لمحة عامة عن مسحوق FeCoNiCrMo-1

يُعد مسحوق FeCoNiCrMo-1 سبيكة عالية الاستقطاب (HEA) تكتسب رواجًا في مجال التصنيع المتقدم وعلوم المواد نظرًا لخصائصها الميكانيكية الاستثنائية ومقاومتها للتآكل والاستقرار الهيكلي. تتميز سبائك HEAs مثل FeCoNiCrMo-1 بنسب متساوية الأقطاب تقريبًا للعناصر المكونة لها، مما يمنحها سمات فريدة مقارنة بالسبائك التقليدية.

ما أهمية هذا المسحوق؟ فكر في الأمر على أنه البطل الخارق للمساحيق المعدنية، حيث يوفر مزيجًا من الصلابة والمرونة والمقاومة. سواء كنت تستكشف التصنيع المتقدم أو تتطلع إلى تحسين الأداء الهيكلي في ظل الظروف القاسية، قد يكون مسحوق FeCoNiCrMo-1 هو الحل الذي تبحث عنه.

تركيبة مسحوق FeCoNiCrMo-1

تتميز تركيبة مسحوق FeCoNiCrMo-1 عن السبائك المعدنية التقليدية. يتم خلط العناصر الأساسية الخمسة - الحديد (Fe) والكوبالت (Co) والنيكل (Ni) والكروم (Cr) والموليبدينوم (Mo) - بنسب متساوية تقريبًا، مما يضمن أداءً فائقًا.

| العنصر | التركيب (% تقريبي) | الدور في السبيكة |

|---|---|---|

| الحديد (Fe) | ~20% | يقوي مصفوفة السبيكة. |

| الكوبالت (Co) | ~20% | يعزز مقاومة التآكل. |

| النيكل (ني) | ~20% | يحسّن الليونة والمتانة. |

| الكروم (Cr) | ~20% | يزيد من مقاومة التآكل. |

| الموليبدينوم (Mo) | ~20% | يوفر صلابة ممتازة ومقاومة ممتازة للزحف. |

خصائص مسحوق FeCoNiCrMo-1

يتميز مسحوق FeCoNiCrMo-1 بمجموعة من الخصائص التي تجعله خيارًا متعدد الاستخدامات لمختلف التطبيقات:

- قوة وصلابة استثنائية: وبفضل تصميمه متعدد العناصر، يُظهر المسحوق نسبة قوة إلى وزن ملحوظة ومناسبة للتطبيقات الفضائية والدفاعية.

- مقاومة التآكل: يساهم الكروم والموليبدينوم في المقاومة في البيئات شديدة التآكل.

- الاستقرار الحراري: تضمن تركيبته الثبات في درجات الحرارة العالية والمنخفضة على حد سواء.

- مقاومة التآكل: يقوي الكوبالت قدرته على تحمل التآكل الميكانيكي بمرور الوقت.

- بنية مجهرية قابلة للتخصيص: مناسبة للطباعة ثلاثية الأبعاد وتقنيات التصنيع المضافة الأخرى.

تطبيقات مسحوق FeCoNiCrMo-1

بفضل خصائصه الرائعة، يستخدم مسحوق FeCoNiCrMo-1 في العديد من الصناعات. إليك نظرة سريعة:

| الصناعة | التطبيقات |

|---|---|

| الفضاء | شفرات التوربينات، والمكونات الهيكلية، والدروع الحرارية |

| السيارات | أجزاء محرك عالية الأداء، تروس مقاومة للاهتراء |

| الطبية | الأطراف الصناعية، وزراعة الأسنان، والأدوات الجراحية |

| الدفاع | تصفيح الدروع ومكونات الصواريخ |

| الطاقة | مكونات المفاعل النووي، ومنصات الحفر البحرية |

| التصنيع الإضافي | الأجزاء المطبوعة ثلاثية الأبعاد التي تتطلب دقة عالية |

نماذج محددة من المساحيق القائمة على FeCoNiCrMo

فيما يلي بعض نماذج المساحيق البارزة القائمة على FeCoNiCrMo مع ميزاتها الفريدة:

1. مواصفة FeCoNiCrMo-1 القياسية

- الوصف: يوفر المسحوق الأساسي توازنًا بين القوة ومقاومة التآكل والاستقرار الحراري.

- الأفضل لـ التطبيقات الصناعية العامة والأغراض البحثية.

2. FeCoNiCrMo-1 HTP

- الوصف: متغير الأداء في درجات الحرارة العالية المحسّن للاستخدام في ظروف الحرارة الشديدة.

- الأفضل لـ صناعات الطيران والفضاء والطاقة.

3. FeCoNiCrMo-1 XR

- الوصف: مقاومة فائقة للتآكل والتآكل، وذلك بفضل محتوى الموليبدينوم المحسّن.

- الأفضل لـ التطبيقات البحرية والبحرية.

4. FeCoNiCrMo-1 Flex

- الوصف: التركيز على المرونة والليونة دون المساس بالقوة.

- الأفضل لـ الغرسات الطبية والأطراف الصناعية.

5. FeCoNiCrMo-1 Nano

- الوصف: جزيئات المسحوق النانوية لدقة الطباعة ثلاثية الأبعاد المتقدمة.

- الأفضل لـ التصنيع المضاف في مجال الإلكترونيات والفضاء.

