Electrolytic Manganese Powder: Industrial Uses & Supply Guide

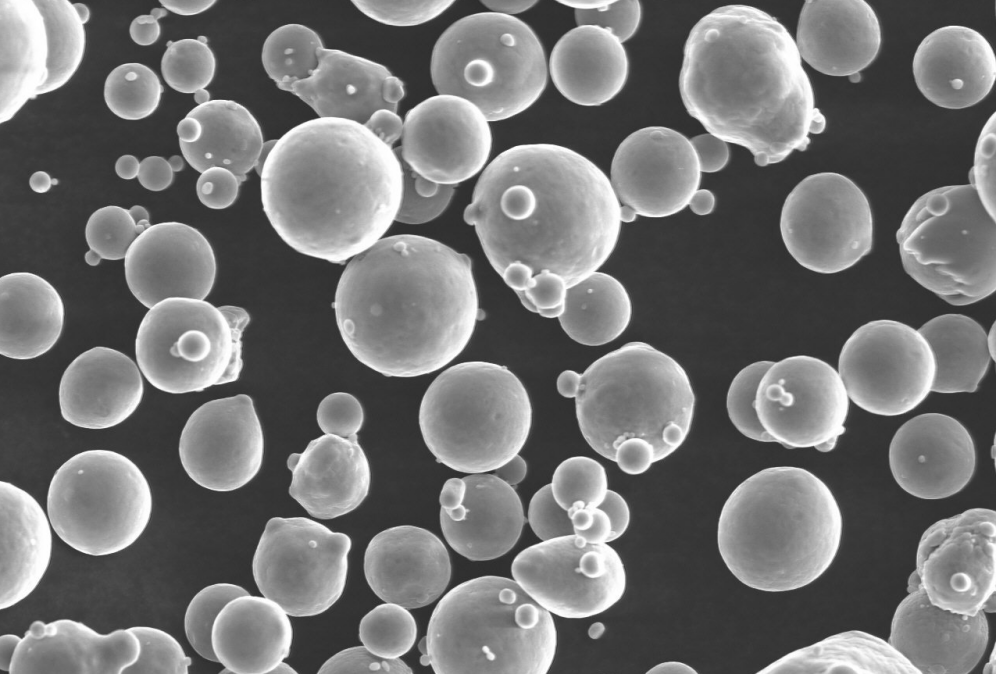

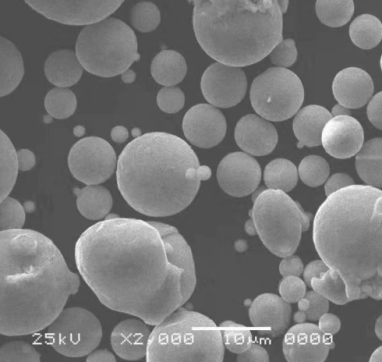

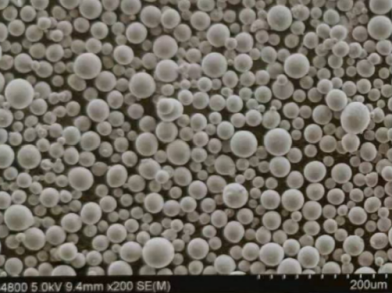

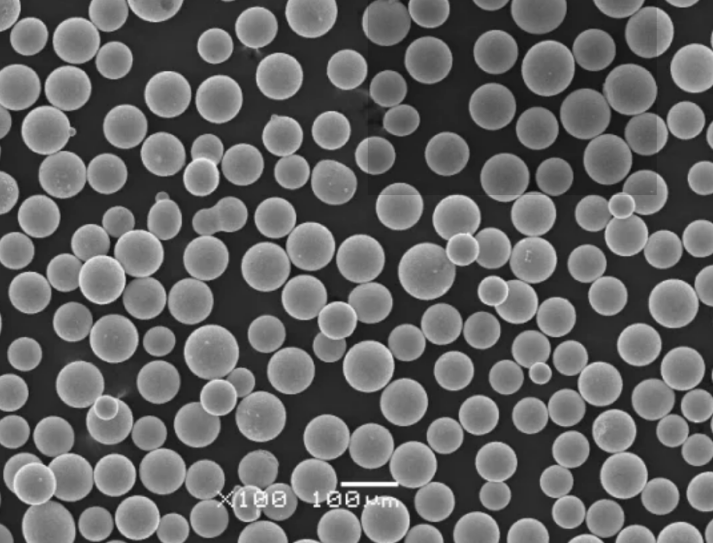

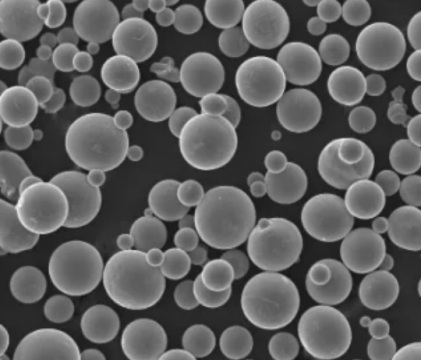

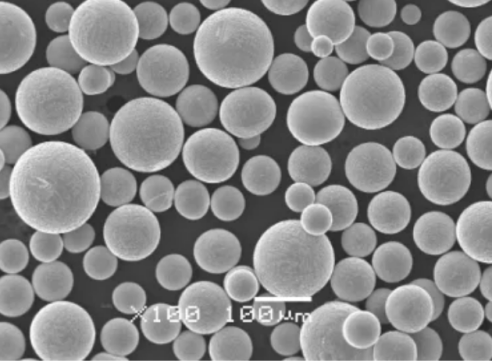

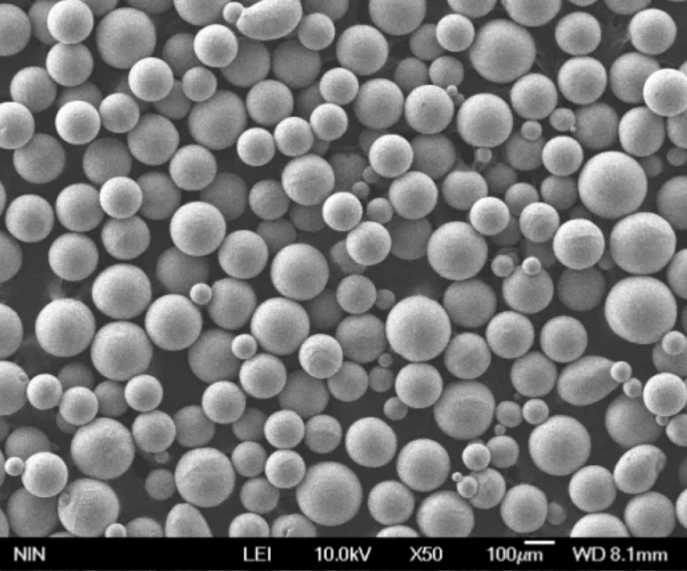

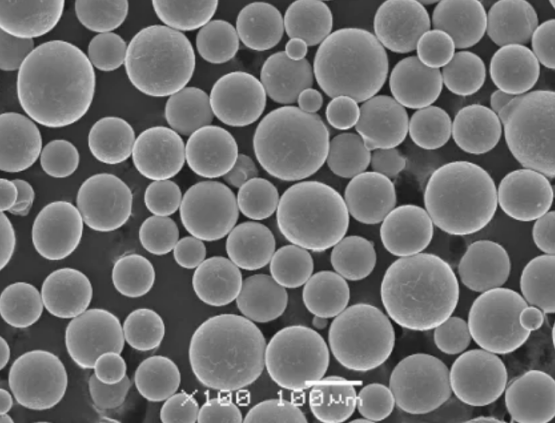

1. Introduction to Electrolytic Manganese Powder Electrolytic manganese powder (EMP) is a high-purity manganese material produced through electrolytic deposition followed by mechanical pulverization. Known for its exceptional purity (>99.7%) and controlled particle size, EMP is a critical raw material in various industrial sectors, especially in powder metallurgy (PM), battery production, and high-performance alloy manufacturing. Key […]

Electrolytic Manganese Powder: Industrial Uses & Supply Guide Daha Fazla Oku "