Introduction: Why FeCrBSi Powder Matters in Modern Manufacturing

FeCrBSi powder, a specialized alloy composed primarily of iron (Fe), chromium (Cr), boron (B), and silicon (Si), plays a critical role in modern manufacturing — particularly in thermal spray coatings, additive manufacturing, and wear-resistant applications. This powder is widely recognized for its exceptional hardness, corrosion resistance, and wear protection, making it an essential raw material for B2B buyers in aerospace, automotive, machinery, and energy sectors.

Why B2B Buyers Are Interested in FeCrBSi Powder

- High-performance coatings: FeCrBSi powder is frequently used in flame spray and high-velocity oxygen fuel (HVOF) coatings for industrial parts.

- المتانة: Its high hardness and wear resistance extend the life of critical components, reducing downtime and replacement costs.

- مقاومة التآكل: Especially useful in marine and chemical processing industries.

Common Industries Using FeCrBSi Powder

| الصناعة | مثال على التطبيق | المزايا |

|---|---|---|

| الفضاء | Landing gear and turbine parts | مقاومة عالية للتآكل |

| السيارات | Brake discs, engine parts | Enhanced performance under heat |

| النفط والغاز | Pipelines and valves | مقاومة التآكل في البيئات القاسية |

| Manufacturing Equipment | Shafts, rollers, dies | Longer service life and reliability |

Industrial Applications of FeCrBSi Powder

FeCrBSi powder is a multi-functional material that provides surface enhancement and structural improvement for a wide array of industrial parts. It is most commonly used in thermal spray processes, including flame spraying and HVOF, as well as in laser cladding and 3D printing.

التطبيقات الصناعية الرئيسية

- طلاءات الرش الحراري

- Used in HVOF and plasma spraying techniques to coat parts exposed to wear and corrosion.

- Forms a dense, adherent coating that enhances component life.

- الكسوة بالليزر

- FeCrBSi powder is fused onto metal surfaces using high-power lasers.

- Improves mechanical strength and protects against corrosion.

- التصنيع الإضافي (AM)

- Used in Directed Energy Deposition (DED) and binder jetting methods.

- Allows for the fabrication of complex parts with superior wear properties.

- Repair and Rebuild of Industrial Components

- Suitable for rebuilding worn turbine blades, engine parts, and hydraulic cylinders.

- Cost-effective alternative to replacing entire components.

Advantages in B2B Use

- Lower Total Cost of Ownership: Extending the lifespan of high-value machinery parts.

- Improved Operational Efficiency: Fewer breakdowns and maintenance cycles.

- Customization for OEMs: Powders can be tailored to meet specific density, flowability, and particle size distribution criteria.

Properties and Benefits of FeCrBSi Powder

Understanding the physical and chemical properties of FeCrBSi powder is crucial for B2B buyers aiming to enhance their manufacturing quality and reduce costs.

التركيب الكيميائي

The typical composition of FeCrBSi powder includes:

| العنصر | نطاق النسبة المئوية |

|---|---|

| الحديد | الرصيد |

| سجل تجاري | 10–20% |

| ب | 1–3% |

| سي | 2–5% |

| ج | Optional <1% |

الخصائص الفيزيائية

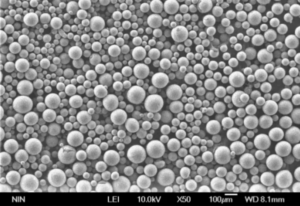

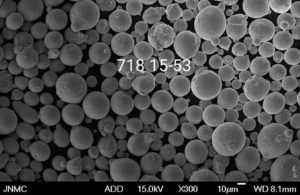

- توزيع حجم الجسيمات: Customizable, typically 15–45 µm or 45–106 µm depending on application.

- مورفولوجيا المسحوق: Spherical or irregular, optimized for flowability in AM or thermal spray applications.

- الكثافة: 6.8–7.2 g/cm³

- الصلابة: Up to 65 HRC after processing

فوائد الأداء

- Excellent Bond Strength: Ensures durability of coatings under mechanical stress.

- High Thermal Stability: Maintains performance even under extreme heat.

- مقاومة الأكسدة: Protects components in high-temperature or corrosive environments.