6. FeCoNiCrMo-1 AM

- الوصف: مصممة خصيصًا للتصنيع بالإضافة، مما يوفر قابلية طباعة فائقة.

- الأفضل لـ النماذج الأولية السريعة.

7. FeCoNiCrMo-1 Ultra

- الوصف: تتميز بمقاومة عالية جداً للتآكل.

- الأفضل لـ معدات المعالجة الكيميائية.

8. FeCoNiCrMo-1 HP

- الوصف: متغير عالي الأداء مع زيادة محتوى الكوبالت لتحسين مقاومة التآكل.

- الأفضل لـ مكونات ميكانيكية عالية الإجهاد.

9. FeCoNiCrMo-1 Lite

- الوصف: إصدار خفيف الوزن بكثافة أقل.

- الأفضل لـ المكونات الحساسة للوزن في صناعة الطيران والسيارات.

10. FeCoNiCrMo-1 Bio

- الوصف: مسحوق متوافق حيوياً مصمم للاستخدام الطبي.

- الأفضل لـ الغرسات الجراحية وتطبيقات طب الأسنان.

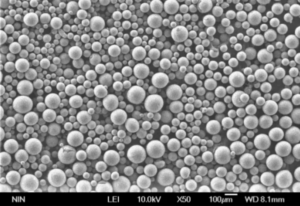

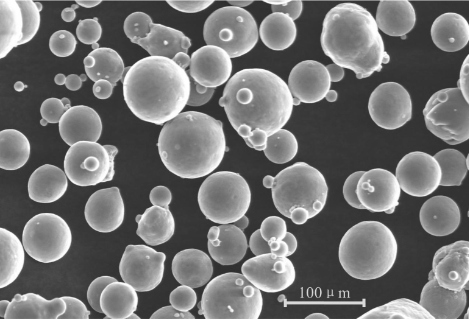

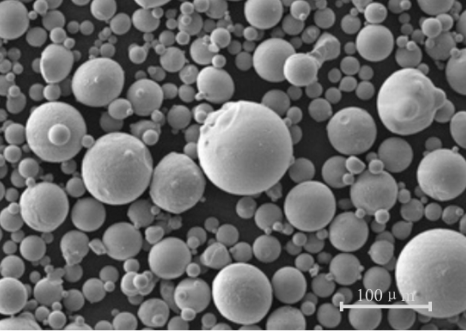

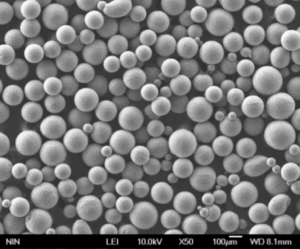

مواصفات مسحوق FeCoNiCrMo-1

| المواصفات | التفاصيل |

|---|---|

| حجم الجسيمات | 10-45 ميكرومتر (قابل للتخصيص) |

| الكثافة | ~حوالي 7.8 جم/سم مكعب |

| نقطة الانصهار | ~1300-1400°C |

| الصلابة | 300-400 فولت هيدروجيني 300-400 فولت هيدروجيني |

| المعايير | أستم B212، أيزو 9001 |

| خيارات التغليف | 1 كغم، 5 كغم، 10 كغم |

الموردين ومعلومات التسعير

| المورد | المنطقة | السعر (دولار/كجم) | الملاحظات |

|---|---|---|---|

| شركة السبائك المتقدمة | أمريكا الشمالية | $150-$180 | تقدم خصومات بالجملة. |

| شركة ميتال ووركس | أوروبا | $140-$170 | التركيبات المخصصة متاحة. |

| Asia Alloys Pvt Ltd. | آسيا والمحيط الهادئ | $120-$160 | أسعار تنافسية. |

| المتداولون العالميون للمعادن | في جميع أنحاء العالم | $130-$175 | شحن سريع في جميع أنحاء العالم. |

مزايا وعيوب مسحوق FeCoNiCrMo-1

| مزايا | سلبيات |

|---|---|

| مقاومة استثنائية للتآكل والتآكل. | تكلفة أولية أعلى مقارنةً بالسبائك التقليدية. |

| أداء ممتاز في درجات الحرارة القصوى. | التوفر محدود في بعض المناطق. |

| متعدد الاستخدامات للاستخدامات المتعددة. | تتطلب معدات متخصصة للمعالجة. |

| ثبات ومتانة عالية. | عملية إعادة تدوير معقدة بسبب تعدد العناصر. |

أسئلة وأجوبة

| سؤال | الإجابة |

|---|---|

| فيمَ يُستخدم مسحوق FeCoNiCrMo-1؟ | صناعة الطيران والفضاء والسيارات والطب والطاقة والطباعة ثلاثية الأبعاد. |

| كيف يكون FeCoNiCrMo-1 أفضل من الفولاذ؟ | فهو يوفر مقاومة أفضل للتآكل، ومقاومة التآكل، ومقاومة التآكل، وثبات درجة الحرارة. |

| هل يمكن طباعتها ثلاثية الأبعاد؟ | نعم، تم تحسين العديد من النماذج للتصنيع الإضافي. |

| هل هي باهظة الثمن؟ | وهي أغلى ثمناً من السبائك التقليدية ولكنها تقدم خصائص فائقة. |

| من هم الموردون الرئيسيون؟ | شركة السبائك المتقدمة، وشركة MetalWorks، وشركة Global Metal Traders. |