Kovar Powder for Precision Manufacturing and Wholesale Supply

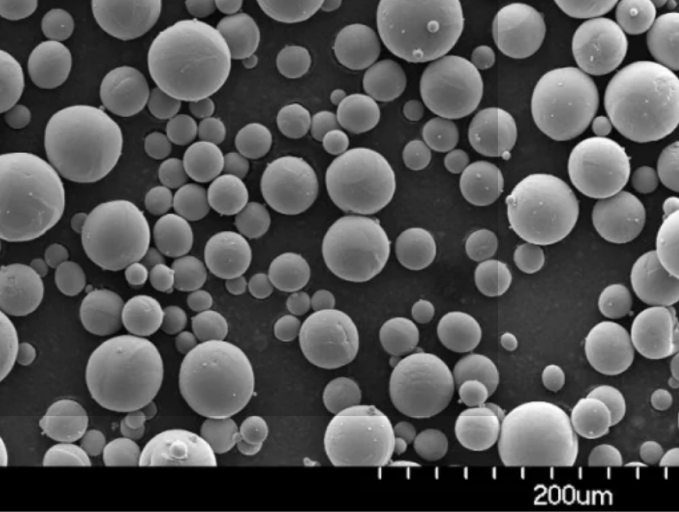

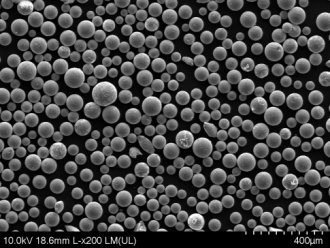

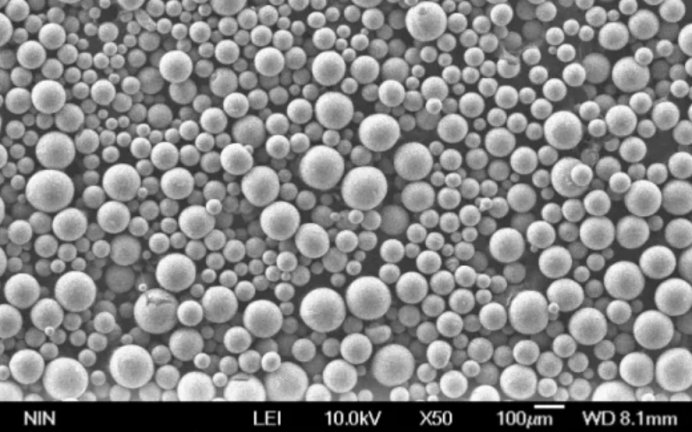

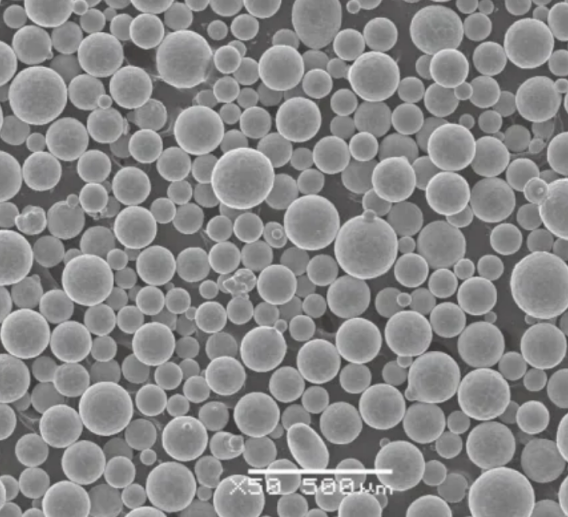

1. Introduction: Why Kovar Powder Is Critical for Precision Industries Kovar powder, an iron-nickel-cobalt alloy, is a staple material in industries that demand zero thermal expansion mismatch between metals and ceramics. It’s particularly critical in precision applications such as: This powder form is especially suited for powder metallurgy (PM) techniques and additive manufacturing (AM), allowing […]

Kovar Powder for Precision Manufacturing and Wholesale Supply اقرأ المزيد "