Comparison with Other Hardfacing Powders

| الممتلكات | FeCrBSi | WC-Co | نيكربسي |

|---|---|---|---|

| كفاءة التكلفة | عالية | متوسط | عالية |

| الصلابة | عالية جداً | الأعلى | متوسط |

| مقاومة التآكل | عالية | متوسط | عالية |

| قابلية التصنيع | معتدل | منخفضة | عالية |

| Thermal Spray Friendly | نعم | لا يوجد | نعم |

FeCrBSi powder offers an ideal balance between performance and cost, making it attractive for B2B purchasers sourcing materials for bulk manufacturing or OEM integration.

For those interested in a wide selection of PM powders including FeCrBSi, Shanghai Truer Technology offers a robust catalog of حلول تعدين المساحيق tailored for industrial use.

Market Demand and Global Trends for FeCrBSi Powder

The global demand for FeCrBSi powder is steadily increasing due to its critical role in surface engineering and advanced manufacturing technologies. As industries like aerospace, automotive, and energy push for more durable and efficient materials, FeCrBSi has emerged as a key material in the coatings and wear-protection segment.

Global Market Drivers

- Growth of Thermal Spray and Laser Cladding Applications

- Expansion of thermal spray coatings in aerospace and oil & gas sectors is accelerating demand.

- Laser cladding technologies, which utilize FeCrBSi for wear resistance, are being adopted across manufacturing facilities globally.

- Additive Manufacturing Boom

- As 3D printing of metal components becomes mainstream in industrial production, FeCrBSi powder is gaining traction in Directed Energy Deposition (DED) and other AM techniques for functional parts.

- Infrastructure Investment and Industrial Automation

- Increased investment in infrastructure and automation, especially in Asia-Pacific and Europe, is boosting demand for wear-resistant coatings and surface-enhancing materials.

Market Size and Forecast

| السنة | Estimated Global Market for FeCrBSi Powder (USD Million) |

|---|---|

| 2021 | $120M |

| 2023 | $165M |

| 2026 (Projected) | $250M |

الاتجاهات الإقليمية

- آسيا والمحيط الهادئ: Rapid industrialization in China, India, and Southeast Asia is driving the highest consumption.

- أمريكا الشمالية: Strong adoption in aerospace and defense sectors.

- أوروبا: High demand in automotive OEMs and industrial equipment manufacturers.

Key Trends Impacting B2B Buyers

- التخصيص: OEMs and Tier 1 suppliers are demanding powders customized to their machinery and coating systems.

- الاستدامة: Recyclable and low-emission powder production methods are increasingly valued.

- Turnkey Solutions: Buyers prefer suppliers who offer not only powder but also application guidance and integrated services.

How to Select a Reliable FeCrBSi Powder Supplier

Choosing the right FeCrBSi powder supplier is crucial for manufacturers looking to maintain consistency, quality, and cost-effectiveness in their production lines. Below are key evaluation criteria for wholesale buyers, distributors, and OEMs.

Selection Criteria for B2B Buyers

| العامل | ما أهمية ذلك | ما الذي تبحث عنه |

|---|---|---|

| جودة المسحوق | Ensures performance in coating or AM applications | ISO-certified production, consistent particle sizes |

| موثوقية التسليم | Avoids production delays and inventory shortages | Local warehousing, strong logistics network |

| إمكانيات التخصيص | Tailors powder for specific thermal spray or AM systems | Capability to alter morphology, PSD, and chemistry |

| الدعم الفني | Helps optimize usage and performance | Access to engineers, documentation, application data |

| الشهادات | Meets industry/regulatory standards | ISO 9001, REACH, RoHS, etc. |

Questions to Ask Potential Suppliers

- Can you provide technical data sheets (TDS) and material safety data sheets (MSDS)?

- Do you offer trial samples for performance testing?

- What is your lead time for bulk orders?

- Can you support custom particle size distribution or additive formulations?

- Are you able to supply in tonnage quantities globally?

A reliable supplier should act not only as a material source but as a strategic partner in your supply chain.

Top Global Suppliers of FeCrBSi Powder

Finding the right wholesale supplier with international credibility and technical expertise is essential for B2B buyers. Below are some of the top global players in the FeCrBSi powder market.

