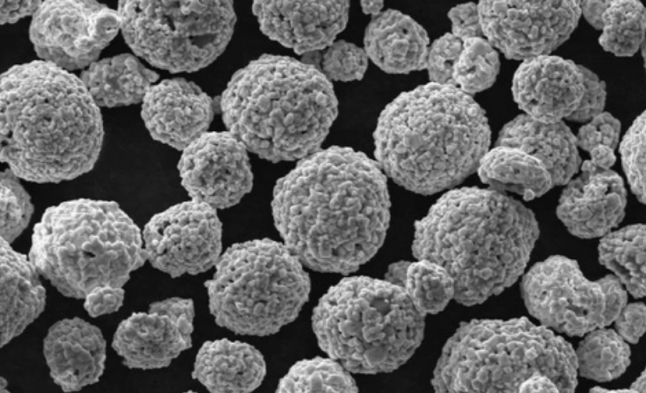

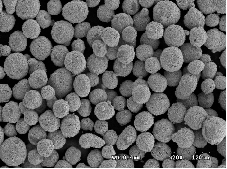

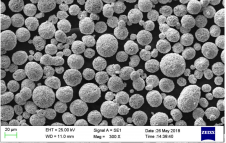

Physical & Chemical Characteristics

| الممتلكات | القيمة النموذجية |

|---|---|

| حجم الجسيمات | 20–150 µm (customizable) |

| الكثافة الظاهرة | 2.7–3.2 g/cm³ |

| كثافة الحنفية | 3.5–4.5 g/cm³ |

| النفاذية المغناطيسية | 300–800 µH/m |

| المقاوماتية الكهربائية | 40–60 µΩ·cm |

| درجة حرارة التلبيد | 1100–1300 درجة مئوية |

Benefits for Wholesale Buyers & Manufacturers:

- 🔧 Customizable composition and particle size for different applications

- 🔧 High yield in PM and AM production processes

- 🔧 Cost-effective alternative to pure iron or FeSi materials

- 🔧 Compatibility with both water and gas atomization methods

For businesses engaged in powder metallurgy or looking to scale 3D printing operations, FeSiAl powder offers a reliable and high-performance material choice. For more technical specifications and product options, you can explore the FeSiAl powder product page here.

4. Market Trends for FeSiAl Alloy in Powder Metallurgy

FeSiAl powder is gaining attention in global powder metallurgy (PM) and additive manufacturing (AM) markets due to its superior magnetic and structural properties. As both industries evolve, FeSiAl powder is becoming a critical material for developing lightweight, energy-efficient, and customizable components.

رؤى السوق العالمية

- 🌍 The global soft magnetic materials market is projected to exceed USD 30 billion by 2030, with FeSiAl playing a significant role in this growth.

- 📈 Demand from EV, renewable energy, and industrial automation sectors is accelerating adoption.

- 💡 Additive manufacturing is expected to grow at a CAGR of 20.8% over the next 5 years, increasing the need for high-performance powders like FeSiAl.

Use in Emerging Technologies

FeSiAl powders are increasingly used in:

- Electric and hybrid vehicle motors

- 5G and IoT hardware requiring EMI shielding

- Decentralized energy systems like microgrids

- Smart devices with compact inductive components

Industrial Powder Metallurgy Trends

| الاتجاه | Impact on FeSiAl Demand |

|---|---|

| Shift toward energy efficiency | Greater use in motors and transformers |

| Miniaturization of devices | Demand for high-frequency magnetic materials |

| تطوير سبائك مخصصة | Need for tailored FeSiAl compositions |

| Sustainable manufacturing | Use of recyclable and eco-friendly powders |

FeSiAl powders, especially those developed using sustainable production methods like water atomization, are preferred by global OEMs aiming to reduce carbon footprints.

5. Choosing the Right FeSiAl Powder Supplier

Selecting a reliable FeSiAl powder supplier is critical for wholesale buyers, OEM manufacturers, and distributors. Key considerations include powder quality, customization capabilities, consistency, and supply chain reliability.

عوامل يجب مراعاتها:

- ✅ Powder Purity and Particle Uniformity

- ✅ Availability of Water and Gas Atomized Grades

- ✅ Customization for Specific Applications (e.g. particle size, sintering behavior)

- ✅ Certifications and Quality Control Standards (ISO, RoHS, REACH)

- ✅ Global Logistics and Delivery Options

- ✅ Technical Support and On-Site Consultation

أسئلة لطرحها على الموردين المحتملين:

- Can you provide material traceability and quality certifications?

