لمحة عامة عن مسحوق عالي النقاء

في عالم علوم المواد، تُعد المساحيق عالية النقاء اللبنات الأساسية للتصنيع والتكنولوجيا المتقدمة. هذه الجسيمات المطحونة بدقة - غالبًا ما تكون معادن أو سبائك معدنية - تحظى بتقدير كبير لنقائها الاستثنائي وحجم الجسيمات المتسق والتركيب الكيميائي الدقيق. ولكن ما هو المسحوق عالي النقاء بالضبط؟ وما سبب أهميتها؟ وما هي الأنواع المختلفة التي يمكنك العثور عليها؟

إذا كنت تغوص في عالم المساحيق عالية النقاء، فمن الضروري أن تفهم خصوصيات وعموميات هذه المواد المتخصصة. في هذا الدليل، سنستكشف كل شيء بدءًا من تركيبة هذه المساحيق وخصائصها إلى تطبيقاتها ومورديها وكيفية اختيار الأفضل لاحتياجاتك.

ما هو المسحوق عالي النقاء؟

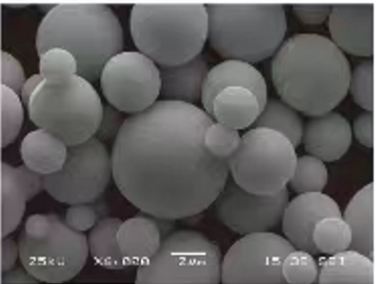

المساحيق عالية النقاء هي مواد مقسمة بدقة، وعادةً ما تكون معادن أو سبائك، تتميز بمستوى نقاء 99.9% أو أعلى. هذه المساحيق ضرورية في الصناعات التي يمكن أن تؤدي فيها أدنى شوائب إلى مشاكل كبيرة في الأداء أو أعطال، مثل الإلكترونيات والفضاء والمستحضرات الصيدلانية.

تخيل أنك تحاول خبز كعكة بدقيق يحتوي على قطع صغيرة من الرمل. لن تكون النتيجة كما تتوقع، أليس كذلك؟ وينطبق المنطق نفسه على عمليات التصنيع التي تستخدم مساحيق المعادن - فالنقاء أمر بالغ الأهمية.

تركيبة المسحوق عالي النقاء

تأتي المساحيق عالية النقاء في تركيبات مختلفة اعتمادًا على المعدن أو السبيكة المعنية. ولكل نوع خصائصه الفريدة، مما يجعله مناسبًا لتطبيقات محددة. فيما يلي جدول يوضح بالتفصيل بعض مساحيق المعادن عالية النقاء الأكثر شيوعًا وتركيباتها وخصائصها الرئيسية.

| المسحوق المعدني | التركيب | مستوى النقاء | الخصائص الرئيسية |

|---|---|---|---|

| مسحوق الألومنيوم | آل (99.9% أو أعلى) | 99.9% | خفيفة الوزن وموصلية عالية ومقاومة للتآكل |

| مسحوق النحاس | النحاس (99.99% أو أعلى) | 99.99% | توصيل كهربائي ممتاز، مطيل |

| مسحوق التيتانيوم | Ti (99.5% أو أعلى) | 99.5% | نسبة عالية من القوة إلى الوزن ومقاومة للتآكل |

| مسحوق الفضة | Ag (99.99% أو أعلى) | 99.99% | موصلية حرارية وكهربائية عالية |

| مسحوق الذهب | الذهب الأصفر (99.99% أو أعلى) | 99.99% | مقاومة عالية للتآكل، وموصلية ممتازة |

| مسحوق الحديد | الحديد (99.9% أو أعلى) | 99.9% | مغناطيسية وسهلة الخلط مع معادن أخرى |

| مسحوق النيكل | ني (99.8% أو أعلى) | 99.8% | مقاومة عالية للأكسدة والتآكل |

| مسحوق الزنك | الزنك (99.9% أو أعلى) | 99.9% | مقاوم للتآكل، يستخدم في الجلفنة |

| مسحوق البلاتين | Pt (99.95% أو أعلى) | 99.95% | مقاومة شديدة للتآكل، وخصائص تحفيزية شديدة المقاومة للتآكل |

| مسحوق البلاديوم | Pd (99.95% أو أعلى) | 99.95% | خواص تحفيزية ممتازة، مقاومة للتآكل |