Leading FeCrBSi Powder Suppliers

| اسم المورد | الموقع | نقاط القوة الرئيسية |

|---|---|---|

| شنغهاي تروير تكنولوجي | الصين | Wide PM powder range, custom solutions, AM integration |

| هوغاناس إيه بي | السويد | رائد عالمي في مساحيق المعادن، وبحث وتطوير قوي |

| أورليكون ميتكو | Switzerland/USA | Advanced thermal spray powders, global distribution |

| ساندفيك للتصنيع الإضافي | السويد | High-quality AM powders, vertical integration |

| HC Starck Tantalum & Niobium | ألمانيا | Specialty alloy powders, high purity and customization |

لماذا تبرز شركة Shanghai Truer Technology

- Over 14 years of experience in powder metallurgy and additive manufacturing.

- Strong focus on integration of طباعة ثلاثية الأبعاد powder-making and equipment services.

- Offers a full spectrum of PM powders including FeCrBSi, stainless steel, and soft magnetic materials.

- Flexible production methods: water atomization, gas atomization, carbonyl, and reduction techniques.

- Serves automotive, aerospace, oil & gas, and tool manufacturing industries globally.

For more information about Shanghai Truer’s capabilities, visit their صفحة من نحن.

Why More Manufacturers Are Switching to Chinese FeCrBSi Powder Sources

Over the past decade, China has rapidly emerged as a global powerhouse in the production of metal powders, including FeCrBSi powder. B2B buyers, OEMs, and industrial distributors are increasingly turning to Chinese suppliers not only for cost advantages but also for technological innovation, customization capabilities, and global logistics support.

الأسباب الرئيسية للتحول

1. Competitive Pricing Without Compromising Quality

- Chinese manufacturers offer high-quality FeCrBSi powders at 20–40% lower costs than Western counterparts.

- High production volumes and localized raw material sourcing reduce overhead costs.

2. قدرات التصنيع المتقدمة

- Companies like Shanghai Truer Technology utilize الانحلال المائي والغازي, carbonyl, and reduction processes.

- Ability to produce powders with tailored particle size distribution (PSD), flowability, and morphology for specific applications.

3. Rapid Turnaround and Scalable Supply

- Shorter lead times and large-scale production facilities make it easier to fulfill high-volume orders globally.

- Warehousing and logistics partnerships ensure timely delivery to North America, Europe, and Southeast Asia.

4. الدعم الفني والتخصيص

- Chinese suppliers offer co-development of powder solutions with clients, including performance trials and prototyping.

- In-house R&D teams provide technical consultation, helping B2B clients achieve optimal results in coating or AM processes.

Case Study: Shanghai Truer Technology’s FeCrBSi Supply Chain

| الميزة | Shanghai Truer Technology Advantage |

|---|---|

| تكنولوجيا الإنتاج | Water & gas atomization, carbonyl, diffusion, hybrid methods |

| تخصيص المنتج | Particle size, chemistry, and morphology tailored to application |

| Additive Manufacturing Integration | Dedicated AM division with powder and equipment solutions |

| Global Shipping and Logistics | Export-ready packaging, international freight support |

| After-Sales and Technical Consultation | Full documentation, usage guidance, and process optimization |

With growing confidence in Chinese metallurgy and powder quality, more international buyers are shifting their sourcing strategies. Shanghai Truer’s solutions are a leading example of how Chinese suppliers are elevating their global competitiveness.

To explore Truer’s full range of powders, visit their official homepage.

(Anchor Text: official homepage → https://am-material.com/)

Why Choose Shanghai Truer Technology for FeCrBSi Powder

Shanghai Truer Technology Co., Ltd. is one of China’s leading suppliers of high-performance metal powders for additive manufacturing, thermal spray, and powder metallurgy. Established in 2009, Truer has built a reputation among B2B buyers for reliability, innovation, and technical expertise.

ما الذي يميز ترور عن غيره؟

1. Full-Service Powder Manufacturing

- Offers a wide variety of PM powders including FeCrBSi, PM steel, PM stainless steel, PM bronze, and more.

- Production methods include water atomization, gas atomization, carbonyl, and hybrid techniques.

2. Additive Manufacturing Expertise

- Since 2019, Truer has operated a dedicated AM division.

- Supplies both 3D printing powder and powder-making equipment, ensuring seamless integration for OEMs and service bureaus.

