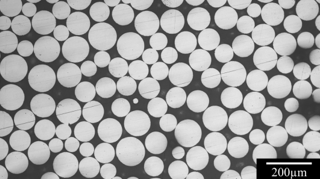

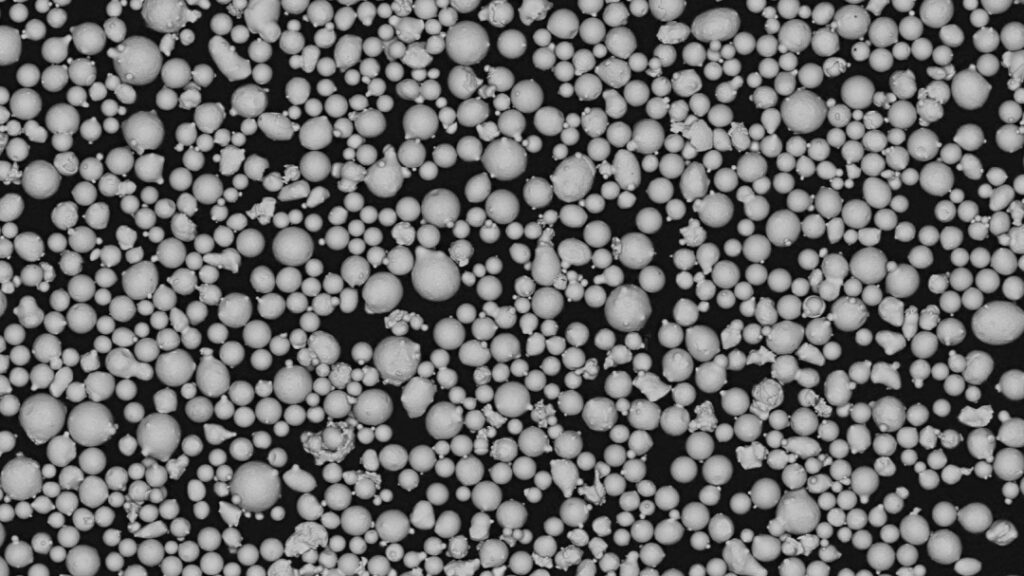

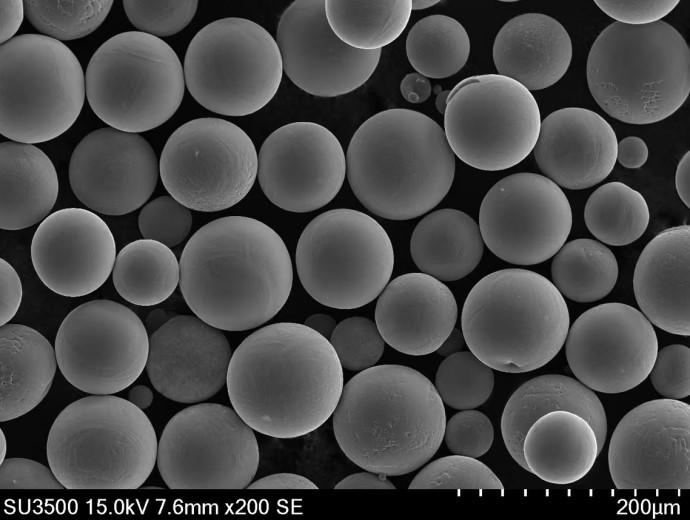

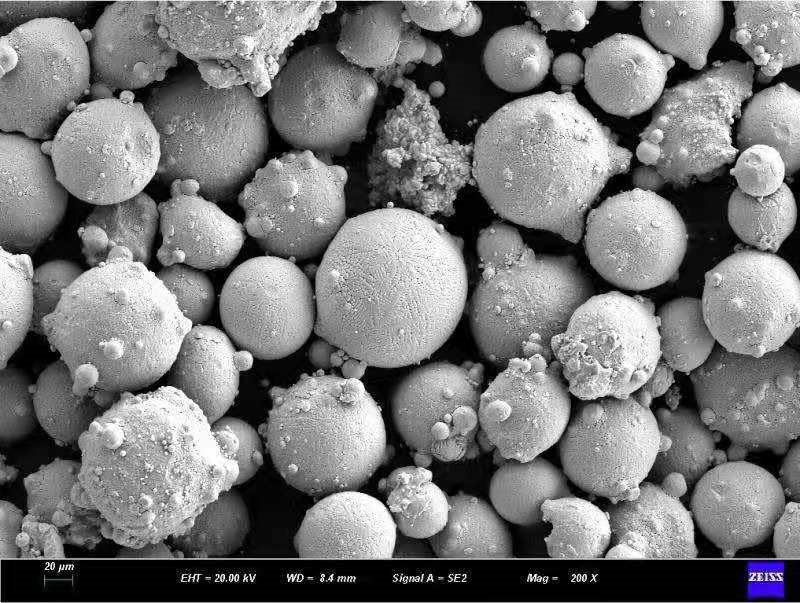

904L stainless steel powder for laser cladding

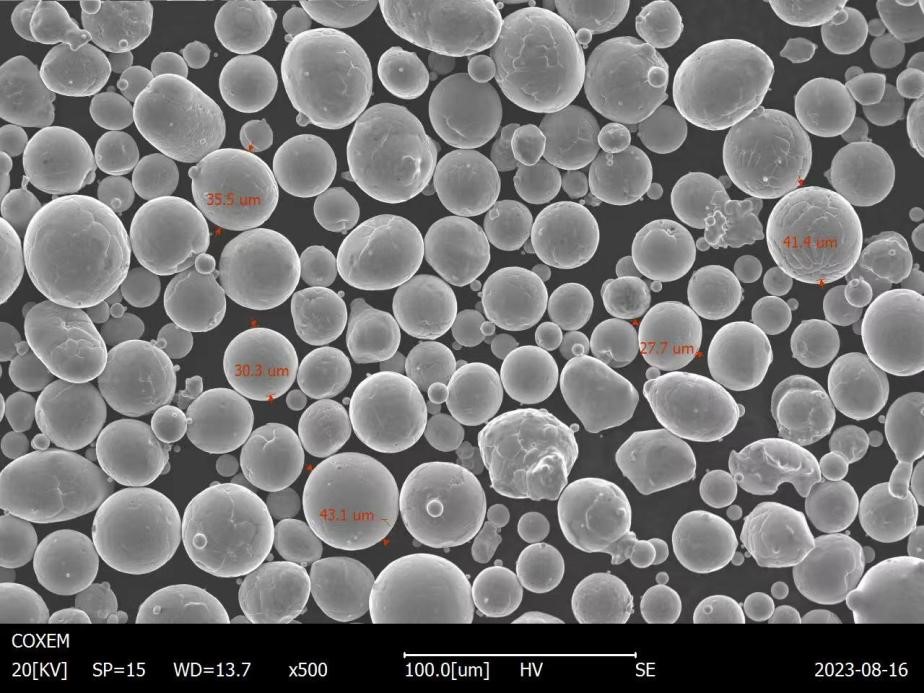

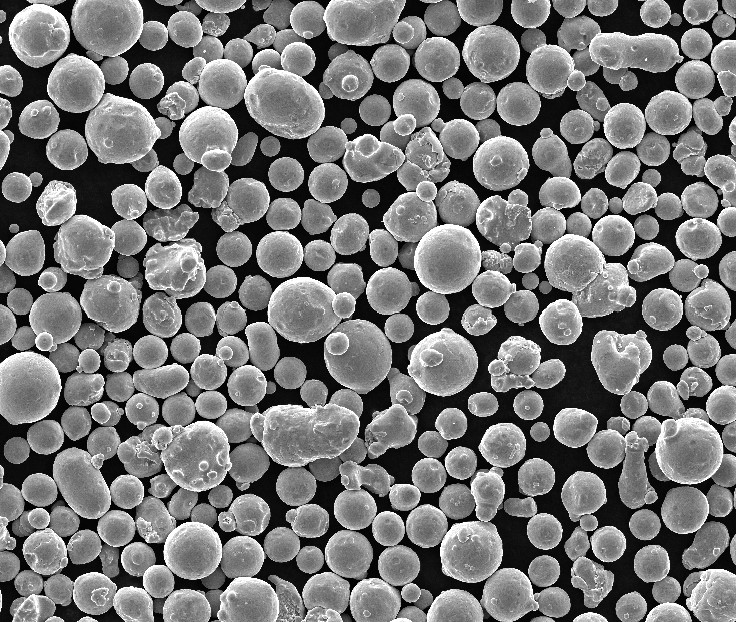

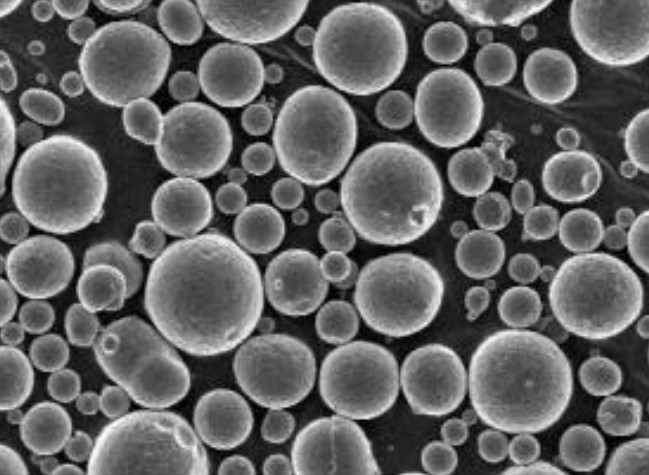

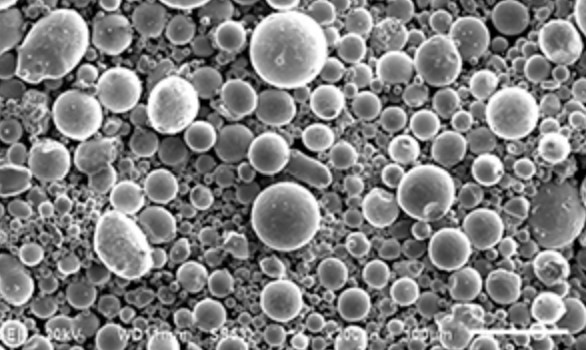

904L stainless steel powder for laser cladding 904L stainless steel, as an ultra-low-carbon and highly alloyed austenitic stainless steel, is renowned worldwide for its outstanding corrosion resistance. When this material is applied in powder form to laser cladding technology, its application field is further enhanced and expanded. This article will systematically analyze the technical characteristics […]

904L stainless steel powder for laser cladding Leer Más "