1. Introduction: What Is 420 Powder and Why It Matters in PM

420 powder refers to a type of stainless steel powder, specifically martensitic stainless steel, used in powder metallurgy (PM) applications that require high hardness and moderate corrosion resistance. This grade is a popular choice for manufacturing wear-resistant components, surgical instruments, and industrial parts via sintering or additive manufacturing processes.

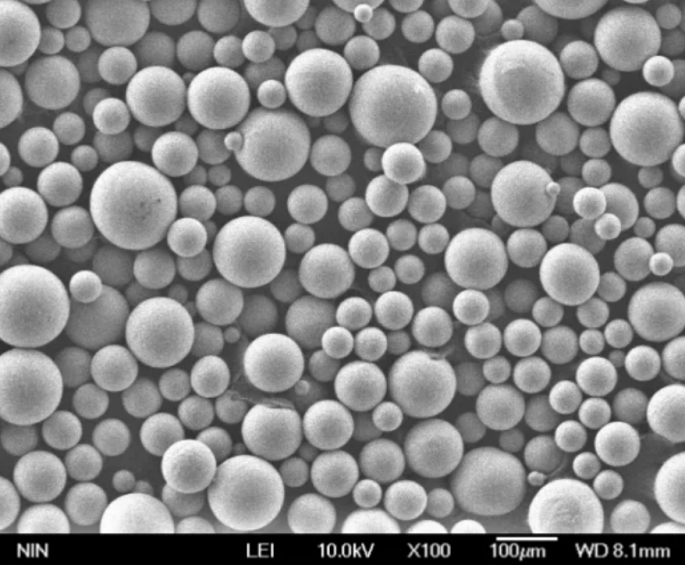

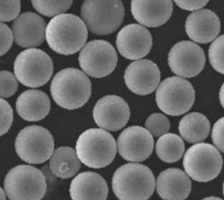

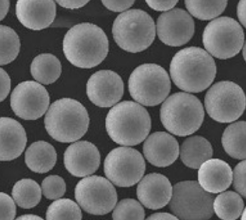

In the context of powder metallurgy, 420 stainless steel powder is typically produced using either water atomization or gas atomization methods, making it suitable for a range of fabrication technologies, including metal injection molding (MIM) and press-and-sinter techniques.

لماذا يهم مشتري الشركات:

- Consistency & Purity: Reliable composition for high-performance parts

- قابلية التوسع: Ideal for mass production in automotive, medical, and tooling sectors

- تعدد الاستخدامات: Compatible with multiple manufacturing methods

High-Intent Keywords Integrated:

420 stainless steel powder, PM 420 powder, martensitic PM powder, 420 steel for sintering, wholesale stainless PM powder, 420 powder supplier

2. Industrial Applications of PM 420 Stainless Steel Powder

420 PM powder is widely used across several B2B-focused industries due to its unique combination of hardness, corrosion resistance, and machinability.

التطبيقات الشائعة:

| الصناعة | طلب | الوصف |

|---|---|---|

| السيارات | Transmission parts, gears | Wear-resistant components under cyclic load |

| الطبية | Surgical tools, dental instruments | Sterilizable and high-hardness parts |

| الآلات الصناعية | Blades, valves | Long-life components for abrasive environments |

| الفضاء | Structural brackets, bushings | High-strength and corrosion-resistant parts |

| السلع الاستهلاكية | Cutlery, tools | Aesthetic and durable end-use products |

Manufacturing Methods for 420 Powder-Based Components:

- Press & Sinter: Cost-effective for large-scale production

- قولبة حقن المعادن (MIM): Ideal for small, complex parts

- التصنيع الإضافي (AM): Custom, on-demand fabrication

Pro-tip for Buyers:

For high-volume orders, ensure the powder particle size distribution and flowability meet your equipment’s specs to avoid yield loss.

3. Key Properties and Use Cases of 420 PM Powder

420 powder offers a unique set of mechanical and physical properties that make it a go-to material for functional and durable PM parts.

Key Properties of 420 PM Powder:

| الممتلكات | القيمة | الملاحظات |

|---|---|---|

| الصلابة | Up to 50 HRC (after heat treatment) | مقاومة ممتازة للتآكل |

| قوة الشد | 700–900 MPa | Suitable for load-bearing applications |

| مقاومة التآكل | معتدل | Better than carbon steel, lower than austenitic SS |

| الكثافة | ~7.5 g/cm³ (sintered) | High-density sintered components |

| قابلية التصنيع | جيد | Improved with proper additives |

حالات الاستخدام:

- Tooling Parts: Where edge retention is critical

- Wear Components: Such as bushings and bearings

- الأجهزة الطبية: Especially where sterilization is required

- Injection Mold Inserts: High precision and strength

To explore a wide range of stainless and alloy-based powders including 420, visit the صفحة منتج مسحوق مسحوق PM.

