FeNi30 Alloy Powder for 3D Printing

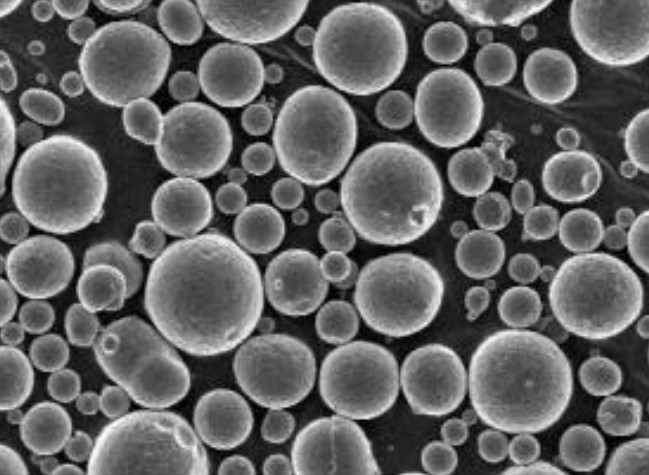

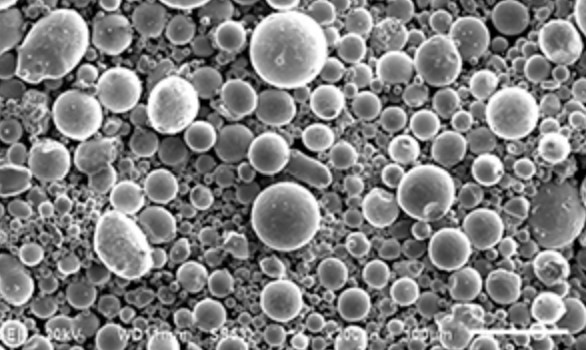

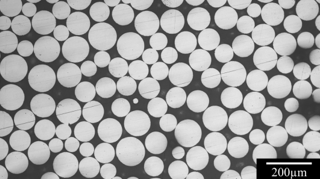

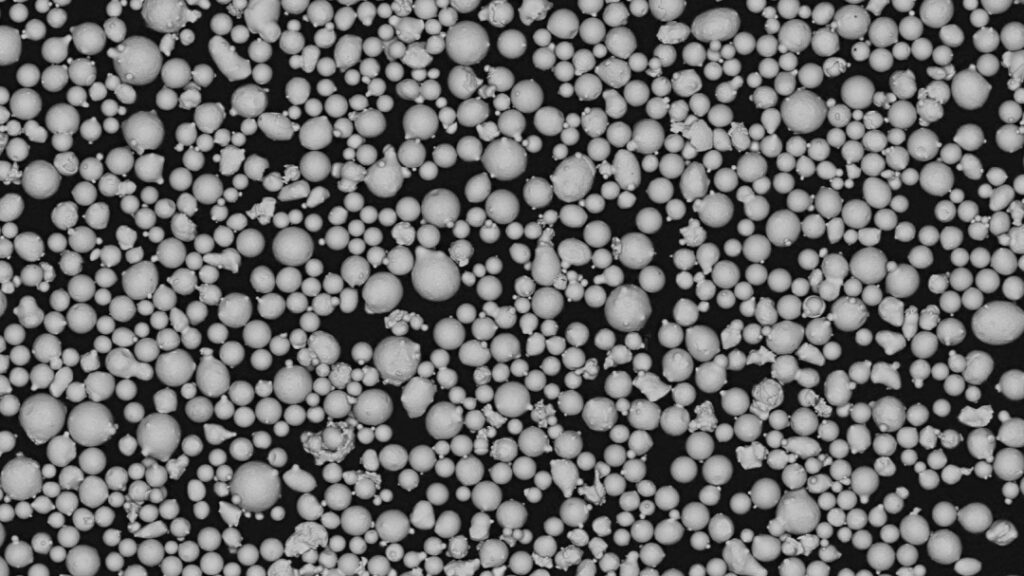

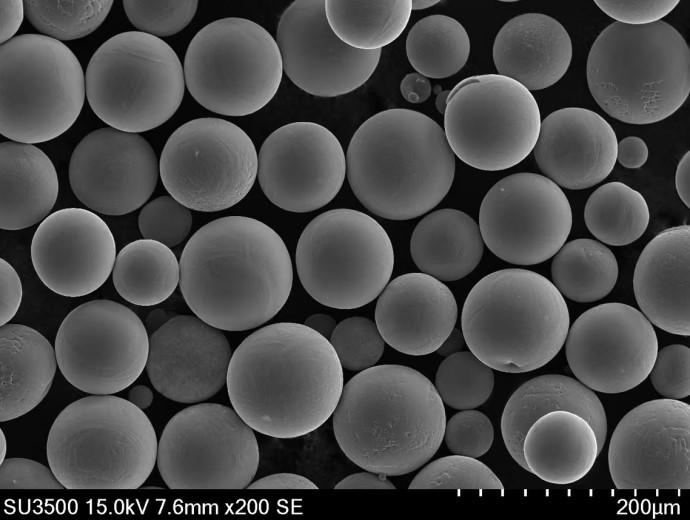

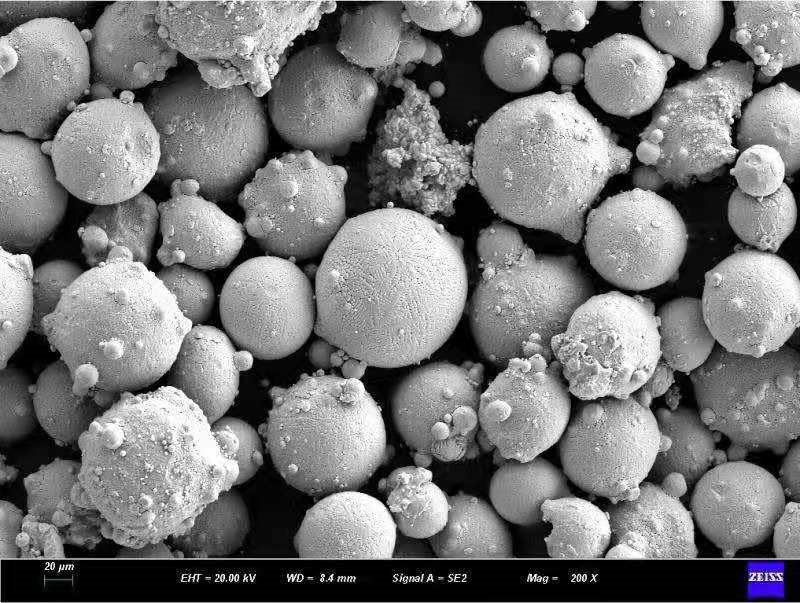

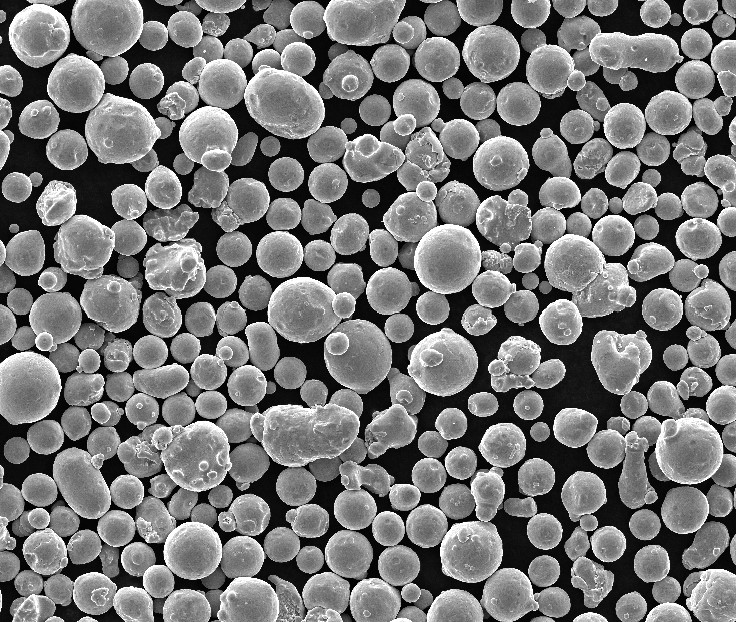

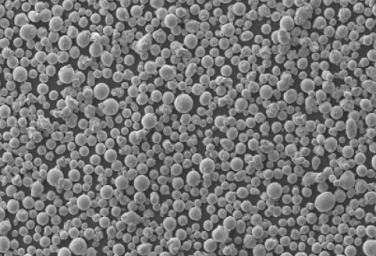

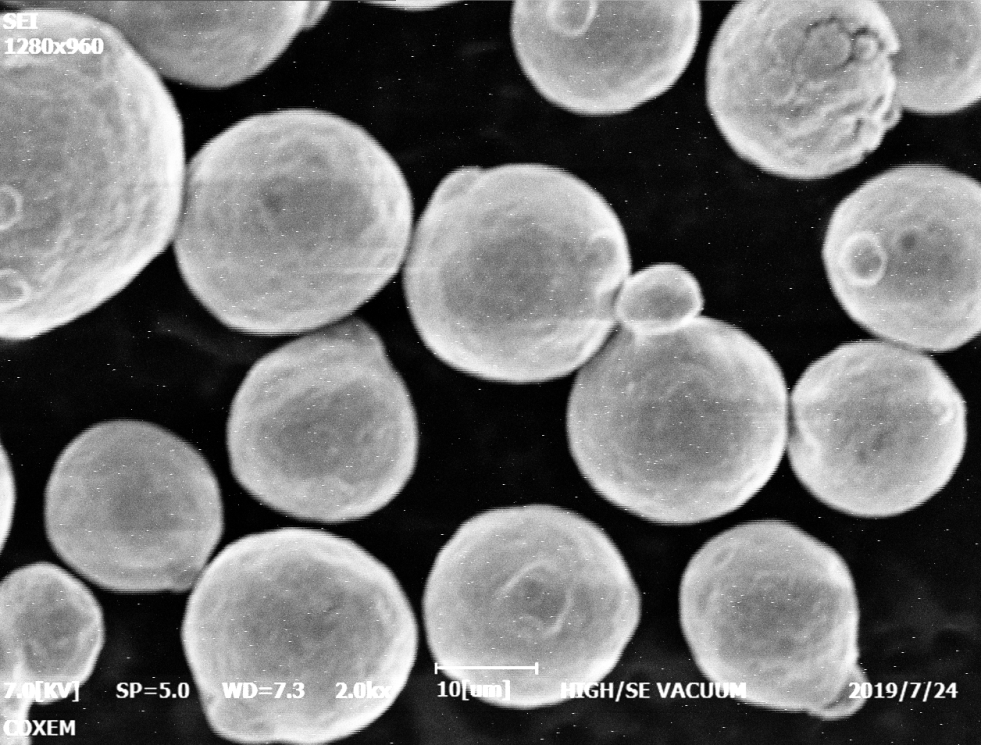

FeNi30 Alloy Powder for 3D Printing FeNi30 alloy powder is a type of iron-nickel alloy powder material with a nickel content of approximately 30%, which is corresponding to the soft magnetic alloy grade 1J30. It achieves an excellent balance between cost and performance through ingenious composition design, making it an indispensable basic material in multiple […]

FeNi30 Alloy Powder for 3D Printing Read More »