3. Extensive Product Portfolio

- Powder grades include: CT-1000, CZ-1000, F-0000, FC-0208, FL-4605, SBF2218, and many more.

- Offers specialty additives such as Lube-W lubricants, SME-100 sulfur-free agents, and QHP-330 graphite.

4. التخصيص والدعم الفني

- Truer works closely with clients to develop powders that meet specific mechanical and chemical requirements.

- Provides documentation, TDS, MSDS, and application support.

Certifications and Quality Control

| التصديق | الوصف |

|---|---|

| آيزو 9001 | أنظمة إدارة الجودة |

| RoHS | Restriction of Hazardous Substances |

| REACH | Compliance with EU chemical safety standards |

All powders undergo rigorous quality testing to ensure consistency in bulk production and application performance.

Testimonials from Industry Clients

“Truer has helped us reduce coating costs by 30% while extending wear life of our components by over 50%.”

— Procurement Manager, Global Oilfield Services Company

“Their FeCrBSi powder performs exceptionally well in both HVOF and laser cladding, and their technical team is always available.”

— Senior Engineer, Aerospace OEM

To connect with Shanghai Truer’s sales and technical team, visit their صفحة الاتصال.

(Anchor Text: contact page → https://am-material.com/contact-us/)

How to Order Wholesale FeCrBSi Powder from China

Ordering FeCrBSi powder in bulk from China is now more streamlined than ever, thanks to digital communication, improved logistics, and bilingual support teams. Here’s a step-by-step guide for B2B buyers, OEMs, and distributors.

عملية الطلب خطوة بخطوة

1. Define Your Technical Requirements

- Identify particle size distribution, morphology, and chemical composition.

- Determine the application type: thermal spray, AM, or general PM.

2. Request Product Samples

- Contact the supplier to request TDS, MSDS, and trial samples.

- Test the sample in your application environment for performance validation.

3. Confirm Pricing and Logistics Terms

- Request a formal quotation (FOB, CIF, or DDP terms).

- Discuss payment terms (TT, LC) and lead time.

4. Place Bulk Order

- Finalize the purchase order (PO).

- Arrange for packaging and shipping.

5. دعم ما بعد البيع

- Receive technical support and implementation guidance.

- Schedule follow-ups for future orders or customization.

Typical Packaging Options

| نوع التعبئة والتغليف | سعة الوزن | الملاحظات |

|---|---|---|

| Sealed Aluminum Bags | 5-25 كجم | Moisture-proof, vacuum-sealed |

| براميل فولاذية | 100–200 كجم | Suitable for bulk shipping |

| IBC Containers | 500–1000 kg | For large industrial orders |

Shanghai Truer’s logistics team handles customs documentation and global shipping, ensuring a smooth end-to-end process for international clients.

For a complete list of FeCrBSi and related PM powders, visit their كتالوج المنتجات.

(Anchor Text: product catalog → https://am-material.com/pm-powder/)

FAQs: Buying Wholesale FeCrBSi Powder for Industrial Use

Q1: What is the minimum order quantity (MOQ) for wholesale FeCrBSi powder?

A: Shanghai Truer’s standard MOQ is 50 kg, but this can be adjusted for trial orders.

Q2: Can I request custom particle sizes or compositions?

A: Yes, Truer offers bespoke powder customization to match your coating or AM process.

Q3: How long is the lead time for international shipments?

A: Typically 2–4 weeks, depending on quantity and destination.

Q4: Is Truer’s FeCrBSi powder compatible with HVOF and laser cladding?

A: Absolutely. The powder is engineered for high-performance in both thermal spray and laser cladding.

Q5: Does Truer provide technical consultation for new applications?

A: Yes. Truer’s engineers assist with application testing, process parameters, and optimization.

Q6: What certifications does Truer carry?

A: ISO 9001, REACH, RoHS, and other customer-specified quality documentation.

Q7: How do I get a quote or sample?

A: Simply visit the صفحة الاتصال and submit your inquiry.

By strategically partnering with a trusted supplier like Shanghai Truer Technology, industrial buyers can secure high-quality FeCrBSi powder with dependable lead times, technical support, and competitive pricing. Whether you are developing new wear-resistant coatings or expanding your additive manufacturing capabilities, Truer delivers the reliability and performance that global manufacturers demand.