خصائص مسحوق عالي النقاء

خصائص المساحيق عالية النقاء هي ما يجعلها ذات قيمة كبيرة في مختلف الصناعات. وفيما يلي بعض أهم هذه الخصائص:

- النقاء: تضمن مستويات النقاء العالية (99.9% وما فوق) وجود الحد الأدنى من الشوائب التي يمكن أن تؤثر على أداء المادة.

- حجم الجسيمات وتوزيعها: يعد اتساق حجم الجسيمات وتوزيعها أمرًا بالغ الأهمية لتحقيق الاتساق في المنتج النهائي.

- الاستقرار الكيميائي: هذه المساحيق مستقرة كيميائيًا، مما يعني أنها لن تتفاعل بسهولة مع المواد الأخرى، وهو أمر حيوي في البيئات التي يمكن أن يؤدي فيها التفاعل إلى مخاوف تتعلق بالسلامة أو فشل المنتج.

- قابلية التدفق: تُعد قدرة المسحوق على التدفق بسلاسة أمرًا ضروريًا في عمليات التصنيع مثل الطباعة ثلاثية الأبعاد أو تعدين المسحوق.

- الكثافة: يمكن أن تؤثر كثافة المسحوق على خصائص المنتج النهائي، مثل القوة والمتانة.

أنواع المساحيق المعدنية عالية النقاء

دعونا نتعمق أكثر في مساحيق معدنية محددة عالية النقاء، ونفحص خصائصها الفريدة وتطبيقاتها وسبب تميزها.

1. مسحوق الألومنيوم

- الخصائص: يشتهر مسحوق الألومنيوم بخفة وزنه وتوصيله الكهربائي العالي. كما أنه مقاوم للتآكل، مما يجعله مثاليًا للتطبيقات في صناعات الطيران والسيارات.

- التطبيقات: يستخدم على نطاق واسع في إنتاج الدهانات والمتفجرات وكمكون في طلاء المعادن.

2. مسحوق النحاس

- الخصائص: بفضل التوصيل الكهربائي الممتاز والليونة الممتازة، يُعد مسحوق النحاس مادة أساسية في الإلكترونيات.

- التطبيقات: يستخدم في إنتاج المكونات الكهربائية والأحبار الموصلة والطلاءات.

3. مسحوق التيتانيوم

- الخصائص: يوفر مسحوق التيتانيوم نسبة عالية من القوة إلى الوزن وهو مقاوم للتآكل، مما يجعله مثاليًا للغرسات الطبية والمكونات الفضائية.

- التطبيقات: يشيع استخدامها في الطباعة ثلاثية الأبعاد والفضاء والمجالات الطبية الحيوية.

4. مسحوق الفضة

- الخصائص: مسحوق الفضة عالي التوصيل وله خصائص مضادة للميكروبات، مما يجعله ذا قيمة في الإلكترونيات والتطبيقات الطبية.

- التطبيقات: تستخدم في المعاجين الموصلة والخلايا الشمسية والطلاءات المضادة للميكروبات.

5. مسحوق الذهب

- الخصائص: مسحوق الذهب مقاوم للغاية للتآكل ويتمتع بتوصيل كهربائي ممتاز، مما يجعله مثاليًا للإلكترونيات المتطورة والأجهزة الطبية.

- التطبيقات: تستخدم في الإلكترونيات والمجوهرات وكمحفز في التفاعلات الكيميائية.