- What are the minimum and maximum lot sizes for wholesale orders?

- Do you offer technical assistance for new product development?

- How do you ensure consistency across batches?

- What are your lead times and shipping options for international buyers?

Sample Supplier Evaluation Table

| المعايير | المورد أ | المورد ب | Truer Technology |

|---|---|---|---|

| شهادة الأيزو | ✅ | ❌ | ✅ |

| Custom Particle Sizes | ❌ | ✅ | ✅ |

| Water & Gas Atomization | ✅ | ❌ | ✅ |

| Global Shipping | ✅ | ✅ | ✅ |

| Competitive Wholesale Pricing | ❌ | ✅ | ✅ |

| الدعم الفني | ✅ | ❌ | ✅ |

Shanghai Truer Technology Co., Ltd stands out as a full-service supplier offering high-quality FeSiAl powder with customizable specifications, full material traceability, and global delivery. Learn more about Truer’s capabilities and company background.

6. Top 5 Global Suppliers of FeSiAl Powder

Finding the right partner for your FeSiAl powder supply can significantly impact your manufacturing quality and profitability. Here are five leading suppliers recognized for their innovation, production capacity, and reliability.

1. شركة Shanghai Truer Technology Co., Ltd (الصين)

- 💼 Founded in 2009, specialized in PM powders since 2019

- 🌐 Offers FeSiAl powder via water and gas atomization

- 🎯 Customizable grades for SMC, sintering, and additive manufacturing

- 📦 Global distribution network

- 📞 Integrated support through on-site consultation and R&D

Truer also offers a variety of alloy types including PM Bronze, PM nickel silver, and PM stainless steel, making it a one-stop solution for wholesalers and manufacturers. Explore مجموعة Truer الكاملة من مساحيق PM.

2. Höganäs AB (Sweden)

- 🌍 Global leader in powder metallurgy materials

- 🧪 Advanced R&D and application testing labs

- 📈 Strong presence in automotive and energy sectors

3. Rio Tinto Metal Powders (Canada)

- ⛏️ Integrated supply chain from mining to powder production

- 🔍 Focus on high-purity iron-based powders

- 🌎 Strong logistics for North American clients

4. Daido Steel Co., Ltd (Japan)

- 🇯🇵 High-quality magnetic and structural powders

- 💡 Specializes in advanced soft magnetic alloys

5. GKN Hoeganaes (USA)

- 🚗 Strong focus on automotive applications

- 🧪 Offers tailored powder solutions for sintering and AM

Each of these suppliers has unique strengths, but Shanghai Truer Technology combines technical expertise with competitive pricing and a broad product portfolio, making it a preferred choice for global manufacturers and distributors.

7. Why More Buyers Are Turning to Chinese FeSiAl Powder Sources

Over the past decade, China has emerged as a dominant force in the global powder metallurgy (PM) and additive manufacturing (AM) markets. Buyers from across North America, Europe, Southeast Asia, and the Middle East are increasingly sourcing FeSiAl powder from Chinese manufacturers due to several compelling advantages.

الأسباب الرئيسية للتحول إلى الموردين الصينيين:

- كفاءة التكلفة: Chinese suppliers offer highly competitive pricing without compromising on quality.

- نطاق الإنتاج: High-volume manufacturing enables faster turnaround and better availability.

- إمكانيات التخصيص: Chinese producers are more flexible in customizing particle size, morphology, and alloy composition.

- تكنولوجيا الانحلال المتقدمة: Many Chinese companies, like Shanghai Truer Technology, use both water and gas atomization techniques.

- الابتكار السريع: Strong investments in R&D allow for quick adaptation to market demands and emerging applications.

Comparison: Domestic vs. Chinese FeSiAl Powder Suppliers

| المعايير | Domestic (US/EU) Suppliers | الموردون الصينيون (على سبيل المثال، تروير) |

|---|---|---|

| السعر لكل كجم (الطلبات بالجملة) | Higher ($30–$50) | Lower ($15–$25) |

| المهلة الزمنية | 4-6 أسابيع | 2–4 weeks |

| تطوير السبائك المخصصة | محدودة | واسعة النطاق |

| مرونة موك | Rigid | مرن |

| الدعم الفني | قياسي | Personalized + Multilingual |

As more businesses aim to improve margins while maintaining high quality, Chinese FeSiAl powder suppliers offer a strategic sourcing advantage, especially for wholesale buyers and industrial manufacturers. To contact a trusted supplier directly, visit صفحة الاتصال الخاصة بشركة Shanghai Truer.