4. Market Trends and Demand Growth in Stainless PM Powders

The global powder metallurgy (PM) market is experiencing rapid growth, driven by the automotive, medical, and additive manufacturing sectors. Within this market, 420 stainless steel powder is gaining traction because of its exceptional mechanical properties and compatibility with both traditional and advanced PM processes.

Key Market Trends:

- Shift Toward High-Performance Alloys: Industries are replacing carbon steels with martensitic stainless steels like 420 for better wear resistance and corrosion performance.

- Additive Manufacturing Boom: The rise of طباعة ثلاثية الأبعاد is increasing demand for AM-compatible powders like gas-atomized 420 powder.

- Medical Device Growth: The global push for minimally invasive surgical tools is driving demand for high-hardness, corrosion-resistant powders.

- Localization of Supply Chains: Manufacturers are increasingly sourcing from regional suppliers to reduce lead times and cut logistics costs.

Market Data Snapshot:

| المنطقة | CAGR (2023–2029) | المحركات الرئيسية |

|---|---|---|

| أمريكا الشمالية | 6.5% | Automotive, aerospace, defense |

| أوروبا | 5.8% | Medical devices, green tech |

| آسيا والمحيط الهادئ | 7.3% | Manufacturing outsourcing, metal AM adoption |

| الصين | 8.1% | Domestic PM production and exports |

High-Intent Keywords Used:

420 powder market growth, stainless PM powder trends, additive manufacturing powder suppliers, medical-grade PM powder, 420 powder for 3D printing

5. Choosing the Right 420 Powder Supplier: Key Factors

For B2B buyers, selecting the right 420 powder supplier is critical to ensuring consistent part quality, cost efficiency, and timely delivery. Here are the top criteria to consider:

What to Look for in a 420 Powder Supplier:

| المعايير | ما أهمية ذلك | What to Ask |

|---|---|---|

| طريقة إنتاج المسحوق | Affects purity and flowability | Water- or gas-atomized? |

| الشهادات | Guarantees compliance and traceability | ISO, ASTM, RoHS? |

| خيارات التخصيص | Tailored to your process needs | Can they adjust particle size or composition? |

| الحد الأدنى لكمية الطلب والمهلة الزمنية | Impacts your inventory and production planning | What’s the standard MOQ? Lead time? |

| الدعم الفني | Critical for process optimization | Do they offer engineering consultation? |

العلامات الحمراء التي يجب تجنبها:

- Inconsistent batch quality

- Lack of traceability

- Poor customer service or support

- No documentation or technical data sheets (TDS)

Expert Tip: Always request a technical data sheet and sample batch before committing to large orders.

6. Top Global and Chinese Suppliers of 420 PM Powder

Below are some of the top-performing suppliers of 420 stainless steel powder, trusted by manufacturers, distributors, and e-commerce sellers sourcing PM materials in bulk.

كبار الموردين العالميين

| شركة | الموقع | القوة |

|---|---|---|

| هوغاناس إيه بي | السويد | الشركة الرائدة عالميًا في مساحيق PM |

| GKN Hoeganaes | الولايات المتحدة الأمريكية | Large-scale production for auto and industrial sectors |

| ساندفيك أوسبري | المملكة المتحدة | High-quality gas atomized stainless powders |

كبار الموردين الصينيين

| شركة | التخصص | Unique Offering |

|---|---|---|

| شركة شنغهاي تروير تكنولوجي المحدودة (Shanghai Truer Technology Co., Ltd.) | Full-spectrum PM powders | Custom 420 powder production, additive services, and integrated 3D powder solutions |

| مسحوق CNPC | Stainless steel and alloy powders | Gas atomized options |

| Changsha Hunan Powder | PM and metal injection molding powders | Competitive pricing for domestic market |

Shanghai Truer Technology stands out for their integrated solution: they not only manufacture 420 PM powder but also provide custom powder atomization equipment and additive manufacturing services. Since 2009, Truer has built solid credibility in the Chinese PM industry and internationally. They’ve expanded their additive division in 2019 to meet growing global demand.

👉 Learn more about Truer’s commitment to quality and innovation on their صفحة من نحن.

Why Distributors Prefer Truer:

- Flexible order quantities

- Custom composition and particle size options

- Full technical support from experienced PM engineers

- Competitive pricing without compromising quality

- Fast shipping and global logistics support

7. Why More Distributors Are Switching to Direct Factory Supply

Distributors and wholesale buyers are increasingly bypassing traditional middlemen to source directly from powder manufacturers like Shanghai Truer Technology. Here’s why:

Benefits of Direct-from-Factory Sourcing:

- Lower Costs: Eliminate distributor mark-ups

- Better Customization: Work directly with engineers on specs

- دوران أسرع: Reduce delays from middle-tier logistics

- Quality Assurance: Transparent QC processes and traceability

- Bulk Discounts: Volume-based pricing and flexible MoQs

Case Study: Switching to Direct Supply

| نوع المشتري | Before | After Switching to Truer |

|---|---|---|

| Automotive Parts Manufacturer | 3-week lead time, inconsistent batches | 1-week lead time, consistent quality |

| Medical Device OEM | Limited customization | Tailored particle size and lubricants |

| Industrial Distributor | High unit cost | 18% cost savings on bulk orders |

For example, one of Truer’s clients in the EU region reported a 20% increase in production efficiency simply by switching to Truer’s gas atomized 420 powder with optimized flowability for their MIM process.