6. مسحوق الحديد

- الخصائص: مسحوق الحديد مغناطيسي ويسهل خلطه، مما يسمح بمجموعة واسعة من التطبيقات في التصنيع والمعادن.

- التطبيقات: يستخدم في قطع غيار السيارات والمواد المغناطيسية وكمحفز في التفاعلات الكيميائية.

7. مسحوق النيكل

- الخصائص: مسحوق النيكل شديد المقاومة للأكسدة والتآكل، مما يجعله مناسبًا للبيئات القاسية.

- التطبيقات: يستخدم في البطاريات والسبائك الفائقة، وكمحفز في عمليات الهدرجة.

8. مسحوق الزنك

- الخصائص: يشتهر مسحوق الزنك في المقام الأول بمقاومته للتآكل وغالبًا ما يستخدم في الطلاءات الواقية.

- التطبيقات: يستخدم على نطاق واسع في الجلفنة، كعامل مضاد للتآكل، وفي إنتاج البطاريات.

9. مسحوق البلاتين

- الخصائص: مسحوق البلاتين مقاوم للتآكل بشكل لا يصدق ويمتلك خصائص تحفيزية ممتازة، مما يجعله ذا قيمة في كل من المجالات الصناعية والطبية.

- التطبيقات: يستخدم في المحولات الحفازة وخلايا الوقود وكمحفز في التفاعلات الكيميائية المختلفة.

10. مسحوق البلاديوم

- الخصائص: يُعرف مسحوق البلاديوم بخصائصه الحفازة ومقاومته للتلطيخ، مما يجعله مثاليًا لمجموعة متنوعة من العمليات الكيميائية.

- التطبيقات: يشيع استخدامها في الإلكترونيات والمحولات الحفازة وتنقية الهيدروجين.

تطبيقات المسحوق عالي النقاء

تُستخدم المساحيق عالية النقاء في مجموعة متنوعة من الصناعات، ويتطلب كل منها خصائص مختلفة حسب التطبيق. فيما يلي تفصيل لكيفية استخدام هذه المساحيق في مختلف المجالات:

| الصناعة | التطبيقات الشائعة | أمثلة على المساحيق المستخدمة |

|---|---|---|

| الإلكترونيات | الأحبار الموصلة ولوحات الدوائر المطبوعة (PCBs) وأشباه الموصلات | النحاس والفضة والذهب والبلاديوم والنحاس والفضة والذهب والبلاديوم |

| الفضاء | المكونات خفيفة الوزن، والطلاءات، والأجزاء المطبوعة ثلاثية الأبعاد | الألومنيوم، والتيتانيوم، والنيكل |

| السيارات | مكونات المحرك، والمحولات الحفازة، وأقطاب البطارية الكهربائية | البلاتين، والبلاديوم، والبلاديوم، والزنك، والحديد |

| الطبية | الغرسات والأطراف الصناعية والطلاءات المضادة للميكروبات | التيتانيوم، والفضة، والذهب، والبلاتين |

| الطاقة | خلايا الوقود، والألواح الشمسية، والبطاريات | بلاتين، نيكل، نيكل، نحاس، فضة |

| المواد الكيميائية | المحفزات، عمليات الهدرجة | البلاديوم، والبلاتين، والنيكل، والبلاتين، والنيكل |

| المجوهرات | المجوهرات الراقية والطلاءات المقاومة للتآكل | الذهب، والفضة، والبلاتين |

المواصفات والأحجام والدرجات والمعايير

فهم مواصفات وأحجام ودرجات مساحيق عالية النقاء أمر بالغ الأهمية لاختيار المادة المناسبة لاحتياجاتك. وفيما يلي جدول يوضح المواصفات الرئيسية لكل مسحوق معدني.