8. Why Choose Shanghai Truer Technology for FeSiAl Powder

Shanghai Truer Technology Co., Ltd is one of China’s most recognized names in powder metallurgy and additive manufacturing. Since entering the PM powder industry in 2019, Truer has quickly distinguished itself by delivering high-quality materials, technical expertise, and full-spectrum support to global clients.

Core Advantages of Truer:

- 🏭 Comprehensive Manufacturing: Produces a wide range of PM powders including FeSiAl, bronze, nickel silver, stainless steel, and prealloyed steels.

- 🔬 التكنولوجيا المتقدمة: Uses both water and gas atomization, as well as combined hybrid atomization for specialized requirements.

- 🧪 خبرات البحث والتطوير: Offers tailored solutions for soft magnetic composites (SMCs), sintered parts, and 3D printing.

- 🌍 الوصول العالمي: Ships to over 30 countries with multilingual support and responsive international sales teams.

- 🛠️ حلول إضافية: Supplies not just powders, but also PM additives like lubricants (Lube-W, SUW-5000B), cutting agents (SME-100), and soft magnetic additives (QH-150).

Product Range Snapshot

| الفئة | أمثلة على المنتجات |

|---|---|

| PM Powders | FeSiAl, PM Bronze, PM Stainless Steel |

| طريقة الإنتاج | Water Atomized, Gas Atomized, Hybrid Atomized |

| المضافات | Graphite (TBC-400), Lubricants (SUW-8000) |

| Special Materials | Diffusion CuSn Powder, Soft Magnetic Additives |

Truer’s FeSiAl powders are available in standard and custom grades, optimized for both traditional PM and additive manufacturing applications. For a more detailed overview of Truer’s PM materials, visit their صفحة منتج مسحوق PM.

9. FAQs: Buying Wholesale FeSiAl Powder

Here are answers to the most frequently asked questions by distributors, OEMs, and purchasing managers seeking to source FeSiAl powder in bulk.

Q1: What is the minimum order quantity (MOQ) for wholesale FeSiAl powder?

A: Shanghai Truer typically offers flexible MOQs starting from 50 kg, depending on the grade and customization required.

Q2: What particle size ranges are available?

A: Standard particle sizes range from 20 μm to 150 μm. Custom sizes can be produced upon request for specific applications like 3D printing or high-density PM parts.

Q3: Is FeSiAl powder suitable for additive manufacturing?

A: Yes. Gas-atomized FeSiAl powder from Truer is optimized for use in binder jetting, SLM, and DMLS 3D printing technologies.

Q4: Can you provide technical data sheets and COAs?

A: Absolutely. Truer provides comprehensive technical documentation, including material composition, magnetic properties, and batch-specific certificates of analysis.

Q5: What are the available packaging options?

A: Standard packaging includes 25 kg bags or 1-ton bulk bags with moisture-proof lining. Custom packaging is available upon request.

Q6: Can Truer assist in developing new FeSiAl-based materials?

A: Yes. Truer has a dedicated R&D team that collaborates with clients on custom powder development and performance optimization.

Q7: How do I place a wholesale order?

A: You can initiate your order or request a quote via Truer’s contact us page. A representative will reach out to support you through the process.

Q8: Does Truer offer samples for testing?

A: Yes. Samples (1–5 kg) are available for qualified industrial clients to evaluate powder performance before placing bulk orders.

Internal Links Summary (5 Anchor Texts Used)

- FeSiAl powder product page

- Truer’s capabilities and company background

- صفحة الاتصال الخاصة بشركة Shanghai Truer

- صفحة منتج مسحوق PM

- Contact us page

By choosing Shanghai Truer Technology as your FeSiAl powder supplier, you’re not just buying a product—you’re gaining a long-term partner in innovation. Whether you’re in automotive, electronics, or additive manufacturing, Truer’s commitment to quality, customization, and customer support makes it the ideal choice for your business.

Ready to elevate your product performance with premium FeSiAl powder? تواصل مع Truer اليوم to request a quote or technical datasheet.