Looking for a reliable, factory-direct source for stainless PM powder? Connect with the Truer team via their صفحة الاتصال.

8. How to Order Wholesale 420 Powder from Shanghai Truer

If you’re a distributor, manufacturer, or e-commerce B2B seller looking to secure a stable supply of 420 stainless steel powder, Shanghai Truer Technology offers a seamless and scalable ordering process designed for enterprise buyers.

Here’s how to get started:

عملية الطلب خطوة بخطوة:

- الاستفسار الأولي

- قم بزيارة صفحة منتج مسحوق مسحوق PM to view specifications.

- Use the contact form or email to request a quote.

- Specify powder type (e.g., 420), quantity, particle size range, and application.

- الاستشارة الفنية

- Truer’s engineering team will review your requirements.

- Recommendations are made based on sintering tech, lubricant additives, or flowability needs.

- Sample testing support is offered for validation.

- Quotation and Lead Time

- Receive a formal quotation with pricing tiers for bulk orders.

- Typical lead times:

- In-stock powders: 5–7 working days

- Custom blends: 10–15 working days

- تأكيد الطلب

- Confirm order specifications and sign purchase agreement.

- Payment via TT (Telegraphic Transfer), LC (Letter of Credit), or other B2B-verified methods.

- Production and Quality Control

- Powders are produced using either water atomization or gas atomization.

- Each batch is tested for:

- توزيع حجم الجسيمات

- الكثافة الظاهرة

- معدل التدفق

- التركيب الكيميائي

- A Certificate of Analysis (CoA) is included in every shipment.

- التعبئة والتغليف والخدمات اللوجستية

- Standard packaging: vacuum-sealed 25kg or 50kg drums

- Custom packaging available

- Global shipping coordinated via air or sea freight

- دعم ما بعد البيع

- Technical assistance for powder application

- Re-order reminders and batch consistency tracking

Payment & Delivery Snapshot:

| البند | الخيارات |

|---|---|

| موك | 100 kg (standard); lower for samples |

| المهلة الزمنية | 5–15 days based on spec |

| الشحن | FOB Shanghai, EXW, CIF available |

| شروط الدفع | TT, LC, PayPal (for samples) |

Need help choosing the right spec for your process? Reach out to Truer’s sales engineers via their صفحة الاتصال.

9. FAQs: Buying 420 Powder in the B2B Market

Q1: What is the typical particle size range available for 420 PM powder?

A: Shanghai Truer offers particle sizes ranging from −45μm to −150μm, depending on the application. For MIM applications, finer powders (15–45μm) are recommended, whereas press-and-sinter processes may use coarser grades.

Q2: Is the powder gas atomized or water atomized?

A: Both options are available:

- Gas atomized: For high sphericity, flowability, and AM/MIM applications

- Water atomized: Cost-effective for press-and-sinter and structural components

Q3: Can I request custom additives or lubricants?

A: Yes. Truer provides custom additive solutions like:

- Lube-W, SUW-5000B, SUW-8000 for improved compaction

- SME-100 (sulfur-free cutting agent)

- QHP-330 graphite و إضافات مغناطيسية ناعمة QH-150

Q4: Does Truer export internationally?

A: Absolutely. Truer has clients in Europe, North America, Southeast Asia, and the Middle East. The company supports all standard export documentation and compliance.

Q5: How is quality ensured?

A: Every production batch is tested in-house using:

- Laser diffraction particle size analysis

- Spectrometer for chemical composition

- Flowability and apparent density testing

Certificates of Analysis (CoA) and Material Safety Data Sheets (MSDS) are provided with every shipment.

For more information on how Truer ensures consistent powder quality, visit their صفحة من نحن.

Final Recommendations for Wholesale Buyers

If you’re sourcing stainless steel powders for industrial-scale production, selecting the right 420 powder supplier can directly impact your product performance, production efficiency, and bottom line. Shanghai Truer Technology offers a reliable, customizable, and globally trusted solution for B2B clients.

Why Choose Shanghai Truer Technology:

✅ Over a decade of experience in powder metallurgy

✅ Complete range of PM stainless steel powders, including 420

✅ Customization options for particle size, additives, and packaging

✅ ISO-certified production and rigorous QC

✅ Responsive technical and after-sales support

Ready to streamline your 420 powder sourcing? Browse the full range of stainless and alloy powders on the صفحة منتج مسحوق مسحوق PM أو Contact Truer Now for a custom quote.