| المسحوق المعدني | نطاق حجم الجسيمات (ميكرومتر) | درجة النقاء | المعايير |

|---|---|---|---|

| مسحوق الألومنيوم | 1 – 100 | 99.9% (عالي النقاء) | أستم B928/B928M-15 |

| مسحوق النحاس | 0.5 – 75 | 99.991.99% (نقاء فائق النقاء) | ASTM B170 |

| مسحوق التيتانيوم | 5 – 45 | 99.5% (عالي النقاء) | أستم F67، أستم F136 |

| مسحوق الفضة | 1 – 50 | 99.991.99% (نقاء فائق النقاء) | ASTM B832 |

| مسحوق الذهب | 1 – 10 | 99.991.99% (نقاء فائق النقاء) | ASTM B488 |

| مسحوق الحديد | 10 – 150 | 99.9% (عالي النقاء) | astm A575، astm A876 |

| مسحوق النيكل | 5 – 20 | 99.8% (عالي النقاء) | ASTM B330 |

| مسحوق الزنك | 1 – 50 | 99.9% (عالي النقاء) | ASTM B822 |

| مسحوق البلاتين | 1 – 25 | 99.951.95% (فائق النقاء) | ASTM B562 |

| مسحوق البلاديوم | 0.5 – 5 | 99.951.95% (فائق النقاء) | ASTM B563 |

تفاصيل الموردين والتسعير للمساحيق عالية النقاء

عندما يتعلق الأمر بالحصول على مساحيق عالية النقاء، يقدم العديد من الموردين ذوي السمعة الطيبة مجموعة من المنتجات. يمكن أن تختلف الأسعار بشكل كبير حسب النقاء وحجم الجسيمات والكمية المشتراة.

| المورد | المساحيق المتوفرة | نطاق السعر (لكل كيلوغرام) | الموقع |

|---|---|---|---|

| العناصر الأمريكية | ألومنيوم، نحاس، نحاس، تيتانيوم، نيكل | $150 – $800 | الولايات المتحدة الأمريكية |

| شركة أدفانسد ماتيريالز إنك | الفضة، والذهب، والبلاتين، والبلاديوم، والذهب، والبلاتين، والبلاديوم | $500 – $2,000 | الولايات المتحدة الأمريكية |

| جودفيلو | الزنك والحديد والنحاس والنيكل والزنك والنحاس والنيكل | $100 – $600 | المملكة المتحدة |

| ألفا أيزار | التيتانيوم والألومنيوم والذهب والفضة | $200 – $1,500 | الولايات المتحدة الأمريكية |

| مساحيق المعادن بالولايات المتحدة الأمريكية | النحاس، الزنك، النيكل، النيكل، البلاديوم | $250 – $1,200 | الولايات المتحدة الأمريكية |

مقارنة المساحيق عالية النقاء: المزايا والقيود

غالبًا ما يتضمن اختيار المسحوق المناسب عالي النقاء مقارنة مزايا وقيود كل خيار. إليك جدول يفصل هذه العوامل لكل مسحوق معدني تمت مناقشته.

| المسحوق المعدني | مزايا | محددات |

|---|---|---|

| مسحوق الألومنيوم | خفيفة الوزن، ومقاومة للتآكل، وموصلة للتيار الكهربائي | يتأكسد بسهولة، درجة انصهار أقل |

| مسحوق النحاس | توصيل ممتاز، مطاطي | عرضة للأكسدة، وباهظة الثمن نسبياً |

| مسحوق التيتانيوم | نسبة قوة إلى وزن عالية، متوافقة حيوياً | باهظة الثمن وصعبة المعالجة |

| مسحوق الفضة | موصلية فائقة وخصائص مضادة للميكروبات | باهظ الثمن، يبهت بمرور الوقت |

| مسحوق الذهب | موصلية ممتازة، ومقاومة للتآكل | باهظة الثمن وثقيلة للغاية |

| مسحوق الحديد | مغناطيسية، سهلة الخلط | معرضة للصدأ، ثقيلة |

| مسحوق النيكل | مقاومة للتآكل، ودرجة انصهار عالية | ردود الفعل التحسسية في بعض التطبيقات |

| مسحوق الزنك | مقاومة للتآكل وبأسعار معقولة | درجة انصهار منخفضة، ليست قوية جدًا |

| مسحوق البلاتين | مقاومة شديدة للتآكل، وخصائص تحفيزية ممتازة | باهظة الثمن وثقيلة للغاية |

| مسحوق البلاديوم | كفاءة تحفيزية عالية، مقاومة للتشويه | باهظة الثمن للغاية، وتوافرها محدود |

أسئلة وأجوبة

فيما يلي بعض الأسئلة الشائعة حول المساحيق عالية النقاء، إلى جانب إجابات مفصلة.

| سؤال | الإجابة |

|---|---|

| ما الذي يحدد المسحوق عالي النقاء؟ | تحتوي المساحيق عالية النقاء على مستوى نقاء 99.9% أو أعلى، مما يضمن الحد الأدنى من الشوائب. |

| ما أهمية النقاء في مساحيق المعادن؟ | النقاء أمر بالغ الأهمية لأن الشوائب يمكن أن تؤثر على أداء المنتج النهائي وتوصيله وسلامته. |

| ما هي الصناعات التي تستخدم مساحيق عالية النقاء؟ | تُستخدم المساحيق عالية النقاء في الإلكترونيات والفضاء والسيارات والصناعات الطبية والطبية والطاقة والصناعات الكيميائية. |

| كيف يمكنني اختيار المسحوق المناسب عالي النقاء؟ | ضع في اعتبارك الاستخدام المحدد والخصائص المطلوبة والميزانية لاختيار المسحوق المناسب. |

| ما هي التحديات في التعامل مع المساحيق عالية النقاء؟ | قد تكون المناولة صعبة بسبب حجم الجسيمات الدقيقة والتفاعلية المحتملة. تعتبر ممارسات التخزين والمناولة السليمة ضرورية. |

| هل المساحيق عالية النقاء باهظة الثمن؟ | نعم، تميل المساحيق عالية النقاء إلى أن تكون أكثر تكلفة بسبب عملية التصنيع المعقدة والحاجة إلى مواد عالية الجودة. |

| كيف يتم إنتاج مساحيق عالية النقاء؟ | وعادةً ما يتم إنتاجها من خلال عمليات مثل الانحلال والاختزال الكيميائي والتحليل الكهربائي لضمان درجة نقاء واتساق عالية. |

| هل يمكن تخصيص مساحيق عالية النقاء؟ | نعم، يقدم العديد من الموردين خيارات تخصيص من حيث حجم الجسيمات وتوزيعها ومستويات النقاء. |

| ما هي المخاوف البيئية المتعلقة بالمساحيق عالية النقاء؟ | يجب إدارة إنتاج المساحيق عالية النقاء والتخلص منها بعناية لتجنب التلوث البيئي. ويمكن أن تخفف إعادة التدوير والتوريد المسؤول من هذه المخاوف. |

| هل هناك أي بدائل للمساحيق عالية النقاء؟ | واعتمادًا على التطبيق، يمكن استخدام مساحيق أقل نقاءً أو مواد مختلفة، ولكنها قد لا تقدم نفس مستوى الأداء. |

خاتمة

مساحيق عالية النقاء هي الأبطال المجهولون في التصنيع والتكنولوجيا المتقدمة. وبفضل نقاوتها الاستثنائية وخصائصها الفريدة، تلعب هذه المساحيق دورًا حاسمًا في صناعات تتراوح من الفضاء إلى الإلكترونيات. وسواء كنت تتطلع إلى تحسين أداء منتج ما أو تطوير تقنيات متطورة، فإن فهم الفروق الدقيقة للمساحيق عالية النقاء أمر ضروري. من خلال اختيار المسحوق المناسب لتطبيقك، يمكنك ضمان الأداء الأمثل والموثوقية والكفاءة في مشاريعك.